CIESC Journal ›› 2021, Vol. 72 ›› Issue (12): 6340-6350.DOI: 10.11949/0438-1157.20210813

• Energy and environmental engineering • Previous Articles Next Articles

Yu WANG1( ),Yu ZHANG2,Weiwen TONG1,Guanghua YE1(

),Yu ZHANG2,Weiwen TONG1,Guanghua YE1( ),Xinggui ZHOU1,Weikang YUAN1

),Xinggui ZHOU1,Weikang YUAN1

Received:2021-06-17

Revised:2021-09-08

Online:2021-12-22

Published:2021-12-05

Contact:

Guanghua YE

汪宇1( ),张禹2,童微雯1,叶光华1(

),张禹2,童微雯1,叶光华1( ),周兴贵1,袁渭康1

),周兴贵1,袁渭康1

通讯作者:

叶光华

作者简介:汪宇 (1998—),男,硕士研究生,基金资助:CLC Number:

Yu WANG, Yu ZHANG, Weiwen TONG, Guanghua YE, Xinggui ZHOU, Weikang YUAN. Engineering hierarchical pore network for Li-ion battery electrodes[J]. CIESC Journal, 2021, 72(12): 6340-6350.

汪宇, 张禹, 童微雯, 叶光华, 周兴贵, 袁渭康. 锂离子电池电极中多级孔道结构设计[J]. 化工学报, 2021, 72(12): 6340-6350.

Add to citation manager EndNote|Ris|BibTeX

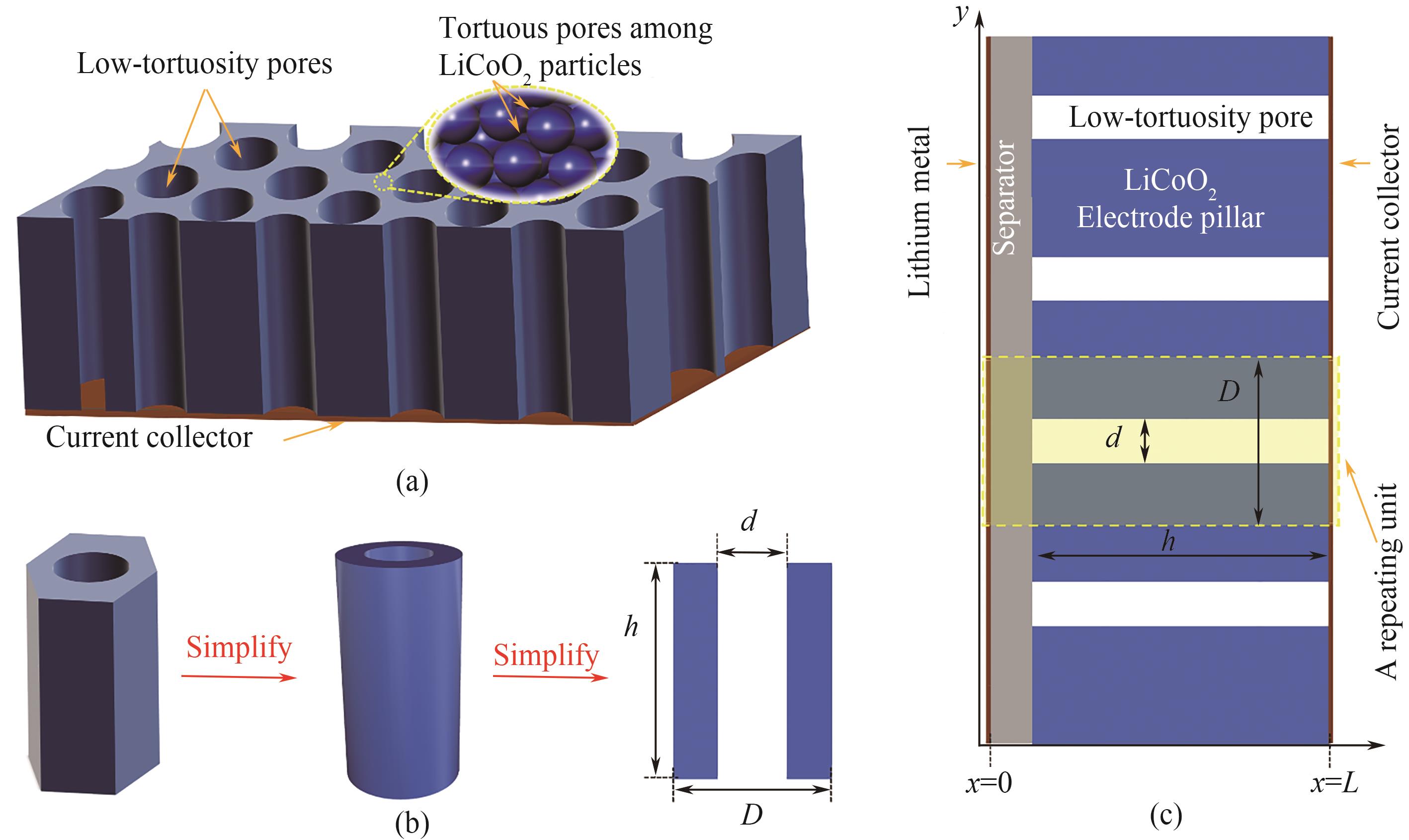

Fig.1 A schematic of the electrode with the hierarchical pore network (a); Simplification of a three-dimensional repeating unit into a two-dimensional one (b); A two-dimensional schematic of the half-cell with the hierarchically structured electrode as LiCoO2 the cathode and the lithium metal as the anode (c)

| 参数 | 单位 | 数值 |

|---|---|---|

| 初始电解质盐浓度 (c0) | mol/m3 | 1200 ① |

| 最大嵌锂浓度 (cs,max) | mol/m3 | 20434 |

| 初始嵌锂浓度 (cs0) | mol/m3 | 9604 |

| 锂在电极材料内的扩散系数 (Ds) | m2/s | 10-11 ① |

| 锂离子在电解液中的扩散系数 (Dl) | m2/s | 2.6×10-10 ① |

| 电导率 (σ) | S/m | 10 ① |

| 膈膜厚度 (hs) | μm | 20 |

| 集流体的总厚度 (hc) | μm | 40 |

| 阳极锂金属厚度 (ha) | μm | 50 |

| 钴酸锂材料颗粒半径 (Rs) | μm | 4 ① |

| 阳极电荷转移系数 (αa) | — | 0.5 ① |

| 阴极电荷转移系数 (αc) | — | 0.5 ① |

| 添加剂所占孔隙率 (εadd) | — | 0.007 |

| 锂离子传递系数 ( | — | 0.363 ① |

| 温度 (T) | K | 298 |

| Bruggeman系数 (m) | — | 2.5 |

| 1C时电流密度 (I) | A/m2 | 38.2 |

| 钴酸锂阴极厚度 (h) | μm | 50~150 |

| 钴酸锂阴极总孔隙率 (εt) | — | 0.28~0.48 |

| 分层结构中孔的孔径 (d) | μm | 10~90 |

| 分层孔道结构的孔隙率 (d2/D2) | — | 0.04~0.25 |

Table 1 Parameters for the numerical simulations in this work

| 参数 | 单位 | 数值 |

|---|---|---|

| 初始电解质盐浓度 (c0) | mol/m3 | 1200 ① |

| 最大嵌锂浓度 (cs,max) | mol/m3 | 20434 |

| 初始嵌锂浓度 (cs0) | mol/m3 | 9604 |

| 锂在电极材料内的扩散系数 (Ds) | m2/s | 10-11 ① |

| 锂离子在电解液中的扩散系数 (Dl) | m2/s | 2.6×10-10 ① |

| 电导率 (σ) | S/m | 10 ① |

| 膈膜厚度 (hs) | μm | 20 |

| 集流体的总厚度 (hc) | μm | 40 |

| 阳极锂金属厚度 (ha) | μm | 50 |

| 钴酸锂材料颗粒半径 (Rs) | μm | 4 ① |

| 阳极电荷转移系数 (αa) | — | 0.5 ① |

| 阴极电荷转移系数 (αc) | — | 0.5 ① |

| 添加剂所占孔隙率 (εadd) | — | 0.007 |

| 锂离子传递系数 ( | — | 0.363 ① |

| 温度 (T) | K | 298 |

| Bruggeman系数 (m) | — | 2.5 |

| 1C时电流密度 (I) | A/m2 | 38.2 |

| 钴酸锂阴极厚度 (h) | μm | 50~150 |

| 钴酸锂阴极总孔隙率 (εt) | — | 0.28~0.48 |

| 分层结构中孔的孔径 (d) | μm | 10~90 |

| 分层孔道结构的孔隙率 (d2/D2) | — | 0.04~0.25 |

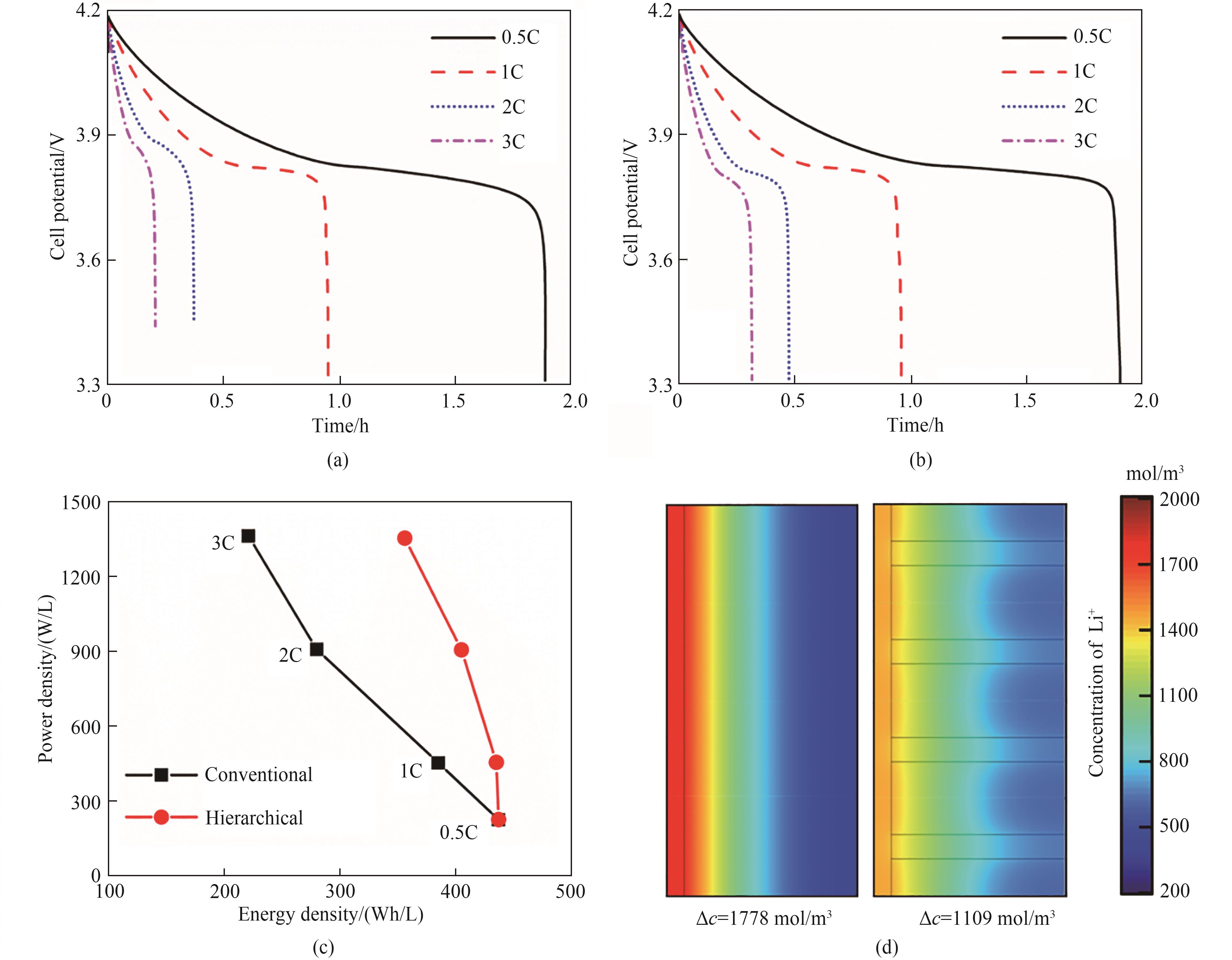

Fig.2 Time-dependent cell potentials under the discharge rates of 0.5C, 1C, 2C and 3C for a conventional electrode (a) and a hierarchically structured electrode (b); The Ragone plots obtained from Figs. 2(a) and 2(b) (c); Typical concentration profiles of Li+ at t=120 s under the discharge rate of 2C for the conventional electrode and the hierarchically structured electrode (d) (Simulation parameters: h=200 μm, εt=0.36, d=20 μm, and d2/D2=0.0625. The other parameters are given in Table 1)

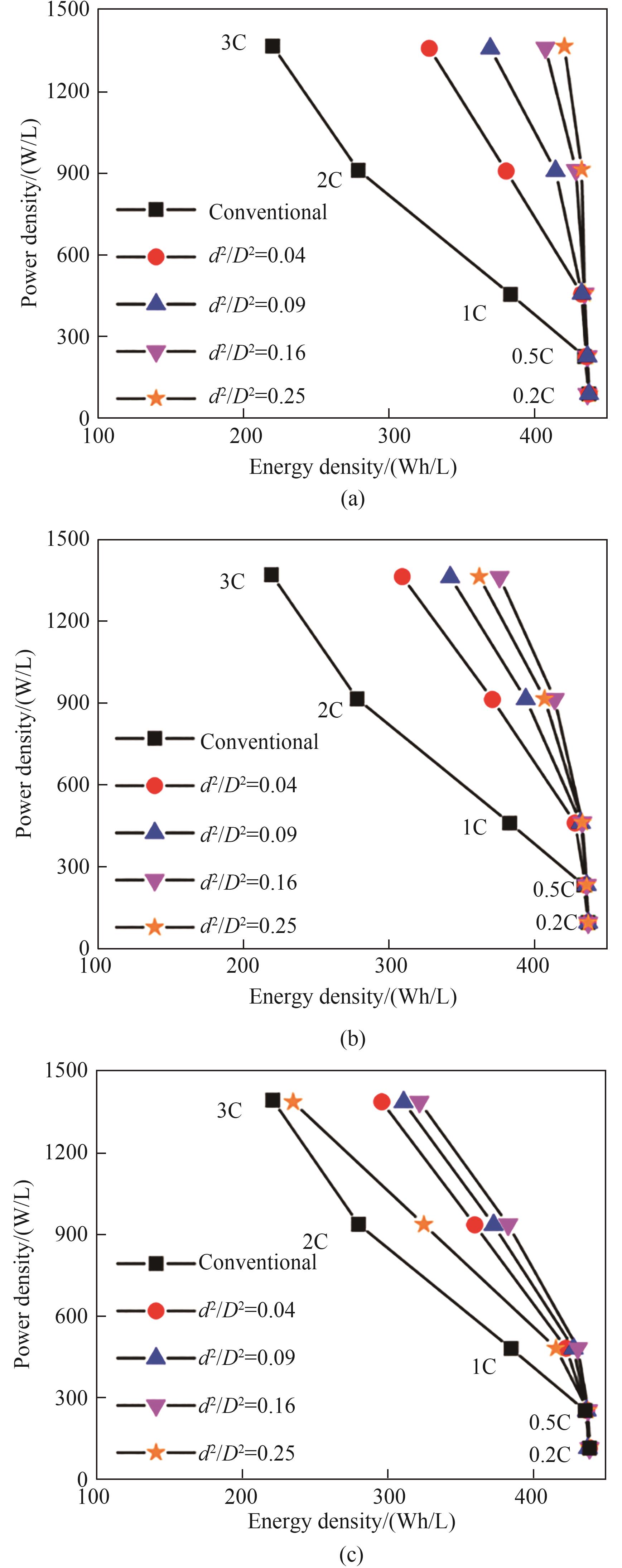

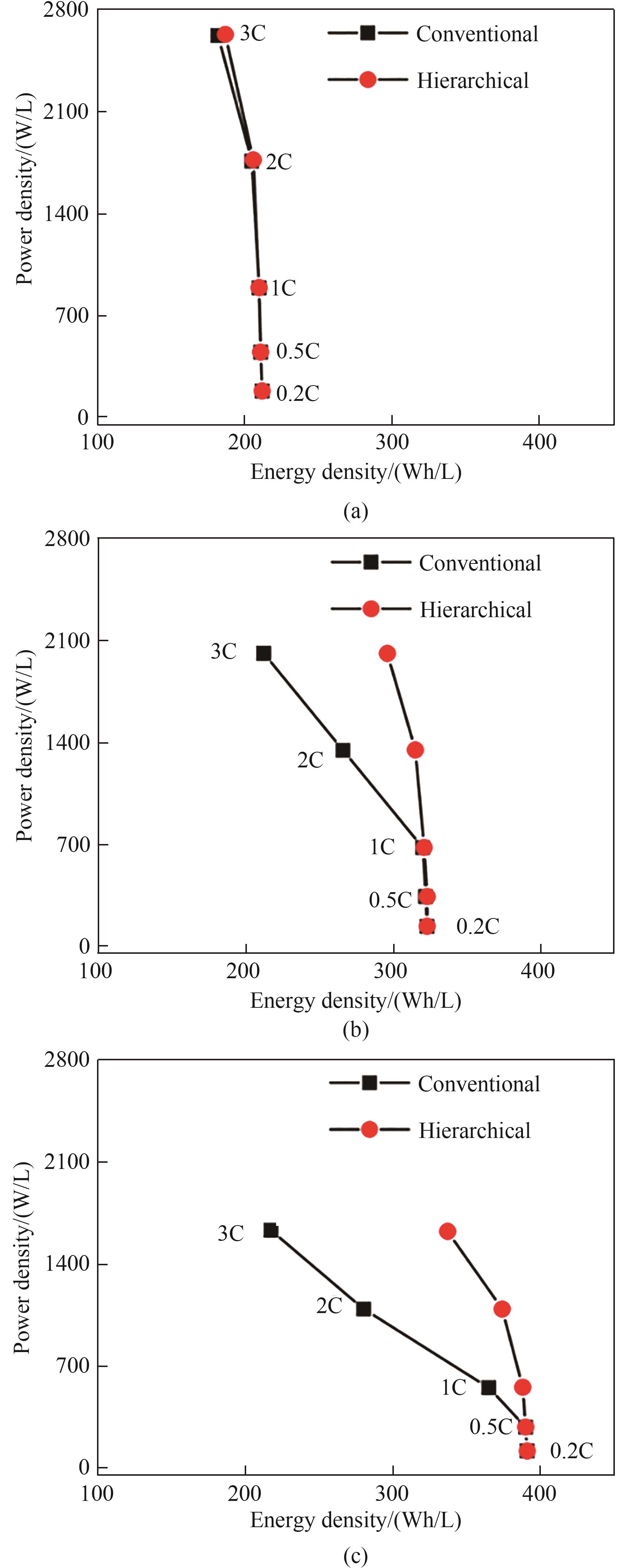

Fig.3 Ragone plots for the conventional electrode and the hierarchically structured electrodes with d2/D2=0.04, 0.09, 0.16, and 0.25. (a) d=30 μm; (b) d=60 μm; (c) d=90 μm (Simulation parameters: h=200 μm, εt=0.36. The other parameters are given in Table 1)

| d2/D2 | 能量密度/(Wh/L) | |||

|---|---|---|---|---|

| 0 μm | 30 μm | 60 μm | 90 μm | |

| 0 | 220① | — | — | — |

| 0.04 | — | 328 | 310 | 295 |

| 0.09 | — | 370 | 343 | 308 |

| 0.16 | — | 408 | 377 | 321 |

| 0.25 | — | 421 | 363 | 234 |

Table 2 Energy densities at the 3C discharge rate for the conventional electrode and the hierarchically structured electrodes with different porosities

| d2/D2 | 能量密度/(Wh/L) | |||

|---|---|---|---|---|

| 0 μm | 30 μm | 60 μm | 90 μm | |

| 0 | 220① | — | — | — |

| 0.04 | — | 328 | 310 | 295 |

| 0.09 | — | 370 | 343 | 308 |

| 0.16 | — | 408 | 377 | 321 |

| 0.25 | — | 421 | 363 | 234 |

Fig.4 Concentration profiles of Li+ in the hierarchically structured electrodes at t=120 s under the discharge rate of 2C. (a) d=30 μm, d2/D2=0.04; (b) d=30 μm, d2/D2=0.09; (c) d=30 μm, d2/D2=0.16; (d) d=30 μm, d2/D2=0.25; (e) d=90 μm, d2/D2=0.04; (f) d=90 μm, d2/D2=0.09; (g) d=90 μm, d2/D2=0.16; (h) d=90 μm, d2/D2=0.25 (Simulation parameters: h=200 μm, εt=0.36. The other parameters are given in Table 1)

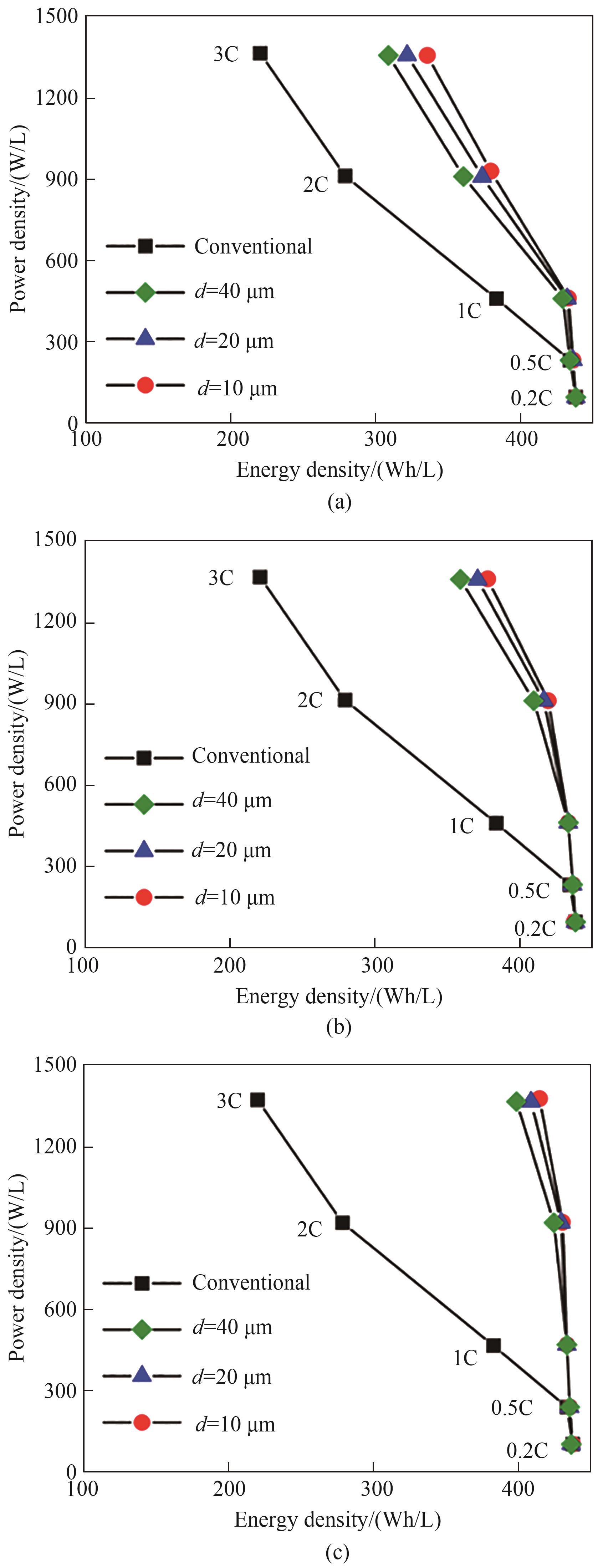

Fig.5 Ragone plots for the conventional electrode and the hierarchically structured electrodes with d=10, 20, and 40 μm. (a) d2/D2=0.04; (b) d2/D2=0.09; (c) d2/D2=0.16 (Simulation parameters: h=200 μm, εt=0.36. The other parameters are given in Table 1)

Fig.6 Ragone plots for the conventional electrode and the hierarchically structured electrode under different electrode thicknesses. (a) h=50 μm; (b) h=100 μm; (c) h=150 μm (simulation parameters: d=25 μm, d2/D2=0.0625, εt=0.36. The other parameters are given in Table 1)

Fig.7 Ragone plots for the conventional electrode and the hierarchically structured electrode under different total porosities. (a) εt=0.28; (b) εt=0.38; (c) εt=0.48 (simulation parameters: d=30 μm, D=100 μm, h=200 μm. The other parameters are given in Table 1)

| d/μm | 能量密度/(Wh/L) | |||

|---|---|---|---|---|

| d2/D2=0 | d2/D2=0.04 | d2/D2=0.09 | d2/D2=0.16 | |

| 0 | 220① | — | — | — |

| 10 | — | 336 | 378 | 416 |

| 20 | — | 322 | 371 | 410 |

| 40 | — | 309 | 359 | 400 |

Table 3 Energy densities at the 3C discharge rate for the conventional electrode and the hierarchically structured electrodes with different pore diameters

| d/μm | 能量密度/(Wh/L) | |||

|---|---|---|---|---|

| d2/D2=0 | d2/D2=0.04 | d2/D2=0.09 | d2/D2=0.16 | |

| 0 | 220① | — | — | — |

| 10 | — | 336 | 378 | 416 |

| 20 | — | 322 | 371 | 410 |

| 40 | — | 309 | 359 | 400 |

| 电极 | 能量密度/(Wh/L) | ||

|---|---|---|---|

| 50 μm | 100 μm | 150 μm | |

| 传统电极 | 182 | 212 | 217 |

| 多级孔电极 | 187 | 296 | 337 |

Table 4 Energy densities at the 3C discharge rate for the conventional electrode and the hierarchically structured electrodes with different electrode thicknesses

| 电极 | 能量密度/(Wh/L) | ||

|---|---|---|---|

| 50 μm | 100 μm | 150 μm | |

| 传统电极 | 182 | 212 | 217 |

| 多级孔电极 | 187 | 296 | 337 |

| 电极 | 能量密度/(Wh/L) | ||

|---|---|---|---|

| 0.28 | 0.38 | 0.48 | |

| 传统电极 | 252 | 239 | 295 |

| 多级孔电极 | 368 | 302 | 302 |

Table 5 Energy densities at the 3C discharge rate for the conventional electrode and the hierarchically structured electrodes with different total porosities

| 电极 | 能量密度/(Wh/L) | ||

|---|---|---|---|

| 0.28 | 0.38 | 0.48 | |

| 传统电极 | 252 | 239 | 295 |

| 多级孔电极 | 368 | 302 | 302 |

| 1 | Etacheri V, Marom R, Elazari R, et al. Challenges in the development of advanced Li-ion batteries: a review[J]. Energy & Environmental Science, 2011, 4(9):3243-3262. |

| 2 | Manthiram A. A reflection on lithium-ion battery cathode chemistry[J]. Nature Communications, 2020, 11: 1550. |

| 3 | Nitta N, Wu F X, Lee J T, et al. Li-ion battery materials: present and future[J]. Materials Today, 2015, 18(5): 252-264. |

| 4 | Lu L G, Han X B, Li J Q, et al. A review on the key issues for lithium-ion battery management in electric vehicles[J]. Journal of Power Sources, 2013, 226:272-288. |

| 5 | Kang B, Ceder G. Battery materials for ultrafast charging and discharging[J]. Nature, 2009, 458(7235):190-193. |

| 6 | Palacín M R. Recent advances in rechargeable battery materials: a chemist's perspective [J]. Chemical Society Reviews, 2009, 38(9):2565-2575. |

| 7 | Bae C J, Erdonmez C K, Halloran J W, et al. Design of battery electrodes with dual-scale porosity to minimize tortuosity and maximize performance[J]. Advanced Materials, 2013, 25(9): 1254-1258. |

| 8 | Billaud J, Bouville F, Magrini T, et al. Magnetically aligned graphite electrodes for high-rate performance Li-ion batteries[J]. Nature Energy, 2016, 1: 16097. |

| 9 | Park M, Zhang X C, Chung M, et al. A review of conduction phenomena in Li-ion batteries[J]. Journal of Power Sources, 2010, 195(24):7904-7929. |

| 10 | Zheng H H, Li J, Song X Y, et al. A comprehensive understanding of electrode thickness effects on the electrochemical performances of Li-ion battery cathodes[J]. Electrochimica Acta, 2012, 71: 258-265. |

| 11 | Dai Y L, Srinivasan V. On graded electrode porosity as a design tool for improving the energy density of batteries[J]. Journal of the Electrochemical Society, 2015, 163(3): A406-A416. |

| 12 | De S, Northrop P W C, Ramadesigan V, et al. Model-based simultaneous optimization of multiple design parameters for lithium-ion batteries for maximization of energy density[J]. Journal of Power Sources, 2013, 227:161-170. |

| 13 | Golmon S, Maute K, Dunn M L. A design optimization methodology for Li+ batteries[J]. Journal of Power Sources, 2014, 253:239-250. |

| 14 | Fuller T F, Doyle M, Newman J. Simulation and optimization of the dual lithium ion insertion cell[J]. Journal of the Electrochemical Society, 1994, 141(1): 1-10. |

| 15 | Henquín E R, Aguirre P A. Model based analysis of lithium batteries considering particle-size distribution[J]. AIChE Journal, 2018, 64(3): 904-915. |

| 16 | Lueth S, Sauter U S, Bessler W G. An agglomerate model of lithium-ion battery cathodes[J]. Journal of the Electrochemical Society, 2015, 163(2): A210-A222. |

| 17 | Newman J. Optimization of porosity and thickness of a battery electrode by means of a reaction-zone model[J]. Journal of the Electrochemical Society, 1995, 142(1): 97-101. |

| 18 | Srinivasan V, Newman J. Design and optimization of a natural graphite/iron phosphate lithium-ion cell[J]. Journal of the Electrochemical Society, 2004, 151(10): A1530. |

| 19 | Ramadesigan V, Methekar R N, Latinwo F, et al. Optimal porosity distribution for minimized ohmic drop across a porous electrode[J]. Journal of the Electrochemical Society, 2010, 157(12): A1328. |

| 20 | Pérez-Ramírez J, Christensen C H, Egeblad K, et al. Hierarchical zeolites: enhanced utilisation of microporous crystals in catalysis by advances in materials design[J]. Chemical Society Reviews, 2008, 37(11): 2530-2542. |

| 21 | Schwieger W, Machoke A G, Weissenberger T, et al. Hierarchy concepts: classification and preparation strategies for zeolite containing materials with hierarchical porosity[J]. Chemical Society Reviews, 2016, 45(12): 3353-3376. |

| 22 | Yang X Y, Chen L H, Li Y, et al. Hierarchically porous materials: synthesis strategies and structure design[J]. Chemical Society Reviews, 2017, 46(2): 481-558. |

| 23 | Sander J S, Erb R M, Li L, et al. High-performance battery electrodes via magnetic templating[J]. Nature Energy, 2016, 1: 16099. |

| 24 | Delattre B, Amin R, Sander J, et al. Impact of pore tortuosity on electrode kinetics in lithium battery electrodes: study in directionally freeze-cast LiNi0.8Co0.15Al0.05O2(NCA)[J]. Journal of the Electrochemical Society, 2018, 165(2): A388-A395. |

| 25 | Ye G H, Tong W W, Liu X L, et al. An analytical method for the optimization of pore network in lithium-ion battery electrodes[J]. Chemical Engineering Research and Design, 2019, 149: 226-234. |

| 26 | Newman J, Tiedemann W. Porous-electrode theory with battery applications[J]. AIChE Journal, 1975, 21(1): 25-41. |

| 27 | Doyle M, Fuller T F, Newman J. Modeling of galvanostatic charge and discharge of the lithium/polymer/insertion cell[J]. Journal of the Electrochemical Society, 1993, 140(6): 1526-1533. |

| 28 | Antolini E. LiCoO2: formation, structure, lithium and oxygen nonstoichiometry, electrochemical behaviour and transport properties[J]. Solid State Ionics, 2004, 170(3/4): 159-171. |

| 29 | Marom R, Amalraj S F, Leifer N, et al. A review of advanced and practical lithium battery materials[J]. Journal of Materials Chemistry, 2011, 21(27): 9938. |

| 30 | Hutzenlaub T, Asthana A, Becker J, et al. FIB/SEM-based calculation of tortuosity in a porous LiCoO2 cathode for a Li-ion battery[J]. Electrochemistry Communications, 2013, 27: 77-80. |

| 31 | Cobb C L., Blanco M. Modeling mass and density distribution effects on the performance of co-extruded electrodes for high energy density lithium-ion batteries[J]. Journal of Power Sources, 2014, 249:357-366. |

| 32 | Doyle M, Fuentes Y. Computer simulations of a lithium-ion polymer battery and implications for higher capacity next-generation battery designs[J]. Journal of the Electrochemical Society, 2003, 150(6): A706. |

| [1] | Xin YANG, Wen WANG, Kai XU, Fanhua MA. Simulation analysis of temperature characteristics of the high-pressure hydrogen refueling process [J]. CIESC Journal, 2023, 74(S1): 280-286. |

| [2] | Fei KANG, Weiguang LYU, Feng JU, Zhi SUN. Research on discharge path and evaluation of spent lithium-ion batteries [J]. CIESC Journal, 2023, 74(9): 3903-3911. |

| [3] | Song HE, Qiaomai LIU, Guangshuo XIE, Simin WANG, Juan XIAO. Two-phase flow simulation and surrogate-assisted optimization of gas film drag reduction in high-concentration coal-water slurry pipeline [J]. CIESC Journal, 2023, 74(9): 3766-3774. |

| [4] | Lei XING, Chunyu MIAO, Minghu JIANG, Lixin ZHAO, Xinya LI. Optimal design and performance analysis of downhole micro gas-liquid hydrocyclone [J]. CIESC Journal, 2023, 74(8): 3394-3406. |

| [5] | Manzheng ZHANG, Meng XIAO, Peiwei YAN, Zheng MIAO, Jinliang XU, Xianbing JI. Working fluid screening and thermodynamic optimization of hazardous waste incineration coupled organic Rankine cycle system [J]. CIESC Journal, 2023, 74(8): 3502-3512. |

| [6] | Chengying ZHU, Zhenlei WANG. Operation optimization of ethylene cracking furnace based on improved deep reinforcement learning algorithm [J]. CIESC Journal, 2023, 74(8): 3429-3437. |

| [7] | Guoze CHEN, Dong WEI, Qian GUO, Zhiping XIANG. Optimal power point optimization method for aluminum-air batteries under load tracking condition [J]. CIESC Journal, 2023, 74(8): 3533-3542. |

| [8] | Wenzhu LIU, Heming YUN, Baoxue WANG, Mingzhe HU, Chonglong ZHONG. Research on topology optimization of microchannel based on field synergy and entransy dissipation [J]. CIESC Journal, 2023, 74(8): 3329-3341. |

| [9] | Wentao WU, Liangyong CHU, Lingjie ZHANG, Weimin TAN, Liming SHEN, Ningzhong BAO. High-efficient preparation of cardanol-based self-healing microcapsules [J]. CIESC Journal, 2023, 74(7): 3103-3115. |

| [10] | Xiaoling TANG, Jiarui WANG, Xuanye ZHU, Renchao ZHENG. Biosynthesis of chiral epichlorohydrin by halohydrin dehalogenase based on Pickering emulsion system [J]. CIESC Journal, 2023, 74(7): 2926-2934. |

| [11] | Zhilong WANG, Ye YANG, Zhenzhen ZHAO, Tao TIAN, Tong ZHAO, Yahui CUI. Influence of mixing time and sequence on the dispersion properties of the cathode slurry of lithium-ion battery [J]. CIESC Journal, 2023, 74(7): 3127-3138. |

| [12] | Zedong WANG, Zhiping SHI, Liyan LIU. Numerical simulation and optimization of acoustic streaming considering inhomogeneous bubble cloud dissipation in rectangular reactor [J]. CIESC Journal, 2023, 74(5): 1965-1973. |

| [13] | Chunlei ZHAO, Liang GUO, Cong GAO, Wei SONG, Jing WU, Jia LIU, Liming LIU, Xiulai CHEN. Metabolic engineering of Escherichia coli for chondroitin production [J]. CIESC Journal, 2023, 74(5): 2111-2122. |

| [14] | Hanbing HE, Zhen LIU, Yong CHEN, Xiaofeng WANG, Jing ZENG. Synthesis and slurry control of manganese oxide powder for direct ink writing electrode [J]. CIESC Journal, 2023, 74(5): 2239-2247. |

| [15] | Xiaodan SU, Ganyu ZHU, Huiquan LI, Guangming ZHENG, Ziheng MENG, Fang LI, Yunrui YANG, Benjun XI, Yu CUI. Optimization of wet process phosphoric acid hemihydrate process and crystallization of gypsum [J]. CIESC Journal, 2023, 74(4): 1805-1817. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||