化工学报 ›› 2025, Vol. 76 ›› Issue (8): 4165-4176.DOI: 10.11949/0438-1157.20250039

收稿日期:2025-01-10

修回日期:2025-02-12

出版日期:2025-08-25

发布日期:2025-09-17

通讯作者:

彭旭东

作者简介:王梦娇(1992—),女,博士,讲师,mjwangzj@163.com

基金资助:

Mengjiao WANG( ), Kaixue HU, Xiangkai MENG, Jinbo JIANG, Xudong PENG(

), Kaixue HU, Xiangkai MENG, Jinbo JIANG, Xudong PENG( )

)

Received:2025-01-10

Revised:2025-02-12

Online:2025-08-25

Published:2025-09-17

Contact:

Xudong PENG

摘要:

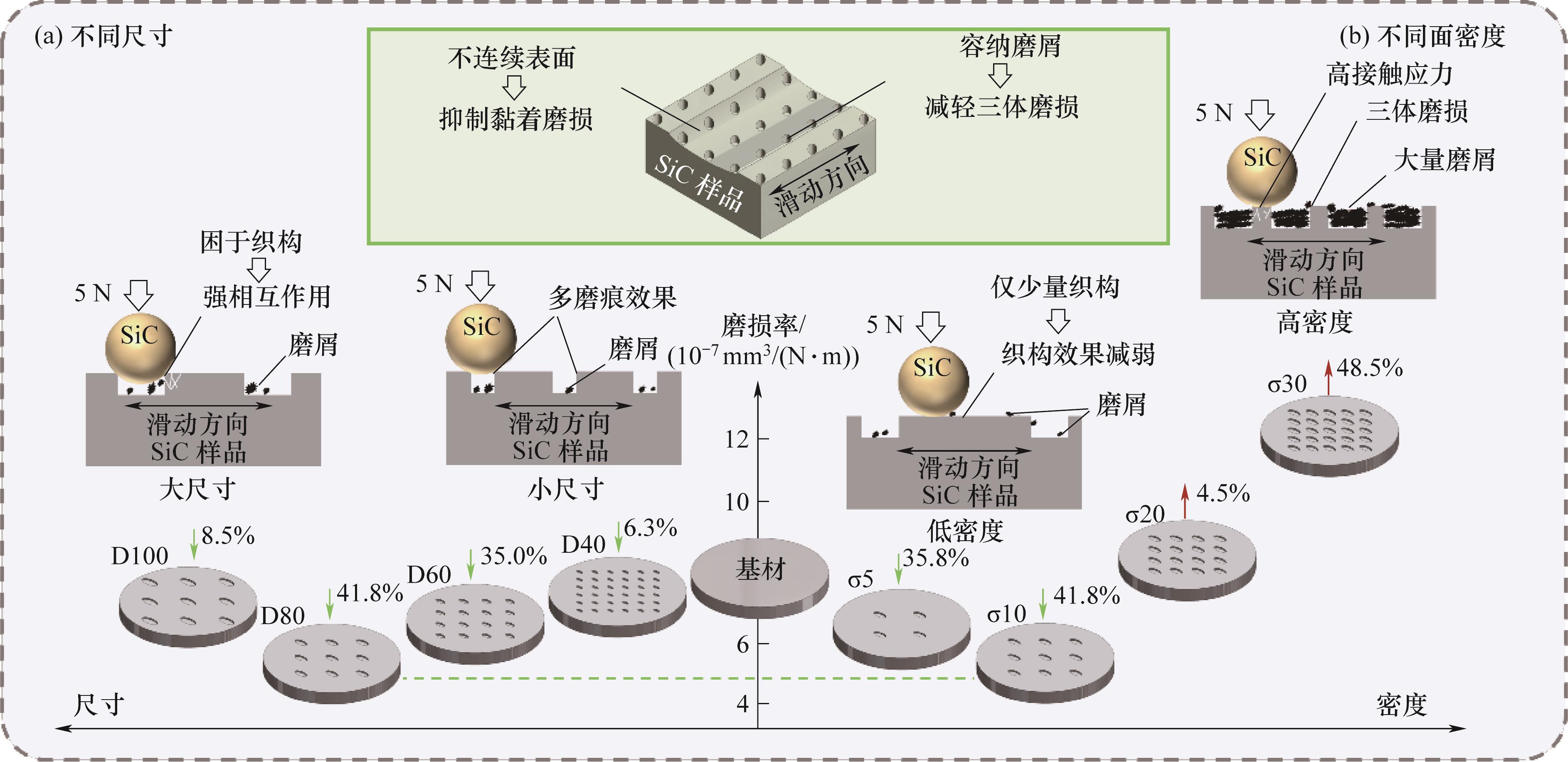

干气密封端面过度摩擦磨损是其常见失效形式之一,为研究微织构尺寸和面密度对织构化碳化硅(SiC)干气密封环摩擦学性能的影响,采用激光加工技术在SiC陶瓷表面制造45°椭圆微织构,探究织构尺寸和面密度对摩擦学性能影响规律。试验结果表明:随织构尺寸和面密度增加,摩擦系数和磨损率均呈现先降低后升高的趋势,在等效直径80 μm、面密度10%时摩擦学性能最好。织构尺寸过小,织构刮擦损伤严重;织构尺寸过大,摩擦副间剪切力增大。织构面密度过小,改形效果不显著;织构面密度过大,易引发应力集中和加剧磨粒磨损。尺寸和面密度均适宜的织构才可以发挥其收容磨屑、减小接触面积、减轻磨粒磨损与黏着磨损的效果,提升SiC的摩擦学性能。

中图分类号:

王梦娇, 胡凯学, 孟祥铠, 江锦波, 彭旭东. 碳化硅表面微织构尺寸和面密度对滑动密封面摩擦学性能的影响[J]. 化工学报, 2025, 76(8): 4165-4176.

Mengjiao WANG, Kaixue HU, Xiangkai MENG, Jinbo JIANG, Xudong PENG. Influence of micro-texture size and areal density on surface of silicon carbide on tribological properties of sliding sealing surfaces[J]. CIESC Journal, 2025, 76(8): 4165-4176.

| 技术参数 | 数值 |

|---|---|

| 密度/(g/cm3) | >3.10 |

| 热导率/(W/(m·K)) | 110 |

| 弹性模量/GPa | 400 |

| 弯曲强度/MPa | 400 |

| 硬度/HS | 115 |

| 粗糙度Ra/μm | 0.15 |

| 泊松比ν | 0.14 |

表1 SiC基材性能参数

Table 1 Performance parameter of SiC substrate

| 技术参数 | 数值 |

|---|---|

| 密度/(g/cm3) | >3.10 |

| 热导率/(W/(m·K)) | 110 |

| 弹性模量/GPa | 400 |

| 弯曲强度/MPa | 400 |

| 硬度/HS | 115 |

| 粗糙度Ra/μm | 0.15 |

| 泊松比ν | 0.14 |

图2 (a) 激光织构加工原理图;(b) 不同尺寸和面密度织构参数示意图

Fig.2 (a) Schematic diagram of laser texturing processing; (b) Schematic diagram of texture parameters with different sizes and areal densities

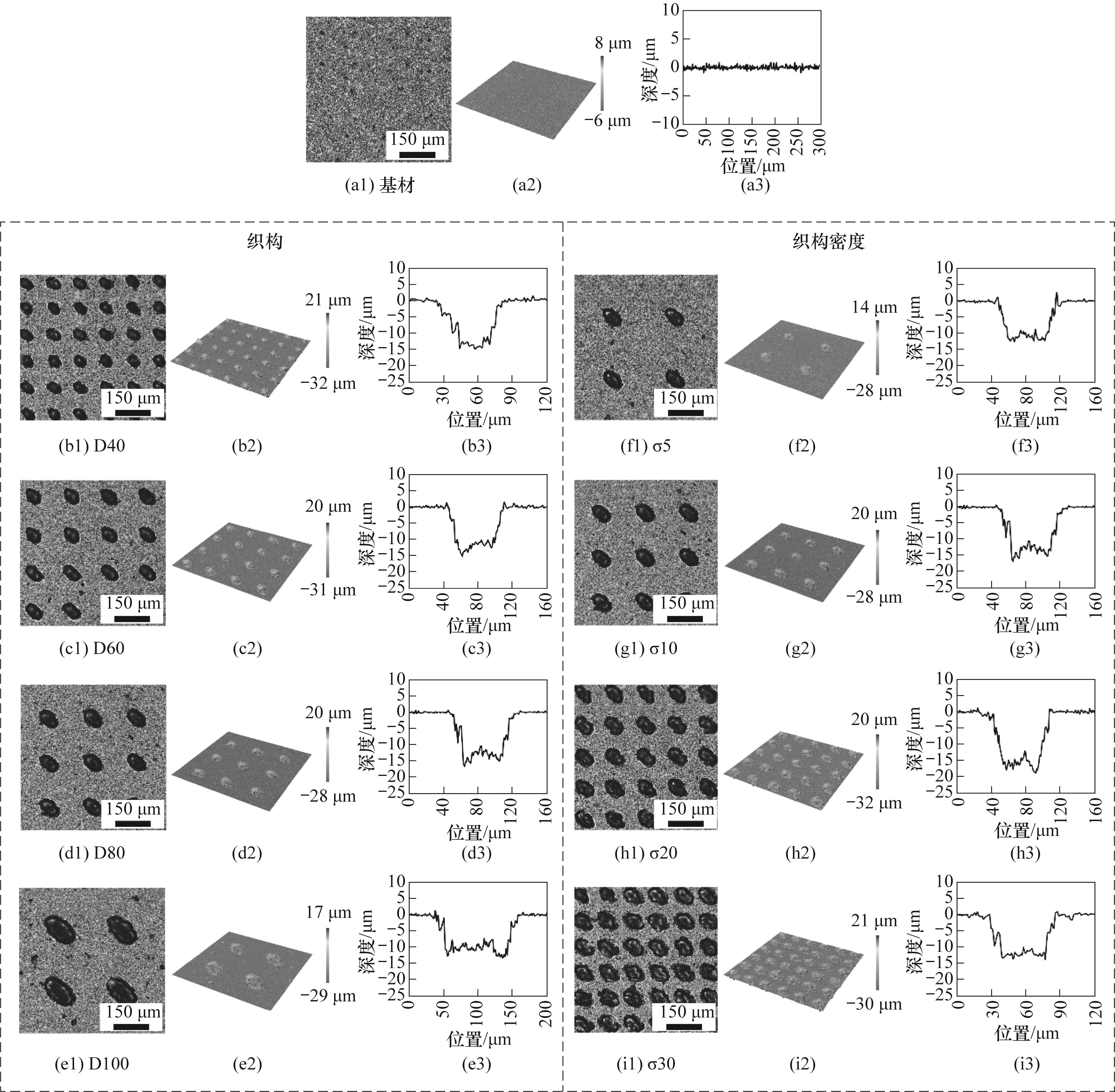

图4 SiC基材与不同尺寸和面密度的45°椭圆形织构化SiC的光学显微镜、三维形貌和二维轮廓图

Fig.4 Optical microscopy images, 3D photographs and 2D contour maps of SiC substrates and 45° elliptical-textured SiC with different sizes and areal densities

图5 SiC基材及不同尺寸和不同面密度的45°椭圆形织构化SiC表面粗糙度Sa

Fig.5 Surface roughness of SiC substrate and 45° elliptical-textured SiC with different sizes and different areal densities

图6 SiC基材和不同尺寸的45°椭圆形织构化SiC的摩擦系数曲线(a)、平均摩擦系数(b)和磨损率(c)

Fig.6 Friction coefficient (a), average friction coefficient (b) and wear rate (c) of SiC substrates and 45° elliptical-textured SiC with different sizes

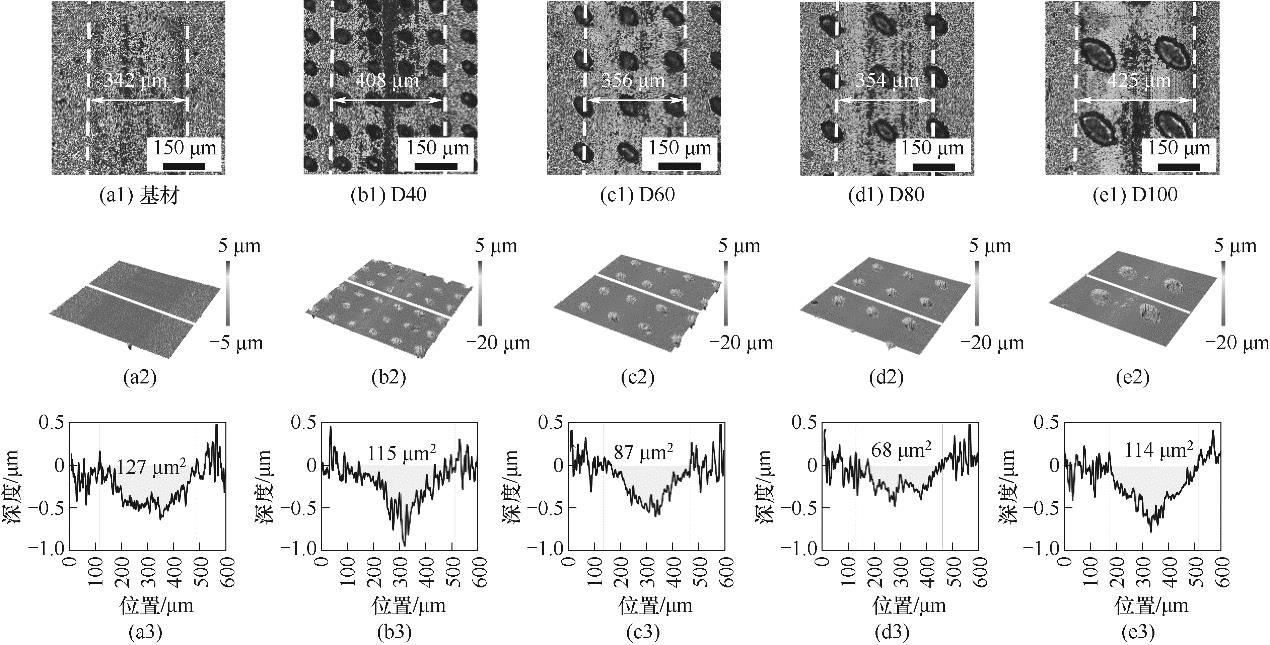

图7 SiC基材和不同尺寸的45°椭圆形织构化SiC表面磨损形貌的光学显微镜、三维形貌和二维轮廓图

Fig.7 Optical microscopy images, 3D photographs, and 2D contour maps of the surface wear morphologies of SiC substrates and 45° elliptical-textured SiC with different sizes

图8 SiC基材和不同尺寸的45°椭圆形织构化SiC表面磨损的SEM形貌图

Fig.8 SEM images of surface wear morphologies of SiC substrates and 45° elliptical-textured SiC with different sizes

图9 SiC基材和不同面密度的45°椭圆形织构化SiC的摩擦系数(a)、平均摩擦系数(b)和磨损率(c)

Fig.9 Friction coefficient (a), average friction coefficient (b) and wear rate (c) of SiC substrates and 45° elliptical-textured SiC with different areal densities

图10 SiC基材和不同面密度的45°椭圆形织构化SiC表面磨损形貌的光学显微镜、三维形貌和二维轮廓图

Fig.10 Optical microscope images, 3D and 2D contour maps of surface wear morphologies of SiC substrates and 45° elliptical-textured SiC with different areal densities

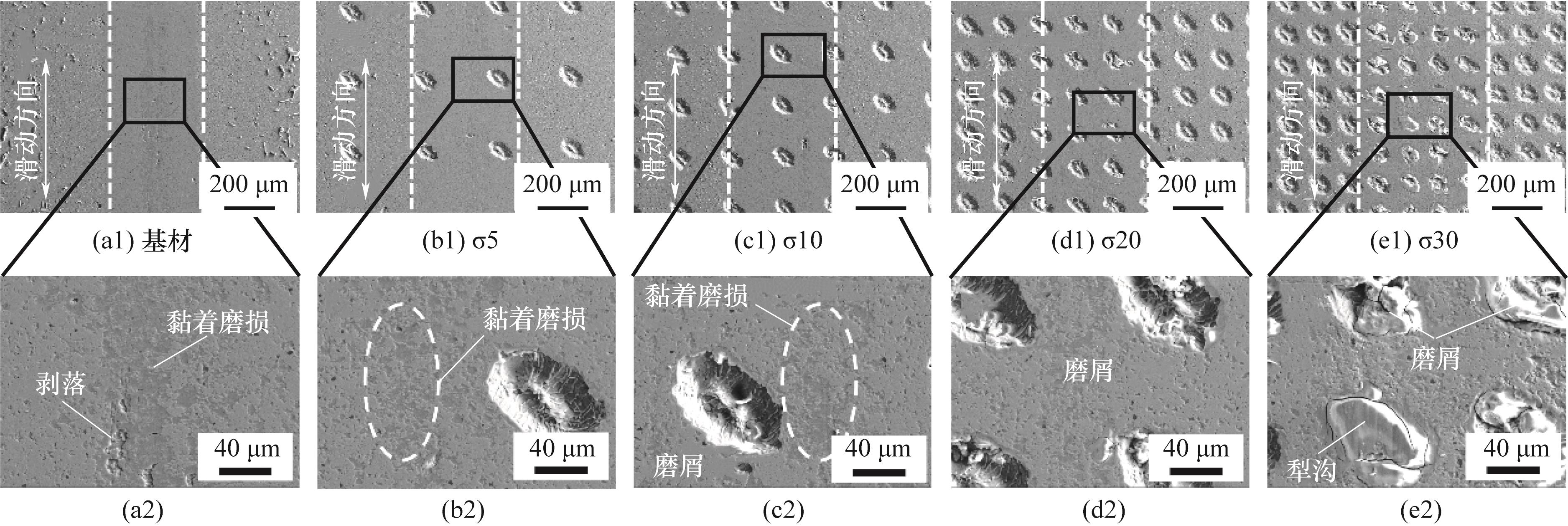

图11 SiC基材和不同面密度的45°椭圆形织构化SiC表面磨损的SEM形貌图

Fig.11 SEM images of surface wear morphologies of SiC substrates and 45° elliptical-textured SiC with different areal densities

图12 不同尺寸和面密度的45°椭圆形织构化SiC表面摩擦磨损机理图

Fig.12 Mechanism diagrams of surface friction and wear for 45° elliptical-textured SiC with different sizes and areal densities

| [1] | Zhang L X, Ding X X, Wang S P, et al. Research progress on the dynamic stability of dry gas seals[J]. Processes, 2024, 12(3): 575. |

| [2] | 江鹏, 江锦波, 彭旭东, 等. 传热模型对近临界工况CO2干气密封温压分布和稳态性能影响[J]. 化工学报, 2021, 72(8): 4239-4254. |

| Jiang P, Jiang J B, Peng X D, et al. Influence of heat transfer model on temperature and pressure distribution and steady state performance of CO2 dry gas seal under near critical condition[J]. CIESC Journal, 2021, 72(8): 4239-4254. | |

| [3] | 柴杨洋, 彭旭东, 江锦波, 等. 浸锑石墨与无压烧结SiC和3D打印SiC密封材料配对副的摩擦磨损特性研究[J]. 化工学报, 2024, 75(5): 1966-1976. |

| Chai Y Y, Peng X D, Jiang J B, et al. Study on friction and wear behaviors of antimony impregnated graphite with pressureless sintered SiC and 3D-printed SiC sealing materials pairs[J]. CIESC Journal, 2024, 75(5): 1966-1976. | |

| [4] | Fan W J, Huang W F, Liu Y, et al. State evolution of dry gas seal during repeated start-stop operation using acoustic emission method[J]. Tribology Transactions, 2020, 63(1): 173-181. |

| [5] | 马宏军. 长输管线压缩机Burgmann干气密封国内维修技术探讨[J]. 油气田地面工程, 2019, 38(7): 60-66. |

| Ma H J. Domestic repair technology discussion on Burgmann dry gas seal used for the long distance transportation pipeline compressor[J]. Oil-Gas Field Surface Engineering, 2019, 38(7): 60-66. | |

| [6] | 李敦钫. 碳化硅和氧化铝基陶瓷材料的摩擦磨损特性研究[D]. 昆明: 昆明理工大学, 2003. |

| Li D F. Study on friction and wear characteristics of silicon carbide and alumina-based ceramic materials[D]. Kunming: Kunming University of Science and Technology, 2003. | |

| [7] | Dorkar N V, Kim Y W, Venkata Manoj Kumar B. Role of hBN content, humidity, and temperature on the sliding wear behaviour of SiC ceramics[J]. Journal of the European Ceramic Society, 2023, 43(16): 7282-7295. |

| [8] | 赵文静, 屠治荣, 孟祥铠, 等. 非规则V形表面织构化机械端面密封性能研究[J]. 化工学报, 2022, 73(10): 4585-4593. |

| Zhao W J, Tu Z R, Meng X K, et al. Effect of irregular V-shaped surface texture on the performance of mechanical face seal[J]. CIESC Journal, 2022, 73(10): 4585-4593. | |

| [9] | 马文林, 未亮亮. 微织构对铜基自润滑复合材料摩擦磨损性能的影响[J]. 表面技术, 2023, 52(1): 93-102. |

| Ma W L, Wei L L. Effect of micro-texture on the friction and wear performance of copper-based self-lubricating composites[J]. Surface Technology, 2023, 52(1): 93-102. | |

| [10] | Zhang K D, Deng J X, Ding Z L, et al. Improving dry machining performance of TiAlN hard-coated tools through combined technology of femtosecond laser-textures and WS2 soft—coatings[J]. Journal of Manufacturing Processes, 2017, 30: 492-501. |

| [11] | Rosenkranz A, Costa H L, Baykara M Z, et al. Synergetic effects of surface texturing and solid lubricants to tailor friction and wear — a review[J]. Tribology International, 2021, 155: 106792. |

| [12] | Arslan A, Masjuki H H, Varman M, et al. Effects of texture diameter and depth on the tribological performance of DLC coating under lubricated sliding condition[J]. Applied Surface Science, 2015, 356: 1135-1149. |

| [13] | 黄云磊, 钟林, 王国荣, 等. 表面织构润滑减摩的国内外研究现状及进展[J]. 表面技术, 2021, 50(12): 217-232. |

| Huang Y L, Zhong L, Wang G R, et al. Research status and progress of surface texture lubrication and friction reduction[J]. Surface Technology, 2021, 50(12): 217-232. | |

| [14] | Segu D Z, Choi S G, Choi J H, et al. The effect of multi-scale laser textured surface on lubrication regime[J]. Applied Surface Science, 2013, 270: 58-63. |

| [15] | 赵立新, 章宝玲, 刘洋, 等. 基于表面织构技术改善摩擦学性能的研究进展[J]. 摩擦学学报, 2022, 42(1): 202-224. |

| Zhao L X, Zhang B L, Liu Y, et al. State of the art for improving tribological performance based on of surface texturing technology[J]. Tribology, 2022, 42(1): 202-224. | |

| [16] | Zhu C X, Wang X Y, Ma W B. Experimental study on the wear characteristics of textured joint surfaces under bionic lubrication[J]. Key Engineering Materials, 2023, 945: 19-25. |

| [17] | 于海武, 袁思欢, 孙造, 等. 微凹坑形状对试件表面摩擦特性的影响[J]. 华南理工大学学报(自然科学版), 2011, 39(1): 106-110, 123. |

| Yu H W, Yuan S H, Sun Z, et al. Effect of micro-dimple shapes on tribological properties of specimen surfaces[J]. Journal of South China University of Technology (Natural Science Edition), 2011, 39(1): 106-110, 123. | |

| [18] | 彭旭东, 佘宝瑛, 孟祥铠, 等. 不同排布方向性椭圆孔液体润滑机械密封性能的研究[J]. 摩擦学学报, 2013, 33(5): 481-487. |

| Peng X D, She B Y, Meng X K, et al. Sealing performance of liquid-lubricated mechanical seals with different arrangements inclined elliptical dimples[J]. Tribology, 2013, 33(5): 481-487. | |

| [19] | 刘凯. 干气密封双端面织构的摩擦磨损与密封性能[D]. 济南: 山东大学, 2022. |

| Liu K. Friction, wear and sealing performance of double-end texture of dry gas seal[D]. Jinan: Shandong University, 2022. | |

| [20] | 王丽丽, 张伟, 赵兴堂, 等. 微织构尺寸对轴承摩擦磨损性能的影响[J]. 摩擦学学报, 2021, 41(5): 723-730. |

| Wang L L, Zhang W, Zhao X T, et al. Effect of micro-texture size on friction and wear performance of journal bearing[J]. Tribology, 2021, 41(5): 723-730. | |

| [21] | Panigrahi D K, Sarangi M. Tribological performance of positive deterministic textured surfaces in parallel sliding lubricated contacts: effect of texture size and height[J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2020, 234(12): 1908-1925. |

| [22] | Janssen A, Pinedo B, Igartua A, et al. Study on friction and wear reducing surface micro-structures for a positive displacement pump handling highly abrasive shale oil[J]. Tribology International, 2017, 107: 1-9. |

| [23] | 杨程, 彭迎娇, 刘思琪, 等. 表面圆形凹坑微织构对DC53模具钢的摩擦学性能影响[J]. 塑性工程学报, 2024, 31(2): 208-217. |

| Yang C, Peng Y J, Liu S Q, et al. Influence of surface circular pit micro-texture on tribological properties of DC53 die steel[J]. Journal of Plasticity Engineering, 2024, 31(2): 208-217. | |

| [24] | 杨洋, 龙伟民, 程战, 等. 仿生六边形织构对40Cr钢摩擦学性能的影响[J]. 金属热处理, 2023, 48(12): 250-254. |

| Yang Y, Long W M, Cheng Z, et al. Effect of bionic hexagonal texture on tribological properties of 40Cr steel[J]. Heat Treatment of Metals, 2023, 48(12): 250-254. | |

| [25] | Zou H B, Yan S, Shen T, et al. Efficiency of surface texturing in the reducing of wear for tests starting with initial point contact[J]. Wear, 2021, 482: 203957. |

| [26] | Xing Y Q, Deng J X, Feng X T, et al. Effect of laser surface texturing on Si3N4/TiC ceramic sliding against steel under dry friction[J]. Materials & Design, 2013, 52: 234-245. |

| [27] | 周跃杰, 彭旭东, 江锦波, 等. 端面宽度对机械密封极限pc v(pressure × velocity)值的影响[J]. 摩擦学学报, 2022, 42(1): 176-186. |

| Zhou Y J, Peng X D, Jiang J B, et al. Effects of end face width of mechanical seals on the limit pc v(pressure × velocity) value[J]. Tribology, 2022, 42(1): 176-186. | |

| [28] | 邓雯, 赵晓琴, 李双建, 等. Al2O3/MoS2复合涂层的制备及摩擦磨损性能[J]. 中国表面工程, 2017, 30(5): 110-118. |

| Deng W, Zhao X Q, Li S J, et al. Preparation and tribological properties of Al2O3/MoS2 composite coating[J]. China Surface Engineering, 2017, 30(5): 110-118. | |

| [29] | 张力, 朱传军, 吴剑钊, 等. 激光淬火化表面织构对盾构滚刀特种钢摩擦磨损性能影响的研究[J]. 热加工工艺, 2023, 52(22): 24-28. |

| Zhang L, Zhu C J, Wu J Z, et al. Effect of laser quenched surface texture on friction and wear properties of shield hob special steel[J]. Hot Working Technology, 2023, 52(22): 24-28. | |

| [30] | 孙建芳, 李傲松, 苏峰华, 等. 表面织构钛合金的干摩擦和全氟聚醚油润滑下的摩擦学性能研究[J]. 摩擦学学报, 2018, 38(6): 658-664. |

| Sun J F, Li A S, Su F H, et al. Tribological property of titanium alloy surface with different texture structure under dry friction and perfluoropolyether lubrication[J]. Tribology, 2018, 38(6): 658-664. | |

| [31] | 吴高灿. 复合涂层表面织构化刀具微量润滑切削钛合金试验研究[D]. 湘潭: 湘潭大学, 2021. |

| Wu G C. Experimental study on micro-lubrication cutting of titanium alloy with textured tool on composite coating surface[D]. Xiangtan: Xiangtan University, 2021. | |

| [32] | 何霞, 廖文玲, 王国荣, 等. 织构边缘凸起对压裂泵柱塞密封副摩擦性能的影响[J]. 润滑与密封, 2016, 41(7): 96-101. |

| He X, Liao W L, Wang G R, et al. Influence of edges bulgeof texture on tribological performances of plunger-seal pair in fracturing pump[J]. Lubrication Engineering, 2016, 41(7): 96-101. | |

| [33] | 黄志强, 熊辰, 钱韦吉, 等. 采油液力马达转子表面织构参数对其摩擦副摩擦学性能的影响[J]. 表面技术, 2022, 51(2): 176-184, 231. |

| Huang Z Q, Xiong C, Qian W J, et al. The effect of surface texture parameters of the rotor surface texture of oil production hydraulic motor on the tribological performance of the friction pair[J]. Surface Technology, 2022, 51(2): 176-184, 231. | |

| [34] | 解长鹏, 刘国东, 刘祁文, 等. 沟槽微织构硬质合金刀具的摩擦仿真分析[J]. 工具技术, 2022, 56(2): 43-47. |

| Xie C P, Liu G D, Liu Q W, et al. Attrition simulation analysis of carbide tool with groove microtexture[J]. Tool Engineering, 2022, 56(2): 43-47. |

| [1] | 江锦波, 陈竹鑫, 肖洋溢, 彭新, 陈源, 于辰, 孟祥铠, 彭旭东. 运行工况对超临界CO2干气密封端面热力学过程及稳态性能影响研究[J]. 化工学报, 2025, 76(6): 2913-2928. |

| [2] | 柴杨洋, 彭旭东, 江锦波, 孟祥铠, 马艺. 浸锑石墨与无压烧结SiC和3D打印SiC密封材料配对副的摩擦磨损特性研究[J]. 化工学报, 2024, 75(5): 1966-1976. |

| [3] | 朱芝, 许恒杰, 陈维, 毛文元, 邓强国, 孙雪剑. 超临界二氧化碳螺旋槽干气密封热流耦合润滑临界阻塞特性研究[J]. 化工学报, 2024, 75(2): 604-615. |

| [4] | 赵志萍, 陈晨, 汤琼, 徐红, 刘雷, 董晋湘. 多己基萘/聚α-烯烃锂基润滑脂的流变学和摩擦学性能[J]. 化工学报, 2023, 74(6): 2555-2564. |

| [5] | 丁俊华, 俞树荣, 王世鹏, 洪先志, 包鑫, 丁雪兴. 多重效应下超高速干气密封流场模拟及密封性能试验[J]. 化工学报, 2023, 74(5): 2088-2099. |

| [6] | 宋伟, 李万佳, 俞树荣, 马荣荣. 热力耦合下TC4合金微动磨损行为影响的研究[J]. 化工学报, 2022, 73(3): 1324-1334. |

| [7] | 孙雪剑, 宋鹏云, 毛文元, 邓强国, 许恒杰, 陈维. 考虑密封环材料属性和表面形貌干气密封启停阶段的动态接触特性分析[J]. 化工学报, 2021, 72(8): 4279-4291. |

| [8] | 江鹏, 江锦波, 彭旭东, 孟祥铠, 马艺. 传热模型对近临界工况CO2干气密封温压分布和稳态性能影响[J]. 化工学报, 2021, 72(8): 4239-4254. |

| [9] | 严如奇, 丁雪兴, 徐洁, 洪先志, 包鑫. 基于湍流模型的S-CO2干气密封流场与稳态性能分析[J]. 化工学报, 2021, 72(8): 4292-4303. |

| [10] | 周剑, 江倩, 杨怡, 冯厦厦, 仲兆祥, 邢卫红. 烧结助剂对低温制备碳化硅多孔陶瓷性能的影响[J]. 化工学报, 2021, 72(4): 2293-2299. |

| [11] | 陆鹏飞, 金志浩, 崔彦斌, 许光文, 武荣成. 原料粒度对合成碳化硅的影响研究[J]. 化工学报, 2021, 72(4): 2300-2308. |

| [12] | 商浩, 陈源, 李孝禄, 王冰清, 李运堂, 彭旭东. 膜厚扰动下的非线性效应对干气密封性能影响研究[J]. 化工学报, 2021, 72(4): 2213-2222. |

| [13] | 江锦波, 滕黎明, 孟祥铠, 李纪云, 彭旭东. 基于多变量摄动的超临界CO2干气密封动态特性[J]. 化工学报, 2021, 72(4): 2190-2202. |

| [14] | 于辰,江锦波,赵文静,李纪云,彭旭东,王玉明. 基于微段组合的干气密封端面型槽结构模型及其参数影响[J]. 化工学报, 2021, 72(10): 5294-5309. |

| [15] | 严如奇, 洪先志, 包鑫, 徐洁, 丁雪兴. 超临界二氧化碳干气密封相态分布规律与密封性能研究[J]. 化工学报, 2020, 71(8): 3681-3690. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号