CIESC Journal ›› 2023, Vol. 74 ›› Issue (12): 4997-5005.DOI: 10.11949/0438-1157.20230971

• Material science and engineering, nanotechnology • Previous Articles Next Articles

Bo ZHANG1( ), Zhuangzhuang LI2,3, Dan ZHAO1, Cuizhu QIAN1, Bao WANG2,3(

), Zhuangzhuang LI2,3, Dan ZHAO1, Cuizhu QIAN1, Bao WANG2,3( ), Pengju PAN2,3

), Pengju PAN2,3

Received:2023-09-21

Revised:2023-12-24

Online:2024-02-19

Published:2023-12-25

Contact:

Bao WANG

张博1( ), 李壮壮2,3, 赵丹1, 钱翠珠1, 王宝2,3(

), 李壮壮2,3, 赵丹1, 钱翠珠1, 王宝2,3( ), 潘鹏举2,3

), 潘鹏举2,3

通讯作者:

王宝

作者简介:张博(1978—),男,硕士,高级工程师,zhangbo@zjtobacco.com

基金资助:CLC Number:

Bo ZHANG, Zhuangzhuang LI, Dan ZHAO, Cuizhu QIAN, Bao WANG, Pengju PAN. Fabrication of isotactic polypropylene casting film and its structural evolution during stretching[J]. CIESC Journal, 2023, 74(12): 4997-5005.

张博, 李壮壮, 赵丹, 钱翠珠, 王宝, 潘鹏举. 聚丙烯流延膜的制备与拉伸过程中的结构演变[J]. 化工学报, 2023, 74(12): 4997-5005.

Add to citation manager EndNote|Ris|BibTeX

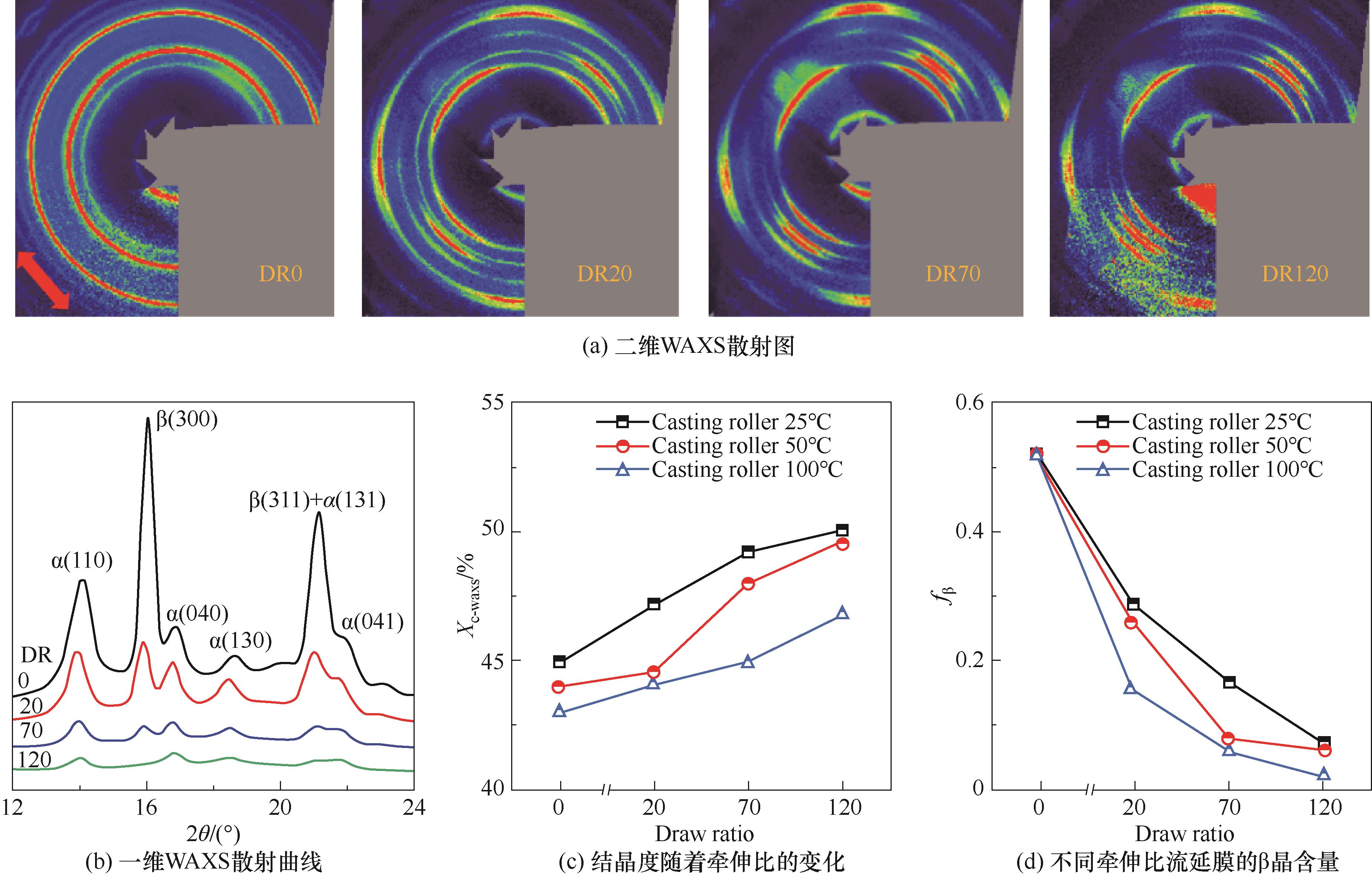

Fig.2 Properties of iPP/WBG with different stretch ratios [the temperature of casting roller in (a) is 25℃, the stretch direction is indicated as the red arrow]

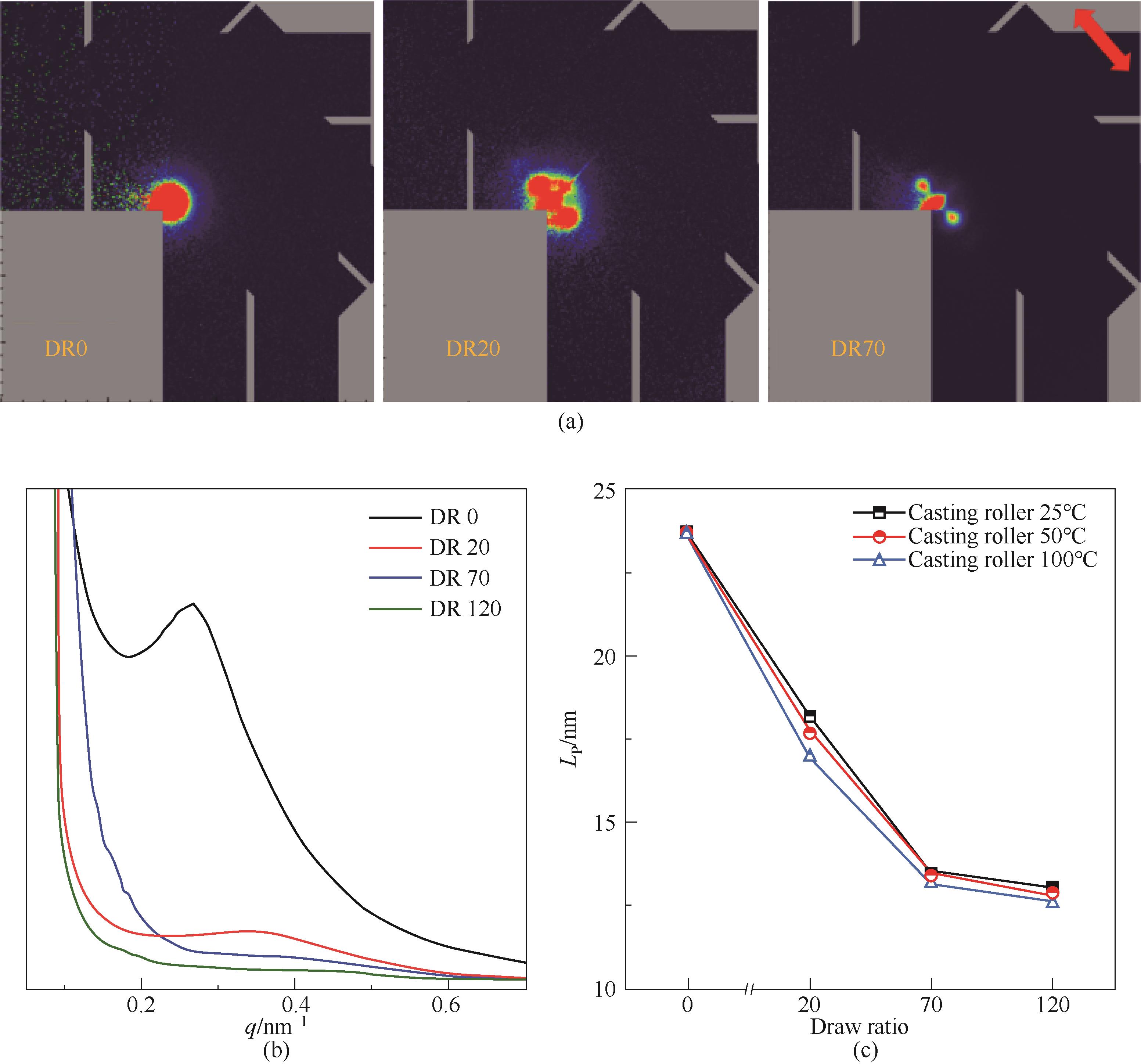

Fig.3 SAXS patterns (a), SAXS curves (b) and long periods (c) of iPP/WBG casting films with different stretch ratios[the temperature of casting roller in (a) is 25℃, the stretch direction is indicated as the red arrow]

| 1 | Demeuse M T. Biaxial Stretching of Film: Principles and Applications[M]. Oxford: Woodhead Publishing Ltd., 2011. |

| 2 | Deimede V, Elmasides C. Separators for lithium-ion batteries: a review on the production processes and recent developments[J]. Energy Technology, 2015, 3(5): 453-468. |

| 3 | Tan D, Zhang L L, Chen Q, et al. High-temperature capacitor polymer films[J]. Journal of Electronic Materials, 2014, 43(12): 4569-4575. |

| 4 | Tabatabaei S H, Carreau P J, Ajji A. Structure and properties of MDO stretched polypropylene[J]. Polymer, 2009, 50(16): 3981-3989. |

| 5 | Tabatabaei S H, Carreau P J, Ajji A. Effect of processing on the crystalline orientation, morphology, and mechanical properties of polypropylene cast films and microporous membrane formation[J]. Polymer, 2009, 50(17): 4228-4240. |

| 6 | Arora P, Zhang Z J. Battery separators[J]. Chemical Reviews, 2004, 104(10): 4419-4462. |

| 7 | Brückner S, Meille S V, Petraccone V, et al. Polymorphism in isotactic polypropylene[J]. Progress in Polymer Science, 1991, 16(2/3): 361-404. |

| 8 | Luo F, Geng C Z, Wang K, et al. New understanding in tuning toughness of β-polypropylene: the role of β-nucleated crystalline morphology[J]. Macromolecules, 2009, 42(23): 9325-9331. |

| 9 | Wang B, Cavallo D, Zhang X L, et al. Evolution of chain entanglements under large amplitude oscillatory shear flow and its effect on crystallization of isotactic polypropylene[J]. Polymer, 2020, 186: 121899. |

| 10 | Wu T, Xiang M, Cao Y, et al. Influence of lamellar structure on the stress-strain behavior of β nucleated polypropylene under tensile loading at elevated temperatures[J]. RSC Advances, 2015, 5(54): 43496-43507. |

| 11 | Zhang D X, Ding L, Yang F, et al. Effect of annealing on the microvoid formation and evolution during biaxial stretching of β nucleated isotactic polypropylene[J]. Polymer-Plastics Technology and Materials, 2020, 59(14): 1595-1607. |

| 12 | Tordjeman P, Robert C, Marin G, et al. The effect of α, β crystalline structure on the mechanical properties of polypropylene[J]. The European Physical Journal E, 2001, 4(4): 459-465. |

| 13 | Pukánszky B, Mudra I, Staniek P. Relation of crystalline structure and mechanical properties of nucleated polypropylene[J]. Journal of Vinyl and Additive Technology, 1997, 3(1): 53-57. |

| 14 | Bai H W, Deng H A, Zhang Q, et al. Effect of annealing on the microstructure and mechanical properties of polypropylene with oriented Shish-Kebab structure[J]. Polymer International, 2012, 61(2): 252-258. |

| 15 | Wang B, Cavallo D, Chen J B. Delay of re-entanglement kinetics by shear-induced nucleation precursors in isotactic polypropylene melt[J]. Polymer, 2020, 210: 123000. |

| 16 | Mi D S, Xia C, Jin M, et al. Quantification of the effect of shish-kebab structure on the mechanical properties of polypropylene samples by controlling shear layer thickness[J]. Macromolecules, 2016, 49(12): 4571-4578. |

| 17 | Balzano L, Ma Z, Cavallo D, et al. Molecular aspects of the formation of Shish-Kebab in isotactic polypropylene[J]. Macromolecules, 2016, 49(10): 3799-3809. |

| 18 | Qin Y J, Xu Y H, Zhang L Y, et al. Interfacial interaction enhancement by shear-induced β-cylindrite in isotactic polypropylene/glass fiber composites[J]. Polymer, 2016, 100: 111-118. |

| 19 | Li Z M, Yang W, Li L B, et al. Morphology and nonisothermal crystallization of in situ microfibrillar poly(ethylene terephthalate)/polypropylene blend fabricated through slit-extrusion, hot-stretch quenching[J]. Journal of Polymer Science Part B: Polymer Physics, 2004, 42(3): 374-385. |

| 20 | Varga J. β-modification of polypropylene and its two-component systems[J]. Journal of Thermal Analysis, 1989, 35(6): 1891-1912. |

| 21 | Cowking A, Rider J G. On molecular and textural reorientations in polyethylene caused by applied stress[J]. Journal of Materials Science, 1969, 4(12): 1051-1058. |

| 22 | Young R J, Bowden P B, Ritchie J M, et al. Deformation mechanisms in oriented high-density polyethylene[J]. Journal of Materials Science, 1973, 8(1): 23-36. |

| 23 | Peterlin A. Drawing and extrusion of semi-crystalline polymers[J]. Colloid and Polymer Science, 1987, 265(5): 357-382. |

| 24 | Lu Y, Chen R, Zhao J Y, et al. Stretching temperature dependency of fibrillation process in isotactic polypropylene[J]. The Journal of Physical Chemistry B, 2017, 121(28): 6969-6978. |

| 25 | Luo F, Wang K, Ning N Y, et al. Dependence of mechanical properties on β-form content and crystalline morphology for β-nucleated isotactic polypropylene[J]. Polymers for Advanced Technologies, 2011, 22(12): 2044-2054. |

| 26 | Pi L, Nie M, Wang Q. Crystalline composition and morphology in isotactic polypropylene pipe under combining effects of rotation extrusion and fibril β-nucleating agent[J]. Journal of Vinyl and Additive Technology, 2019, 25(S1): E195-E202. |

| 27 | Wen X, Li Y, Nie M, et al. Formation mechanism of hybrid shish kebab and its reinforcing effects on polypropylene[J]. Polymer-Plastics Technology and Engineering, 2016, 55(8): 775-783. |

| 28 | Wang Z F, Yang W H, Liu G M, et al. Probing into the epitaxial crystallization of β form isotactic polypropylene: from experimental observations to molecular mechanics computation[J]. Journal of Polymer Science Part B: Polymer Physics, 2017, 55(5): 418-424. |

| 29 | Wang B, Utzeri R, Castellano M, et al. Heterogeneous nucleation and self-nucleation of isotactic polypropylene microdroplets in immiscible blends: from nucleation to growth-dominated crystallization[J]. Macromolecules, 2020, 53(14): 5980-5991. |

| 30 | Li S W, Zheng G Q, Jia Z H, et al. Effect of stretching on β-phase content of isotactic polypropylene melt containing β-nucleating agent[J]. Journal of Macromolecular Science, Part B, 2012, 51(5): 828-838. |

| 31 | Flory P J. Thermodynamics of crystallization in high polymers(Ⅰ): Crystallization induced by stretching[J]. Journal of Chemical Physics, 1947, 15(6): 397-408. |

| 32 | Ji H J, Zhou X L, Chen X, et al. Deformation-induced crystallization behavior of isotactic polypropylene sheets containing a β-nucleating agent under solid-state stretching[J]. Polymers, 2020, 12(6): 1258. |

| 33 | Mollova A, Androsch R, Mileva D, et al. Crystallization of isotactic polypropylene containing beta-phase nucleating agent at rapid cooling[J]. European Polymer Journal, 2013, 49(5): 1057-1065. |

| 34 | Rhoades A M, Wonderling N, Gohn A, et al. Effect of cooling rate on crystal polymorphism in beta-nucleated isotactic polypropylene as revealed by a combined WAXS/FSC analysis[J]. Polymer, 2016, 90: 67-75. |

| [1] | Hongxin YU, Shuangquan SHAO. Simulation analysis of water crystallization process [J]. CIESC Journal, 2023, 74(S1): 250-258. |

| [2] | Jianbo HU, Hongchao LIU, Qi HU, Meiying HUANG, Xianyu SONG, Shuangliang ZHAO. Molecular dynamics simulation insight into translocation behavior of organic cage across the cellular membrane [J]. CIESC Journal, 2023, 74(9): 3756-3765. |

| [3] | Cong QI, Zi DING, Jie YU, Maoqing TANG, Lin LIANG. Study on solar thermoelectric power generation characteristics based on selective absorption nanofilm [J]. CIESC Journal, 2023, 74(9): 3921-3930. |

| [4] | Song HE, Qiaomai LIU, Guangshuo XIE, Simin WANG, Juan XIAO. Two-phase flow simulation and surrogate-assisted optimization of gas film drag reduction in high-concentration coal-water slurry pipeline [J]. CIESC Journal, 2023, 74(9): 3766-3774. |

| [5] | Yu FU, Xingchong LIU, Hanyu WANG, Haimin LI, Yafei NI, Wenjing ZOU, Yue LEI, Yongshan PENG. Research on F3EACl modification layer for improving performance of perovskite solar cells [J]. CIESC Journal, 2023, 74(8): 3554-3563. |

| [6] | Ben ZHANG, Songbai WANG, Ziya WEI, Tingting HAO, Xuehu MA, Rongfu WEN. Capillary liquid film condensation and heat transfer enhancement driven by superhydrophilic porous metal structure [J]. CIESC Journal, 2023, 74(7): 2824-2835. |

| [7] | Jie LIU, Lisheng WU, Jinjin LI, Zhenghong LUO, Yinning ZHOU. Preparation and properties of polyether-based vinylogous urethane reversible crosslinked polymers [J]. CIESC Journal, 2023, 74(7): 3051-3057. |

| [8] | Bin CAI, Xiaolin ZHANG, Qian LUO, Jiangtao DANG, Liyuan ZUO, Xinmei LIU. Research progress of conductive thin film materials [J]. CIESC Journal, 2023, 74(6): 2308-2321. |

| [9] | Zihan YUAN, Shuyan WANG, Baoli SHAO, Lei XIE, Xi CHEN, Yimei MA. Investigation on flow characteristics of wet particles with power-law liquid-solid drag models in fluidized bed [J]. CIESC Journal, 2023, 74(5): 2000-2012. |

| [10] | Jianhua ZHANG, Mengmeng CHEN, Yawen SUN, Yongzhen PENG. Efficient nitrogen and phosphorus removal from domestic wastewater via simultaneous partial nitritation and phosphorus removal combined Anammox [J]. CIESC Journal, 2023, 74(5): 2147-2156. |

| [11] | Xuehong WU, Linlin LUAN, Yanan CHEN, Min ZHAO, Cai LYU, Yong LIU. Preparation and thermal properties of degradable flexible phase change films [J]. CIESC Journal, 2023, 74(4): 1818-1826. |

| [12] | Qingchao LIU, Hui JIA, Yifei XU, Na LU, Yanmei YIN, Jie WANG. Study on shear-force distribution in biological aerated filter based on FBG sensing technology [J]. CIESC Journal, 2023, 74(4): 1755-1763. |

| [13] | Xiaodan SU, Ganyu ZHU, Huiquan LI, Guangming ZHENG, Ziheng MENG, Fang LI, Yunrui YANG, Benjun XI, Yu CUI. Optimization of wet process phosphoric acid hemihydrate process and crystallization of gypsum [J]. CIESC Journal, 2023, 74(4): 1805-1817. |

| [14] | Yuming CHEN, Wei LI, Xiang YAN, Jingdai WANG, Yongrong YANG. Research progress on regulation of aggregation structure for nascent polyethylene [J]. CIESC Journal, 2023, 74(2): 487-499. |

| [15] | Weijiang CHENG, Heqi WANG, Xiang GAO, Na LI, Sainan MA. Research progress on film-forming electrolyte additives for Si-based lithium-ion batteries [J]. CIESC Journal, 2023, 74(2): 571-584. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||