化工学报 ›› 2025, Vol. 76 ›› Issue (8): 3864-3872.DOI: 10.11949/0438-1157.20250117

收稿日期:2025-02-07

修回日期:2025-03-18

出版日期:2025-08-25

发布日期:2025-09-17

通讯作者:

刘剑

作者简介:周航(2000—),男,硕士研究生,zhouhang18866@163.com

基金资助:

Hang ZHOU1( ), Sijing ZHANG1, Jian LIU1,2(

), Sijing ZHANG1, Jian LIU1,2( ), Xiaosong ZHANG1,2

), Xiaosong ZHANG1,2

Received:2025-02-07

Revised:2025-03-18

Online:2025-08-25

Published:2025-09-17

Contact:

Jian LIU

摘要:

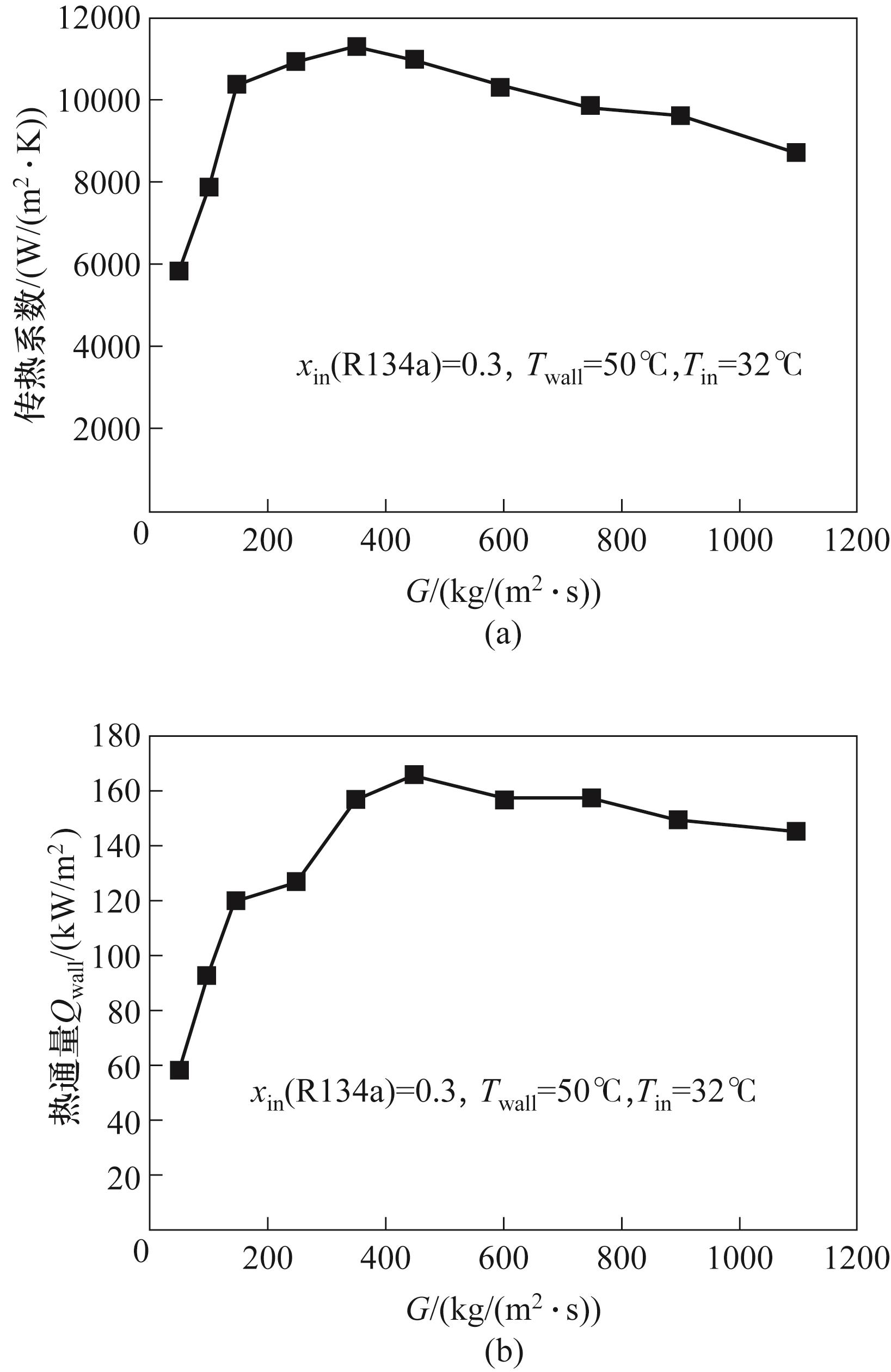

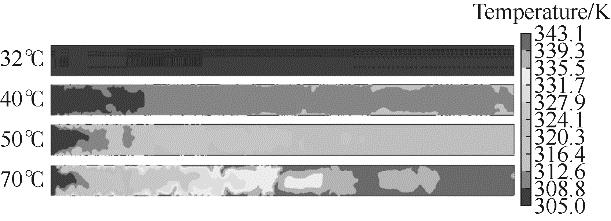

为研究非共沸工质在小通道内的流动沸腾换热特性,基于VOF多相流模型并结合改进Lee相变模型,研究了非共沸工质(R134a/R245fa)在水平小通道内的流动沸腾换热特性。通过与实验数据对比,验证了模型的可靠性。进一步在恒定壁温条件下,分析了质量流密度[50~1100 kg/(m²·s)]、工质组分配比[R134a入口浓度(质量分数)为0.1~0.9]和加热壁温(32~70℃)对流动沸腾换热性能的影响。结果表明,低质量流密度对传热系数影响明显,在低质量流密度下,当质量流密度从50 kg/(m²·s)上升至400 kg/(m²·s)时,传热系数提高超过90%,在高质量流密度条件下,当质量流密度增大到1100 kg/(m²·s)时,传热系数降低约27%。同时,当低沸点组分R134a入口浓度从0.1升至0.3时,传热系数下降15%~45%;而在高浓度下,当壁温从32℃升到40℃时,传热系数显著提升,随后趋于平稳,最大值出现在40℃左右。研究结果为非共沸工质在小通道内的研究和应用提供支撑。

中图分类号:

周航, 张斯婧, 刘剑, 张小松. 小通道内非共沸工质流动沸腾换热数值分析[J]. 化工学报, 2025, 76(8): 3864-3872.

Hang ZHOU, Sijing ZHANG, Jian LIU, Xiaosong ZHANG. Numerical analysis of flow boiling heat transfer of zeotropic mixtures in mini-channels[J]. CIESC Journal, 2025, 76(8): 3864-3872.

图5 质量流密度对小通道中R134a/R245fa流动沸腾传热系数(a)和总热通量(b)的影响

Fig.5 Effect of mass flux density on the flow boiling heat transfer coefficient (a) and total heat flux density (b) in a mini-channel for R134a/R245fa

图12 壁面温度对小通道中R134a/R245fa流动沸腾流体温度分布的影响

Fig.12 Effect of wall temperature on flow boiling fluid temperature distribution of R134a/R245fa in mini-channels

| [1] | Kadam S T, Kumar R. Twenty first century cooling solution: microchannel heat sinks[J]. International Journal of Thermal Sciences, 2014, 85: 73-92. |

| [2] | Zheng N, Wei J J, Zhao L. Analysis of a solar Rankine cycle powered refrigerator with zeotropic mixtures[J]. Solar Energy, 2018, 162: 57-66. |

| [3] | Richardson E S. Thermodynamic performance of new thermofluidic feed pumps for organic rankine cycle applications[J]. Applied Energy, 2016, 161: 75-84. |

| [4] | Wang J L, Zhao L, Wang X D. A comparative study of pure and zeotropic mixtures in low-temperature solar Rankine cycle[J]. Applied Energy, 2010, 87(11): 3366-3373. |

| [5] | Guo C, Wang J, Du X Z, et al. Experimental flow boiling characteristics of R134a/R245fa mixture inside smooth horizontal tube[J]. Applied Thermal Engineering, 2016, 103: 901-908. |

| [6] | Dang C, Jia L, Zhang X, et al. Experimental investigation on flow boiling characteristics of zeotropic binary mixtures (R134a/R245fa) in a rectangular micro-channel[J]. International Journal of Heat and Mass Transfer, 2017, 115: 782-794. |

| [7] | Dang C, Jia L, Peng Q, et al. Experimental study on flow boiling heat transfer for pure and zeotropic refrigerants in multi-microchannels with segmented configurations[J]. International Journal of Heat and Mass Transfer, 2018, 127: 758-768. |

| [8] | 代宝民. CO2/低GWP工质二元混合物微小通道内流动换热机理的研究[D]. 天津: 天津大学, 2015. |

| Dai B M. Research on heat transfer mechanism of CO2/low-GWP refrigerant binary mixtures flowing in micro- and mini-channels[D]. Tianjin: Tianjin University, 2015. | |

| [9] | Azzolin M, Bortolin S, Del Col D. Flow boiling heat transfer of a zeotropic binary mixture of new refrigerants inside a single microchannel[J]. International Journal of Thermal Sciences, 2016, 110: 83-95. |

| [10] | In S, Baek S, Jin L X, et al. Flow boiling heat transfer of R123/R134a mixture in a microchannel[J]. Experimental Thermal and Fluid Science, 2018, 99: 474-486. |

| [11] | Bamorovat Abadi G, Yun E, Kim K C. Flow boiling characteristics of R134a and R245fa mixtures in a vertical circular tube[J]. Experimental Thermal and Fluid Science, 2016, 72: 112-124. |

| [12] | Azzolin M, Berto A, Bortolin S, et al. Condensation of ternary low GWP zeotropic mixtures inside channels[J]. International Journal of Refrigeration, 2019, 103: 77-90. |

| [13] | Deng H, Rossato M, Fernandino M, et al. A new simplified model for condensation heat transfer of zeotropic mixtures inside horizontal tubes[J]. Applied Thermal Engineering, 2019, 153: 779-790. |

| [14] | Mastrullo R, Mauro A W, Napoli G, et al. Flow boiling of azeotropic and non-azeotropic mixtures. Effect of the glide temperature difference on the nucleate boiling contribution: assessment of methods[J]. Journal of Physics: Conference Series, 2020, 1599(1): 012053. |

| [15] | Chen J Y, Bao L L, Xu W C, et al. Experimental study on flow boiling heat transfer characteristics of zeotropic mixture R1233zd(E)/R1234yf in horizontal tube[J]. Applied Thermal Engineering, 2024, 254: 123942. |

| [16] | Qi Z L, Jia L, Dang C, et al. Heat transfer enhancement for flow boiling of zeotropic mixtures with regulating liquid mass transfer resistance[J]. International Journal of Heat and Fluid Flow, 2024, 107: 109402. |

| [17] | Patra C K, Bhattacharya A, Das P K. Heat transfer characteristics of acetone and methanol flow boiling in parallel microchannel heat sink: a parametric study and assessment of predictive correlations[J]. Applied Thermal Engineering, 2025, 270: 126217. |

| [18] | Szczukiewicz S, Magnini M, Thome J R. Proposed models, ongoing experiments, and latest numerical simulations of microchannel two-phase flow boiling[J]. International Journal of Multiphase Flow, 2014, 59: 84-101. |

| [19] | ANSYS Inc. ANSYS FLUENT Theory Guide[M]. Canonsburg, PA: ANSYS Inc., 2009. |

| [20] | Lee J, O'Neill L E, Lee S, et al. Experimental and computational investigation on two-phase flow and heat transfer of highly subcooled flow boiling in vertical upflow[J]. International Journal of Heat and Mass Transfer, 2019, 136: 1199-1216. |

| [21] | Li K, Liu Y C, Wen J, et al. A numerical model for the flow condensation of the binary zeotropic mixture[J]. International Communications in Heat and Mass Transfer, 2022, 130: 105767. |

| [22] | Lee W H. Computational Methods for Two-Phase Flow and Particle Transport[M]. Singapore: World Scientific, 2013. |

| [23] | 杨志强, 贺波, 刘鹏飞. R14和R23及其非共沸混合物在水平管内沸腾换热特性的模拟研究[J]. 制冷技术, 2024, 44(1): 31-38. |

| Yang Z Q, He B, Liu P F. Simulation of boiling heat transfer characteristics of pure refrigerants of R14 and R23 and their zeotropic mixtures inside horizontal tube[J]. Chinese Journal of Refrigeration Technology, 2024, 44(1): 31-38. | |

| [24] | Revellin R, Dupont V, Ursenbacher T, et al. Characterization of diabatic two-phase flows in microchannels: flow parameter results for R-134a in a 0.5mm channel[J]. International Journal of Multiphase Flow, 2006, 32(7): 755-774. |

| [25] | Lee W H. A Pressure Iteration Scheme for Two-Phase Flow Modeling[M]. Washington D.C.: Hemisphere Publishing, 1980. |

| [26] | Luo Y, Li W, Zhang J Z, et al. Analysis of thermal performance and pressure loss of subcooled flow boiling in manifold microchannel heat sink[J]. International Journal of Heat and Mass Transfer, 2020, 162: 120362. |

| [27] | Luo Y, Zhang J Z, Li W. A comparative numerical study on two-phase boiling fluid flow and heat transfer in the microchannel heat sink with different manifold arrangements[J]. International Journal of Heat and Mass Transfer, 2020, 156: 119864. |

| [28] | Fang C, David M, Rogacs A, et al. Volume of fluid simulation of boiling two-phase flow in a vapor-venting microchannel[J]. Frontiers in Heat and Mass Transfer, 2010, 1(1): 1-11. |

| [29] | Wong K C, Chong J H. Hydrodynamics and heat transfer prior to onset of nucleate boiling in a rectangular microchannel heat sink[J]. International Communications in Heat and Mass Transfer, 2015, 64: 34-41. |

| [30] | Luo Y, Li J Y, Zhou K, et al. A numerical study of subcooled flow boiling in a manifold microchannel heat sink with varying inlet-to-outlet width ratio[J]. International Journal of Heat and Mass Transfer, 2019, 139: 554-563. |

| [31] | Kim J, Cho J Y, Lee J S. Flow boiling enhancement by bubble mobility on heterogeneous wetting surface in microchannel[J]. International Journal of Heat and Mass Transfer, 2020, 153: 119631. |

| [32] | Qu W L, Mudawar I. Flow boiling heat transfer in two-phase micro-channel heat sinks ( Ⅰ ) : Experimental investigation and assessment of correlation methods[J]. International Journal of Heat and Mass Transfer, 2003, 46(15): 2755-2771. |

| [33] | Li W, Zhou K, Li J Y, et al. Effects of heat flux, mass flux and two-phase inlet quality on flow boiling in a vertical superhydrophilic microchannel[J]. International Journal of Heat and Mass Transfer, 2018, 119: 601-613. |

| [34] | Yang B, Wang P, Bar-Cohen A. Mini-contact enhanced thermoelectric cooling of hot spots in high power devices[J]. IEEE Transactions on Components and Packaging Technologies, 2007, 30(3): 432-438. |

| [1] | 孙云龙, 徐肖肖, 黄永方, 郭纪超, 陈卫卫. 水平光滑管内CO2流动沸腾的非绝热可视化研究[J]. 化工学报, 2025, 76(S1): 230-236. |

| [2] | 马永丽, 安澍, 杨捷, 刘明言. 气液固流化床直接数值模拟研究进展[J]. 化工学报, 2025, 76(8): 3772-3788. |

| [3] | 张淇栋, 艾立强, 马原, 吴胜宝, 王磊, 厉彦忠. 基于一维漂移流模型的低温管路预冷过程两相流动与换热特性研究[J]. 化工学报, 2025, 76(8): 3842-3852. |

| [4] | 刘建海, 王磊, 鲁朝金, 白志山, 张平雨. 耦合电化学与多相流模型的电解槽性能研究[J]. 化工学报, 2025, 76(8): 3885-3893. |

| [5] | 陈科拯, 高蓬辉, 焉富春, 程博. 考虑液滴动态行为的亲-疏水复合结构表面冷凝特性影响因素分析[J]. 化工学报, 2025, 76(8): 3976-3989. |

| [6] | 常心泉, 张克学, 王军, 夏国栋. 自由分子区内不规则颗粒的热泳力计算[J]. 化工学报, 2025, 76(8): 3944-3953. |

| [7] | 陈曦, 王淑彦, 邵宝力, 丁诺, 谢磊. 基于颗粒动态恢复系数二阶矩模型的液固流化床数值模拟研究[J]. 化工学报, 2025, 76(7): 3246-3258. |

| [8] | 郭江悦, 常守金, 胡海涛. 水平管内甲醇流动冷凝数值模拟研究[J]. 化工学报, 2025, 76(6): 2580-2588. |

| [9] | 王令颁, 孙漪霏, 卜禹豪, 许振彬, 孙贤, 邵瀚锋, 孙长宇, 陈光进. 大尺度扇柱形反应釜内甲烷水合物降压开采规律研究[J]. 化工学报, 2025, 76(6): 2958-2973. |

| [10] | 何昌秋, 田加猛, 陈义齐, 朱宇琛, 刘鑫, 王海, 王贞涛, 王军锋, 周致富, 陈斌. 电场-宏观结构表面协同强化薄液膜沸腾传热特性[J]. 化工学报, 2025, 76(6): 2589-2602. |

| [11] | 王光磊, 刘晓玲, 徐震, 李琳. 面向压缩空气储能的气-水直接接触换热特性[J]. 化工学报, 2025, 76(4): 1595-1603. |

| [12] | 齐聪, 岳林菲. 交织网状小通道热沉的传热特性[J]. 化工学报, 2025, 76(4): 1534-1544. |

| [13] | 张鑫源, 何呈祥, 李亚婷, 朱春英, 马友光, 付涛涛. 微通道内液液非均相传质的模拟和实验研究方法进展[J]. 化工学报, 2025, 76(2): 484-503. |

| [14] | 李雨诗, 陈源, 李运堂, 彭旭东, 王冰清, 李孝禄. 新型柔性坝箔片端面气膜密封变形协调分析及性能智能优化[J]. 化工学报, 2025, 76(1): 324-334. |

| [15] | 李焱, 郑利军, 张恩勇, 王云飞. 深水海底管道软管内部流体渗透特性模型与试验研究[J]. 化工学报, 2024, 75(S1): 118-125. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号