CIESC Journal ›› 2021, Vol. 72 ›› Issue (8): 4346-4353.DOI: 10.11949/0438-1157.20201672

• Energy and environmental engineering • Previous Articles Next Articles

Received:2020-11-19

Revised:2021-02-17

Online:2021-08-05

Published:2021-08-05

Contact:

Chongwen JIANG

通讯作者:

蒋崇文

作者简介:谢乐(1989—),男,博士,讲师,基金资助:CLC Number:

Le XIE, Chongwen JIANG. Simulation study on the removal of high concentration H2S waste gas by biotrickling filter[J]. CIESC Journal, 2021, 72(8): 4346-4353.

谢乐, 蒋崇文. 生物滴滤塔去除高浓度H2S废气的模拟研究[J]. 化工学报, 2021, 72(8): 4346-4353.

Add to citation manager EndNote|Ris|BibTeX

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| 气相中H2S扩散系数( | 1.8×10-5 m2/s | 气相中O2扩散系数(Dog) | 1.775×10-5 m2/s |

| 生物膜中H2S扩散系数( | 1.28×10-9 m2/s | 生物膜中O2扩散系数(Dos) | 2.86×10-9 m2/s |

| H2S半饱和常数 (Kh) | 0.039 g/m3 | O2半饱和常数 (Ko) | 0.26 g/m3 |

| 最大比生长速率 (μmax) | 3.61 d-1 | O2亨利系数 (mo) | 34.13 |

| H2S亨利系数 (mh) | 0.47 | 生物膜密度(Xb) | 28 kg/m3 |

| 产率(Yh) | 0.03 | 产率(Yo) | 0.3436 |

Table 1 Diffusion coefficients and kinetic parameters of biodegradation

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| 气相中H2S扩散系数( | 1.8×10-5 m2/s | 气相中O2扩散系数(Dog) | 1.775×10-5 m2/s |

| 生物膜中H2S扩散系数( | 1.28×10-9 m2/s | 生物膜中O2扩散系数(Dos) | 2.86×10-9 m2/s |

| H2S半饱和常数 (Kh) | 0.039 g/m3 | O2半饱和常数 (Ko) | 0.26 g/m3 |

| 最大比生长速率 (μmax) | 3.61 d-1 | O2亨利系数 (mo) | 34.13 |

| H2S亨利系数 (mh) | 0.47 | 生物膜密度(Xb) | 28 kg/m3 |

| 产率(Yh) | 0.03 | 产率(Yo) | 0.3436 |

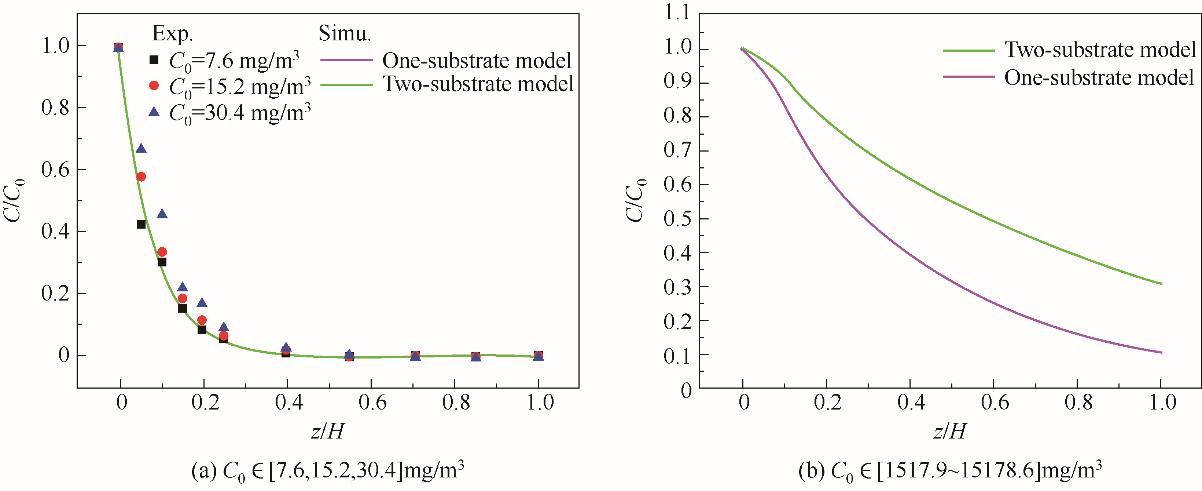

Fig.2 The obtained axial H2S concentration distribution using the one-substrate and two-substrate models were compared with each other at different H2S inlet concentrations (EBRT is 10.9 s and biofilm thick is 20 μm)

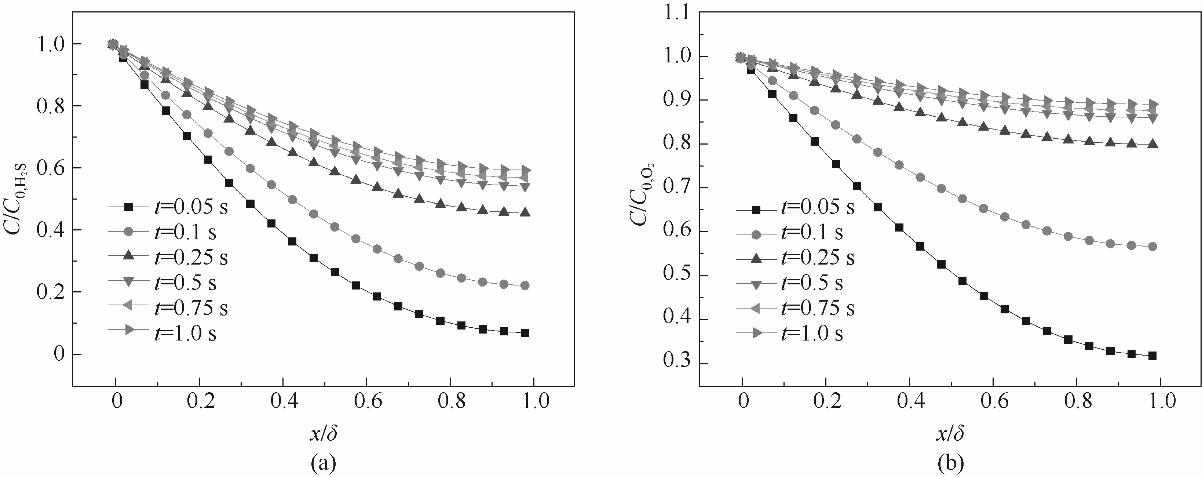

Fig.3 The dynamic changes of the dimensionless H2S and O2 concentration in the biofilm when the H2S interfacial concentration is 7589.3 mg/m3 and the biofilm thickness is 20 μm

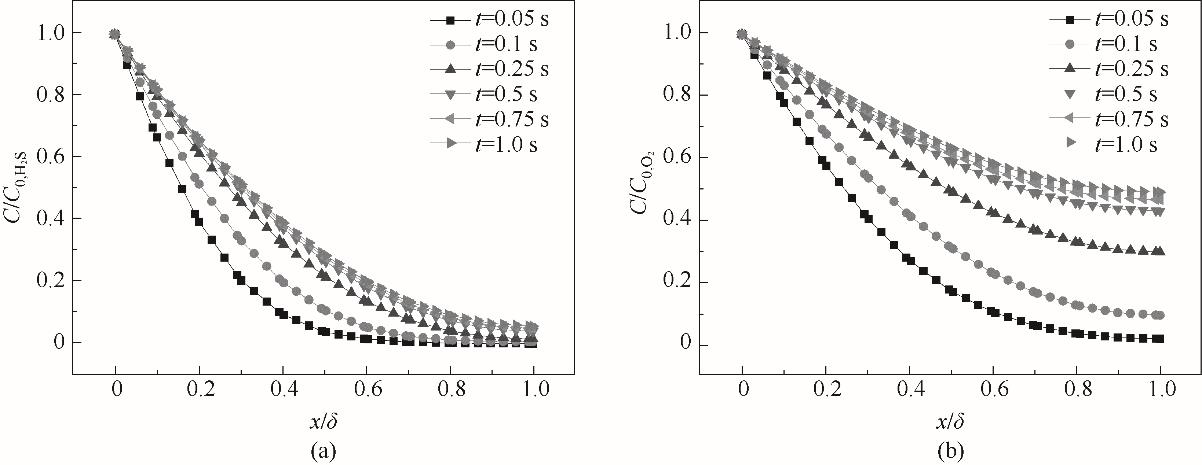

Fig.4 The dynamic changes of the dimensionless H2S and O2 concentration in the biofilm when the H2S interfacial concentration is 7589.3 mg/m3 and the biofilm thickness is 40 μm

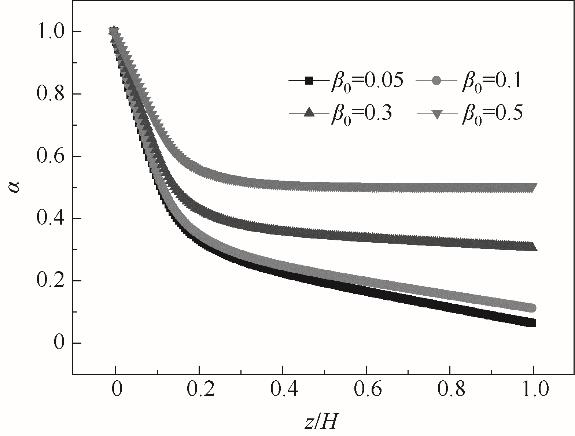

Fig.6 Dimensionless H2S concentration in gas phase along the axial direction of the BTF at different H2S concentrations in the recirculated liquid phase

| 1 | Bonilla-Blancas W, Mora M, Revah S, et al. Application of a novel respirometric methodology to characterize mass transfer and activity of H2S-oxidizing biofilms in biotrickling filter beds[J]. Biochem. Eng. J., 2015, 99: 24-34. |

| 2 | Jia T, Sun S, Chen K, et al. Simultaneous methanethiol and dimethyl sulfide removal in a single-stage biotrickling filter packed with polyurethane foam: performance, parameters and microbial community analysis[J]. Chemosphere, 2020, 244: 125460. |

| 3 | Rybarczyk P, Szulczyński B, Gębicki J, et al. Treatment of malodorous air in biotrickling filters: a review[J]. Biochem. Eng. J., 2019, 141: 146-162. |

| 4 | 钱东升, 房俊逸, 陈东之, 等. 板式生物滴滤塔高效净化硫化氢废气的研究[J]. 环境科学, 2011, 32(9): 2786-2793. |

| Qian D S, Fang J Y, Chen D Z, et al. Removal of hydrogen sulfide by plate type-biotrickling filter[J]. Environmental Science, 2011, 32(9): 2786-2793. | |

| 5 | 廖强, 田鑫, 朱恂, 等. 陶瓷球填料生物滴滤塔降解甲苯废气[J]. 化工学报, 2003, 54(12): 1774-1778. |

| Liao Q, Tian X, Zhu X, et al. Purifying waste gas containing low concentration toluene in trickling biofilter with ceramic spheres[J]. Journal of Chemical Industry and Engineering (China), 2003, 54(12): 1774-1778. | |

| 6 | 廖强, 田鑫, 朱恂. 生物膜滴滤床内温度及其分布特性对废气净化性能的影响[J]. 化工学报, 2006, 57(7): 1643-1648. |

| Liao Q, Tian X, Zhu X. Effects of temperature and its profile on purification performance of biotrickling bed for waste gas treatment[J]. Journal of Chemical Industry and Engineering (China), 2006, 57(7): 1643-1648. | |

| 7 | Dupnock T L, Deshusses M A. Biological co-treatment of H2S and reduction of CO2 to methane in an anoxic biological trickling filter upgrading biogas[J]. Chemosphere, 2020, 256: 127078. |

| 8 | Zhang Y, Liu J, Xing H, et al. Performance and fungal diversity of bio-trickling filters packed with composite media of polydimethylsiloxane and foam ceramics for hydrophobic VOC removal[J]. Chemosphere, 2020, 256: 127093. |

| 9 | Zhang Y, Oshita K, Kusakabe T, et al. Simultaneous removal of siloxanes and H2S from biogas using an aerobic biotrickling filter[J]. J. Hazard. Mater., 2020, 391: 122187. |

| 10 | Estrada J M, Dudek A, Muñoz R, et al. Fundamental study on gas-liquid mass transfer in a biotrickling filter packed with polyurethane foam[J]. J. Chem. Technol. Biotechnol., 2014, 89: 1419-1424. |

| 11 | Fernandez M, Ramírez M, Perez R M, et al. Hydrogen sulphide removal from biogas by an anoxic biotrickling filter packed with pall rings[J]. Chem. Eng. J., 2013, 225: 456-463. |

| 12 | San-Valero P, Penya-Roja J M, Álvarez-Hornos F J, et al. Modelling mass transfer properties in a biotrickling filter for the removal of isopropanol[J]. Chem. Eng. Sci., 2014, 108: 47-56. |

| 13 | Liu D, Andreasen R R, Poulsen T G, et al. A comparative study of mass transfer coefficients of reduced volatile sulfur compounds for biotrickling filter packing materials[J]. Chem. Eng. J., 2015, 260: 209-221. |

| 14 | Gonzalez-Sanchez A, Arellano-García L, Bonilla-Blancas W, et al. Kinetic characterization by respirometry of volatile organic compound-degrading biofilms from gas-phase biological filters[J]. Ind. Eng. Chem. Res., 2014, 53: 19405-19415. |

| 15 | Wang X, Wang Q, Li S, et al. Degradation pathway and kinetic analysis for p-xylene removal by a novel Pandoraea sp. strain WL1 and its application in a biotrickling filter[J]. J. Hazard. Mater., 2015, 288: 17-24. |

| 16 | Mathur A K, Sundaramurthy J, Balomajumder C. Kinetics of the removal of mono-chlorobenzene vapour from waste gases using a trickle bed air biofilter[J]. J. Hazard. Mater., 2006, 137: 1560-1568. |

| 17 | Malhautier L, Quijano G, Avezac M, et al. Kinetic characterization of toluene biodegradation by Rhodococcus erythropolis: towards a rationale for microflora enhancement in bioreactors devoted to air treatment[J]. Chem. Eng. J., 2014, 247: 199-204. |

| 18 | Giri B S, Goswami M, Pandey R A, et al. Kinetics and biofiltration of dimethyl sulfide emitted from P&P industry[J]. Biochem. Eng. J., 2015, 102: 108-114. |

| 19 | van Krevelen D W, Hoftijzer P J. Kinetics of simultaneous absorption and chemical reaction[J]. Chem. Eng. Pro., 1948, 44: 529-536. |

| 20 | Shulman H L, Ullrich C F, Proulx A Z, et al. Performance of packed columns(Ⅱ): Wetted and effective-interfacial areas, gas- and liquid-phase mass transfer rates[J]. AIChE J., 1955, 1: 253-258. |

| 21 | Billet R, Schultes M. Prediction of mass transfer columns with dumped and arranged packings: updated summary of the calculation method of billet and schultes[J]. Chem. Eng. Res. Des. ,1999, 77: 498-504. |

| 22 | Onda K, Takeuchi H, Okumoto Y. Mass transfer coefficients between gas and liquid phases in packed columns[J]. J. Chem. Eng. Jap., 1968, 1: 56-62. |

| 23 | Kim S, Deshusses M A. Determination of mass transfer coefficients for packing materials used in biofilters and biotrickling filters for air pollution control(2): Development of mass transfer coefficients correlations[J]. Chem. Eng. Sci., 2008, 63: 856-861. |

| 24 | Kim S, Deshusses M A. Determination of mass transfer coefficients for packing materials used in biofilters and biotrickling filters for air pollution control (1): Experimental results[J]. Chem. Eng. Sci., 2008, 63: 841-855. |

| 25 | Cox H H J, Deshusses M A. Co-treatment of H2S and toluene in a biotrickling filter[J]. Chem. Eng. J., 2002, 87: 101-110. |

| 26 | Jin Y, Veiga M C, Kennes C. Co-treatment of hydrogen sulfide and methanol in a single-stage biotrickling filter under acidic conditions[J]. Chemosphere, 2007, 68: 1186-1193. |

| 27 | Montebello A M, Fernández M, Almenglo F, et al. Simultaneous methylmercaptan and hydrogen sulfide removal in the desulfurization of biogas in aerobic and anoxic biotrickling filters[J]. Chem. Eng. J., 2012, 200/201/202: 237-246. |

| 28 | López L R, Luis R, Bezerra T, et al. Influence of trickling liquid velocity and flow pattern in the improvement of oxygen transport in aerobic biotrickling filters for biogas desulfurization[J]. J. Chem. Technol. Biotechnol., 2016, 91: 1031-1039. |

| 29 | Gaszczak A, Bartelmus G, Burghardt A, et al. Experiments and modelling of a biotrickling filter (BTF) for removal of styrene from airstreams[J]. J. Chem. Technol. Biotechnol., 2018, 93: 2659-2670. |

| 30 | Xie L, Zhu J, Hu J, et al. Study of the mass transfer-biodegradation kinetics in a pilot-scale biotrickling filter for the removal of H2S[J]. Indus. Eng. Chem. Res., 2020, 59: 8383-8392. |

| 31 | Chen Y, Xie L, Cai W, et al. Pilot-scale study using biotrickling filter to remove H2S from sewage lift station: experiment and CFD simulation[J]. Biochem. Eng. J., 2019, 144: 177-184. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||