化工学报 ›› 2025, Vol. 76 ›› Issue (9): 4838-4849.DOI: 10.11949/0438-1157.20250196

钱慧慧( ), 王文婕(

), 王文婕( ), 陈文尧, 周兴贵, 张晶(

), 陈文尧, 周兴贵, 张晶( ), 段学志(

), 段学志( )

)

收稿日期:2025-02-28

修回日期:2025-05-04

出版日期:2025-09-25

发布日期:2025-10-23

通讯作者:

张晶,段学志

作者简介:钱慧慧(2000—), 女, 硕士研究生, Y30220137@mail.ecust.edu.cn基金资助:

Huihui QIAN( ), Wenjie WANG(

), Wenjie WANG( ), Wenyao CHEN, Xinggui ZHOU, Jing ZHANG(

), Wenyao CHEN, Xinggui ZHOU, Jing ZHANG( ), Xuezhi DUAN(

), Xuezhi DUAN( )

)

Received:2025-02-28

Revised:2025-05-04

Online:2025-09-25

Published:2025-10-23

Contact:

Jing ZHANG, Xuezhi DUAN

摘要:

废弃塑料中聚丙烯约占25%,将其选择性转化为高值芳烃原料对于推动循环经济和实现碳中和目标具有重要意义。尽管金属-分子筛催化剂已被证明能够促进聚烯烃催化转化为芳烃,但聚丙烯在分子筛外表面裂化的反应路径及金属对该裂化反应的影响仍不明确。本研究通过构筑选择性暴露外表面位点的金属-分子筛催化剂,研究了聚丙烯转化过程中主要中间物种2,4-二甲基-1-庚烯在催化剂外表面的催化裂化行为,揭示金属能够显著增强富含甲基取代基的烯烃中间物种在分子筛外表面的裂化深度,生成的小分子烯烃物种扩散至分子筛微孔中,进一步发生芳构化反应,从而提高微孔内芳构化位点的利用效率。在优化条件下,聚丙烯催化转化制芳烃的总收率为73.5%,其中三苯收率为65.6%。本研究建立了金属-分子筛催化剂结构与多步反应性能之间的关联机制,为化学回收聚丙烯制芳烃的高效催化剂设计提供了理论依据和技术支持。

中图分类号:

钱慧慧, 王文婕, 陈文尧, 周兴贵, 张晶, 段学志. 聚丙烯定向转化制芳烃:金属-分子筛协同催化机制[J]. 化工学报, 2025, 76(9): 4838-4849.

Huihui QIAN, Wenjie WANG, Wenyao CHEN, Xinggui ZHOU, Jing ZHANG, Xuezhi DUAN. Synergistic metal-zeolite catalysis for conversion of polypropylene into aromatics[J]. CIESC Journal, 2025, 76(9): 4838-4849.

| 催化剂 | SiO2/Al2O3 | 孔结构性质 | ||

|---|---|---|---|---|

| 比表面积/(m2·g-1) | 孔容/(cm3·g-1) | 微孔孔容/(cm3·g-1) | ||

| ZSM-5(25) | 25 | 284.5 | 0.190 | 0.131 |

| ZSM-5(38) | 38 | 333.5 | 0.178 | 0.161 |

| ZSM-5(50) | 50 | 246.3 | 0.134 | 0.123 |

| ZSM-5(70) | 70 | 285.2 | 0.175 | 0.133 |

| Pt-ZSM-5(38) | 38 | 314.3 | 0.171 | 0.149 |

| ZSM-5-B | 40 | 16.3 | 0.066 | 0.002 |

| Pt-ZSM-5-B | 40 | 12.0 | 0.048 | 0.001 |

表1 催化剂的孔结构参数

Table 1 Pore structure parameters of catalysts

| 催化剂 | SiO2/Al2O3 | 孔结构性质 | ||

|---|---|---|---|---|

| 比表面积/(m2·g-1) | 孔容/(cm3·g-1) | 微孔孔容/(cm3·g-1) | ||

| ZSM-5(25) | 25 | 284.5 | 0.190 | 0.131 |

| ZSM-5(38) | 38 | 333.5 | 0.178 | 0.161 |

| ZSM-5(50) | 50 | 246.3 | 0.134 | 0.123 |

| ZSM-5(70) | 70 | 285.2 | 0.175 | 0.133 |

| Pt-ZSM-5(38) | 38 | 314.3 | 0.171 | 0.149 |

| ZSM-5-B | 40 | 16.3 | 0.066 | 0.002 |

| Pt-ZSM-5-B | 40 | 12.0 | 0.048 | 0.001 |

| 催化剂 | 酸位数量/(mmol·g-1) | |

|---|---|---|

| 弱酸 | 强酸 | |

| ZSM-5(38) | 0.5 | 0.6 |

| Pt-ZSM-5(38) | 0.6 | 0.9 |

表2 基于NH3-TPD分析的催化剂酸位数量

Table 2 The number of acid sites of the catalyst based on NH3-TPD analysis

| 催化剂 | 酸位数量/(mmol·g-1) | |

|---|---|---|

| 弱酸 | 强酸 | |

| ZSM-5(38) | 0.5 | 0.6 |

| Pt-ZSM-5(38) | 0.6 | 0.9 |

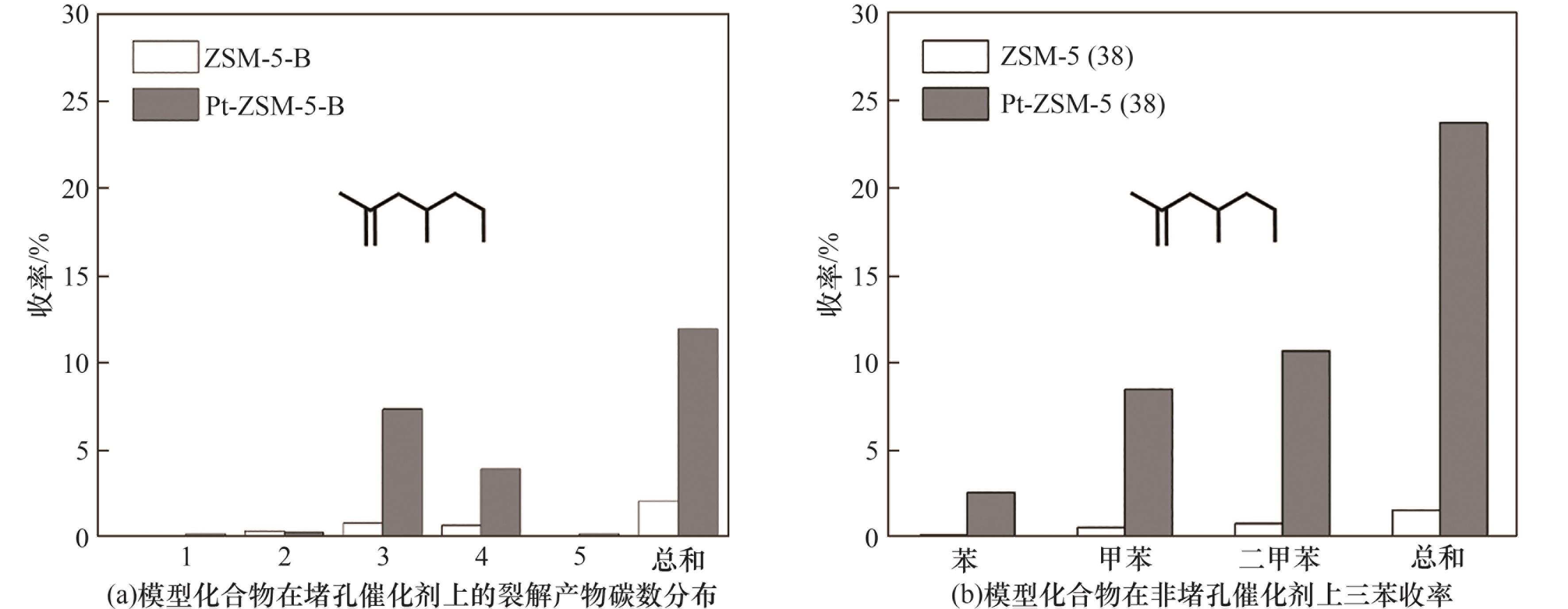

图6 模型化合物在堵孔催化剂上的裂解产物碳数分布与非堵孔催化剂上三苯收率

Fig.6 The carbon number distribution of cracking products from the model compound on the pore-blocking catalyst and the BTX yield on the conventional catalyst

| [1] | Samuel Pottinger A, Geyer R, Biyani N, et al. Pathways to reduce global plastic waste mismanagement and greenhouse gas emissions by 2050[J]. Science, 2024, 386(6726): 1168-1173. |

| [2] | Matveev A E. The effect of the concentration of plastic waste on the formation of reaction products of the Ti-PET system[J]. Green Chemical Engineering, 2024, 5(3): 374-382. |

| [3] | Luo Y J, Sun J Y, Li Z. Rapid chemical recycling of waste polyester plastics catalyzed by recyclable catalyst[J]. Green Chemical Engineering, 2024, 5(2): 257-265. |

| [4] | Zhao Z Y, Bai J Y, Tao H, et al. Ionic liquids with multiple hydrogen bonds as metal-free catalysts for efficient hydrolysis of PET under relatively mild conditions[J]. Green Chemical Engineering, . |

| [5] | Ahamed A, Veksha A, Yin K, et al. Environmental impact assessment of converting flexible packaging plastic waste to pyrolysis oil and multi-walled carbon nanotubes[J]. Journal of Hazardous Materials, 2020, 390: 121449. |

| [6] | Zhang S, Xia B Q, Qu Y, et al. Photocatalytic production of ethylene and propionic acid from plastic waste by titania-supported atomically dispersed Pd species[J]. Science Advances, 2023, 9(49): eadk2407. |

| [7] | Cui Y L, Zhang Y N, Cui L F, et al. Microwave-assisted pyrolysis of polypropylene plastic for liquid oil production[J]. Journal of Cleaner Production, 2023, 411: 137303. |

| [8] | Qu B Y, Wang T, Ji X R, et al. Effect of reduction temperatures of Ni-modified zeolites on the product distribution, catalyst deactivation, and reaction mechanism during polypropylene pyrolysis[J]. Fuel, 2025, 384: 133947. |

| [9] | Martín A J, Mondelli C, Jaydev S D, et al. Catalytic processing of plastic waste on the rise[J]. Chem, 2021, 7(6): 1487-1533. |

| [10] | Zhang W, Kim S, Wahl L, et al. Low-temperature upcycling of polyolefins into liquid alkanes via tandem cracking-alkylation[J]. Science, 2023, 379(6634): 807-811. |

| [11] | Wang J, Jiang J C, Wang X B, et al. Converting polycarbonate and polystyrene plastic wastes intoaromatic hydrocarbons via catalytic fast co-pyrolysis[J]. Journal of Hazardous Materials, 2020, 386: 121970. |

| [12] | Settle A E, Berstis L, Rorrer N A, et al. Heterogeneous Diels-Alder catalysis for biomass-derived aromatic compounds[J]. Green Chemistry, 2017, 19(15): 3468-3492. |

| [13] | Li H Q, Aguirre-Villegas H A, Allen R D, et al. Expanding plastics recycling technologies: chemical aspects, technology status and challenges[J]. Green Chemistry, 2022, 24(23): 8899-9002. |

| [14] | Zhang F, Zeng M H, Yappert R D, et al. Polyethylene upcycling to long-chain alkylaromatics by tandem hydrogenolysis/aromatization[J]. Science, 2020, 370(6515): 437-441. |

| [15] | Dong Z W, Chen W J, Xu K Q, et al. Understanding the structure-activity relationships in catalytic conversion of polyolefin plastics by zeolite-based catalysts: a critical review[J]. ACS Catalysis, 2022, 12(24): 14882-14901. |

| [16] | Qian K Z, Tian W M, Yang Z X, et al. Unraveling the role of mesoporosity and acidity of hierarchical aggregated HZSM-5 in HDPE vapor catalytic cracking for value-added hydrocarbons[J]. Industrial & Engineering Chemistry Research, 2024, 63(38): 16324-16334. |

| [17] | Yuan H R, Li C Y, Shan R, et al. Recent developments on the zeolites catalyzed polyolefin plastics pyrolysis[J]. Fuel Processing Technology, 2022, 238: 107531. |

| [18] | Abbas-Abadi M S, Ureel Y, Eschenbacher A, et al. Challenges and opportunities of light olefin production via thermal and catalytic pyrolysis of end-of-life polyolefins: towards full recyclability[J]. Progress in Energy and Combustion Science, 2023, 96: 101046. |

| [19] | Wang Y, Zhang Y H, Fan H C, et al. Elucidating the structure-performance relationship of typical commercial zeolites in catalytic cracking of low-density polyethylene[J]. Catalysis Today, 2022, 405: 135-143. |

| [20] | Santos B P S, Almeida D, de Fatima V Marques M, et al. Petrochemical feedstock from pyrolysis of waste polyethylene and polypropylene using different catalysts[J]. Fuel, 2018, 215: 515-521. |

| [21] | Yao D D, Yang H P, Chen H P, et al. Investigation of nickel-impregnated zeolite catalysts for hydrogen/syngas production from the catalytic reforming of waste polyethylene[J]. Applied Catalysis B: Environmental, 2018, 227: 477-487. |

| [22] | Yaripour F, Shariatinia Z, Sahebdelfar S, et al. Effect of boron incorporation on the structure, products selectivities and lifetime of H-ZSM-5 nanocatalyst designed for application in methanol-to-olefins (MTO) reaction[J]. Microporous and Mesoporous Materials, 2015, 203: 41-53. |

| [23] | Bozkurt O D, Toraman H E. Conversion of polypropylene into light hydrocarbons and aromatics by metal exchanged zeolite catalysts[J]. Langmuir, 2024, 40(18): 9636-9650. |

| [24] | Qian K Z, Tian W M, Yan S W, et al. Aromatization of HDPE and PP over Ga-promoted zeolite: effects of pretreatment and zeolite type[J]. Fuel, 2024, 357: 129781. |

| [25] | Pyo S, Kim Y M, Park Y, et al. Catalytic pyrolysis of polypropylene over Ga loaded HZSM-5[J]. Journal of Industrial Engineering Chemistry, 2021, 103: 136-141. |

| [26] | Yousefi M R, Rahimi S, Rostamizadeh M. Effective high silica ZSM-5 nanocatalyst including Fe and B promoters for production of high value petrochemicals in plastic upgrading process[J]. Journal of Analytical and Applied Pyrolysis, 2021, 156: 105108. |

| [27] | Du J J, Zeng L, Yan T, et al. Efficient solvent- and hydrogen-free upcycling of high-density polyethylene into separable cyclic hydrocarbons[J]. Nature Nanotechnology, 2023, 18(7): 772-779. |

| [28] | Wang W J, Yao C, Ge X H, et al. Catalytic conversion of polyethylene into aromatics with Pt/ZSM-5: insights into reaction pathways and rate-controlling step regulation[J]. Journal of Materials Chemistry A, 2023, 11(27): 14933-14940. |

| [29] | Li Y R, Cao Y Q, Ge X H, et al. Pt-O4 moiety induced electron localization toward In2O-triggered acetylene semi-hydrogenation [J]. Journal of Catalysis, 2022, 407: 290-299. |

| [30] | Zhang Y T, Li A M, Zhang Y S, et al. In-situ catalytic pyrolysis of polyethylene to co-produce BTX aromatics and H2 by Ni/ZSM-5 in the rotary reactor with solid heat carriers[J]. Fuel, 2024, 371: 131950. |

| [31] | Feng X, Duan X Z, Qian G, et al. Au nanoparticles deposited on the external surfaces of TS-1: enhanced stability and activity for direct propylene epoxidation with H2 and O2 [J]. Applied Catalysis B: Environmental, 2014, 150: 396-401. |

| [32] | Qian K Z, Tian W M, Yin L J, et al. Aromatic production from high-density polyethylene over zinc promoted HZSM-5[J]. Applied Catalysis B: Environmental, 2023, 339: 123159. |

| [33] | Yue X, Wang S, Li D F, et al. Experimental and numerical investigations on the adsorption/desorption performance of low-concentration VOCs over H-ZSM-5 with different SiO2/Al2O3 ratios[J]. Industrial & Engineering Chemistry Research, 2023, 62(12): 5408-5419. |

| [34] | Caiola A, Robinson B, Bai X W, et al. Study of the hydrogen pretreatment of gallium and platinum promoted ZSM-5 for the ethane dehydroaromatization reaction[J]. Industrial & Engineering Chemistry Research, 2021, 60(30): 11421-11431. |

| [35] | Song S F, Wu Y J, Ge S S, et al. A facile way to improve Pt atom efficiency for CO oxidation at low temperature: modification by transition metal oxides[J]. ACS Catalysis, 2019, 9(7): 6177-6187. |

| [36] | Xu L Y, Wen C H, Luo X H, et al. Regulating the synergy of sulfate and Pt species in Pt/ZSM-5 for propane complete oxidation[J]. Applied Catalysis B: Environment and Energy, 2024, 354: 124135. |

| [37] | Gil B, Zones S I, Hwang S J, et al. Acidic properties of SSZ-33 and SSZ-35 novel zeolites: a complex infrared and MAS NMR study[J]. The Journal of Physical Chemistry C, 2008, 112(8): 2997-3007. |

| [38] | Sang S Y, Chang F X, Liu Z M, et al. Difference of ZSM-5 zeolites synthesized with various templates[J]. Catalysis Today, 2004, 93: 729-734. |

| [39] | Lim B, Jiang M J, Camargo P H C, et al. Pd-Pt bimetallic nanodendrites with high activity for oxygen reduction[J]. Science, 2009, 324(5932): 1302-1305. |

| [40] | Song Y Q, Zhu X X, Xie S J, et al. The effect of acidity on olefin aromatization over potassium modified ZSM-5 catalysts[J]. Catalysis Letters, 2004, 97(1): 31-36. |

| [41] | Negelein D L, Lin R, White R L. Effects of catalyst acidity and HZSM-5 channel volume on polypropylene cracking[J]. Journal of Applied Polymer Science, 1998, 67(2): 341-348. |

| [42] | Sun B Y, Xu H F, Li T, et al. Hydrogen-free upcycling of polyethylene waste to methylated aromatics over Ni/ZSM-5 under mild conditions[J]. Journal of Hazardous Materials, 2025, 482: 136564. |

| [43] | Boronat M, Corma A. Are carbenium and carbonium ions reaction intermediates in zeolite-catalyzed reactions?[J]. Applied Catalysis A: General, 2008, 336(1): 2-10. |

| [44] | Hou X, Ni N, Wang Y, et al. Roles of the free radical and carbenium ion mechanisms in pentane cracking to produce light olefins[J]. Journal of Analytical and Applied Pyrolysis, 2019, 138: 270-280. |

| [45] | Corma A, Orchillés A V. Current views on the mechanism of catalytic cracking[J]. Microporous and Mesoporous Materials, 2000, 35: 21-30. |

| [46] | Luda M P, Dall'Anese R. On the microstructure of polypropylenes by pyrolysis GC-MS[J]. Polymer Degradation and Stability, 2014, 110: 35-43. |

| [47] | Hassibi N, Quiring Y, Carré V, et al. Analysis and control of products obtained from pyrolysis of polypropylene using a reflux semi-batch reactor and GC-MS/FID and FT-ICR MS[J]. Journal of Analytical and Applied Pyrolysis, 2023, 169: 105826. |

| [48] | Park C, Lee J. Pyrolysis of polypropylene for production of fuel-range products: effect of molecular weight of polypropylene[J]. International Journal of Energy Research, 2021, 45(9): 13088-13097. |

| [49] | Das P, Tiwari P. The effect of slow pyrolysis on the conversion of packaging waste plastics (PE and PP) into fuel[J]. Waste Management, 2018, 79: 615-624. |

| [50] | Duan J D, Chen W, Wang C T, et al. Coking-resistant polyethylene upcycling modulated by zeolite micropore diffusion[J]. Journal of the American Chemical Society, 2022, 144(31): 14269-14277. |

| [1] | 赵维, 邢文乐, 韩朝旭, 袁兴中, 蒋龙波. g-C3N4基非金属异质结光催化降解水中有机污染物的研究进展[J]. 化工学报, 2025, 76(9): 4752-4769. |

| [2] | 佟丽丽, 陈英, 艾敏华, 舒玉美, 张香文, 邹吉军, 潘伦. ZnO/WO3异质结光催化环烯烃[2+2]环加成制备高能量密度燃料[J]. 化工学报, 2025, 76(9): 4882-4892. |

| [3] | 解勤勤, 翁俊旗, 林振利, 叶光华, 周兴贵. 固定床反应器中甲醇制芳烃工业催化剂结构影响的研究[J]. 化工学报, 2025, 76(9): 4487-4498. |

| [4] | 范夏雨, 孙建辰, 李可莹, 姚馨雅, 商辉. 机器学习驱动液态有机储氢技术的系统优化[J]. 化工学报, 2025, 76(8): 3805-3821. |

| [5] | 杨宁, 李皓男, LIN Xiao, GEORGIADOU Stella, LIN Wen-Feng. 从塑料废弃物到能源催化剂:塑料衍生碳@CoMoO4复合材料在电解水析氢反应中的应用[J]. 化工学报, 2025, 76(8): 4081-4094. |

| [6] | 巢欣旖, 陈文尧, 张晶, 钱刚, 周兴贵, 段学志. 甲醇和乙酸甲酯一步法制丙酸甲酯催化剂的可控制备与性能调控[J]. 化工学报, 2025, 76(8): 4030-4041. |

| [7] | 周媚, 曾浩桀, 蒋火炎, 蒲婷, 曾星星, 刘宝玉. 二次晶化法改性合成MTW分子筛及其在苯和环己烯烷基化反应中的催化性能[J]. 化工学报, 2025, 76(8): 4071-4080. |

| [8] | 赵世颖, 左志帅, 贺梦颖, 安华良, 赵新强, 王延吉. Co-Pt/HAP的制备及其催化1,2-丙二醇氨化反应[J]. 化工学报, 2025, 76(7): 3305-3315. |

| [9] | 刘沁雯, 叶恒冰, 张逸伟, 朱法华, 钟文琪. 煤与禽类粪便混合燃料的加压富氧燃烧特性研究[J]. 化工学报, 2025, 76(7): 3487-3497. |

| [10] | 陆学瑞, 周帼彦, 方琦, 俞孟正, 张秀成, 涂善东. 固体氧化物燃料电池外重整器积炭效应数值模拟研究[J]. 化工学报, 2025, 76(7): 3295-3304. |

| [11] | 吴雷, 胡紫璇, 高渊, 刘长波, 曹虎生, 刘田田, 朱瑞玉, 周军. 微波联合生物炭活化过硫酸盐氧化修复多环芳烃污染土壤研究[J]. 化工学报, 2025, 76(7): 3659-3670. |

| [12] | 李愽龙, 蒋雨希, 任傲天, 秦雯琪, 傅杰, 吕秀阳. TS-1/In-TS-1催化果糖一步法醇解制备乳酸甲酯连续化试验[J]. 化工学报, 2025, 76(6): 2678-2686. |

| [13] | 何军, 李勇, 赵楠, 何孝军. 碳负载硒掺杂硫化钴在锂硫电池中的性能研究[J]. 化工学报, 2025, 76(6): 2995-3008. |

| [14] | 宋粉红, 王文光, 郭亮, 范晶. C元素修饰g-C3N4对TiO2的调控及复合材料光催化产氢性能研究[J]. 化工学报, 2025, 76(6): 2983-2994. |

| [15] | 何燎, 李俊, 高梦舒, 刘东阳, 张宇豪, 赵亮, 高金森, 徐春明. 石油烃中芳烃分离技术研究进展[J]. 化工学报, 2025, 76(5): 1909-1926. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号