CIESC Journal ›› 2023, Vol. 74 ›› Issue (2): 674-689.DOI: 10.11949/0438-1157.20221068

• Fluid dynamics and transport phenomena • Previous Articles Next Articles

Jianglong DU1,3( ), Wenqi YANG2,3(

), Wenqi YANG2,3( ), Kai HUANG1,3, Cheng LIAN1,2,3(

), Kai HUANG1,3, Cheng LIAN1,2,3( ), Honglai LIU1,2,3

), Honglai LIU1,2,3

Received:2022-08-01

Revised:2022-12-22

Online:2023-03-21

Published:2023-02-05

Contact:

Cheng LIAN

杜江龙1,3( ), 杨雯棋2,3(

), 杨雯棋2,3( ), 黄凯1,3, 练成1,2,3(

), 黄凯1,3, 练成1,2,3( ), 刘洪来1,2,3

), 刘洪来1,2,3

通讯作者:

练成

作者简介:杜江龙(1995—),男,博士研究生,2294567652@qq.com基金资助:CLC Number:

Jianglong DU, Wenqi YANG, Kai HUANG, Cheng LIAN, Honglai LIU. Heat dissipation performance of the module combined CPCM with air cooling for lithium-ion batteries[J]. CIESC Journal, 2023, 74(2): 674-689.

杜江龙, 杨雯棋, 黄凯, 练成, 刘洪来. 复合相变材料/空冷复合式锂离子电池模块散热性能[J]. 化工学报, 2023, 74(2): 674-689.

Add to citation manager EndNote|Ris|BibTeX

| 参数 | 数值 |

|---|---|

| F/(C·mol-1) | 96485 |

| R/(J·mol-1·K-1) | 8.3145 |

| L/m | 3.4×10-5(负极),2.5×10-5(隔膜),7.0×10-5(正极) |

| rp/m | 3.65×10-8(负极),3.5×10-6(正极) |

| εs | 0.55(负极),0.43(正极) |

| εe | 0.33(负极),0.54(隔膜),0.332(正极) |

| cs,max/(mol·m-3) | 31370(负极),22806(正极) |

| cs,0/(mol·m-3) | 26978(负极),501.73(正极) |

| σs/(S·m-1) | 100(负极),10(正极) |

| Ds/(m2·s-1) | 3.9×10-14(负极),3.2×10-13(正极) |

| ce,0/(mol·m-3) | 1200 |

| k0/(S·m-1) | |

| Dc/(m2·s-1) | |

| f± | |

| Eeq/V | |

| (dEeq/dT)/(V·K-1) |

Table 1 Parameters of the electrochemical model[49-50]

| 参数 | 数值 |

|---|---|

| F/(C·mol-1) | 96485 |

| R/(J·mol-1·K-1) | 8.3145 |

| L/m | 3.4×10-5(负极),2.5×10-5(隔膜),7.0×10-5(正极) |

| rp/m | 3.65×10-8(负极),3.5×10-6(正极) |

| εs | 0.55(负极),0.43(正极) |

| εe | 0.33(负极),0.54(隔膜),0.332(正极) |

| cs,max/(mol·m-3) | 31370(负极),22806(正极) |

| cs,0/(mol·m-3) | 26978(负极),501.73(正极) |

| σs/(S·m-1) | 100(负极),10(正极) |

| Ds/(m2·s-1) | 3.9×10-14(负极),3.2×10-13(正极) |

| ce,0/(mol·m-3) | 1200 |

| k0/(S·m-1) | |

| Dc/(m2·s-1) | |

| f± | |

| Eeq/V | |

| (dEeq/dT)/(V·K-1) |

| 材料 | 密度/ (kg·m-3) | 比定压热容/ (J·kg-1·K-1) | 热导率/ (W·m-1·K-1) |

|---|---|---|---|

| 电池 | 3000 | 1375 | — |

| 铝 | 2700 | 900 | 238 |

| 空气 | 1.29 | 1005 | 0.023 |

| 正极材料 | — | — | 1.48 |

| 负极材料 | — | — | 1.04 |

| 隔膜 | — | — | 1.0 |

Table 2 Properties of materials[51-52]

| 材料 | 密度/ (kg·m-3) | 比定压热容/ (J·kg-1·K-1) | 热导率/ (W·m-1·K-1) |

|---|---|---|---|

| 电池 | 3000 | 1375 | — |

| 铝 | 2700 | 900 | 238 |

| 空气 | 1.29 | 1005 | 0.023 |

| 正极材料 | — | — | 1.48 |

| 负极材料 | — | — | 1.04 |

| 隔膜 | — | — | 1.0 |

CPCM中EG的 含量/%(质量) | 热导率(kCPCM)/ (W·K-1·m-1) | 潜热(l)/ (J·g-1) | 相变温度/ K | 有效热容(Ceff)/ (J·g-1·K-1) |

|---|---|---|---|---|

| 0 | 0.20 | 275 | 314~317 | 2.000 |

| 3 | 0.58 | 266.8 | 314~317 | 1.963 |

| 6 | 1.23 | 258.5 | 314~317 | 1.926 |

| 9 | 3.15 | 250.3 | 314~317 | 1.889 |

| 12 | 5.74 | 242 | 314~317 | 1.852 |

| 20 | 10.6 | 220 | 314~317 | 1.754 |

| 30 | 13.85 | 192.5 | 314~317 | 1.631 |

Table 3 Physical parameters of CPCM with different EG contents[34]

CPCM中EG的 含量/%(质量) | 热导率(kCPCM)/ (W·K-1·m-1) | 潜热(l)/ (J·g-1) | 相变温度/ K | 有效热容(Ceff)/ (J·g-1·K-1) |

|---|---|---|---|---|

| 0 | 0.20 | 275 | 314~317 | 2.000 |

| 3 | 0.58 | 266.8 | 314~317 | 1.963 |

| 6 | 1.23 | 258.5 | 314~317 | 1.926 |

| 9 | 3.15 | 250.3 | 314~317 | 1.889 |

| 12 | 5.74 | 242 | 314~317 | 1.852 |

| 20 | 10.6 | 220 | 314~317 | 1.754 |

| 30 | 13.85 | 192.5 | 314~317 | 1.631 |

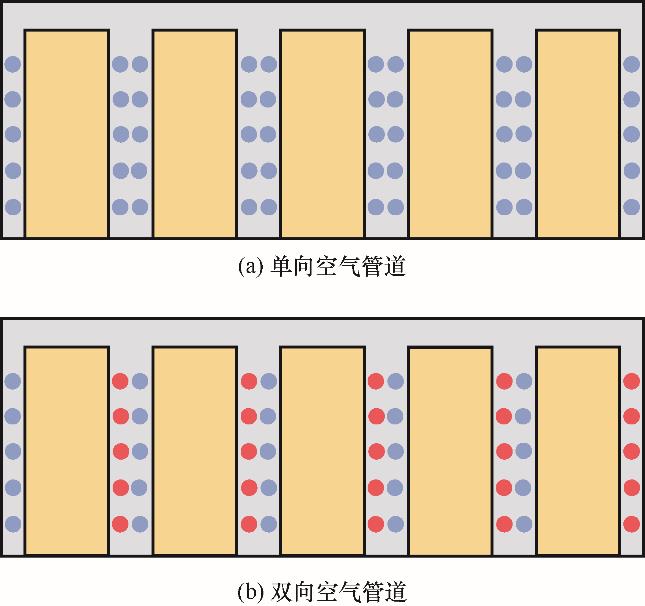

Fig.12 Battery pack structure in different ventilation directions (yellow: battery; gray: PCM; light blue: ventilation duct inlet; red: vent pipe outlet)

| 1 | Yang X F, Doyle-Davis K, Gao X J, et al. Recent progress and perspectives on designing high-performance thick electrodes for all-solid-state lithium batteries[J]. eTransportation, 2022, 11: 100152. |

| 2 | Zhang X, Wang B Y, Zhao S, et al. Oxygen anionic redox activated high-energy cathodes: status and prospects[J]. eTransportation, 2021, 8: 100118. |

| 3 | Lai X, Chen Q W, Tang X P, et al. Critical review of life cycle assessment of lithium-ion batteries for electric vehicles: a lifespan perspective[J]. eTransportation, 2022, 12: 100169. |

| 4 | Lu L G, Han X B, Li J Q, et al. A review on the key issues for lithium-ion battery management in electric vehicles[J]. Journal of Power Sources, 2013, 226: 272-288. |

| 5 | Sato N, Yagi K. Thermal behavior analysis of nickel metal hydride batteries for electric vehicles[J]. JSAE Review, 2000, 21(2): 205-211. |

| 6 | Zhang X H, Li Z, Luo L G, et al. A review on thermal management of lithium-ion batteries for electric vehicles[J]. Energy, 2022, 238: 121652. |

| 7 | Chen Z Y, Xiong R, Lu J H, et al. Temperature rise prediction of lithium-ion battery suffering external short circuit for all-climate electric vehicles application[J]. Applied Energy, 2018, 213: 375-383. |

| 8 | de Hoog J, Jaguemont J, Abdel-Monem M, et al. Combining an electrothermal and impedance aging model to investigate thermal degradation caused by fast charging[J]. Energies, 2018, 11(4): 804. |

| 9 | 杜江龙, 林伊婷, 杨雯棋, 等. 模拟仿真在锂离子电池热安全设计中的应用[J]. 储能科学与技术, 2022, 11(3): 866-877. |

| Du J L, Lin Y T, Yang W Q, et al. Application of simulation in thermal safety design of lithium-ion batteries[J]. Energy Storage Science and Technology, 2022, 11(3): 866-877. | |

| 10 | Bandhauer T M, Garimella S, Fuller T F. A critical review of thermal issues in lithium-ion batteries[J]. Journal of The Electrochemical Society, 2011, 158(3): R1. |

| 11 | Taheri P, Yazdanpour M, Bahrami M. Transient three-dimensional thermal model for batteries with thin electrodes[J]. Journal of Power Sources, 2013, 243: 280-289. |

| 12 | Du S L, Jia M, Cheng Y, et al. Study on the thermal behaviors of power lithium iron phosphate (LFP) aluminum-laminated battery with different tab configurations[J]. International Journal of Thermal Sciences, 2015, 89: 327-336. |

| 13 | 王建, 郭航, 叶芳, 等. 热管散热装置对车用锂离子电池组内温度分布影响数值模拟[J]. 化工学报, 2016, 67(S2): 340-347. |

| Wang J, Guo H, Ye F, et al. Numerical simulation of effect of heat pipe cooling device on temperature distribution in lithium-ion battery pack of vehicle[J]. CIESC Journal, 2016, 67(S2): 340-347. | |

| 14 | Huang P, Tao H L, Yang J, et al. Four stages of thermal effect coupled with ion‐charge transports during the charging process of porous electrodes[J]. AIChE Journal, 2022, 68(10): e17790. |

| 15 | 黄盼, 练成, 刘洪来. 基于模拟退火算法的真实多孔电极中热-质传递的研究[J]. 化工学报, 2022, 73(6): 2529-2542. |

| Huang P, Lian C, Liu H L. Heat-mass transfer in real porous electrode based on simulated annealing algorithm[J]. CIESC Journal, 2022, 73(6): 2529-2542. | |

| 16 | Lin Y T, Lian C, Berrueta M U, et al. Microscopic model for cyclic voltammetry of porous electrodes[J]. Physical Review Letters, 2022, 128(20): 206001. |

| 17 | Lian C, Janssen M, Liu H L, et al. Blessing and curse: how a supercapacitor's large capacitance causes its slow charging[J]. Physical Review Letters, 2020, 124(7): 076001. |

| 18 | Bai F F, Chen M B, Song W J, et al. Thermal management performances of PCM/water cooling-plate using for lithium-ion battery module based on non-uniform internal heat source[J]. Applied Thermal Engineering, 2017, 126: 17-27. |

| 19 | Du J L, Tao H L, Chen Y X, et al. Thermal management of air-cooling lithium-ion battery pack[J]. Chinese Physics Letters, 2021, 38(11): 122-135. |

| 20 | Zou D Q, Liu X S, He R J, et al. Preparation of a novel composite phase change material (PCM) and its locally enhanced heat transfer for power battery module[J]. Energy Conversion and Management, 2019, 180: 1196-1202. |

| 21 | Panchal S, Khasow R, Dincer I, et al. Thermal design and simulation of mini-channel cold plate for water cooled large sized prismatic lithium-ion battery[J]. Applied Thermal Engineering, 2017, 122: 80-90. |

| 22 | Qian Z, Li Y M, Rao Z H. Thermal performance of lithium-ion battery thermal management system by using mini-channel cooling[J]. Energy Conversion and Management, 2016, 126: 622-631. |

| 23 | 赵春荣, 曹文炅, 董缇, 等. 圆柱形锂离子电池模组微通道液冷热模型[J]. 化工学报, 2017, 68(8): 3232-3241. |

| Zhao C R, Cao W J, Dong T, et al. Thermal modeling of cylindrical lithium-ion battery module with micro-channel liquid cooling[J]. CIESC Journal, 2017, 68(8): 3232-3241. | |

| 24 | Huo Y T, Rao Z H, Liu X J, et al. Investigation of power battery thermal management by using mini-channel cold plate[J]. Energy Conversion and Management, 2015, 89: 387-395. |

| 25 | Zhao J T, Rao Z H, Li Y M. Thermal performance of mini-channel liquid cooled cylinder based battery thermal management for cylindrical lithium-ion power battery[J]. Energy Conversion and Management, 2015, 103: 157-165. |

| 26 | Liu H Q, Wei Z B, He W D, et al. Thermal issues about Li-ion batteries and recent progress in battery thermal management systems: a review[J]. Energy Conversion and Management, 2017, 150: 304-330. |

| 27 | Yang N X, Zhang X W, Li G J, et al. Assessment of the forced air-cooling performance for cylindrical lithium-ion battery packs: a comparative analysis between aligned and staggered cell arrangements[J]. Applied Thermal Engineering, 2015, 80: 55-65. |

| 28 | Fan Y Q, Bao Y, Ling C, et al. Experimental study on the thermal management performance of air cooling for high energy density cylindrical lithium-ion batteries[J]. Applied Thermal Engineering, 2019, 155: 96-109. |

| 29 | Fan L W, Khodadadi J M, Pesaran A A. A parametric study on thermal management of an air-cooled lithium-ion battery module for plug-in hybrid electric vehicles[J]. Journal of Power Sources, 2013, 238: 301-312. |

| 30 | Mahamud R, Park C. Reciprocating air flow for Li-ion battery thermal management to improve temperature uniformity[J]. Journal of Power Sources, 2011, 196(13): 5685-5696. |

| 31 | Chen D F, Jiang J C, Kim G H, et al. Comparison of different cooling methods for lithium ion battery cells[J]. Applied Thermal Engineering, 2016, 94: 846-854. |

| 32 | Alrashdan A, Mayyas A T, Al-Hallaj S. Thermo-mechanical behaviors of the expanded graphite-phase change material matrix used for thermal management of Li-ion battery packs[J]. Journal of Materials Processing Technology, 2010, 210(1): 174-179. |

| 33 | Wang Z C, Zhang Z Q, Jia L, et al. Paraffin and paraffin/aluminum foam composite phase change material heat storage experimental study based on thermal management of Li-ion battery[J]. Applied Thermal Engineering, 2015, 78: 428-436. |

| 34 | Jiang G W, Huang J H, Fu Y S, et al. Thermal optimization of composite phase change material/expanded graphite for Li-ion battery thermal management[J]. Applied Thermal Engineering, 2016, 108: 1119-1125. |

| 35 | Lin C J, Xu S C, Chang G F, et al. Experiment and simulation of a LiFePO4 battery pack with a passive thermal management system using composite phase change material and graphite sheets[J]. Journal of Power Sources, 2015, 275: 742-749. |

| 36 | Khateeb S A, Farid M M, Selman J R, et al. Design and simulation of a lithium-ion battery with a phase change material thermal management system for an electric scooter[J]. Journal of Power Sources, 2004, 128(2): 292-307. |

| 37 | Attia A A A, Altohamy A A, Abd Rabbo M F, et al. Comparative study on AL2O3 nanoparticle addition on cool storage system performance[J]. Applied Thermal Engineering, 2016, 94: 449-457. |

| 38 | Goli P, Legedza S, Dhar A, et al. Graphene-enhanced hybrid phase change materials for thermal management of Li-ion batteries[J]. Journal of Power Sources, 2014, 248: 37-43. |

| 39 | Ling Z Y, Chen J J, Fang X M, et al. Experimental and numerical investigation of the application of phase change materials in a simulative power batteries thermal management system[J]. Applied Energy, 2014, 121: 104-113. |

| 40 | Wu W X, Yang X Q, Zhang G Q, et al. Experimental investigation on the thermal performance of heat pipe-assisted phase change material based battery thermal management system[J]. Energy Conversion and Management, 2017, 138: 486-492. |

| 41 | Zhang H Y, Wu X Y, Wu Q Y, et al. Experimental investigation of thermal performance of large-sized battery module using hybrid PCM and bottom liquid cooling configuration[J]. Applied Thermal Engineering, 2019, 159: 113968. |

| 42 | An Z G, Chen X, Zhao L, et al. Numerical investigation on integrated thermal management for a lithium-ion battery module with a composite phase change material and liquid cooling[J]. Applied Thermal Engineering, 2019, 163: 114345. |

| 43 | Xie Y Q, Tang J C, Shi S, et al. Experimental and numerical investigation on integrated thermal management for lithium-ion battery pack with composite phase change materials[J]. Energy Conversion and Management, 2017, 154: 562-575. |

| 44 | Lv Y F, Liu G J, Zhang G Q, et al. A novel thermal management structure using serpentine phase change material coupled with forced air convection for cylindrical battery modules[J]. Journal of Power Sources, 2020, 468: 228398. |

| 45 | Lazrak A, Fourmigué J F, Robin J F. An innovative practical battery thermal management system based on phase change materials: numerical and experimental investigations[J]. Applied Thermal Engineering, 2018, 128: 20-32. |

| 46 | Fuller T F, Doyle M, Newman J. Relaxation phenomena in lithium‐ion‐insertion cells[J]. Journal of The Electrochemical Society, 1994, 141(4): 982-990. |

| 47 | Doyle M, Fuller T F, Newman J. Modeling of galvanostatic charge and discharge of the lithium/polymer/insertion cell[J]. Journal of The Electrochemical Society, 1993, 140(6): 1526-1533. |

| 48 | 王慧艳, 陈怡沁, 周静红, 等. 锂离子电池正极涂层孔隙结构优化的数值模拟[J]. 化工学报, 2022, 73(1): 376-383. |

| Wang H Y, Chen Y Q, Zhou J H, et al. Numerical simulation of cathode coating of lithium-ion battery for porosity optimization[J]. CIESC Journal, 2022, 73(1): 376-383. | |

| 49 | COMSOL AB. AC/DC Module User's Guide[DB]. Stockholm, 2020. |

| 50 | Li J, Cheng Y, Jia M, et al. An electrochemical-thermal model based on dynamic responses for lithium iron phosphate battery[J]. Journal of Power Sources, 2014, 255: 130-143. |

| 51 | Chiew J, Chin C S, Toh W D, et al. A pseudo three-dimensional electrochemical-thermal model of a cylindrical LiFePO4/graphite battery[J]. Applied Thermal Engineering, 2019, 147: 450-463. |

| 52 | Xin Q Q, Xiao J S, Yang T Q, et al. Thermal management of lithium-ion batteries under high ambient temperature and rapid discharging using composite PCM and liquid cooling[J]. Applied Thermal Engineering, 2022, 210: 118230. |

| 53 | Chen S C, Wang Y Y, Wan C C. Thermal analysis of spirally wound lithium batteries[J]. Journal of The Electrochemical Society, 2006, 153(4): A637-A648. |

| 54 | Ogoh W, Groulx D. Effects of the heat transfer fluid velocity on the storage characteristics of a cylindrical latent heat energy storage system: a numerical study[J]. Heat and Mass Transfer, 2012, 48(3): 439-449. |

| [1] | Fei KANG, Weiguang LYU, Feng JU, Zhi SUN. Research on discharge path and evaluation of spent lithium-ion batteries [J]. CIESC Journal, 2023, 74(9): 3903-3911. |

| [2] | Zhilong WANG, Ye YANG, Zhenzhen ZHAO, Tao TIAN, Tong ZHAO, Yahui CUI. Influence of mixing time and sequence on the dispersion properties of the cathode slurry of lithium-ion battery [J]. CIESC Journal, 2023, 74(7): 3127-3138. |

| [3] | Weijiang CHENG, Heqi WANG, Xiang GAO, Na LI, Sainan MA. Research progress on film-forming electrolyte additives for Si-based lithium-ion batteries [J]. CIESC Journal, 2023, 74(2): 571-584. |

| [4] | Lei ZHONG, Xueqing QIU, Wenli ZHANG. Advances in lignin-derived carbon anodes for alkali metal ion batteries [J]. CIESC Journal, 2022, 73(8): 3369-3380. |

| [5] | Huiyan WANG, Yiqin CHEN, Jinghong ZHOU, Yueqiang CAO, Xinggui ZHOU. Numerical simulation of cathode coating of lithium-ion battery for porosity optimization [J]. CIESC Journal, 2022, 73(1): 376-383. |

| [6] | LIANG Kunfeng, WANG Moran, GAO Meijie, LYU Zhenwei, XU Hongyu, DONG Bin, GAO Fengling. Thermodynamic analysis of performance of integrated thermal management system for pure electric vehicle [J]. CIESC Journal, 2021, 72(S1): 494-502. |

| [7] | Ken LIN, Xiaoyong XU, Qiang LI, Dinghua HU. Study on thermal conductivity of paraffin-expanded graphite composite phase change materials [J]. CIESC Journal, 2021, 72(8): 4425-4432. |

| [8] | CHEN Yiqin, XU Yu, ZHOU Jinghong, SUI Zhijun, ZHOU Xinggui. Heterogeneous modeling and internal mass transfer mechanism of lithium-ion batteries: effect of particle size distribution [J]. CIESC Journal, 2021, 72(2): 1078-1088. |

| [9] | CAO Jianing, GAO Xiang, LUO Yingwu, SU Rongxin. Study on preparation and performance of aqueous binder for lithium iron phosphate electrodes in lithium-ion battery [J]. CIESC Journal, 2021, 72(2): 1169-1180. |

| [10] | Yu WANG, Yu ZHANG, Weiwen TONG, Guanghua YE, Xinggui ZHOU, Weikang YUAN. Engineering hierarchical pore network for Li-ion battery electrodes [J]. CIESC Journal, 2021, 72(12): 6340-6350. |

| [11] | Wenbo ZHANG, Ziye LING, Xiaoming FANG, Zhengguo ZHANG. Preparation and thermal properties research of a novel magnesium chloride hexahydrate-magnesium nitrate hexahydrate/graphite phase carbon nitride composite phase change material [J]. CIESC Journal, 2021, 72(12): 6399-6406. |

| [12] | Yiwei WANG, Wenjiong CAO, Peng PENG, Yaodong ZHENG, Bo LEI, Youjie SHI, Fangming JIANG. Electro-thermal characteristics of retired LiFePO4 power battery module [J]. CIESC Journal, 2020, 71(S2): 259-266. |

| [13] | Sheng TIAN, Jiajiang XIAO. Numerical simulation and analysis of lithium-ion battery heat pipe cooling module based on orthogonal analytic hierarchy process [J]. CIESC Journal, 2020, 71(8): 3510-3517. |

| [14] | Zhengzheng XIA, Jialiang LIU, Jianjie NIU, Han HU, Qingshan ZHAO, Mingbo WU. Highly dispersed SiO2/petroleum pitch-derived porous carbon composite as anode material for lithium-ion batteries [J]. CIESC Journal, 2020, 71(6): 2752-2759. |

| [15] | Yu XU, Yiqin CHEN, Jinghong ZHOU, Zhijun SUI, Xinggui ZHOU. Numerical simulation of lithium-ion battery with LiFePO4 as cathode material: effect of particle size [J]. CIESC Journal, 2020, 71(2): 821-830. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||