化工学报 ›› 2025, Vol. 76 ›› Issue (8): 3873-3884.DOI: 10.11949/0438-1157.20250174

收稿日期:2025-02-24

修回日期:2025-04-09

出版日期:2025-08-25

发布日期:2025-09-17

通讯作者:

陈建华

作者简介:朱紫橙(2001—),女,硕士研究生,zhuzicheng@ipe.ac.cn

基金资助:

Zicheng ZHU1,2( ), Yunpeng JIAO1, Mengxi LIU2, Jianhua CHEN1(

), Yunpeng JIAO1, Mengxi LIU2, Jianhua CHEN1( )

)

Received:2025-02-24

Revised:2025-04-09

Online:2025-08-25

Published:2025-09-17

Contact:

Jianhua CHEN

摘要:

三相流化床反应器具有复杂的非均匀动态结构,为了深入理解内构件设计参数对三相反应器性能的影响,基于欧拉-欧拉多流体模型,使用开源软件OpenFOAM对气液固三相流化床内构件进行数值模拟,考察了三种开孔率(0.866、0.219、0.072)的分布器和两种挡板高度(20 m,6.8 m)对颗粒、气体流动的影响。研究结果表明,三种开孔率的分布器在开孔率为0.219时总气泡体积密度最高,相较于0.866和0.072的总开孔率气泡体积密度分别增加了12.4%和22.6%。挡板位置从20 m降低到6.8 m使得更高的床层中有更多的气泡数量,在充分发展段其总气泡数增加了13.4%。研究结果为三相流化床内构件设计提供了依据。

中图分类号:

朱紫橙, 焦云鹏, 刘梦溪, 陈建华. 三相流化床内分布器与挡板效应的模拟分析[J]. 化工学报, 2025, 76(8): 3873-3884.

Zicheng ZHU, Yunpeng JIAO, Mengxi LIU, Jianhua CHEN. Simulation analysis on effects of spargers and baffles in three-phase fluidized bed[J]. CIESC Journal, 2025, 76(8): 3873-3884.

| Parameter | Value |

|---|---|

| reactor diameter/m | 3.2 |

| reactor straight section height/m | 30 |

| superficial gas velocity/(mm/s) | 22.588 |

| superficial liquid velocity/(mm/s) | 2.768 |

| bubble size/mm | 2—10 |

| gas phase density/(kg/m³) | 5.57 (15 MPa, 623.15 K) |

| gas phase viscosity/(Pa·s) | 1.48 × 10-5 (623.15 K) |

| liquid phase density/(kg/m³) | 780 (623.15 K) |

| liquid phase viscosity/(Pa·s) | 0.0187 (15 MPa, 623.15 K) |

| temperature and outlet pressure conditions | 623.15 K/15 MPa |

| catalyst packing height/m | 18 |

| particle density/(kg/m³) | 1500 |

| particle shape | spherical |

| particle size/mm | 0.6 |

| particle packing fraction | 0.41 |

| time step/s | 0.005 |

表1 模拟参数、操作条件及物性参数

Table 1 Simulation parameters, operating conditions and physical property parameters

| Parameter | Value |

|---|---|

| reactor diameter/m | 3.2 |

| reactor straight section height/m | 30 |

| superficial gas velocity/(mm/s) | 22.588 |

| superficial liquid velocity/(mm/s) | 2.768 |

| bubble size/mm | 2—10 |

| gas phase density/(kg/m³) | 5.57 (15 MPa, 623.15 K) |

| gas phase viscosity/(Pa·s) | 1.48 × 10-5 (623.15 K) |

| liquid phase density/(kg/m³) | 780 (623.15 K) |

| liquid phase viscosity/(Pa·s) | 0.0187 (15 MPa, 623.15 K) |

| temperature and outlet pressure conditions | 623.15 K/15 MPa |

| catalyst packing height/m | 18 |

| particle density/(kg/m³) | 1500 |

| particle shape | spherical |

| particle size/mm | 0.6 |

| particle packing fraction | 0.41 |

| time step/s | 0.005 |

| Item | Pressure | Velocity | Phase fraction |

|---|---|---|---|

| inlet | fixedFluxPressure | G&L: interstitialInletVelocity S: fixedValue | zeroGradient |

| walls | fixedFluxPressure | G&L: noSlip S: JohnsonJacksonParticleSlip | zeroGradient |

| outlet | prghPressure | pressureInletOutletVelocity | inletOutlet |

表2 气液固三相流动模拟边界条件

Table 2 Boundary conditions for the simulation of gas-liquid-solid three-phase flow

| Item | Pressure | Velocity | Phase fraction |

|---|---|---|---|

| inlet | fixedFluxPressure | G&L: interstitialInletVelocity S: fixedValue | zeroGradient |

| walls | fixedFluxPressure | G&L: noSlip S: JohnsonJacksonParticleSlip | zeroGradient |

| outlet | prghPressure | pressureInletOutletVelocity | inletOutlet |

| Parameter | Value |

|---|---|

| bed diameter/m | 0.254 |

| bed height/m | 2.5 |

| superficial gas velocity/(m/s) | 0.04 |

| superficial liquid velocity/(m/s) | 0.06 |

| air density/(kg/m³) | 1.29 |

| liquid phase density/(kg/m³) | 1000 |

| solid particle density/(kg/m³) | 2500 |

| particle diameter/mm | 2.3 |

表3 三相流化床实验参数

Table 3 Experimental parameters of three-phase fluidized bed

| Parameter | Value |

|---|---|

| bed diameter/m | 0.254 |

| bed height/m | 2.5 |

| superficial gas velocity/(m/s) | 0.04 |

| superficial liquid velocity/(m/s) | 0.06 |

| air density/(kg/m³) | 1.29 |

| liquid phase density/(kg/m³) | 1000 |

| solid particle density/(kg/m³) | 2500 |

| particle diameter/mm | 2.3 |

| Parameter | Value |

|---|---|

| bed diameter/m | 0.15 |

| bed height/m | 4.35 |

| superficial gas velocity/(m/s) | 0.031 |

| superficial liquid velocity/(m/s) | 0.049 |

| air density/(kg/m³) | 1.2 |

| liquid phase density/(kg/m³) | 997.4 |

| liquid phase viscosity/(Pa·s) | 3.322 × 10-3 |

| solid particle density/(kg/m³) | 2460 |

| particle diameter/mm | 0.48 |

表4 三相流化床实验参数

Table 4 Experimental parameters of three-phase fluidized bed

| Parameter | Value |

|---|---|

| bed diameter/m | 0.15 |

| bed height/m | 4.35 |

| superficial gas velocity/(m/s) | 0.031 |

| superficial liquid velocity/(m/s) | 0.049 |

| air density/(kg/m³) | 1.2 |

| liquid phase density/(kg/m³) | 997.4 |

| liquid phase viscosity/(Pa·s) | 3.322 × 10-3 |

| solid particle density/(kg/m³) | 2460 |

| particle diameter/mm | 0.48 |

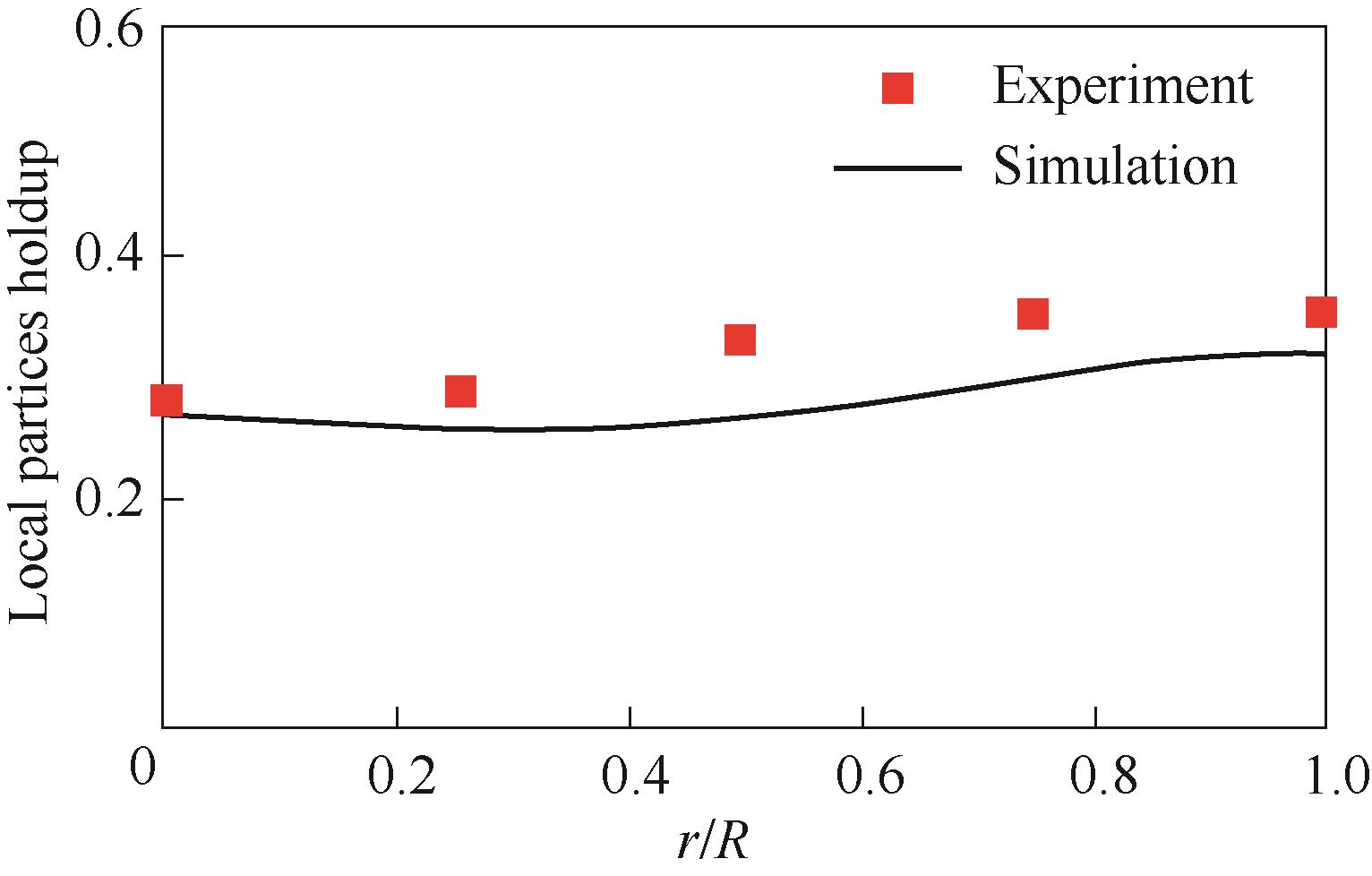

图3 本文模型计算结果与文献[33]中局部固含率实验结果对比

Fig.3 Comparison of the local solid volume fraction between the simulation in this work and the experimental results in Ref.[33]

| Item | Volume fraction | |||

|---|---|---|---|---|

| 20 m baffle | 6.8 m baffle | |||

| Global | Local | Global | Local | |

| gas phase | 0.055 | 0.055 | 0.054 | 0.059 |

| liquid phase | 0.700 | 0.699 | 0.724 | 0.697 |

| solid phase | 0.244 | 0.245 | 0.222 | 0.243 |

表5 不同挡板位置对整体与局部三相含率的影响

Table 5 The effect of different baffle positions on the global and local three-phase volume fraction

| Item | Volume fraction | |||

|---|---|---|---|---|

| 20 m baffle | 6.8 m baffle | |||

| Global | Local | Global | Local | |

| gas phase | 0.055 | 0.055 | 0.054 | 0.059 |

| liquid phase | 0.700 | 0.699 | 0.724 | 0.697 |

| solid phase | 0.244 | 0.245 | 0.222 | 0.243 |

| [1] | Cahanap D R, Mohammadpour J, Jalalifar S, et al. Prediction of three-phase product yield of biomass pyrolysis using artificial intelligence-based models[J]. Journal of Analytical and Applied Pyrolysis, 2023, 172: 106015. |

| [2] | Ercole A, Raganati F, Salatino P, et al. Continuous succinic acid production by immobilized cells of Actinobacillus succinogenes in a fluidized bed reactor: entrapment in alginate beads[J]. Biochemical Engineering Journal, 2021, 169: 107968. |

| [3] | Han J K, Liu T S, Li Y F, et al. Bed hydrodynamics of a new three-phase fluidized bed flotation column with steel ball particles[J]. Minerals Engineering, 2022, 184: 107669. |

| [4] | Leng E W, He B, Chen J W, et al. Prediction of three-phase product distribution and bio-oil heating value of biomass fast pyrolysis based on machine learning[J]. Energy, 2021, 236: 121401. |

| [5] | Pauletto G, Galli F, Gaillardet A, et al. Techno economic analysis of a micro gas-to-liquid unit for associated natural gas conversion[J]. Renewable and Sustainable Energy Reviews, 2021, 150: 111457. |

| [6] | Xia Z H, Cui Z Q, Chen Y X, et al. Generative adversarial networks for dual-modality electrical tomography in multi-phase flow measurement[J]. Measurement, 2021, 173: 108608. |

| [7] | Pan H, Chen X Z, Liang X F, et al. CFD simulations of gas-liquid-solid flow in fluidized bed reactors: a review[J]. Powder Technology, 2016, 299: 235-258. |

| [8] | Zhou X H, Ma Y L, Liu M Y, et al. New measurements on hydrodynamics in a gas-liquid-solid expanded bed[J]. Particuology, 2021, 58: 276-284. |

| [9] | 张昊哲. 气-液-固三相流中复杂气泡行为的VOF-DEM数值模拟[D]. 天津: 天津大学, 2022. |

| Zhang H Z. VOF-DEM numerical simulation of complex bubble behavior in gas-liquid-solid three-phase flow[D]. Tianjin: Tianjin University, 2022. | |

| [10] | Sur D H, Mukhopadhyay M. COD reduction of textile effluent in three-phase fluidized bed bioreactor using Pseudomonas aureofaciens and Escherichia coli [J]. 3 Biotech, 2017, 7(2): 141. |

| [11] | See T Y, Raman A A A, Shah R S S R E, et al. Study of sparger location on solid suspension in a triple-impeller stirred vessel[J]. Asia-Pacific Journal of Chemical Engineering, 2016, 11(2): 229-236. |

| [12] | Jena H M, Roy G K, Mahapatra S S. Determination of optimum gas holdup conditions in a three-phase fluidized bed by genetic algorithm[J]. Computers & Chemical Engineering, 2010, 34(4): 476-484. |

| [13] | Baqir A S, Mahood H B, Hameed M S, et al. Heat transfer measurement in a three-phase spray column direct contact heat exchanger for utilisation in energy recovery from low-grade sources[J]. Energy Conversion and Management, 2016, 126: 342-351. |

| [14] | Panda S K, Singh K K, Shenoy K T, et al. Numerical simulations of liquid-liquid flow in a continuous gravity settler using OpenFOAM and experimental verification[J]. Chemical Engineering Journal, 2017, 310: 120-133. |

| [15] | Bilińska M, Bilińska L, Kędzierska-Sar A, et al. Novel bubble column design constructed for catalytic ozonation-effectiveness assessment by hydrodynamics and kinetic regime determination[J]. Ozone: Science & Engineering, 2024, 46(6): 509-525. |

| [16] | Tamburini A, Cipollina A, Micale G, et al. Particle suspension in vortexing unbaffled stirred tanks[J]. Industrial & Engineering Chemistry Research, 2016, 55(27): 7535-7547. |

| [17] | Bao Y Y, Gao Z M, Hao Z G, et al. Effects of equipment and process variables on the suspension of buoyant particles in gas-sparged vessels[J]. Industrial & Engineering Chemistry Research, 2005, 44(20): 7899-7906. |

| [18] | 韦朝海, 李磊. 底隙设置挡板内循环流化床水力特性分析[J]. 化工学报, 2007, 58(10): 2480-2484. |

| Wei C H, Li L. Hydraulic characteristics of internal loop fluidized bed with baffle setting on bottom[J]. Journal of Chemical Industry and Engineering (China), 2007, 58(10): 2480-2484. | |

| [19] | Amblard B, Singh R, Gbordzoe E, et al. CFD modeling of the coke combustion in an industrial FCC regenerator[J]. Chemical Engineering Science, 2017, 170: 731-742. |

| [20] | Khan M J H, Hussain M A, Mansourpour Z, et al. CFD simulation of fluidized bed reactors for polyolefin production—a review[J]. Journal of Industrial and Engineering Chemistry, 2014, 20(6): 3919-3946. |

| [21] | Zhao Z J, Zhou L, Bai L, et al. Recent advances and perspectives of CFD-DEM simulation in fluidized bed[J]. Archives of Computational Methods in Engineering, 2024, 31(2): 871-918. |

| [22] | Hulburt H M, Katz S. Some problems in particle technology: a statistical mechanical formulation[J]. Chemical Engineering Science, 1964, 19(8): 555-574. |

| [23] | Deng J H, Lan S L, Wu J C, et al. CFD-PBM coupled modeling of the liquid-liquid dispersion characteristics and structure optimization for kenics static mixer[J]. Chinese Journal of Chemical Engineering, 2024, 70: 173-188. |

| [24] | 邢继远. CFD-PBM框架下旋流式微泡发生器气泡动力学行为[J]. 化学工程, 2024, 52(3): 59-65. |

| Xing J Y. Bubble dynamics in micro-bubble generator with swirl flow based on CFD-PBM framework[J]. Chemical Engineering (China), 2024, 52(3): 59-65. | |

| [25] | Zhang B, Kong L T, Jin H B, et al. CFD simulation of gas-liquid flow in a high-pressure bubble column with a modified population balance model[J]. Chinese Journal of Chemical Engineering, 2018, 26(6): 1350-1358. |

| [26] | Duan W, Wang C, Zheng Q. CFD-PBM simulation of three-phase flow in the mixing zone of a centrifugal contactor[J]. Fluid Machinery, 2021, 49(11): 25-32. |

| [27] | Ji S M, Ge J Q, Tan D P, et al. Three-phase abrasive flow polishing and distribution characteristics of bubble collapse[J]. Optics and Precision Engineering, 2018, 26(2): 388-398. |

| [28] | Li L, Xu H L, Yang F Q. Three-phase flow of submarine gas hydrate pipe transport[J]. Journal of Central South University, 2015, 22(9): 3650-3656. |

| [29] | Pan H, Liu Q, Luo Z H. Modeling and simulation of particle size distribution behavior in gas-liquid-solid polyethylene fluidized bed reactors[J]. Powder Technology, 2018, 328: 95-107. |

| [30] | Zhang H, Yin Z G, Chi W Q, et al. A new Eulerian-Eulerian-Lagrangian solver in OpenFOAM and its application in a three-phase bubble column[J]. Powder Technology, 2023, 426: 118661. |

| [31] | Zhou X H, Ma Y L, Liu M Y, et al. CFD-PBM simulations on hydrodynamics and gas-liquid mass transfer in a gas-liquid-solid circulating fluidized bed[J]. Powder Technology, 2020, 362: 57-74. |

| [32] | Yu Y H, Kim S D. Bubble characteristics in the radial direction of three-phase fluidized beds[J]. AIChE Journal, 1988, 34(12): 2069-2072. |

| [33] | Cao C Q, Liu M Y, Guo Q J. Experimental investigation into the radial distribution of local phase holdups in a gas-liquid-solid fluidized bed[J]. Industrial & Engineering Chemistry Research, 2007, 46(11): 3841-3848. |

| [34] | Gidaspow D. Multiphase Flow and Fluidization[M]. New York: Academic Press, 1994. |

| [35] | Ishii M, Zuber N. Drag coefficient and relative velocity in bubbly, droplet or particulate flows[J]. AIChE Journal, 1979, 25(5): 843-855. |

| [36] | Liao Y, Oertel R, Kriebitzsch S, et al. A discrete population balance equation for binary breakage[J]. International Journal for Numerical Methods in Fluids, 2018, 87(4): 202-215. |

| [37] | Prince M J, Blanch H W. Bubble coalescence and break-up in air-sparged bubble columns[J]. AIChE Journal, 1990, 36(10): 1485-1499. |

| [38] | Luo H A, Svendsen H F. Theoretical model for drop and bubble breakup in turbulent dispersions[J]. AIChE Journal, 1996, 42(5): 1225-1233. |

| [39] | Kataoka I, Serizawa A. Basic equations of turbulence in gas-liquid two-phase flow[J]. International Journal of Multiphase Flow, 1989, 15(5): 843-855. |

| [40] | Menter F R. Two-equation eddy-viscosity turbulence models for engineering applications[J]. AIAA Journal, 1994, 32(8): 1598-1605. |

| [41] | Che X X, Wu F, Ma X X. Effect of adjusted mesoscale drag model on flue gas desulfurization in powder-particle spouted beds[J]. Frontiers of Chemical Science and Engineering, 2022, 16(6): 909-920. |

| [42] | Islam M T, Nguyen A V. Parametric investigations of different variables on liquid-solid fluidization in a HydroFloat cell using computational fluid dynamics[J]. Chemical Engineering Research and Design, 2020, 159: 13-26. |

| [43] | Mitra-Majumdar D, Farouk B, Shah Y T. Hydrodynamic modeling of three-phase flows through a vertical column[J]. Chemical Engineering Science, 1997, 52(24): 4485-4497. |

| [44] | Fan L S. Gas-Liquid-Solid Fluidization Engineering[M]. London: Butterworths, 1989. |

| [1] | 陈宇航, 陈金国, 陈炜毅, 王康, 郑昊, 韩昌亮. 沉浸式气化器烟气分布器布气性能与多目标参数优化[J]. 化工学报, 2025, 76(7): 3274-3285. |

| [2] | 赵碧丹, 代伊杨, 王军武, 张永民. CFD-DEM-IBM方法探究流化床倾斜挡板内构件受力特性[J]. 化工学报, 2024, 75(1): 255-267. |

| [3] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [4] | 施炜斌, 龙姗姗, 杨晓钢, 蔡心悦. 计及气泡诱导与剪切湍流的气泡破碎、湍流相间扩散及传质模型[J]. 化工学报, 2022, 73(6): 2573-2588. |

| [5] | 吴林, 李季, 朱家骅, 宫源, 葛敬. 磷石膏-氨-水固碳反应体系氨浓度对石膏颗粒溶解速率的影响[J]. 化工学报, 2020, 71(8): 3575-3584. |

| [6] | 刘宗跃, 杨宏, 王少伦, 王佳伟. 硝化细菌工业化快速富集[J]. 化工学报, 2020, 71(8): 3722-3729. |

| [7] | 叶思施, 唐巧, 王运东. 混合澄清槽澄清室内流场特性测量[J]. 化工学报, 2020, 71(2): 535-543. |

| [8] | 杨国强,曾伟,罗华勋,杨高东,张志炳. 亚硫酸铵微界面强化氧化特性研究[J]. 化工学报, 2020, 71(11): 4918-4926. |

| [9] | 王健,潘伶,王帅,张昊. 工程相变凝并器内超细颗粒长大与脱除性能分析[J]. 化工学报, 2020, 71(11): 5090-5098. |

| [10] | 董鑫, 许晓飞, 刘凤霞, 曾倩, 王晓娟, 魏炜, 刘志军. 鼓泡反应器中幂律型流体流动与传质特性[J]. 化工学报, 2018, 69(6): 2446-2454. |

| [11] | 石睿捷, 王创博, 马玲, 严超宇, 魏耀东. 催化裂化再生器树枝状气体分布器喷嘴的射流特性[J]. 化工学报, 2018, 69(2): 655-663. |

| [12] | 李登稳, 程振民. 文丘里型气液分布器的实验与数值研究[J]. 化工学报, 2018, 69(11): 4625-4632. |

| [13] | 宫源, 罗安安, 朱家骅, 薛潇, 王茜. 传质控制下宽分布石膏颗粒群溶解特性[J]. 化工学报, 2018, 69(10): 4177-4183. |

| [14] | 李振亮, 卢培利, 张代钧, 周志恩, 张晟, 何强. 二项式分布在种群平衡模型模拟粒度分布中的应用[J]. 化工学报, 2017, 68(9): 3397-3403. |

| [15] | 王珏, 杨宁. 基于EMMS方法的鼓泡塔反应器CFD及群平衡模拟[J]. 化工学报, 2017, 68(7): 2667-2677. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号