CIESC Journal ›› 2025, Vol. 76 ›› Issue (2): 695-706.DOI: 10.11949/0438-1157.20240859

• Separation engineering • Previous Articles

Xiaonan YOU1( ), Xiaoqiang FAN1,2(

), Xiaoqiang FAN1,2( ), Yao YANG1,3, Jingdai WANG1,3, Yongrong YANG1,3

), Yao YANG1,3, Jingdai WANG1,3, Yongrong YANG1,3

Received:2024-07-29

Revised:2024-09-19

Online:2025-03-10

Published:2025-03-25

Contact:

Xiaoqiang FAN

尤潇楠1( ), 范小强1,2(

), 范小强1,2( ), 杨遥1,3, 王靖岱1,3, 阳永荣1,3

), 杨遥1,3, 王靖岱1,3, 阳永荣1,3

通讯作者:

范小强

作者简介:尤潇楠(1998—),男,硕士,youxiaonan@zju.edu.cn

基金资助:CLC Number:

Xiaonan YOU, Xiaoqiang FAN, Yao YANG, Jingdai WANG, Yongrong YANG. Modeling method of depressurization separation process of the mixture of high-pressure polyethylene and supercritical ethylene[J]. CIESC Journal, 2025, 76(2): 695-706.

尤潇楠, 范小强, 杨遥, 王靖岱, 阳永荣. 超临界乙烯和高压聚乙烯混合物的减压分离过程建模方法[J]. 化工学报, 2025, 76(2): 695-706.

Add to citation manager EndNote|Ris|BibTeX

| 参数 | C2H4 | LDPE |

|---|---|---|

| kij | -0.0568708 | |

| m | 1.522416 | 0.04131746M |

| σ | 3.4882223 | 3.4750711 |

| ε/kB | 181.331214 | 267.179575 |

Table 1 Pure component parameters in the PC-SAFT equation of state[19]

| 参数 | C2H4 | LDPE |

|---|---|---|

| kij | -0.0568708 | |

| m | 1.522416 | 0.04131746M |

| σ | 3.4882223 | 3.4750711 |

| ε/kB | 181.331214 | 267.179575 |

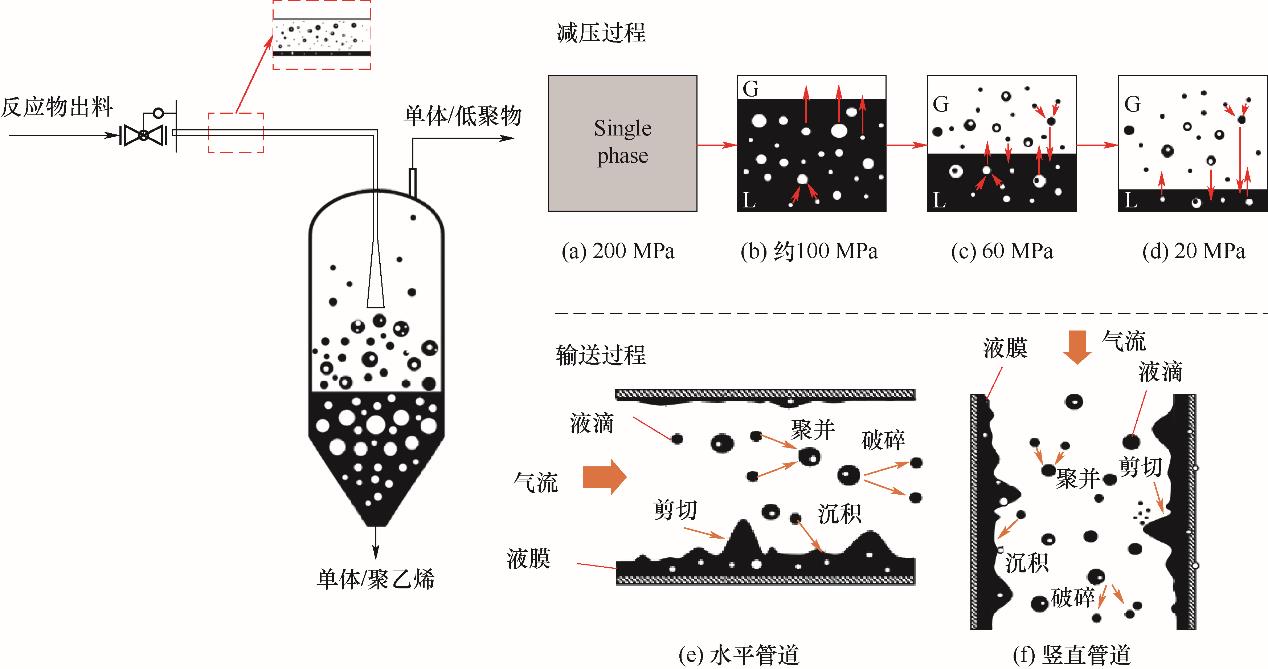

Fig.4 Schematic diagram of the supercritical ethylene-polyethylene separation mechanism (black represents the polyethylene phase, white represents the ethylene phase, gray represents the homogeneous phase)

| 数据 | Mn | Mw | PDI |

|---|---|---|---|

| 原始数据(PE-B) | 15390 | 106031 | 6.9 |

| 46个伪组分 | 17419 | 121314 | 7.0 |

| 91个伪组分 | 16351 | 112950 | 6.9 |

| 226个伪组分 | 15746 | 108571 | 6.9 |

Table 2 Comparison of molecular weight distribution data for polyethylene product (PE-B) before and after data processing

| 数据 | Mn | Mw | PDI |

|---|---|---|---|

| 原始数据(PE-B) | 15390 | 106031 | 6.9 |

| 46个伪组分 | 17419 | 121314 | 7.0 |

| 91个伪组分 | 16351 | 112950 | 6.9 |

| 226个伪组分 | 15746 | 108571 | 6.9 |

| 相关参数 | Model A[ | Model B[ | Model C(this study Ⅰ) |

|---|---|---|---|

| 形成机理 | 相平衡 | 夹带、传质 | 相平衡、气相剪切、减压溶解 |

| 流量信息 | √ | √ | √ |

| 分子量分布 | √ | × | √ |

Table 3 Comparison of predictive capabilities of mathematical models

| 相关参数 | Model A[ | Model B[ | Model C(this study Ⅰ) |

|---|---|---|---|

| 形成机理 | 相平衡 | 夹带、传质 | 相平衡、气相剪切、减压溶解 |

| 流量信息 | √ | √ | √ |

| 分子量分布 | √ | × | √ |

| 1 | Pladis P, Baltsas A, Kanellopoulos V, et al. Dynamic multi-phase, multi-zone modeling of flash separators for highly viscous polymerization processes[J]. Macromolecular Reaction Engineering, 2014, 8(4): 392-405. |

| 2 | Buchelli A, Call M L, Brown A L, et al. Modeling fouling effects in LDPE tubular polymerization reactors(1): Fouling thickness determination[J]. Industrial & Engineering Chemistry Research, 2005, 44(5): 1474-1479. |

| 3 | Folie B, Radosz M. Phase equilibria in high-pressure polyethylene technology[J]. Industrial & Engineering Chemistry Research, 1995, 34(5): 1501-1516. |

| 4 | Bonner D C, Maloney D P, Prausnitz J M. Calculation of high-pressure phase equilibria and molecular-weight distribution in partial decompression of polyethylene-ethylene mixtures[J]. Industrial & Engineering Chemistry Process Design and Development, 1974, 13(1): 91-95. |

| 5 | Spahl R, Luft G. Fraktionierungserscheinungen Bei der entmischung von ethylen-polyethylen-gemischen[J]. Die Angewandte Makromolekulare Chemie, 1983, 115(1): 87-102. |

| 6 | Bogdanovic V, Tasic A, Djordjevic B. Industrial aspects of phase separation in ethylene-polyethylene system at pressures of 15—30 MPa[J]. Industrial & Engineering Chemistry Process Design and Development, 1985, 24(3): 576-581. |

| 7 | Pladis P, Baltsas A, Kiparissides C. A comprehensive investigation on high-pressure LDPE manufacturing: dynamic modelling of compressor, reactor and separation units[J]. Computer Aided Chemical Engineering, 2006, 21: 595-600. |

| 8 | Cernia E M, Mancini C. A thermodynamic approach to phase equilibria investigation of polyethylene-ethylene system at high pressure[J]. Kobunshi Kagaku, 1965, 22(248): 797-803. |

| 9 | Swelheim T, De Swaan Arons J, Diepen G A M. Fluid phase equilibria in the system polyethene-ethene[J]. Recueil Des Travaux Chimiques Des Pays-Bas, 1965, 84(2): 261-266. |

| 10 | Steiner R, Horlé K. Phasenverhalten von Äthylen/Polyäthylen-Gemischen unter hohem Druck[J]. Chemie Ingenieur Technik, 1972, 44(17): 1010-1015. |

| 11 | Maloney D P, Prausnitz J M. Solubility of ethylene in liquid, low-density polyethylene at industrial-separation pressures[J]. Industrial & Engineering Chemistry Process Design and Development, 1976, 15(1): 216-220. |

| 12 | Maloney D P, Prausnitz J M. Solubilities of ethylene and other organic solutes in liquid, low-density polyethylene in the region 124° to 300℃[J]. AIChE Journal, 1976, 22(1): 74-82. |

| 13 | Rätzsch M, Findeisen R, Sernow V S. Untersuchungen zum phasenverhalten von monomer-polymer-systemen unter hohem druck[J]. Zeitschrift Für Physikalische Chemie, 1980, 261(1): 1000-1995. |

| 14 | Luft G, Lindner A. Zum einfluß des polymermolekulargewichts auf das phasenverhalten von gas-polymer-systemen unter hochdruck[J]. Die Angewandte Makromolekulare Chemie, 1976, 56(1): 99-114. |

| 15 | Spahl R, Luft G. Einfluß von molmasse und molekülverzweigungen auf das entmischungsverhalten von ethylen/polyethylen-systemen unter hochdruck[J]. Berichte Der Bunsengesellschaft Für Physikalische Chemie, 1982, 86(7): 621-625. |

| 16 | De Loos T W, Poot W, Diepen G A M. Fluid phase equilibriums in the system polyethylene + ethylene(1): Systems of linear polyethylene + ethylene at high pressure[J]. Macromolecules, 1983, 16(1): 111-117. |

| 17 | Browarzik D, Rätzsch M T, Wohlfarth C. High pressure phase equilibrium in the system ethylene + vinylacetate + (ethylene vinylacetate) copolymer treated by continuous thermodynamics[J]. Acta Polymerica, 1989, 40(7): 457-462. |

| 18 | de Loos T W, Poot W, Lichtenthaler R N. The influence of branching on high-pressure vapor-liquid equilibria in systems of ethylene and polyethylene[J]. The Journal of Supercritical Fluids, 1995, 8(4): 282-286. |

| 19 | Buchelli A, Call M L, Brown A L, et al. Nonequilibrium behavior in ethylene/polyethylene flash separators[J]. Industrial & Engineering Chemistry Research, 2004, 43(7): 1768-1778. |

| 20 | Bogdanović V Ž, Tasić A Ž, Djordjević B D. Importance of solubility phenomena during the separation of the ethylene-polyethylene mixture in the industrial low density polyethylene process[J]. Journal of Applied Polymer Science, 1994, 51(2): 253-258. |

| 21 | Gross J, Sadowski G. Perturbed-chain SAFT: an equation of state based on a perturbation theory for chain molecules[J]. Industrial & Engineering Chemistry Research, 2001, 40(4): 1244-1260. |

| 22 | Heuer T, Peuschel G P, Rätzsch M, et al. Untersuchungen zur löslichkeit von ethen, propan, propen und but-1-en in schmelzen von oligomeren des polyethylens bzw. (Ethen-vinylacetat)-copolymeren bei temperaturen bis 473, 15 K und drücken bis 30 MPa. t e i l ( Ⅱ ) : Modellierung und vorausberechnung[J]. Acta Polymerica, 1989, 40(5): 320-324. |

| 23 | 吕海蛟. LDPE装置高压循环系统分离效果影响因素分析及优化[J]. 化工管理, 2022(31): 123-125. |

| Lyu H J. Analysis and optimization of influencing factors on separation effect of high pressure circulating system in LDPE plant[J]. Chemical Management, 2022(31): 123-125. | |

| 24 | Cheluget E L, Bokis C P, Wardhaugh L, et al. Modeling polyethylene fractionation using the perturbed-chain statistical associating fluid theory equation of state[J]. Industrial & Engineering Chemistry Research, 2002, 41(5): 968-988. |

| 25 | Behme S, Sadowski G, Song Y H, et al. Multicomponent flash algorithm for mixtures containing polydisperse polymers[J]. AIChE Journal, 2003, 49(1): 258-268. |

| 26 | Cheng Y. Thermodynamics of phase equilibrium between ethylene and polyethylene[D]. Graduate Faculty of Texas Tech University, 1976. |

| 27 | Ishii M, Grolmes M A. Inception criteria for droplet entrainment in two-phase concurrent film flow[J]. AIChE Journal, 1975, 21(2): 308-318. |

| 28 | Berna C, Escrivá A, Muñoz-Cobo J L, et al. Review of droplet entrainment in annular flow: characterization of the entrained droplets[J]. Progress in Nuclear Energy, 2015, 79: 64-86. |

| 29 | Aliyu A M, Almabrok A A, Baba Y D, et al. Prediction of entrained droplet fraction in co-current annular gas-liquid flow in vertical pipes[J]. Experimental Thermal and Fluid Science, 2017, 85: 287-304. |

| 30 | Kwok D Y, Cheung L K, Park C B, et al. Study on the surface tensions of polymer melts using axisymmetric drop shape analysis[J]. Polymer Engineering & Science, 1998, 38(5): 757-764. |

| [1] | Panpan WEI, Yinan LIU, Chunying ZHU, Taotao FU, Xiqun GAO, Youguang MA. Preparation of aqueous two-phase droplets in improved T-shaped microchannel [J]. CIESC Journal, 2025, 76(2): 576-583. |

| [2] | Zilin PENG, Lei ZHOU, Qinghang DENG, Guanghua YE, Xinggui ZHOU. Kinetics of 3D NAND flash wet etching with phosphoric acid under the influence of H2SiO3 [J]. CIESC Journal, 2025, 76(2): 645-653. |

| [3] | Chuanchao HE, Jinghong ZHOU, Yueqiang CAO, Yao SHI, Xinggui ZHOU. Bed-particle dual scale coupled simulation on Ag/SiO2 catalyzed hydrogenation of oxalate to methyl glycolate [J]. CIESC Journal, 2025, 76(2): 654-666. |

| [4] | Falu DANG, Zhiguo SUN, Zhao GAO, Gang WANG, Zhengyu CHEN, Linzhou ZHANG, Jingcun LIAN, Meijia LIU, Zhongdong ZHANG, Chaowei LIU. One-step catalytic cracking of crude oil to light olefins: experimental and reaction pathway studies [J]. CIESC Journal, 2025, 76(2): 667-685. |

| [5] | Ke ZHANG, Weijie REN, Mengna WANG, Kaifeng FAN, Liping CHANG, Jiabin LI, Tao MA, Jinping TIAN. Liquid-liquid mixing characteristics of Bunsen reaction products in microchannels [J]. CIESC Journal, 2025, 76(2): 623-636. |

| [6] | Heng ZHANG, Dianlu KUI, Hong CHANG, Zhigang ZHAN. Effect of mechanical stress on the interfacial transport properties of gas diffusion layers [J]. CIESC Journal, 2025, 76(2): 637-644. |

| [7] | Yan LI, Hongli GUO, Guoqing SU, Jianwen ZHANG. Gas-liquid two-phase flow and erosion-corrosion in air cooler of hydrogenation unit [J]. CIESC Journal, 2025, 76(1): 141-150. |

| [8] | Haijun FENG, Bingxuan ZHANG, Jian ZHOU. Predicting and interpreting the toxicity of ionic liquids using graph neural network [J]. CIESC Journal, 2025, 76(1): 93-106. |

| [9] | Xianming GAO, Wenxuan YANG, Shaohui LU, Xiaosong REN, Fangcai LU. Influence of droplet merging and jumping by dual-groove structures on superhydrophobic surfaces [J]. CIESC Journal, 2025, 76(1): 208-220. |

| [10] | Han CHEN, Chang CAI, Hong LIU, Hongchao YIN. Experimental investigation on spray cooling heat transfer enhancement by n-pentanol additive [J]. CIESC Journal, 2025, 76(1): 131-140. |

| [11] | Zhimin HAN, Xiangyu ZHOU, Hongyu ZHANG, Zhiming XU. Local deposition characteristics of CaCO3 fouling under different roughness element structures [J]. CIESC Journal, 2025, 76(1): 151-160. |

| [12] | Yanping JIA, Yanju MA, Wenxin GUAN, Bin YANG, Jian ZHANG, Lanhe ZHANG. Process conditions optimization and degradation mechanism of dye wastewater by Fe0/H2O2 system using response surface methodology [J]. CIESC Journal, 2025, 76(1): 348-362. |

| [13] | Zhengang ZHAO, Mengyao ZHOU, Dian JIN, Dacheng ZHANG. Study on direct methanol fuel cell performance modification based on foam carbon diffusion layer [J]. CIESC Journal, 2024, 75(S1): 259-266. |

| [14] | Yushuang LI, Xincheng WANG, Boyao WEN, Zhengyuan LUO, Bofeng BAI. Two-phase flow of emulsion flooding and its influencing factors in porous media [J]. CIESC Journal, 2024, 75(S1): 56-66. |

| [15] | Lü LIU, Jieru LIU, Liangliang FAN, Liang ZHAO. Study on passive microfluidic method for particle separation based on laminar effect [J]. CIESC Journal, 2024, 75(S1): 67-75. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||