CIESC Journal ›› 2021, Vol. 72 ›› Issue (8): 4371-4380.DOI: 10.11949/0438-1157.20201787

• Energy and environmental engineering • Previous Articles Next Articles

Linzhou ZHAO1( ),Yan'e ZHENG1,2(

),Yan'e ZHENG1,2( ),Kongzhai Li2,3,Yaming WANG1,Lihong JIANG1,Haoxi FAN1,Yajing WANG1,Xing ZHU2,3,Yonggang WEI2,3

),Kongzhai Li2,3,Yaming WANG1,Lihong JIANG1,Haoxi FAN1,Yajing WANG1,Xing ZHU2,3,Yonggang WEI2,3

Received:2020-12-09

Revised:2021-04-02

Online:2021-08-05

Published:2021-08-05

Contact:

Yan'e ZHENG

赵林洲1( ),郑燕娥1,2(

),郑燕娥1,2( ),李孔斋2,3,王亚明1,蒋丽红1,范浩熙1,王雅静1,祝星2,3,魏永刚2,3

),李孔斋2,3,王亚明1,蒋丽红1,范浩熙1,王雅静1,祝星2,3,魏永刚2,3

通讯作者:

郑燕娥

作者简介:赵林洲(1994—),男,硕士研究生,基金资助:CLC Number:

Linzhou ZHAO, Yan'e ZHENG, Kongzhai Li, Yaming WANG, Lihong JIANG, Haoxi FAN, Yajing WANG, Xing ZHU, Yonggang WEI. Application of Ce1-xNixOy oxygen carriers in chemical-looping reforming of methane coupled with CO2 reduction[J]. CIESC Journal, 2021, 72(8): 4371-4380.

赵林洲, 郑燕娥, 李孔斋, 王亚明, 蒋丽红, 范浩熙, 王雅静, 祝星, 魏永刚. Ce1-xNixOy氧载体在化学链甲烷重整耦合CO2还原中的应用[J]. 化工学报, 2021, 72(8): 4371-4380.

Add to citation manager EndNote|Ris|BibTeX

| 样品 | 孔体积/(cm3/g) | 平均孔径/nm | 比表面积/(m2/g) |

|---|---|---|---|

| NiO | 0.031 | 10.725 | 11.45 |

| Ce0.2Ni0.8Oy | 0.120 | 16.092 | 29.59 |

| Ce0.4Ni0.6Oy | 0.079 | 13.857 | 22.74 |

| Ce0.6Ni0.4Oy | 0.070 | 13.726 | 20.25 |

| Ce0.8Ni0.2Oy | 0.054 | 9.989 | 21.53 |

| CeO2 | 0.056 | 16.015 | 13.97 |

Table 1 The pore volumes, average pore diameter and BET surface areas of oxygen carriers

| 样品 | 孔体积/(cm3/g) | 平均孔径/nm | 比表面积/(m2/g) |

|---|---|---|---|

| NiO | 0.031 | 10.725 | 11.45 |

| Ce0.2Ni0.8Oy | 0.120 | 16.092 | 29.59 |

| Ce0.4Ni0.6Oy | 0.079 | 13.857 | 22.74 |

| Ce0.6Ni0.4Oy | 0.070 | 13.726 | 20.25 |

| Ce0.8Ni0.2Oy | 0.054 | 9.989 | 21.53 |

| CeO2 | 0.056 | 16.015 | 13.97 |

| 氧载体 | O百分比 | Osurf/Olatt | Ce百分比 | Ce3+/ Ce4+ | Ni百分比 | Ni2+/Ni3+ | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| OⅠ | OⅡ | OⅢ | Ce3+ | Ce4+ | Ni2+ | Ni3+ | ||||

| Ce0.2Ni0.8Oy | 32.27 | 34.87 | 32.86 | 2.04 | 15.89 | 84.11 | 0.19 | 35.96 | 64.04 | 0.56 |

| Ce0.4Ni0.6Oy | 12.75 | 20.47 | 66.79 | 0.50 | 21.91 | 78.09 | 0.28 | 29.85 | 70.15 | 0.42 |

Table 2 The relevant XPS parameters of Ce0.2Ni0.8Oyand Ce0.4Ni0.6Oy oxygen carriers

| 氧载体 | O百分比 | Osurf/Olatt | Ce百分比 | Ce3+/ Ce4+ | Ni百分比 | Ni2+/Ni3+ | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| OⅠ | OⅡ | OⅢ | Ce3+ | Ce4+ | Ni2+ | Ni3+ | ||||

| Ce0.2Ni0.8Oy | 32.27 | 34.87 | 32.86 | 2.04 | 15.89 | 84.11 | 0.19 | 35.96 | 64.04 | 0.56 |

| Ce0.4Ni0.6Oy | 12.75 | 20.47 | 66.79 | 0.50 | 21.91 | 78.09 | 0.28 | 29.85 | 70.15 | 0.42 |

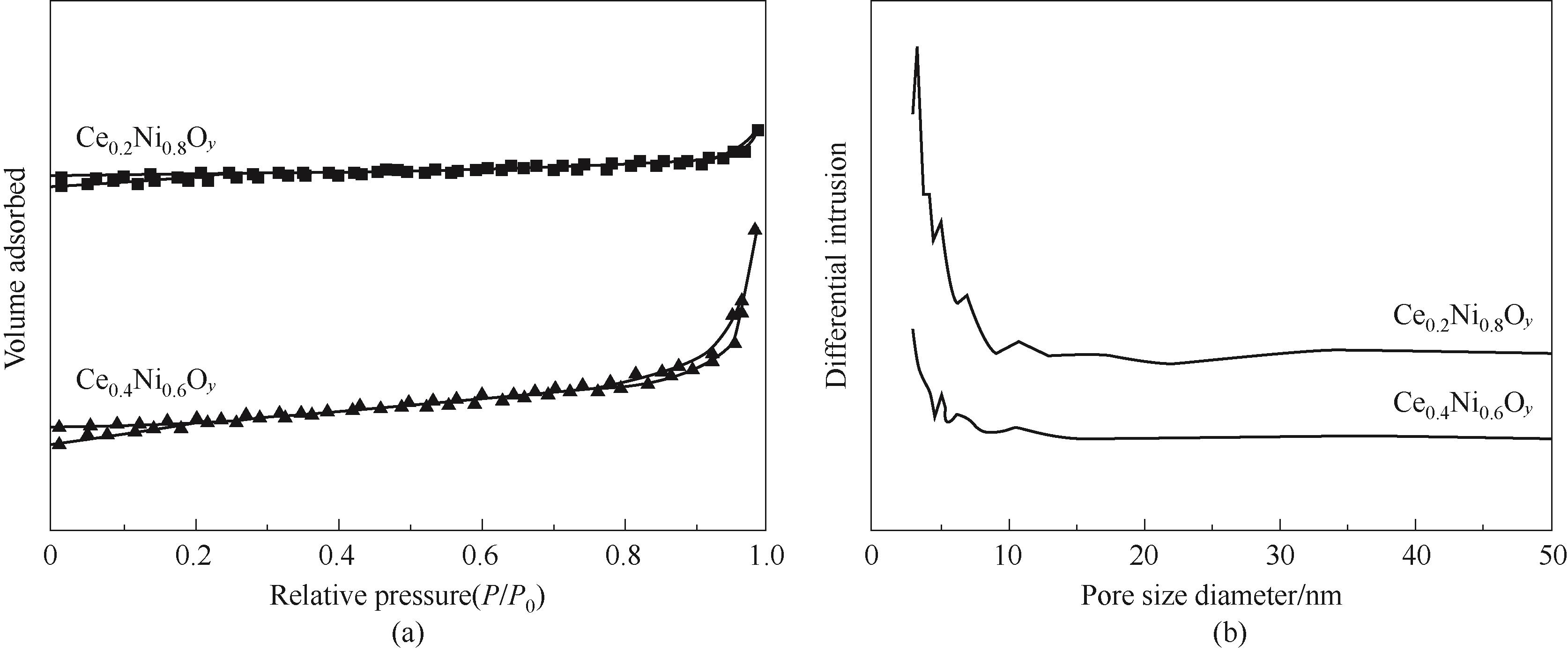

Fig.10 Nitrogen adsorption-desorption isotherms (a) and pore-size distributions (b) of Ce0.2Ni0.8Oy and Ce0.4Ni0.6Oy oxygen carriers after 20 redox cycles

| 样品 | 孔体积/(cm3/g) | 平均孔径/nm | 比表面积/(m2/g) |

|---|---|---|---|

| Ce0.2Ni0.8Oy | 0.038 | 11.525 | 10.09 |

| Ce0.4Ni0.6Oy | 0.028 | 11.531 | 7.24 |

Table 3 The pore volumes, average pore diameter and BET surface areas of Ce0.2Ni0.8Oy and Ce0.4Ni0.6Oy oxygen carriers after 20 redox cycles

| 样品 | 孔体积/(cm3/g) | 平均孔径/nm | 比表面积/(m2/g) |

|---|---|---|---|

| Ce0.2Ni0.8Oy | 0.038 | 11.525 | 10.09 |

| Ce0.4Ni0.6Oy | 0.028 | 11.531 | 7.24 |

| 氧载体 | 氧百分比 | Osurf/Olatt | Ce百分比 | Ce3+/Ce4+ | Ni百分比 | Ni2+/Ni3+ | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| OⅠ | OⅡ | OⅢ | Ce3+ | Ce4+ | Ni2+ | Ni3+ | ||||

| Ce0.2Ni0.8Oy | 23.45 | 39.03 | 37.53 | 1.66 | 10.65 | 89.35 | 0.12 | 39.28 | 60.72 | 0.65 |

| Ce0.4Ni0.6Oy | 14.35 | 27.01 | 58.64 | 0.70 | 7.89 | 92.11 | 0.08 | 34.28 | 65.72 | 0.52 |

Table 4 The relevant XPS parameters of Ce0.2Ni0.8Oy and Ce0.4Ni0.6Oy oxygen carriers after 20 redox cycles

| 氧载体 | 氧百分比 | Osurf/Olatt | Ce百分比 | Ce3+/Ce4+ | Ni百分比 | Ni2+/Ni3+ | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| OⅠ | OⅡ | OⅢ | Ce3+ | Ce4+ | Ni2+ | Ni3+ | ||||

| Ce0.2Ni0.8Oy | 23.45 | 39.03 | 37.53 | 1.66 | 10.65 | 89.35 | 0.12 | 39.28 | 60.72 | 0.65 |

| Ce0.4Ni0.6Oy | 14.35 | 27.01 | 58.64 | 0.70 | 7.89 | 92.11 | 0.08 | 34.28 | 65.72 | 0.52 |

| 1 | Liu L P, Ryu B, Sun Z L, et al. Monitoring and research on environmental impacts related to marine natural gas hydrates: review and future perspective[J]. Journal of Natural Gas Science and Engineering, 2019, 65: 82-107. |

| 2 | Wei C, Wang M H. Spatial distribution of greenhouse gases (CO2 and CH4) on expressways in the megacity Shanghai, China[J]. Environmental Science and Pollution Research, 2020, 27(25): 31143-31152. |

| 3 | Niu J T, Ran J Y, Chen D. Understanding the mechanism of CO2 reforming of methane to syngas on Ni@Pt surface compared with Ni (1 1 1) and Pt (1 1 1)[J]. Applied Surface Science, 2020, 513: 145840-145873. |

| 4 | Liu C C, Chen Y, Zhao Y X, et al. Nano-ZSM-5-supported cobalt for the production of liquid fuel in Fischer-Tropsch synthesis: effect of preparation method and reaction temperature[J]. Fuel, 2020, 263: 116619. |

| 5 | Angeli S D, Monteleone G, Giaconia A, et al. State-of-the-art catalysts for CH4 steam reforming at low temperature[J]. International Journal of Hydrogen Energy, 2014, 39(5): 1979-1997. |

| 6 | Abdullah B, Abd Ghani N A, Vo D V N. Recent advances in dry reforming of methane over Ni-based catalysts[J]. Journal of Cleaner Production, 2017, 162: 170-185. |

| 7 | Christian Enger B, Lødeng R, Holmen A. A review of catalytic partial oxidation of methane to synthesis gas with emphasis on reaction mechanisms over transition metal catalysts[J]. Applied Catalysis A: General, 2008, 346(1/2): 1-27. |

| 8 | Sheu E J, Mokheimer E M A, Ghoniem A F. A review of solar methane reforming systems[J]. International Journal of Hydrogen Energy, 2015, 40(38): 12929-12955. |

| 9 | Mikheyev P A, Demyanov A V, Kochetov I V, et al. Ozone and oxygen atoms production in a dielectric barrier discharge in pure oxygen and O2/CH4 mixtures. Modeling and experiment[J]. Plasma Sources Science and Technology, 2020, 29(1): 015012. |

| 10 | Carrillo A J, Kim K J, Hood Z D, et al. La0.6Sr0.4Cr0.8Co0.2O3 perovskite decorated with exsolved Co nanoparticles for stable CO2 splitting and syngas production[J]. ACS Applied Energy Materials, 2020, 3(5): 4569-4579. |

| 11 | Yang Z Y, Zheng Y E, Li K Z, et al. Chemical-looping reforming of methane over La-Mn-Fe-O oxygen carriers: effect of calcination temperature[J]. Chemical Engineering Science, 2021, 229: 116085. |

| 12 | Wang Y J, Zheng Y E, Wang Y H, et al. Syngas production modified by oxygen vacancies over CeO2-ZrO2-CuO oxygen carrier via chemical looping reforming of methane[J]. Applied Surface Science, 2019, 481: 151-160. |

| 13 | Pérez-Vega R, Abad A, Izquierdo M T, et al. Evaluation of Mn-Fe mixed oxide doped with TiO2 for the combustion with CO2 capture by chemical looping assisted by oxygen uncoupling[J]. Applied Energy, 2019, 237: 822-835. |

| 14 | Wu Y J, Luo C H, Su Q Q. Study of NH3 removal based on chemical-looping combustion[J]. Industrial & Engineering Chemistry Research, 2019, 58(12): 5054-5063. |

| 15 | Liu R, Pei C L, Zhang X H, et al. Chemical looping partial oxidation over FeWOx/SiO2 catalysts[J]. Chinese Journal of Catalysis, 2020, 41(7): 1140-1151. |

| 16 | Forero C R, Gayán P, García-Labiano F, et al. High temperature behaviour of a CuO/γ-Al2O3 oxygen carrier for chemical-looping combustion[J]. International Journal of Greenhouse Gas Control, 2011, 5(4): 659-667. |

| 17 | Zhu M, Song Y H, Chen S Y, et al. Chemical looping dry reforming of methane with hydrogen generation on Fe2O3/Al2O3 oxygen carrier[J]. Chemical Engineering Journal, 2019, 368: 812-823. |

| 18 | Cao Y, He B S, Tong W X, et al. On the kinetics of Mn2O3/ZrO2 oxygen carrier for chemical looping air separation[J]. Chemical Engineering and Processing - Process Intensification, 2019, 136: 82-91. |

| 19 | Zheng Y E, Wei Y G, Li K Z, et al. Chemical-looping steam methane reforming over macroporous CeO2-ZrO2 solid solution: effect of calcination temperature[J]. International Journal of Hydrogen Energy, 2014, 39(25): 13361-13368. |

| 20 | Liu Y K, Long Y H, Tang Y Q, et al. Effect of preparation method on the structural characteristics of NiO-ZrO2 oxygen carriers for chemical-looping combustion[J]. Chemical Research in Chinese Universities, 2019, 35(6): 1024-1031. |

| 21 | Zheng Y E, Li K Z, Wang H, et al. Structure dependence and reaction mechanism of CO oxidation: a model study on macroporous CeO2 and CeO2-ZrO2 catalysts[J]. Journal of Catalysis, 2016, 344: 365-377. |

| 22 | Zheng Y E, Li K Z, Wang H, et al. Enhanced activity of CeO2-ZrO2 solid solutions for chemical-looping reforming of methane via tuning the macroporous structure[J]. Energy & Fuels, 2016, 30(1): 638-647. |

| 23 | Atzori L, Cutrufello M G, Meloni D, et al. Highly active NiO-CeO2 catalysts for synthetic natural gas production by CO2 methanation[J]. Catalysis Today, 2018, 299: 183-192. |

| 24 | Zhou G L, Liu H R, Cui K K, et al. Role of surface Ni and Ce species of Ni/CeO2 catalyst in CO2 methanation[J]. Applied Surface Science, 2016, 383: 248-252. |

| 25 | Hosseini S Y, Khosravi-Nikou M R, Shariati A. Kinetic study of the reduction step for chemical looping steam methane reforming by CeO2-Fe2O3 oxygen carriers[J]. Chemical Engineering & Technology, 2020, 43(3): 540-552. |

| 26 | Nurbaisyatul E S, Azhan H, Kasim A, et al. Effect of CeO2 nanoparticle on the structural and electrical properties of BSCCO-2223 high temperature superconductor[J]. Solid State Phenomena, 2020, 307: 104-109. |

| 27 | Lu C Q, Deng R R, Xu R D, et al. Design of hybrid oxygen carriers with CeO2 particles on MnCo2O4 microspheres for chemical looping combustion[J]. Chemical Engineering Journal, 2021, 404: 126554. |

| 28 | Ma S W, Chen S Y, Ge H J, et al. Synergistic effects of Zr and Sm co-doped Fe2O3/CeO2 oxygen carrier for chemical looping hydrogen generation[J]. Energy & Fuels, 2020, 34(8): 10256-10267. |

| 29 | Zheng Z M, Luo L X, Chen S B, et al. Activating Fe2O3 using K2CO3-containing ethanol solution for corn stalk chemical looping gasification to produce hydrogen[J]. International Journal of Hydrogen Energy, 2020, 45(41): 21004-21013. |

| 30 | Lim H S, Kang D, Lee J W. Phase transition of Fe2O3-NiO to NiFe2O4 in perovskite catalytic particles for enhanced methane chemical looping reforming-decomposition with CO2 conversion[J]. Applied Catalysis B: Environmental, 2017, 202: 175-183. |

| 31 | Isarapakdeetham S, Kim-Lohsoontorn P, Wongsakulphasatch S, et al. Hydrogen production via chemical looping steam reforming of ethanol by Ni-based oxygen carriers supported on CeO2 and La2O3 promoted Al2O3[J]. International Journal of Hydrogen Energy, 2020, 45(3): 1477-1491. |

| 32 | Medrano J A, Hamers H P, Williams G, et al. NiO/CaAl2O4 as active oxygen carrier for low temperature chemical looping applications[J]. Applied Energy, 2015, 158: 86-96. |

| 33 | Li T Y, Jayathilake R S, Taylor D D, et al. Structural studies of the perovskite series La1-xSrxCoO3-δ during chemical looping with methane[J]. Chemical Communications, 2019, 55(34): 4929-4932. |

| 34 | Löfberg A, Guerrero-Caballero J, Kane T, et al. Ni/CeO2 based catalysts as oxygen vectors for the chemical looping dry reforming of methane for syngas production[J]. Applied Catalysis B: Environmental, 2017, 212: 159-174. |

| 35 | Shan W J, Fleys M, Lapicque F, et al. Syngas production from partial oxidation of methane over Ce1-XNiXOY catalysts prepared by complexation-combustion method[J]. Applied Catalysis A: General, 2006, 311: 24-33. |

| 36 | Nematollahi B, Rezaei M, Lay E N. Preparation of highly active and stable NiO-CeO2 nanocatalysts for CO selective methanation[J]. International Journal of Hydrogen Energy, 2015, 40(27): 8539-8547. |

| 37 | Che W, Wei M R, Sang Z S, et al. Perovskite LaNiO3-δ oxide as an anion-intercalated pseudocapacitor electrode[J]. Journal of Alloys and Compounds, 2018, 731: 381-388. |

| [1] | Zefeng GE, Yuqing WU, Mingxun ZENG, Zhenting ZHA, Yuna MA, Zenghui HOU, Huiyan ZHANG. Effect of ash chemical components on biomass gasification properties [J]. CIESC Journal, 2023, 74(5): 2136-2146. |

| [2] | Jiachen SUN, Chunlei PEI, Sai CHEN, Zhijian ZHAO, Shengbao HE, Jinlong GONG. Advances in chemical-looping oxidative dehydrogenation of light alkanes [J]. CIESC Journal, 2023, 74(1): 205-223. |

| [3] | Feng WANG, Shunxin ZHANG, Fangbo YU, Ya LIU, Liejin GUO. Optimization strategy for producing carbon based fuels by photocatalytic CO2 reduction [J]. CIESC Journal, 2023, 74(1): 29-44. |

| [4] | Xin LI, Shaojuan ZENG, Kuilin PENG, Lei YUAN, Xiangping ZHANG. Research progress and tendency of CO2 electrocatalytic reduction to syngas [J]. CIESC Journal, 2023, 74(1): 313-329. |

| [5] | Lianfeng ZHU, Chao WANG, Mengjuan ZHANG, Fangzheng LIU, Xin JIA, Ping AN, Guangwen XU, Zhennan HAN. Fluidized bed two-stage gasification of coal with steam/O2 for production of low-tar syngas [J]. CIESC Journal, 2022, 73(8): 3720-3730. |

| [6] | Zhenyu LIU. Origin of low productivity of underground coal gasification: diffusion and reaction in stagnant boundary layer and gasification tunnel [J]. CIESC Journal, 2022, 73(8): 3299-3306. |

| [7] | Yuelin WANG, Wei CHAO, Xiaocheng LAN, Zhipeng MO, Shuhuan TONG, Tiefeng WANG. Review of ethanol production via biological syngas fermentation [J]. CIESC Journal, 2022, 73(8): 3448-3460. |

| [8] | Le ZHOU, Chengkai SHEN, Chao WU, Beiping HOU, Zhihuan SONG. Deep fusion feature extraction network and its application in chemical process soft sensing [J]. CIESC Journal, 2022, 73(7): 3156-3165. |

| [9] | Bo MENG, Yanping LIU, Xinke JIANG, Yifan HAN. The scale regulation of Fe5C2-MnO x and their catalytic performance for the preparation of olefins from syngas [J]. CIESC Journal, 2022, 73(6): 2677-2689. |

| [10] | Cong YUAN, Ge PU, Jie GAO, Shuaihui JIA. Biomass chemical-looping gasification characteristics of K-modified BaFe2O4 oxygen carrier [J]. CIESC Journal, 2022, 73(3): 1359-1368. |

| [11] | Lin WANG, Qian FU, Shuai XIAO, Zhuo LI, Jun LI, Liang ZHANG, Xun ZHU, Qiang LIAO. High-efficient visible light responsive microbial photoelectrochemical system for CO2 reduction to CH4 [J]. CIESC Journal, 2022, 73(2): 887-893. |

| [12] | Baowen WANG, Gang ZHANG, Tongqing LIU, Weiguang LI, Mengjia WANG, Deshun LIN, Jingjing MA. Research on chemical looping reforming of CH4 by CeO2 doped CuFe2O4 oxygen carrier coupled with CO2 thermocatalytic reduction [J]. CIESC Journal, 2022, 73(12): 5414-5426. |

| [13] | Weiwei XUAN, Yanwu DONG, Hailun WANG. Study on the steam gasification mechanism of waste PP plastics based on ReaxFF-MD and DFT methods [J]. CIESC Journal, 2022, 73(11): 5251-5262. |

| [14] | Shide WU, Feng YI, Dan PING, Yifei ZHANG, Jian HAO, Guoji LIU, Shaoming FANG. NH4Cl assisted preparation of Ni-N-CNTs catalyst and its performance for electrochemical CO2 reduction [J]. CIESC Journal, 2022, 73(10): 4484-4497. |

| [15] | Qianhao WANG, Lu ZHAO, Fulin SUN, Kegong FANG. Production of syngas derived from H2S-CO2via synergy of ZSM-5 catalyst and non-thermal plasma [J]. CIESC Journal, 2022, 73(1): 255-265. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||