化工学报 ›› 2024, Vol. 75 ›› Issue (S1): 267-275.DOI: 10.11949/0438-1157.20240448

蒲黎明1( ), 汪贵1, 郑春来1, 王科1, 向腾龙2, 王治红2(

), 汪贵1, 郑春来1, 王科1, 向腾龙2, 王治红2( )

)

收稿日期:2024-04-24

修回日期:2024-05-31

出版日期:2024-12-25

发布日期:2024-12-17

通讯作者:

王治红

作者简介:蒲黎明(1982—),高级工程师,puliming_sw@swpu.edu.cn

基金资助:

Liming PU1( ), Gui WANG1, Chunlai ZHENG1, Ke WANG1, Tenglong XIANG2, Zhihong WANG2(

), Gui WANG1, Chunlai ZHENG1, Ke WANG1, Tenglong XIANG2, Zhihong WANG2( )

)

Received:2024-04-24

Revised:2024-05-31

Online:2024-12-25

Published:2024-12-17

Contact:

Zhihong WANG

摘要:

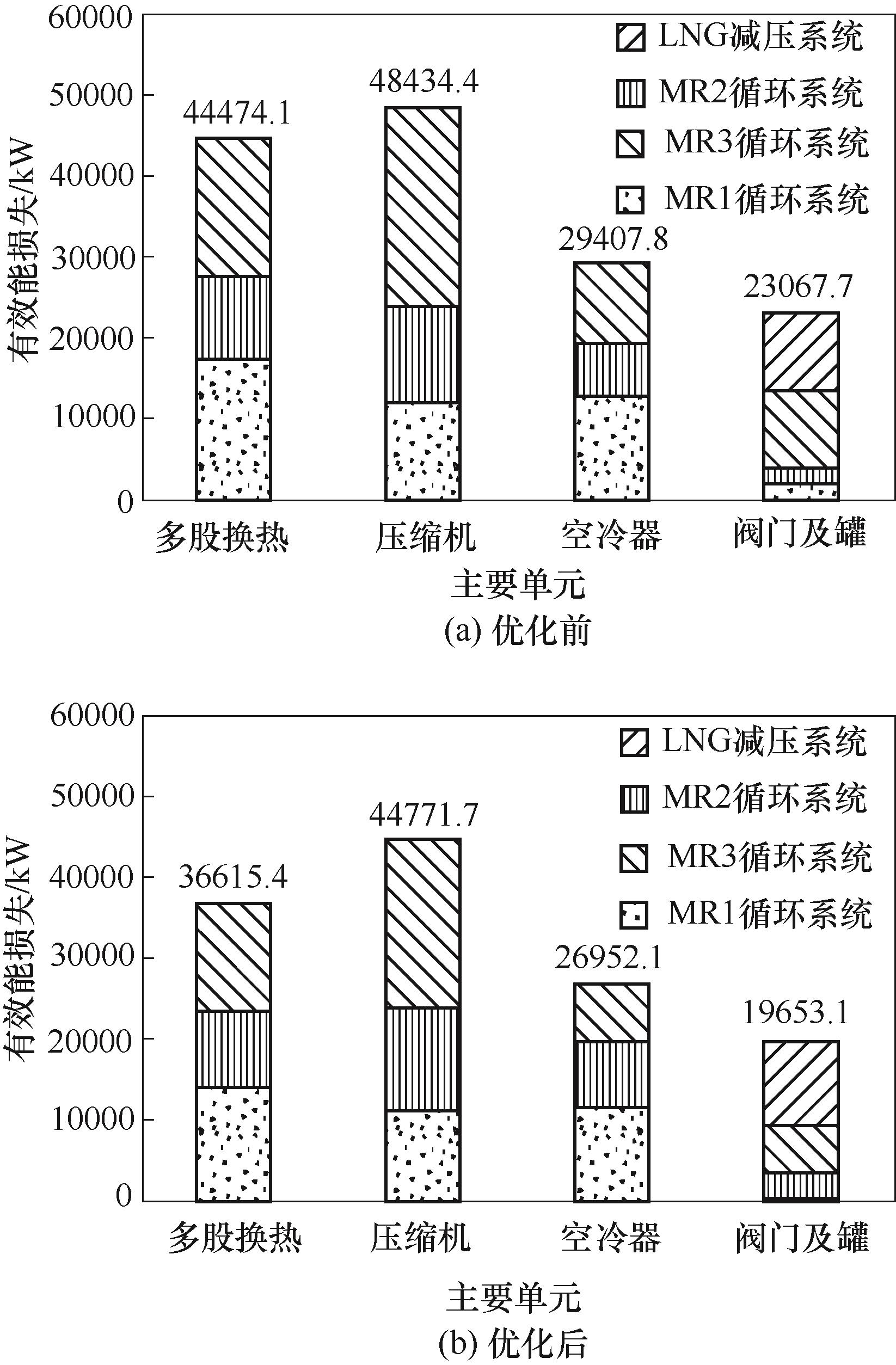

混合制冷级联(MFC)工艺是大型基地负荷型天然气液化过程最具竞争力的工艺之一,其工艺由天然气预冷、液化和过冷三个混合制冷循环构成,涉及冷剂配比、制冷温度及压力等关键参数,使其过程复杂和敏感。针对MFC液化工艺,建立了以比功耗为目标的优化函数,借助Aspen HYSYS流程模拟与物性计算,采用序列二次规划法(SQP)优化算法对MFC工艺进行全局优化,并对工艺过程进行有效能分析。优化结果表明,全局优化后,MFC液化过程的比功耗为899.36 kJ/kg,降低了7.38%;多股流换热器冷热复合曲线匹配得更好。通过有效能分析发现,制冷压缩机机组的有效能损失占比最大,优化后多股流换热器的有效能损失显著降低,液化过程的有效能效率由38.17%提高到41.21%,能量利用效率提高明显。

中图分类号:

蒲黎明, 汪贵, 郑春来, 王科, 向腾龙, 王治红. 混合制冷级联天然气液化工艺优化及分析[J]. 化工学报, 2024, 75(S1): 267-275.

Liming PU, Gui WANG, Chunlai ZHENG, Ke WANG, Tenglong XIANG, Zhihong WANG. Optimization and analysis of natural gas liquefaction process in mixed fluid cascade[J]. CIESC Journal, 2024, 75(S1): 267-275.

| CH2 | C2H6 | C3H8 | iC4H10 | nC4H10 | N2 | H2+He |

|---|---|---|---|---|---|---|

| 0.9481 | 0.0311 | 0.0085 | 0.0024 | 0.0017 | 0.0076 | 0.0006 |

表1 天然气组成(摩尔分数)

Table 1 Natural gas composition(mole fraction)

| CH2 | C2H6 | C3H8 | iC4H10 | nC4H10 | N2 | H2+He |

|---|---|---|---|---|---|---|

| 0.9481 | 0.0311 | 0.0085 | 0.0024 | 0.0017 | 0.0076 | 0.0006 |

| 编号 | 气相分数 | 温度/℃ | 压力/MPa | 摩尔流量/(kmol/h) | 质量流量/(kg/h) | 质量焓/(kJ/kg) | 质量熵/(kJ/(kg·K)) | 质量有效能/(kJ/kg) |

|---|---|---|---|---|---|---|---|---|

| 1 | 1.00 | 22.00 | 8.50 | 53740.43 | 910695.00 | -4535.77 | 8.50 | 620.46 |

| 2 | 1.00 | -35.35 | 7.98 | 53740.43 | 910695.00 | -4720.45 | 7.82 | 637.88 |

| 3 | 0.00 | -71.55 | 7.73 | 53740.43 | 910695.00 | -4952.25 | 6.77 | 721.49 |

| 4 | 0.00 | -155.00 | 5.18 | 41168.33 | 934825.83 | -3734.10 | 3.41 | 739.97 |

| 5 | 0.04 | -156.88 | 0.61 | 41168.33 | 934825.83 | -3734.10 | 3.48 | 720.48 |

| 6 | 0.00 | -159.29 | 0.20 | 51443.44 | 871752.12 | -5336.94 | 4.59 | 1008.16 |

| 7 | 1.00 | -159.29 | 0.20 | 2296.99 | 38942.88 | -4328.54 | 8.74 | 237.92 |

| 8 | 0.00 | -35.35 | 1.10 | 36717.32 | 1493609.51 | -2991.72 | 2.23 | 165.59 |

| 9 | 0.02 | -38.35 | 0.39 | 36717.32 | 1493609.51 | -2991.72 | 2.24 | 164.02 |

| 10 | 1.00 | 18.00 | 0.33 | 36717.32 | 1493609.51 | -2497.90 | 4.21 | 70.83 |

| 11 | 0.01 | 13.76 | 1.57 | 36717.32 | 1493609.51 | -2862.16 | 2.72 | 149.29 |

| 12 | 1.00 | 102.59 | 1.78 | 18358.66 | 746804.76 | -2364.32 | 4.30 | 177.36 |

| 13 | 1.00 | 102.59 | 1.78 | 18358.66 | 746804.76 | -2364.32 | 4.30 | 177.36 |

| 14 | 0.00 | 15.00 | 1.64 | 36717.32 | 1493609.51 | -2862.16 | 2.72 | 149.43 |

| 15 | 0.00 | -35.35 | 3.81 | 31557.60 | 952561.51 | -3373.16 | 3.75 | 298.71 |

| 16 | 0.00 | -71.55 | 3.49 | 31557.60 | 952561.51 | -3468.55 | 3.32 | 332.00 |

| 17 | 0.09 | -81.50 | 0.41 | 31557.60 | 952561.51 | -3468.55 | 3.35 | 321.07 |

| 18 | 1.00 | -41.33 | 3.44 | 31557.60 | 952561.51 | -2973.78 | 5.71 | 113.16 |

| 19 | 1.00 | 118.24 | 4.44 | 15778.80 | 476280.76 | -2731.08 | 5.87 | 308.13 |

| 20 | 1.00 | 118.24 | 4.44 | 15778.80 | 476280.76 | -2731.08 | 5.87 | 308.13 |

| 21 | 0.10 | 15.00 | 4.30 | 31557.60 | 952561.51 | -3180.07 | 4.47 | 276.64 |

| 22 | 0.11 | 14.62 | 4.25 | 31557.60 | 952561.51 | -3180.07 | 4.47 | 276.46 |

| 23 | 0.01 | -71.55 | 6.18 | 41168.33 | 934825.83 | -3492.25 | 4.93 | 529.36 |

| 24 | 0.00 | -156.00 | 5.18 | 41168.33 | 934825.83 | -3734.10 | 3.41 | 739.97 |

| 25 | 0.09 | -160.80 | 0.39 | 41168.33 | 934825.83 | -3734.10 | 3.49 | 716.69 |

| 26 | 1.00 | -74.54 | 0.35 | 41168.33 | 934825.83 | -3159.50 | 7.25 | 169.53 |

| 27 | 1.00 | 93.38 | 3.45 | 20584.16 | 467412.91 | -2883.56 | 7.45 | 386.71 |

| 28 | 1.00 | 93.38 | 3.45 | 20584.16 | 467412.91 | -2883.56 | 7.45 | 386.71 |

| 29 | 1.00 | 15.30 | 3.39 | 20584.16 | 467412.91 | -3046.81 | 6.95 | 370.95 |

| 30 | 1.00 | 15.30 | 3.39 | 20584.16 | 467412.91 | -3046.81 | 6.95 | 370.95 |

| 31 | 1.00 | 80.81 | 7.31 | 20584.16 | 467412.91 | -2944.79 | 7.03 | 451.15 |

| 32 | 1.00 | 80.81 | 7.31 | 20584.16 | 467412.91 | -2944.79 | 7.03 | 451.15 |

| 33 | 1.00 | 14.70 | 7.19 | 41168.33 | 934825.83 | -3105.54 | 6.53 | 439.16 |

| 34 | 0.57 | -35.35 | 6.79 | 41168.33 | 934825.83 | -3311.12 | 5.74 | 468.11 |

表2 模拟流股热力学数据

Table 2 Simulated flow strand thermodynamic data

| 编号 | 气相分数 | 温度/℃ | 压力/MPa | 摩尔流量/(kmol/h) | 质量流量/(kg/h) | 质量焓/(kJ/kg) | 质量熵/(kJ/(kg·K)) | 质量有效能/(kJ/kg) |

|---|---|---|---|---|---|---|---|---|

| 1 | 1.00 | 22.00 | 8.50 | 53740.43 | 910695.00 | -4535.77 | 8.50 | 620.46 |

| 2 | 1.00 | -35.35 | 7.98 | 53740.43 | 910695.00 | -4720.45 | 7.82 | 637.88 |

| 3 | 0.00 | -71.55 | 7.73 | 53740.43 | 910695.00 | -4952.25 | 6.77 | 721.49 |

| 4 | 0.00 | -155.00 | 5.18 | 41168.33 | 934825.83 | -3734.10 | 3.41 | 739.97 |

| 5 | 0.04 | -156.88 | 0.61 | 41168.33 | 934825.83 | -3734.10 | 3.48 | 720.48 |

| 6 | 0.00 | -159.29 | 0.20 | 51443.44 | 871752.12 | -5336.94 | 4.59 | 1008.16 |

| 7 | 1.00 | -159.29 | 0.20 | 2296.99 | 38942.88 | -4328.54 | 8.74 | 237.92 |

| 8 | 0.00 | -35.35 | 1.10 | 36717.32 | 1493609.51 | -2991.72 | 2.23 | 165.59 |

| 9 | 0.02 | -38.35 | 0.39 | 36717.32 | 1493609.51 | -2991.72 | 2.24 | 164.02 |

| 10 | 1.00 | 18.00 | 0.33 | 36717.32 | 1493609.51 | -2497.90 | 4.21 | 70.83 |

| 11 | 0.01 | 13.76 | 1.57 | 36717.32 | 1493609.51 | -2862.16 | 2.72 | 149.29 |

| 12 | 1.00 | 102.59 | 1.78 | 18358.66 | 746804.76 | -2364.32 | 4.30 | 177.36 |

| 13 | 1.00 | 102.59 | 1.78 | 18358.66 | 746804.76 | -2364.32 | 4.30 | 177.36 |

| 14 | 0.00 | 15.00 | 1.64 | 36717.32 | 1493609.51 | -2862.16 | 2.72 | 149.43 |

| 15 | 0.00 | -35.35 | 3.81 | 31557.60 | 952561.51 | -3373.16 | 3.75 | 298.71 |

| 16 | 0.00 | -71.55 | 3.49 | 31557.60 | 952561.51 | -3468.55 | 3.32 | 332.00 |

| 17 | 0.09 | -81.50 | 0.41 | 31557.60 | 952561.51 | -3468.55 | 3.35 | 321.07 |

| 18 | 1.00 | -41.33 | 3.44 | 31557.60 | 952561.51 | -2973.78 | 5.71 | 113.16 |

| 19 | 1.00 | 118.24 | 4.44 | 15778.80 | 476280.76 | -2731.08 | 5.87 | 308.13 |

| 20 | 1.00 | 118.24 | 4.44 | 15778.80 | 476280.76 | -2731.08 | 5.87 | 308.13 |

| 21 | 0.10 | 15.00 | 4.30 | 31557.60 | 952561.51 | -3180.07 | 4.47 | 276.64 |

| 22 | 0.11 | 14.62 | 4.25 | 31557.60 | 952561.51 | -3180.07 | 4.47 | 276.46 |

| 23 | 0.01 | -71.55 | 6.18 | 41168.33 | 934825.83 | -3492.25 | 4.93 | 529.36 |

| 24 | 0.00 | -156.00 | 5.18 | 41168.33 | 934825.83 | -3734.10 | 3.41 | 739.97 |

| 25 | 0.09 | -160.80 | 0.39 | 41168.33 | 934825.83 | -3734.10 | 3.49 | 716.69 |

| 26 | 1.00 | -74.54 | 0.35 | 41168.33 | 934825.83 | -3159.50 | 7.25 | 169.53 |

| 27 | 1.00 | 93.38 | 3.45 | 20584.16 | 467412.91 | -2883.56 | 7.45 | 386.71 |

| 28 | 1.00 | 93.38 | 3.45 | 20584.16 | 467412.91 | -2883.56 | 7.45 | 386.71 |

| 29 | 1.00 | 15.30 | 3.39 | 20584.16 | 467412.91 | -3046.81 | 6.95 | 370.95 |

| 30 | 1.00 | 15.30 | 3.39 | 20584.16 | 467412.91 | -3046.81 | 6.95 | 370.95 |

| 31 | 1.00 | 80.81 | 7.31 | 20584.16 | 467412.91 | -2944.79 | 7.03 | 451.15 |

| 32 | 1.00 | 80.81 | 7.31 | 20584.16 | 467412.91 | -2944.79 | 7.03 | 451.15 |

| 33 | 1.00 | 14.70 | 7.19 | 41168.33 | 934825.83 | -3105.54 | 6.53 | 439.16 |

| 34 | 0.57 | -35.35 | 6.79 | 41168.33 | 934825.83 | -3311.12 | 5.74 | 468.11 |

| 关键/决策变量 | 单位 | 下限 | 上限 | |

|---|---|---|---|---|

| 过冷循环 | 高压压力p31 | MPa | 6.00 | 8.50 |

| 制冷压力p25 | MPa | 0.20 | 0.60 | |

| 过冷温度T24 | ℃ | -140.00 | -160.00 | |

| N2流率 | kmol/h | 5500 | 6200 | |

| CH4流率 | kmol/h | 18000 | 25000 | |

| C2H6流率 | kmol/h | 12000 | 18000 | |

| 液化循环 | 高压压力p19 | MPa | 4.00 | 5.00 |

| 制冷压力p17 | MPa | 0.20 | 0.60 | |

| 液化温度T16 | ℃ | -60.00 | -85.00 | |

| CH4流率 | kmol/h | 4000 | 5000 | |

| C2H6流率 | kmol/h | 20000 | 30000 | |

| C3H8流率 | kmol/h | 3200 | 4500 | |

| 预冷循环 | 高压压力p12 | MPa | 1.50 | 2.50 |

| 制冷压力p9 | MPa | 0.20 | 0.60 | |

| 预冷温度T8 | ℃ | -27.00 | -40.00 | |

| C2H6流率 | kmol/h | 15000 | 18000 | |

| C3H8流率 | kmol/h | 12000 | 18000 | |

| C4H10流率 | kmol/h | 6000 | 9000 | |

表3 MFC工艺的关键/决策变量下限和上限

Table 3 Lower and upper bounds of key/decision variables for the MFC process

| 关键/决策变量 | 单位 | 下限 | 上限 | |

|---|---|---|---|---|

| 过冷循环 | 高压压力p31 | MPa | 6.00 | 8.50 |

| 制冷压力p25 | MPa | 0.20 | 0.60 | |

| 过冷温度T24 | ℃ | -140.00 | -160.00 | |

| N2流率 | kmol/h | 5500 | 6200 | |

| CH4流率 | kmol/h | 18000 | 25000 | |

| C2H6流率 | kmol/h | 12000 | 18000 | |

| 液化循环 | 高压压力p19 | MPa | 4.00 | 5.00 |

| 制冷压力p17 | MPa | 0.20 | 0.60 | |

| 液化温度T16 | ℃ | -60.00 | -85.00 | |

| CH4流率 | kmol/h | 4000 | 5000 | |

| C2H6流率 | kmol/h | 20000 | 30000 | |

| C3H8流率 | kmol/h | 3200 | 4500 | |

| 预冷循环 | 高压压力p12 | MPa | 1.50 | 2.50 |

| 制冷压力p9 | MPa | 0.20 | 0.60 | |

| 预冷温度T8 | ℃ | -27.00 | -40.00 | |

| C2H6流率 | kmol/h | 15000 | 18000 | |

| C3H8流率 | kmol/h | 12000 | 18000 | |

| C4H10流率 | kmol/h | 6000 | 9000 | |

| 关键参数 | 单位 | 优化前 | 优化后 | |

|---|---|---|---|---|

| 过冷循环 | 高压压力p31 | MPa | 8.46 | 7.31 |

| 制冷压力p25 | MPa | 0.41 | 0.38 | |

| 过冷温度T24 | ℃ | -156.00 | -156.00 | |

| 过热温度T26 | ℃ | -69.93 | -74.54 | |

| 液化循环 | 高压压力p19 | MPa | 4.24 | 4.44 |

| 制冷压力p17 | MPa | 0.44 | 0.41 | |

| 液化温度T16 | ℃ | -65.50 | -71.55 | |

| 过热温度T18 | ℃ | -42.01 | -41.33 | |

| 预冷循环 | 高压压力p12 | MPa | 2.50 | 1.78 |

| 制冷压力p9 | MPa | 0.57 | 0.39 | |

| 预冷温度T8 | ℃ | -30.50 | -35.35 | |

| 过热温度T10 | ℃ | 11.96 | 18.00 | |

表4 优化前后液化工艺的关键参数对比

Table 4 Comparison of key parameters of liquefaction process before and after optimization

| 关键参数 | 单位 | 优化前 | 优化后 | |

|---|---|---|---|---|

| 过冷循环 | 高压压力p31 | MPa | 8.46 | 7.31 |

| 制冷压力p25 | MPa | 0.41 | 0.38 | |

| 过冷温度T24 | ℃ | -156.00 | -156.00 | |

| 过热温度T26 | ℃ | -69.93 | -74.54 | |

| 液化循环 | 高压压力p19 | MPa | 4.24 | 4.44 |

| 制冷压力p17 | MPa | 0.44 | 0.41 | |

| 液化温度T16 | ℃ | -65.50 | -71.55 | |

| 过热温度T18 | ℃ | -42.01 | -41.33 | |

| 预冷循环 | 高压压力p12 | MPa | 2.50 | 1.78 |

| 制冷压力p9 | MPa | 0.57 | 0.39 | |

| 预冷温度T8 | ℃ | -30.50 | -35.35 | |

| 过热温度T10 | ℃ | 11.96 | 18.00 | |

| 冷剂组成及循环量 | 优化前 | 优化后 | |

|---|---|---|---|

| 混合制冷剂MR1 | 循环量/(kmol/)h | 42457.92 | 36717.32 |

| C2H6 | 0.648638 | 0.454331 | |

| C3H8 | 0.183213 | 0.335035 | |

| C4H10 | 0.168149 | 0.210633 | |

| 混合制冷剂MR2 | 循环量/(kmol/h) | 31114.37 | 31557.60 |

| CH4 | 0.088813 | 0.128623 | |

| C2H6 | 0.800945 | 0.739691 | |

| C3H8 | 0.110242 | 0.131686 | |

| 混合制冷剂MR3 | 循环量/(kmol/h) | 47319.36 | 41168.33 |

| N2 | 0.149387 | 0.142229 | |

| CH4 | 0.479987 | 0.507300 | |

| C2H6 | 0.370626 | 0.350471 | |

表5 优化后的混合制冷剂组成(摩尔分数)及循环量

Table 5 Optimized refrigerant blend composition (mole fraction) and flow rate

| 冷剂组成及循环量 | 优化前 | 优化后 | |

|---|---|---|---|

| 混合制冷剂MR1 | 循环量/(kmol/)h | 42457.92 | 36717.32 |

| C2H6 | 0.648638 | 0.454331 | |

| C3H8 | 0.183213 | 0.335035 | |

| C4H10 | 0.168149 | 0.210633 | |

| 混合制冷剂MR2 | 循环量/(kmol/h) | 31114.37 | 31557.60 |

| CH4 | 0.088813 | 0.128623 | |

| C2H6 | 0.800945 | 0.739691 | |

| C3H8 | 0.110242 | 0.131686 | |

| 混合制冷剂MR3 | 循环量/(kmol/h) | 47319.36 | 41168.33 |

| N2 | 0.149387 | 0.142229 | |

| CH4 | 0.479987 | 0.507300 | |

| C2H6 | 0.370626 | 0.350471 | |

| 换热器优化变量 | 单位 | 优化前 | 优化后 | |

|---|---|---|---|---|

| 比功耗 | 单位质量LNG | kJ/kg | 970.99 | 899.36 |

| 预冷换热器E-001 | 最小传热温差 | ℃ | 5.97 | 3.00 |

| 对数平均温差 | ℃ | 12.72 | 7.65 | |

| 液化换热器E-002 | 最小传热温差 | ℃ | 3.63 | 3.00 |

| 对数平均温差 | ℃ | 7.20 | 5.47 | |

| 过冷换热器E-003 | 最小传热温差 | ℃ | 3.20 | 3.00 |

| 对数平均温差 | ℃ | 5.87 | 4.95 | |

表6 优化前后工艺比功耗及换热器性能指标

Table 6 Process specific power consumption and heat exchanger performance index before and after optimization

| 换热器优化变量 | 单位 | 优化前 | 优化后 | |

|---|---|---|---|---|

| 比功耗 | 单位质量LNG | kJ/kg | 970.99 | 899.36 |

| 预冷换热器E-001 | 最小传热温差 | ℃ | 5.97 | 3.00 |

| 对数平均温差 | ℃ | 12.72 | 7.65 | |

| 液化换热器E-002 | 最小传热温差 | ℃ | 3.63 | 3.00 |

| 对数平均温差 | ℃ | 7.20 | 5.47 | |

| 过冷换热器E-003 | 最小传热温差 | ℃ | 3.20 | 3.00 |

| 对数平均温差 | ℃ | 5.87 | 4.95 | |

| 单元系统 | 功耗/kW | 物流 | 有效能/kW | ||

|---|---|---|---|---|---|

| 优化前 | 优化后 | 优化前 | 优化后 | ||

| 合计 | 235128.70 | 217782.94 | 有效能效率/% | 38.17 | 41.21 |

| 预冷循环 | 58356.77 | 55419.98 | 天然气进 | 156957.83 | 156957.83 |

| 液化循环 | 59123.69 | 64217.44 | LNG离开 | 246703.67 | 246703.67 |

| 过冷循环 | 117648.24 | 98145.52 | 有效能变化 | 89745.84 | 89745.84 |

表7 优化前后MFC液化过程的功耗及有效能

Table 7 Power consumption and effective energy of MFC liquefaction process before and after optimization

| 单元系统 | 功耗/kW | 物流 | 有效能/kW | ||

|---|---|---|---|---|---|

| 优化前 | 优化后 | 优化前 | 优化后 | ||

| 合计 | 235128.70 | 217782.94 | 有效能效率/% | 38.17 | 41.21 |

| 预冷循环 | 58356.77 | 55419.98 | 天然气进 | 156957.83 | 156957.83 |

| 液化循环 | 59123.69 | 64217.44 | LNG离开 | 246703.67 | 246703.67 |

| 过冷循环 | 117648.24 | 98145.52 | 有效能变化 | 89745.84 | 89745.84 |

图3 优化前后MFC液化过程各设备及系统的有效能损失对比

Fig.3 Comparison of effective energy loss of each equipment and system in MFC liquefaction process before and after optimization

| 参数 | 单位 | 优化前 | 优化后 | 差值 | 变化率 | 升或降 |

|---|---|---|---|---|---|---|

| 总资本 | USD | 164272000 | 166297000 | 2025000 | 1.2327% | 上升 |

| 公用工程 | USD/a | 172323000 | 165778000 | -6545000 | 3.7981% | 下降 |

| 总运行成本 | USD/a | 195599000 | 188585000 | -7014000 | 3.5859% | 下降 |

| 总设备成本 | USD | 166219800 | 168788900 | 2569100 | 1.5456% | 上升 |

| 总安装成本 | USD | 184817700 | 187397200 | 2579500 | 1.3957% | 上升 |

| 总投资成本 | USD | 515309500 | 522483100 | 7173600 | 1.3921% | 上升 |

| 总生产成本 | USD/a | 367922000 | 354363000 | -13559000 | 3.6853% | 下降 |

表8 优化前后MFC液化过程的经济性分析

Table 8 Economic analysis of MFC liquefaction process before and after optimization

| 参数 | 单位 | 优化前 | 优化后 | 差值 | 变化率 | 升或降 |

|---|---|---|---|---|---|---|

| 总资本 | USD | 164272000 | 166297000 | 2025000 | 1.2327% | 上升 |

| 公用工程 | USD/a | 172323000 | 165778000 | -6545000 | 3.7981% | 下降 |

| 总运行成本 | USD/a | 195599000 | 188585000 | -7014000 | 3.5859% | 下降 |

| 总设备成本 | USD | 166219800 | 168788900 | 2569100 | 1.5456% | 上升 |

| 总安装成本 | USD | 184817700 | 187397200 | 2579500 | 1.3957% | 上升 |

| 总投资成本 | USD | 515309500 | 522483100 | 7173600 | 1.3921% | 上升 |

| 总生产成本 | USD/a | 367922000 | 354363000 | -13559000 | 3.6853% | 下降 |

| 参数 | 单位 | 优化前 | 优化后 | 差值 | 变化率 | 升或降 |

|---|---|---|---|---|---|---|

| 冷公用工程 | kW | 4.269×105 | 4.095×105 | -1.740×104 | 4.076% | 下降 |

| CO2排放 | kg/h | 1.718×105 | 1.648×105 | -0.700×104 | 4.075% | 下降 |

表9 优化前后CO2排放分析

Table 9 Analysis of CO2 emissions before and after optimization

| 参数 | 单位 | 优化前 | 优化后 | 差值 | 变化率 | 升或降 |

|---|---|---|---|---|---|---|

| 冷公用工程 | kW | 4.269×105 | 4.095×105 | -1.740×104 | 4.076% | 下降 |

| CO2排放 | kg/h | 1.718×105 | 1.648×105 | -0.700×104 | 4.075% | 下降 |

| 1 | Howarth R W, Santoro R, Ingraffea A. Methane and the greenhouse-gas footprint of natural gas from shale formations[J]. Climatic Change, 2011, 106(4): 679-690. |

| 2 | Feser J S, Bassioni G, Gupta A K. Effect of naphthalene addition to ethanol in distributed combustion[J]. Applied Energy, 2018, 216: 1-7. |

| 3 | plc Shell. Shell LNG outlook 2024[R]. https://www.shell.com/energy-and-innovation/natural-gas/natural-gas-news-and-publications.html. |

| 4 | Revel D. BP statistical review of world energy [R]. http://www.bp.com/en/global/corporate/about-bp/energy-economics/statistical-review-of-world-energy.html. |

| 5 | Dudley B. BP statistical review of world energy[R]. https://www.bp.com/en/global/corporate/energy-economics/statistical-review-of-world-energy.html. |

| 6 | GU. International gas union world LNG report 2017[R]. http://www.igu.org/news/igu-releases-2017-world-lng-report. |

| 7 | Wood D A. A review and outlook for the global LNG trade[J]. Journal of Natural Gas Science and Engineering, 2012, 9: 6-27. |

| 8 | 范峥, 姬盼盼, 林亮, 等. 天然气液化工艺系统模拟与节能优化[J]. 现代化工, 2018, 38(9): 219-223. |

| Fan Z, Ji P P, Lin L, et al. System simulation and energy saving optimization of natural gas liquefaction process[J]. Modern Chemical Industry, 2018, 38(9): 219-223. | |

| 9 | 林畅, 白改玲, 王红, 等. 大型天然气液化技术与装置建设现状与发展[J]. 化工进展, 2014, 33(11): 2916-2922. |

| Lin C, Bai G L, Wang H, et al. Development and trend of liquefaction technology and construction of large-scale natural gas liquefaction plant[J]. Chemical Industry and Engineering Progress, 2014, 33(11): 2916-2922. | |

| 10 | Qyyum M A, Qadeer K, Lee S, et al. Innovative propane-nitrogen two-phase expander refrigeration cycle for energy-efficient and low-global warming potential LNG production[J]. Applied Thermal Engineering, 2018, 139: 157-165. |

| 11 | Moein P, Sarmad M, Ebrahimi H, et al. APCI-LNG single mixed refrigerant process for natural gas liquefaction cycle: analysis and optimization[J]. Journal of Natural Gas Science and Engineering, 2015, 26: 470-479. |

| 12 | Khan M S, Karimi I A, Lee M. Evolution and optimization of the dual mixed refrigerant process of natural gas liquefaction[J]. Applied Thermal Engineering, 2016, 96: 320-329. |

| 13 | Primabudi E, Morosuk T, Tsatsaronis G. Multi-objective optimization of propane pre-cooled mixed refrigerant (C3MR) LNG process[J]. Energy, 2019, 185: 492-504. |

| 14 | Khan M S, Lee M. Design optimization of single mixed refrigerant natural gas liquefaction process using the particle swarm paradigm with nonlinear constraints[J]. Energy, 2013, 49: 146-155. |

| 15 | Ghorbani B, Mafi M, Shirmohammadi R, et al. Optimization of operation parameters of refrigeration cycle using particle swarm and NLP techniques[J]. Journal of Natural Gas Science and Engineering, 2014, 21: 779-790. |

| 16 | Hwang J H, Roh M I, Lee K Y. Determination of the optimal operating conditions of the dual mixed refrigerant cycle for the LNG FPSO topside liquefaction process[J]. Computers & Chemical Engineering, 2013, 49: 25-36. |

| 17 | Zhang J R, Meerman H, Benders R, et al. Technical and economic optimization of expander-based small-scale natural gas liquefaction processes with absorption precooling cycle[J]. Energy, 2020, 191: 116592. |

| 18 | AspenTech. Aspen Plus: getting started using equation oriented modeling, version number: V8.4[Z]. 2013. |

| 19 | Javaloyes- Antón J, Kronqvist J, Caballero J A. Simulation-based optimization of distillation processes using an extended cutting plane algorithm[J]. Computers & Chemical Engineering, 2022, 159: 107655. |

| 20 | Vikse M, Watson H A J, Kim D, et al. Optimization of a dual mixed refrigerant process using a nonsmooth approach[J]. Energy, 2020, 196: 116999. |

| 21 | Kamath R S, Biegler L T, Grossmann I E. An equation-oriented approach for handling thermodynamics based on cubic equation of state in process optimization[J]. Computers & Chemical Engineering, 2010, 34(12): 2085-2096. |

| 22 | Watson H A J, Khan K A, Barton P I. Multistream heat exchanger modeling and design[J]. AIChE Journal, 2015,61(10): 3390-3403. |

| 23 | Matovu F, Mahadzir S, Ahmed R, et al. Synthesis and optimization of multilevel refrigeration systems using generalized disjunctive programming[J]. Computers & Chemical Engineering, 2022, 163: 107856. |

| 24 | Wang M Q, Zhang J, Xu Q. Optimal design and operation of a C3MR refrigeration system for natural gas liquefaction[J]. Computers & Chemical Engineering, 2012, 39: 84-95. |

| 25 | Lee G C, Smith R, Zhu X X. Optimal synthesis of mixed-refrigerant systems for low-temperature processes[J]. Industrial & Engineering Chemistry Research, 2002, 41(20): 5016-5028. |

| 26 | 郭揆常. 液化天然气(LNG)工艺与工程[M]. 北京: 中国石化出版社, 2014: 103. |

| Guo K C. Liquefied Natural Gas (LNG) Technology and Engineering[M]. Beijing: China Petrochemical Press, 2014: 103. | |

| 27 | Peng D Y, Robinson D B. A new two-constant equation of state[J]. Industrial & Engineering Chemistry Fundamentals, 1976, 15(1): 59-64. |

| 28 | Nawaz A, Qyyum M A, Qadeer K, et al. Optimization of mixed fluid cascade LNG process using a multivariate Coggins step-up approach: overall compression power reduction and exergy loss analysis[J]. International Journal of Refrigeration, 2019, 104: 189-200. |

| 29 | 丁贺, 孙恒, 何明, 等. MFC液化流程的分析和优化[J]. 低温与超导, 2015, 43(9): 1-5. |

| Ding H, Sun H, He M, et al. Analysis and optimization of mixed fluid cascade (MFC) process[J]. Cryogenics & Superconductivity, 2015, 43(9): 1-5. | |

| 30 | 尹全森, 李红艳, 季中敏, 等. 混合制冷剂循环的级数对制冷性能的影响[J]. 化工学报, 2009, 60(11): 2689-2693. |

| Yin Q S, Li H Y, Ji Z M, et al. Effect of number of stages of mixed refrigerant cycle on refrigeration performance[J]. CIESC Journal, 2009, 60(11): 2689-2693. |

| [1] | 王军锋, 张俊杰, 张伟, 王家乐, 双舒炎, 张亚栋. 液相放电等离子体分解甲醇制氢:电极配置的优化[J]. 化工学报, 2024, 75(9): 3277-3286. |

| [2] | 李彦熹, 王晔春, 谢向东, 王进芝, 王江, 周煜, 潘盈秀, 丁文涛, 郭烈锦. 蜗壳式多通道气液旋流分离器结构优化及分离特性研究[J]. 化工学报, 2024, 75(8): 2875-2885. |

| [3] | 李子扬, 郑楠, 方嘉宾, 魏进家. 再压缩S-CO2布雷顿循环性能分析及多目标优化[J]. 化工学报, 2024, 75(6): 2143-2156. |

| [4] | 许茹枫, 陈煜成, 高丹, 焦静雨, 高栋, 王海彬, 姚善泾, 林东强. 离子交换层析分离单抗电荷异质体的模型辅助过程优化[J]. 化工学报, 2024, 75(5): 1903-1911. |

| [5] | 黄志鸿, 周利, 柴士阳, 吉旭. 耦合加氢装置优化的多周期氢网络集成[J]. 化工学报, 2024, 75(5): 1951-1965. |

| [6] | 陈彦松, 阮达, 刘渊博, 郑通, 张帅帅, 马学虎. 微通道换热器拓扑结构优化与性能研究[J]. 化工学报, 2024, 75(3): 823-835. |

| [7] | 曾玉娇, 肖炘, 杨刚, 张意博, 郑光明, 李防, 汪凤玲. 基于机理与数据混合驱动的湿法磷酸生产过程代理建模与优化[J]. 化工学报, 2024, 75(3): 936-944. |

| [8] | 张领先, 刘斌, 邓琳, 任宇航. 基于改进TSO优化Xception的PEMFC故障诊断[J]. 化工学报, 2024, 75(3): 945-955. |

| [9] | 李文俊, 赵中阳, 倪震, 周灿, 郑成航, 高翔. 基于气-液传质强化的湿法烟气脱硫CFD模拟研究[J]. 化工学报, 2024, 75(2): 505-519. |

| [10] | 于嘉朋, 徐娜, 张玮, 康清源, 张鸿, 秦睦轩, 方嘉宾. 微反应器内气液磺化反应收率和能耗建模及多目标优化[J]. 化工学报, 2024, 75(10): 3681-3690. |

| [11] | 从文杰, 黄嘉雯, 范小强, 杨遥, 王靖岱, 阳永荣. 高压法LDPE管式反应器的结构优化方法[J]. 化工学报, 2024, 75(10): 3557-3567. |

| [12] | 余洋, 罗祎青, 魏荣辉, 张文慧, 袁希钢. 考虑节点中断风险的弹性供应链设计方法[J]. 化工学报, 2024, 75(1): 338-353. |

| [13] | 杨欣, 王文, 徐凯, 马凡华. 高压氢气加注过程中温度特征仿真分析[J]. 化工学报, 2023, 74(S1): 280-286. |

| [14] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [15] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号