CIESC Journal ›› 2022, Vol. 73 ›› Issue (10): 4692-4706.DOI: 10.11949/0438-1157.20220590

• Energy and environmental engineering • Previous Articles Next Articles

Xiaosong HOU1,2,3( ), Chenxing LIU1,2,3, Ailing REN1,2,3, Bin GUO1,2,3(

), Chenxing LIU1,2,3, Ailing REN1,2,3, Bin GUO1,2,3( ), Yuanming GUO4

), Yuanming GUO4

Received:2022-04-26

Revised:2022-08-08

Online:2022-11-02

Published:2022-10-05

Contact:

Bin GUO

侯晓松1,2,3( ), 刘晨星1,2,3, 任爱玲1,2,3, 郭斌1,2,3(

), 刘晨星1,2,3, 任爱玲1,2,3, 郭斌1,2,3( ), 郭渊明4

), 郭渊明4

通讯作者:

郭斌

作者简介:侯晓松(1995—),男,硕士研究生,15075168995@163.com

基金资助:CLC Number:

Xiaosong HOU, Chenxing LIU, Ailing REN, Bin GUO, Yuanming GUO. Study on purification of toluene waste gas by ultrasonic atomization/surfactants-enhanced absorption coupled with biological scrubbing[J]. CIESC Journal, 2022, 73(10): 4692-4706.

侯晓松, 刘晨星, 任爱玲, 郭斌, 郭渊明. 超声雾化/表面活性剂强化吸收耦合生物洗涤净化甲苯废气[J]. 化工学报, 2022, 73(10): 4692-4706.

Add to citation manager EndNote|Ris|BibTeX

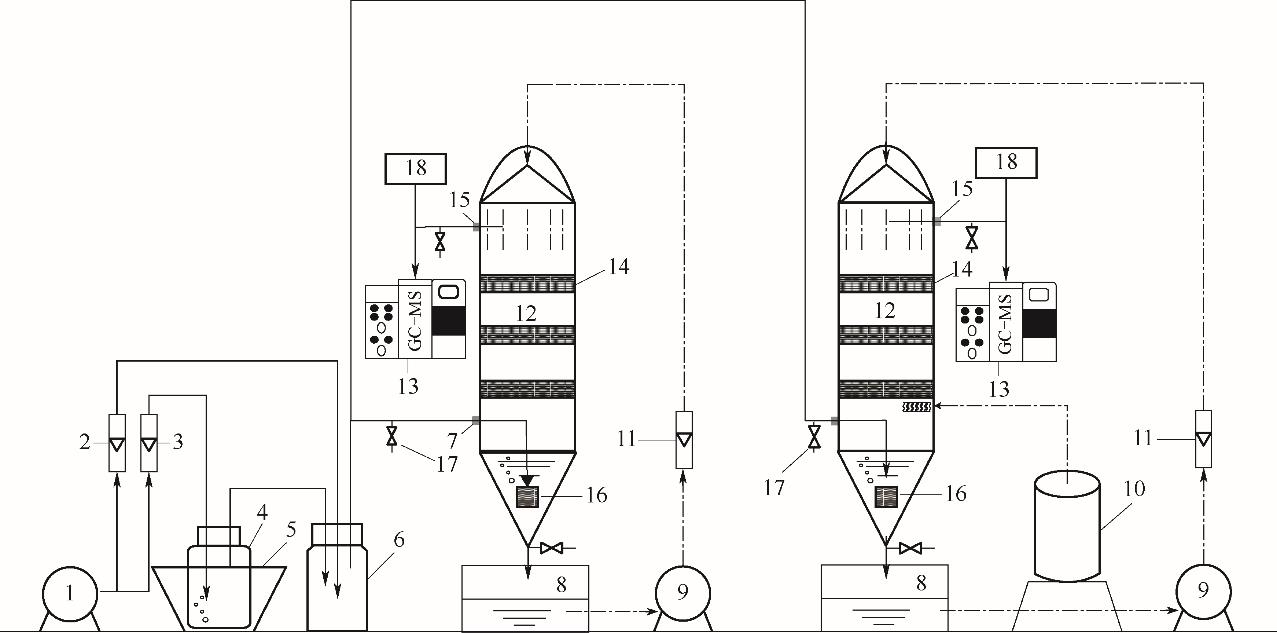

Fig.1 Flow chart of test device1—air pump; 2—air flow meter; 3—toluene flow meter; 4—gas generation bottle; 5—constant temperature water bath; 6—buffer bottle; 7—gas inlet; 8—circulation liquid tank; 9—peristaltic pump; 10—ultrasonic atomization absorption device; 11—liquid rotameter; 12—packed scrubber tower; 13—gas chromatograph-mass spectrometer; 14—packing; 15—gas outlet; 16—aeration head; 17—sampling port; 18—exhaust gas absorption device

| 序号 | 工况条件 | 运行方式 |

|---|---|---|

| 1 | 临时停运事故 | 停运1 h |

| 2 | 设备故障检修 | 停运4 h |

| 3 | 生产系统故障白天检修 | 停运8 h |

| 4 | 夜间停运阶段 | 停运16 h |

| 5 | 生产系统全天停运检修 | 停运24 h |

| 6 | 双休日停运 | 停运48 h |

Table 1 Working conditions and operation mode of biological washing system

| 序号 | 工况条件 | 运行方式 |

|---|---|---|

| 1 | 临时停运事故 | 停运1 h |

| 2 | 设备故障检修 | 停运4 h |

| 3 | 生产系统故障白天检修 | 停运8 h |

| 4 | 夜间停运阶段 | 停运16 h |

| 5 | 生产系统全天停运检修 | 停运24 h |

| 6 | 双休日停运 | 停运48 h |

| 自变量 | 编码水平 | ||

|---|---|---|---|

| -1 | 0 | 1 | |

| 洗涤液pH(A) | 6 | 7 | 8 |

| 液气比(B) | 0.30 | 0.25 | 0.20 |

| 停留时间(C) | 28 | 42 | 56 |

Table 2 Coding and level of test factors

| 自变量 | 编码水平 | ||

|---|---|---|---|

| -1 | 0 | 1 | |

| 洗涤液pH(A) | 6 | 7 | 8 |

| 液气比(B) | 0.30 | 0.25 | 0.20 |

| 停留时间(C) | 28 | 42 | 56 |

| 洗涤液pH | 停留时间/s | 液气比 | 甲苯去除率/% | |

|---|---|---|---|---|

| 预测值 | 实际值 | |||

| 7.07 | 54.60 | 0.23 | 97.71 | 97.26 |

Table 3 USBWR optimum process parameters

| 洗涤液pH | 停留时间/s | 液气比 | 甲苯去除率/% | |

|---|---|---|---|---|

| 预测值 | 实际值 | |||

| 7.07 | 54.60 | 0.23 | 97.71 | 97.26 |

| 反应器 | 模拟方程 | 比降解速率k | R2 | 半衰期/h |

|---|---|---|---|---|

| USBWR | ln(ct /c0)= -0.1421t+0.2719 | 0.1421 | 0.9843 | 4.88 |

| TBWR | ln(ct /c0)= -0.0834t-0.0105 | 0.0834 | 0.9662 | 8.31 |

Table 4 Comparison of kinetic fitting results

| 反应器 | 模拟方程 | 比降解速率k | R2 | 半衰期/h |

|---|---|---|---|---|

| USBWR | ln(ct /c0)= -0.1421t+0.2719 | 0.1421 | 0.9843 | 4.88 |

| TBWR | ln(ct /c0)= -0.0834t-0.0105 | 0.0834 | 0.9662 | 8.31 |

| 距塔底距离/cm | 中位径(D50)/μm | 体积平均径/μm | 面积平均径/μm | 比表面积/ (m2·kg-1) | 跨度 |

|---|---|---|---|---|---|

| 15 | 6.546 | 6.755 | 6.483 | 415.10 | 0.32 |

| 30 | 7.016 | 7.187 | 6.428 | 345.70 | 0.41 |

| 45 | 7.172 | 7.423 | 6.987 | 318.00 | 0.57 |

| 均值 | 6.911 | 7.122 | 6.633 | 359.60 | — |

Table 5 Droplet size distribution of compound surfactant at different heights in the tower

| 距塔底距离/cm | 中位径(D50)/μm | 体积平均径/μm | 面积平均径/μm | 比表面积/ (m2·kg-1) | 跨度 |

|---|---|---|---|---|---|

| 15 | 6.546 | 6.755 | 6.483 | 415.10 | 0.32 |

| 30 | 7.016 | 7.187 | 6.428 | 345.70 | 0.41 |

| 45 | 7.172 | 7.423 | 6.987 | 318.00 | 0.57 |

| 均值 | 6.911 | 7.122 | 6.633 | 359.60 | — |

| 1 | 姚维杰, 王大玮, 谢付莹, 等. 日照市夏季VOCs物种空间分布特征及其对臭氧生成的影响[J]. 环境科学, 2022, 43(2): 714-722. |

| Yao W J, Wang D W, Xie F Y, et al. Spatial distribution characteristics of VOCs and its impact on ozone formation potential in Rizhao City in summer[J]. Environmental Science, 2022, 43(2): 714-722. | |

| 2 | Wang Z W, Xiu G L, Qiao T, et al. Coupling ozone and hollow fibers membrane bioreactor for enhanced treatment of gaseous xylene mixture[J]. Bioresource Technology, 2013, 130: 52-58. |

| 3 | 任义君, 马双良, 王思维, 等. 郑州市春季大气污染过程VOCs特征、臭氧生成潜势及源解析[J]. 环境科学, 2020, 41(6): 2577-2585. |

| Ren Y J, Ma S L, Wang S W, et al. Ambient VOCs characteristics, ozone formation potential, and source apportionment of air pollution in spring in Zhengzhou[J]. Environmental Science, 2020, 41(6): 2577-2585. | |

| 4 | 叶凯, 刘香华, 姜月, 等. 低温等离子体协同CeO2/13X催化降解甲苯[J]. 化工学报, 2021, 72(7): 3706-3715. |

| Ye K, Liu X H, Jiang Y, et al. Combing low-temperature plasma with CeO2/13X for toluene degradation[J]. CIESC Journal, 2021, 72(7): 3706-3715. | |

| 5 | Chalupa J, Pocik O, Halecky M, et al. Thermophilic waste air treatment of an airborne ethyl acetate/toluene mixture in a bubble column reactor: stability towards temperature changes[J]. Journal of Hazardous Materials, 2020, 384: 120744. |

| 6 | El-Naas M H, Acio J A, El Telib A E. Aerobic biodegradation of BTEX: progresses and prospects[J]. Journal of Environmental Chemical Engineering, 2014, 2(2): 1104-1122. |

| 7 | Nisola G M, Cho E, Orata J D, et al. NH3 gas absorption and bio-oxidation in a single bioscrubber system[J]. Process Biochemistry, 2009, 44(2): 161-167. |

| 8 | Kang J, Wang T, Xin H W, et al. A laboratory study of microalgae-based ammonia gas mitigation with potential application for improving air quality in animal production operations[J]. Journal of the Air & Waste Management Association (1995), 2014, 64(3): 330-339. |

| 9 | Barbusinski K, Kalemba K, Kasperczyk D, et al. Biological methods for odor treatment—a review[J]. Journal of Cleaner Production, 2017, 152: 223-241. |

| 10 | San-Valero P, Penya-roja J M, Álvarez-Hornos F J, et al. Fully aerobic bioscrubber for the desulfurization of H2S-rich biogas[J]. Fuel, 2019, 241: 884-891. |

| 11 | Marsolek M D, Torres C I, Hausner M, et al. Intimate coupling of photocatalysis and biodegradation in a photocatalytic circulating-bed biofilm reactor[J]. Biotechnology and Bioengineering, 2008, 101(1): 83-92. |

| 12 | Wei Z S, Li H Q, He J C, et al. Removal of dimethyl sulfide by the combination of non-thermal plasma and biological process[J]. Bioresource Technology, 2013, 146: 451-456. |

| 13 | Muñoz R, Daugulis A J, Hernández M, et al. Recent advances in two-phase partitioning bioreactors for the treatment of volatile organic compounds[J]. Biotechnology Advances, 2012, 30(6): 1707-1720. |

| 14 | Wang L, Yang C P, Cheng Y, et al. Effects of surfactant and Z n ( Ⅱ ) at various concentrations on microbial activity and ethylbenzene removal in biotricking filter[J]. Chemosphere, 2013, 93(11): 2909-2913. |

| 15 | Tu Y H, Yang C P, Cheng Y, et al. Effect of saponins on n-hexane removal in biotrickling filters[J]. Bioresource Technology, 2015, 175: 231-238. |

| 16 | Shao B B, Liu Z F, Zhong H, et al. Effects of rhamnolipids on microorganism characteristics and applications in composting: a review[J]. Microbiological Research, 2017, 200: 33-44. |

| 17 | Trellu C, Mousset E, Pechaud Y, et al. Removal of hydrophobic organic pollutants from soil washing/flushing solutions: a critical review[J]. Journal of Hazardous Materials, 2016, 306: 149-174. |

| 18 | Rezaei M, Moussavi G, Naddafi K, et al. Enhanced biodegradation of styrene vapors in the biotrickling filter inoculated with biosurfactant-generating bacteria under H2O2 stimulation[J]. Science of the Total Environment, 2020, 704: 135325. |

| 19 | 王光旭, 徐国栋, 刘文婧, 等. 应用电声换能超声波雾化方法提高超细颗粒捕集效率[J]. 环境工程学报, 2013, 7(1): 294-300. |

| Wang G X, Xu G D, Liu W J, et al. Improvement of ultrafine particles separation efficiency by electro-acoustic ultrasonic nebulizer[J]. Chinese Journal of Environmental Engineering, 2013, 7(1): 294-300. | |

| 20 | 陈卓楷, 陈凡植, 周炜煌, 等. 超声雾化水雾在除尘试验中的应用[J]. 广东化工, 2006, 33(10): 74-77. |

| Chen Z K, Chen F Z, Zhou W H, et al. The application of atomization water made by ultrasonic technique in dust removal experiment[J]. Guangdong Chemical Industry, 2006, 33(10): 74-77. | |

| 21 | 陈泊豪. 超声波雾化除尘机理的实验探究[D]. 兰州: 兰州大学, 2014. |

| Chen B H. Experimental study on the mechanism of the fine particles separation by the ultrasonic nebulizer[D]. Lanzhou: Lanzhou University, 2014. | |

| 22 | 陈泊豪, 於进, 周万利, 等. 电声换能超声波雾化方法捕集细颗粒物的强化实验研究[J]. 环境工程, 2014, 32(6): 78-82. |

| Chen B H, Yu J, Zhou W L, et al. Experimental study on enhanced performance of the fine particles separation by the electro-acoustic ultrasonic nebulizer[J]. Environmental Engineering, 2014, 32(6): 78-82. | |

| 23 | 郑德康. 基于超声波雾化法的船舶废气NaClO2气雾脱硝实验研究[D]. 大连: 大连海事大学, 2018. |

| Zheng D K. Study on NO removal from marine flue gas by NaClO2 mist based on ultrasonic atomization[D]. Dalian: Dalian Maritime University, 2018. | |

| 24 | Wei J Q, Gu J J, Guo J H, et al. Simultaneous removal of nitrogen oxides and sulfur dioxide using ultrasonically atomized hydrogen peroxide[J]. Environmental Science and Pollution Research International, 2019, 26(22): 22351-22361. |

| 25 | 孙嘉祺, 郭斌, 侯晓松. 新型填料喷雾塔强化吸收甲醇废气的应用[J]. 化学工程, 2020, 48(7): 33-38. |

| Sun J Q, Guo B, Hou X S. Application of new packed spray tower to intensify absorption of methanol waste gas[J]. Chemical Engineering (China), 2020, 48(7): 33-38. | |

| 26 | Shah A, Shahzad S, Munir A, et al. Micelles as soil and water decontamination agents[J]. Chemical Reviews, 2016, 116(10): 6042-6074. |

| 27 | 涂燕红. 表面活性剂强化生物滴滤器处理正己烷废气的净化效果及机理[D]. 长沙: 湖南大学, 2015. |

| Tu Y H. Enhancement and mechamisms of surfactants on n-hexane removal in biotrickling filters[D]. Changsha: Hunan University, 2015. | |

| 28 | Ono Y, Sekiguchi K, Sankoda K, et al. Improved ultrasonic degradation of hydrophilic and hydrophobic aldehydes in water by combined use of atomization and UV irradiation onto the mist surface[J]. Ultrasonics Sonochemistry, 2020, 60: 104766. |

| 29 | 李远啸. 生物洗涤法净化含苯废气及其强化技术研究[D]. 石家庄: 河北科技大学, 2019. |

| Li Y X. Study on purification of benzene containing waste gas by biscrubber and its strengthening technology[D]. Shijiazhuang: Hebei University of Science and Technology, 2019. | |

| 30 | Skjevrak I, Lund V, Ormerod K, et al. Volatile organic compounds in natural biofilm in polyethylene pipes supplied with lake water and treated water from the distribution network[J]. Water Research, 2005, 39(17): 4133-4141. |

| 31 | 凌丹. 挥发性有机物多技术联合治理研究进展[J]. 绿色科技, 2020(12): 147-149. |

| Ling D. Research progress in multi-technology combined treatment technology of volatile organic compounds organic compounds[J]. Journal of Green Science and Technology, 2020(12): 147-149. | |

| 32 | 刘烁. 两相分配生物反应器降解苯乙烯废气的实验研究及CFD模拟[D]. 石家庄: 河北科技大学, 2020. |

| Liu S. Study on using two phase partitioning bioreactor to remove styrene: experiment and CFD simulation[D]. Shijiazhuang: Hebei University of Science and Technology, 2020. | |

| 33 | Hasan H A, Abdullah S R S, Kamarudin S K, et al. Response surface methodology for optimization of simultaneous COD, N H 4 + -N and Mn2+ removal from drinking water by biological aerated filter[J]. Desalination, 2011, 275(1/2/3): 50-61. |

| 34 | 朱连燕, 王玉明, 周幸福. 响应曲面法优化电催化降解染料废水工艺的研究[J]. 化工学报, 2020, 71(3): 1335-1342. |

| Zhu L Y, Wang Y M, Zhou X F. Application of response surface methodology in optimizing electrocatalytic degradation of dye wastewater[J]. CIESC Journal, 2020, 71(3): 1335-1342. | |

| 35 | Li J W, Han Z W. A modeling study of severe winter haze events in Beijing and its neighboring regions[J]. Atmospheric Research, 2016, 170: 87-97. |

| 36 | 任爱玲, 刘烁, 谷丹丹, 等. 两相分配生物反应器降解苯乙烯废气的研究[J]. 安全与环境学报, 2022, 22(3): 1551-1558. |

| Ren A L, Liu S, Gu D D, et al. Study on using two-phase partitioning bioreactor to remove styrene[J]. Journal of Safety and Environment, 2022, 22(3): 1551-1558. | |

| 37 | Littlejohns J V, McAuley K B, Daugulis A J. Model for a solid-liquid stirred tank two-phase partitioning bioscrubber for the treatment of BTEX[J]. Journal of Hazardous Materials, 2010, 175(1/2/3): 872-882. |

| 38 | 姜岩, 张哲. 不同亲水特性VOCs在生物滴滤工艺中的作用规律[J]. 化工学报, 2020, 71(7): 2973-2982. |

| Jiang Y, Zhang Z. Interaction of VOCs with different hydrophilic properties in biotrickling filters[J]. CIESC Journal, 2020, 71(7): 2973-2982. | |

| 39 | 姜岩, 张晓华, 杨颖, 等. 基于约氏不动杆菌的萘生物降解特性[J]. 化工学报, 2016, 67(9): 3981-3987. |

| Jiang Y, Zhang X H, Yang Y, et al. Naphthalene biodegradation by Acinetobacter johnsonii [J]. CIESC Journal, 2016, 67(9): 3981-3987. | |

| 40 | Kan E, Deshusses M. Modeling of a foamed emulsion bioreactor(Ⅰ): Model development and experimental validation[J]. Biotechnology and Bioengineering, 2008, 99(5): 1096-1106. |

| 41 | Fazaelipoor M H. Analysis of a dual liquid phase biofilter for the removal of hydrophobic organic compounds from airstreams[J]. Chemical Engineering Journal, 2009, 147(2/3): 110-116. |

| 42 | Yeom S H. A simplified steady-state model of a hybrid bioreactor composed of a bubble column bioreactor and biofilter compartments[J]. Process Biochemistry, 2007, 42(4): 554-560. |

| 43 | England E, Fitch M W, Mormile M, et al. Toluene removal in membrane bioreactors under recirculating and non-recirculating liquid conditions[J]. Clean Technologies and Environmental Policy, 2005, 7(4): 259-269. |

| 44 | 肖建军, 李亚龙, 杨琦. 苯降解菌的筛选及其对苯的降解研究[J]. 环境工程, 2018, 36(6): 159-162. |

| Xiao J J, Li Y L, Yang Q. Isolation and characterization of benzene degrading bacterium[J]. Environmental Engineering, 2018, 36(6): 159-162. | |

| 45 | Majeau J A, Brar S K, Tyagi R D. Laccases for removal of recalcitrant and emerging pollutants[J]. Bioresource Technology, 2010, 101(7): 2331-2350. |

| 46 | Wang L, Ji G D, Huang S Q. Contribution of the Kodama and 4S pathways to the dibenzothiophene biodegradation in different coastal wetlands under different C/N ratios[J]. Journal of Environmental Sciences, 2019, 76: 217-226. |

| 47 | Wang J, Tian Z, Huo Y B, et al. Monitoring of 943 organic micropollutants in wastewater from municipal wastewater treatment plants with secondary and advanced treatment processes[J]. Journal of Environmental Sciences, 2018, 67: 309-317. |

| 48 | 苏俊朋. 鼠李糖脂强化生物滴滤塔去除VOCs效能及其机理研究[D]. 广州: 广东工业大学, 2018. |

| Su J P. Study on the efficiency and mechanism of the removal of VOCs by rhamnolipid enhanced biotrickling filter[D]. Guangzhou: Guangdong University of Technology, 2018. |

| [1] | Jingwei CHAO, Jiaxing XU, Tingxian LI. Investigation on the heating performance of the tube-free-evaporation based sorption thermal battery [J]. CIESC Journal, 2023, 74(S1): 302-310. |

| [2] | Yitong LI, Hang GUO, Hao CHEN, Fang YE. Study on operating conditions of proton exchange membrane fuel cells with non-uniform catalyst distributions [J]. CIESC Journal, 2023, 74(9): 3831-3840. |

| [3] | Baiyu YANG, Yue KOU, Juntao JIANG, Yali ZHAN, Qinghong WANG, Chunmao CHEN. Chemical conversion of dissolved organic matter in petrochemical spent caustic along a wet air oxidation pretreatment process [J]. CIESC Journal, 2023, 74(9): 3912-3920. |

| [4] | Linzheng WANG, Yubing LU, Ruizhi ZHANG, Yonghao LUO. Analysis on thermal oxidation characteristics of VOCs based on molecular dynamics simulation [J]. CIESC Journal, 2023, 74(8): 3242-3255. |

| [5] | Yuanyuan ZHANG, Jiangyuan QU, Xinxin SU, Jing YANG, Kai ZHANG. Gas-liquid mass transfer and reaction characteristics of SNCR denitration in CFB coal-fired unit [J]. CIESC Journal, 2023, 74(6): 2404-2415. |

| [6] | Lixiang ZHU, Moye LUO, Xiaodong ZHANG, Tao LONG, Ran YU. Application of quinone profile method to indicate structure and activity of functional microbial community in trichloroethylene-contaminated soil [J]. CIESC Journal, 2023, 74(6): 2647-2654. |

| [7] | Ruikang LI, Yingying HE, Weipeng LU, Yuanyuan WANG, Haodong DING, Yongming LUO. Study on the electrochemical enhanced cobalt-based cathode to activate peroxymonosulfate [J]. CIESC Journal, 2023, 74(5): 2207-2216. |

| [8] | Jianhua ZHANG, Mengmeng CHEN, Yawen SUN, Yongzhen PENG. Efficient nitrogen and phosphorus removal from domestic wastewater via simultaneous partial nitritation and phosphorus removal combined Anammox [J]. CIESC Journal, 2023, 74(5): 2147-2156. |

| [9] | Hao WANG, Siyang TANG, Shan ZHONG, Bin LIANG. An investigation of the enhancing effect of solid particle surface on the CO2 desorption behavior in chemical sorption process with MEA solution [J]. CIESC Journal, 2023, 74(4): 1539-1548. |

| [10] | Lufan JIA, Yiying WANG, Yuman DONG, Qinyuan LI, Xin XIE, Hao YUAN, Tao MENG. Aqueous two-phase system based adherent droplet microfluidics for enhanced enzymatic reaction [J]. CIESC Journal, 2023, 74(3): 1239-1246. |

| [11] | Yulong HUANG, Fan LYU, Junjie QIU, Hua ZHANG, Pinjing HE. Physicochemical properties and VOCs molecular characteristics of liquid digestate from anaerobic digestion of putrescible waste [J]. CIESC Journal, 2023, 74(3): 1275-1285. |

| [12] | Zhiguang QIAN, Yue FAN, Shixue WANG, Like YUE, Jinshan WANG, Yu ZHU. Effect of purging conditions on the impedance relaxation phenomenon and low temperature start-up of PEMFC [J]. CIESC Journal, 2023, 74(3): 1286-1293. |

| [13] | Yang HE, Senhu GAO, Qingyun WU, Mingli ZHANG, Tao LONG, Pei NIU, Jinghui GAO, Yingqi MENG. Numerical study on heat and mass transfer characteristics of straight slotted fins under wet conditions [J]. CIESC Journal, 2023, 74(3): 1073-1081. |

| [14] | Wanyuan HE, Yiyu CHEN, Chunying ZHU, Taotao FU, Xiqun GAO, Youguang MA. Study on gas-liquid mass transfer characteristics in microchannel with array bulges [J]. CIESC Journal, 2023, 74(2): 690-697. |

| [15] | Yu XIE, Min ZHANG, Weiguo HU, Yujun WANG, Guangsheng LUO. Study on efficient dissolution of D-7-ACA using membrane dispersion microreactor [J]. CIESC Journal, 2023, 74(2): 748-755. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||