CIESC Journal ›› 2025, Vol. 76 ›› Issue (5): 2327-2336.DOI: 10.11949/0438-1157.20241223

• Separation engineering • Previous Articles Next Articles

Dandong NING1( ), Jianhui LI1, Yang CHEN1,2, Jinping LI1,2, Libo LI1,2(

), Jianhui LI1, Yang CHEN1,2, Jinping LI1,2, Libo LI1,2( )

)

Received:2024-10-31

Revised:2025-02-11

Online:2025-06-13

Published:2025-05-25

Contact:

Libo LI

宁丹东1( ), 李建惠1, 陈杨1,2, 李晋平1,2, 李立博1,2(

), 李建惠1, 陈杨1,2, 李晋平1,2, 李立博1,2( )

)

通讯作者:

李立博

作者简介:宁丹东(1996—),男,硕士研究生,ningdandongtyut@163.com

基金资助:CLC Number:

Dandong NING, Jianhui LI, Yang CHEN, Jinping LI, Libo LI. Study on flocculation techniques in the large-scale production of MIL-101(Cr)[J]. CIESC Journal, 2025, 76(5): 2327-2336.

宁丹东, 李建惠, 陈杨, 李晋平, 李立博. MIL-101(Cr)批量化生产中的絮凝工艺研究[J]. 化工学报, 2025, 76(5): 2327-2336.

Add to citation manager EndNote|Ris|BibTeX

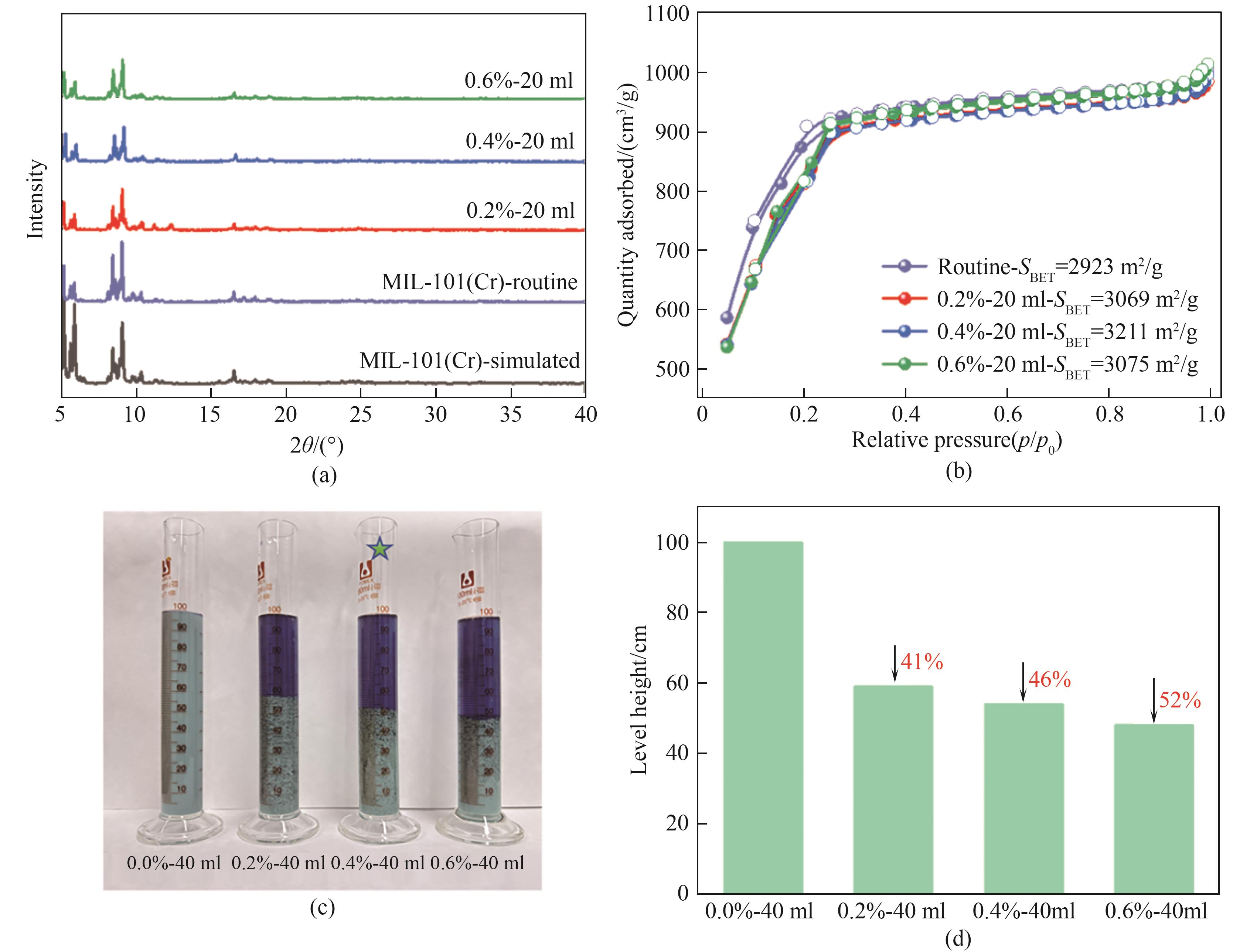

Fig.2 (a) PXRD patterns of MIL-101 (Cr) samples obtained by adding different kinds of flocculants; (b) N2 sorption isotherms at 77 K for MIL-101(Cr) samples obtained by adding different kinds of flocculants; (c), (d) Effects of different types of flocculants after 30 minutes of sedimentation

| Volume mixtures/L | Tadd/h | Twithout/h | Tadd/Twithout | Madd/g | Mwithout/g | Madd/Mwithout |

|---|---|---|---|---|---|---|

| 1 | 0.2 | 2 | 0.10 | 36 | 21 | 1.71 |

| 3 | 0.7 | 8 | 0.09 | 107 | 61 | 1.75 |

| 5 | 1.3 | 15 | 0.08 | 180 | 99 | 1.82 |

Table 1 Parameters for comparing filtration efficiencies of different volume mixtures

| Volume mixtures/L | Tadd/h | Twithout/h | Tadd/Twithout | Madd/g | Mwithout/g | Madd/Mwithout |

|---|---|---|---|---|---|---|

| 1 | 0.2 | 2 | 0.10 | 36 | 21 | 1.71 |

| 3 | 0.7 | 8 | 0.09 | 107 | 61 | 1.75 |

| 5 | 1.3 | 15 | 0.08 | 180 | 99 | 1.82 |

Fig.3 (a) PXRD patterns of MIL-101(Cr) samples treated with different concentrations of flocculants; (b) N2 sorption isotherms at 77 K for MIL-101(Cr) samples treated with different concentrations of flocculants; (c), (d) Effects of different types of flocculants after 30 min of sedimentation

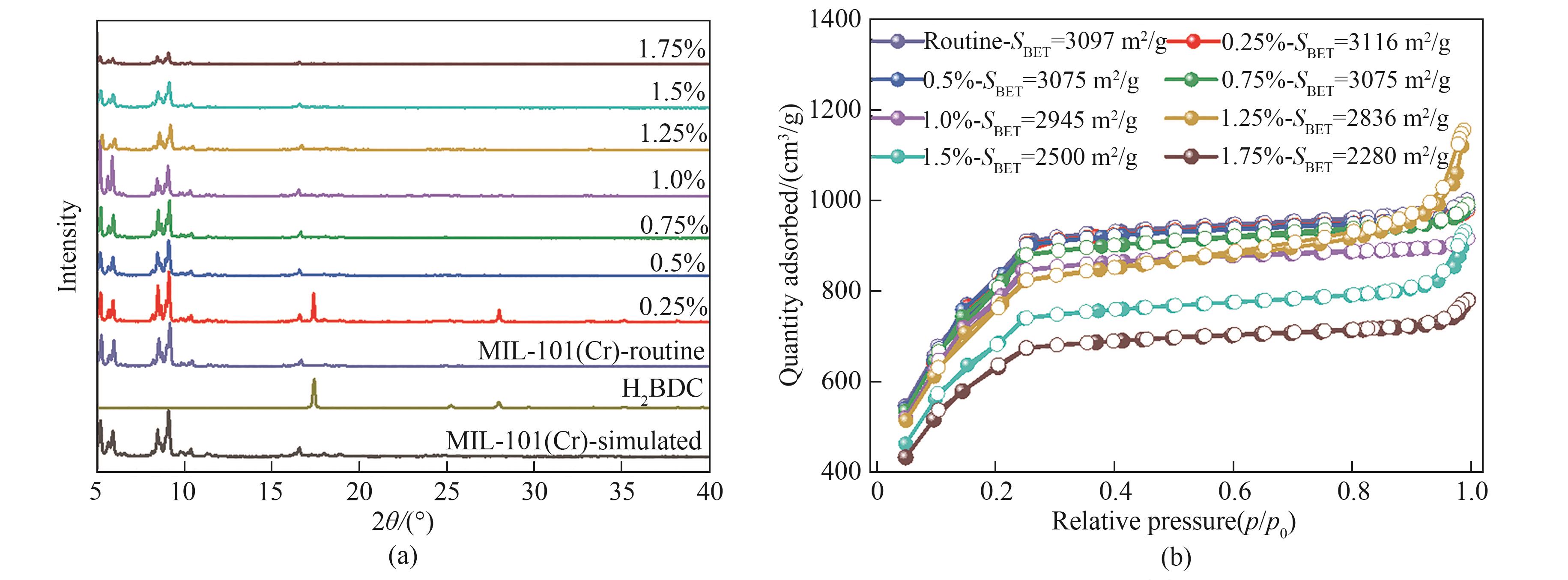

Fig.4 (a) PXRD patterns of MIL-101(Cr) samples obtained by adding different concentrations of ammonia; (b) N2 sorption isotherms at 77 K for MIL-101(Cr) samples obtained by adding different concentrations of ammonia

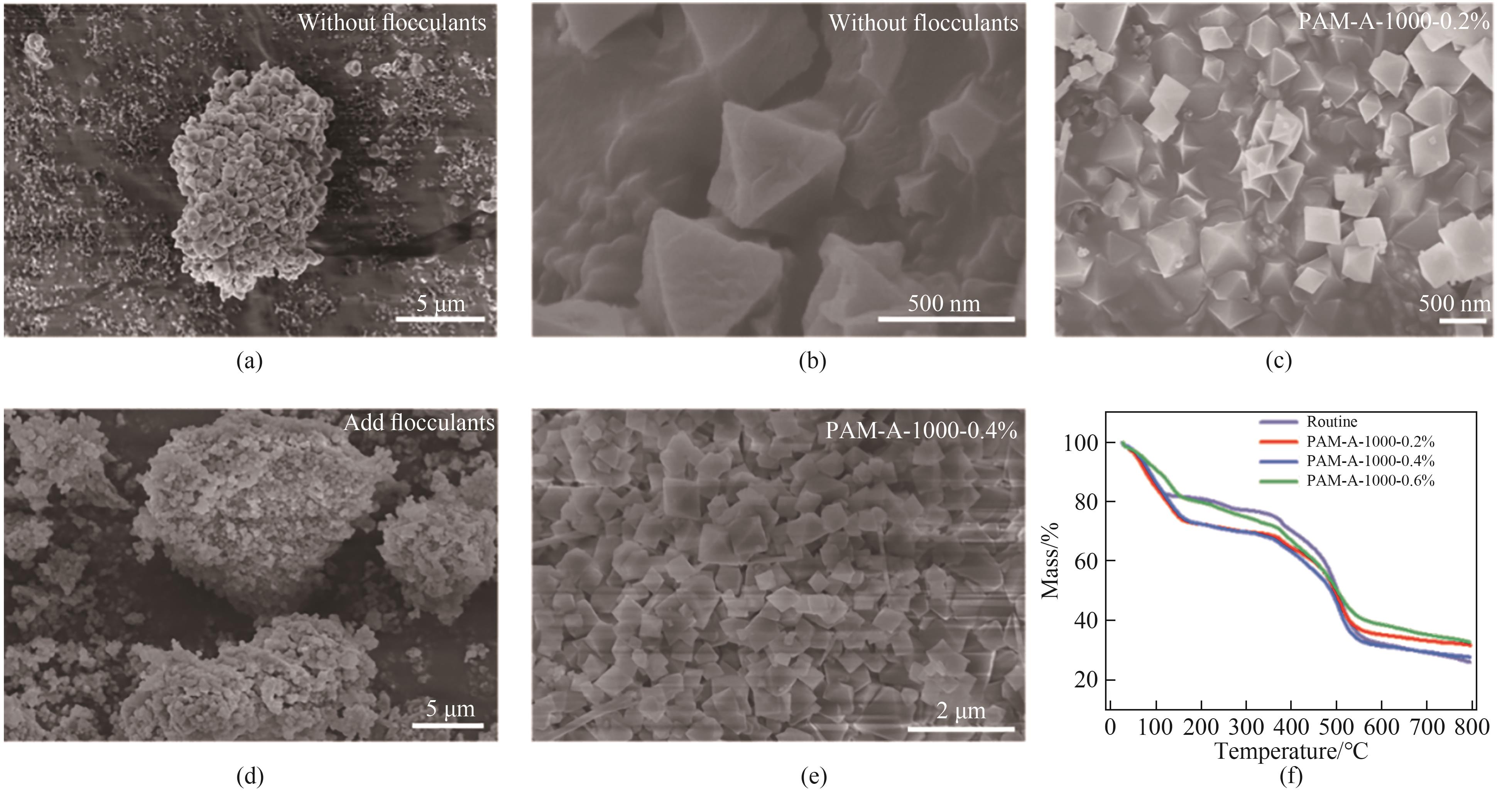

Fig.5 (a), (b) SEM images of sample without flocculant; (c)—(e) SEM images of sample with the addition of flocculant; (f) TGA curves of pristine MIL-101(Cr) and MIL-101(Cr) obtained by adding flocculants

Fig.6 (a) CO2 adsorption isotherms of MIL-101(Cr) samples treated with different concentrations of flocculants at 298 K and 1 bar; (b) The breakthrough curves of CO₂/N₂ (15/85, volume) mixed gas for MIL-101(Cr) samples treated with and without the addition of flocculant at 25 °C and 1 bar; (c) Test chart of breakthrough cycling performance with the addition of flocculant; (d) Test chart of breakthrough cycling performance without the addition of flocculant

| 1 | Li H L, Eddaoudi M, O’Keeffe M, et al. Design and synthesis of an exceptionally stable and highly porous metal-organic framework[J]. Nature, 1999, 402: 276-279. |

| 2 | 李建惠, 兰天昊, 陈杨, 等. MOF复合材料在气体吸附分离中的研究进展[J]. 化工学报, 2021, 72(1): 167-179. |

| Li J H, Lan T H, Chen Y, et al. Research progress of MOF-based composites for gas adsorption and separation[J]. CIESC Journal, 2021, 72(1): 167-179. | |

| 3 | Li L B, Lin R B, Krishna R, et al. Ethane/ethylene separation in a metal-organic framework with iron-peroxo sites[J]. Science, 2018, 362(6413): 443-446. |

| 4 | Surblé S, Millange F, Serre C, et al. Synthesis of MIL-102, a chromium carboxylate metal-organic framework, with gas sorption analysis[J]. Journal of the American Chemical Society, 2006, 128(46): 14889-14896. |

| 5 | Yulia F, Zulys A, Ruliandini R. Metal-organic framework based chromium terephthalate (MIL-101 Cr) growth for carbon dioxide capture: a review[J]. Journal of Advanced Research in Fluid Mechanics and Thermal Sciences, 2019, 57(2): 158-174. |

| 6 | Derrien G, Hassoun J, Panero S, et al. Nanostructured Sn-C composite as an advanced anode material in high-performance lithium-ion batteries[J]. Advanced Materials, 2007, 19(17): 2336-2340. |

| 7 | Li J R, Ma Y G, McCarthy M C, et al. Carbon dioxide capture-related gas adsorption and separation in metal-organic frameworks[J]. Coordination Chemistry Reviews, 2011, 255(15/16): 1791-1823. |

| 8 | Amin J, Kaye M, Skidmore S, et al. HIV and hepatitis C coinfection within the CAESAR study[J]. HIV Medicine, 2004, 5(3): 174-179. |

| 9 | Qiu L G, Li Z Q, Wu Y, et al. Facile synthesis of nanocrystals of a microporous metal-organic framework by an ultrasonic method and selective sensing of organoamines[J]. Chemical Communications, 2008(31): 3642-3644. |

| 10 | Yaghi O M, Li G M, Li H L. Selective binding and removal of guests in a microporous metal-organic framework[J]. Nature, 1995, 378: 703-706. |

| 11 | 张万珍, 占传威, 时双琴, 等. 微波法制备MOFs的研究进展[J]. 应用化工, 2022, 51(5): 1485-1489. |

| Zhang W Z, Zhan C W, Shi S Q, et al. Research progress on preparation of MOFs by microwave method[J]. Applied Chemical Industry, 2022, 51(5):1485-1489. | |

| 12 | Duan Y L, Guo Z G, Zhang J F, et al. Construction of bimetallic phosphide Fe x Co1- x P nanostructured array as a bifunctional electrocatalyst for overall water splitting[J]. Applied Physics A, 2024, 130(10): 673. |

| 13 | Bar A K, Mostafa G, Mukherjee P S. A Pd6 molecular cage via multicomponent self-assembly incorporating both neutral and anionic linkers[J]. Inorganic Chemistry, 2010, 49(17): 7647-7649. |

| 14 | Rubio-Martinez M, Avci-Camur C, Thornton A W, et al. New synthetic routes towards MOF production at scale[J]. Chemical Society Reviews, 2017, 46(11): 3453-3480. |

| 15 | Głowniak S, Szczęśniak B, Choma J, et al. Mechanochemistry: toward green synthesis of metal-organic frameworks[J]. Materials Today, 2021, 46: 109-124. |

| 16 | Kim J, Lee Y R, Ahn W S. Dry-gel conversion synthesis of Cr-MIL-101 aided by grinding: high surface area and high yield synthesis with minimum purification[J]. Chemical Communications, 2013, 49(69): 7647-7649. |

| 17 | Lin J B, Nguyen T T T, Vaidhyanathan R, et al. A scalable metal-organic framework as a durable physisorbent for carbon dioxide capture[J]. Science, 2021, 374(6574): 1464-1469. |

| 18 | Teo W L, Zhou W Q, Qian C, et al. Industrializing metal-organic frameworks: scalable synthetic means and their transformation into functional materials[J]. Materials Today, 2021, 47: 170-186. |

| 19 | Kumar S, Jain S, Nehra M, et al. Green synthesis of metal-organic frameworks: a state-of-the-art review of potential environmental and medical applications[J]. Coordination Chemistry Reviews, 2020, 420: 213407. |

| 20 | Pobłocki K, Drzeżdżon J, Gawdzik B, et al. Latest trends in the large-scale production of MOFs in accordance with the principles of green chemistry[J]. Green Chemistry, 2022, 24(24): 9402-9427. |

| 21 | Nagappan S, Duraivel M, Elayappan V, et al. Metal-organic frameworks-based cathode materials for energy storage applications: a review[J]. Energy Technology, 2023, 11(3): 2201200. |

| 22 | Férey G, Mellot-Draznieks C, Serre C, et al. A chromium terephthalate-based solid with unusually large pore volumes and surface area[J]. Science, 2005, 309(5743): 2040-2042. |

| 23 | Zou M M, Dong M, Zhao T. Advances in metal-organic frameworks MIL-101(Cr)[J]. International Journal of Molecular Sciences, 2022, 23(16): 9396. |

| 24 | Kavun V, van der Veen M A, Repo E. Selective recovery and separation of rare earth elements by organophosphorus modified MIL-101(Cr)[J]. Microporous and Mesoporous Materials, 2021, 312: 110747. |

| 25 | Rajati H, Navarchian A H, Rodrigue D, et al. Effect of immobilizing ionic liquid on amine-functionalized MIL-101(Cr) incorporated in Matrimid membranes for CO2/CH4 separation[J]. Chemical Engineering and Processing - Process Intensification, 2021, 168: 108590. |

| 26 | Wang Y D, Jia M T, Wu X, et al. PEG modified column MIL-101(Cr)/PVA cryogel as a sorbent in stir bar solid phase extraction for determination of non-steroidal anti-inflammatory drugs in water samples[J]. Microchemical Journal, 2019, 146: 214-219. |

| 27 | Wang F C, Zhang X, Wang Q Q, et al. Preparation of MS/MIL-101(Cr) composite material and its properties of atmospheric water collection[J]. Journal of Solid State Chemistry, 2021, 304: 122572. |

| 28 | Yang J F, Zhao Q, Li J P, et al. Synthesis of metal-organic framework MIL-101 in TMAOH-Cr(NO3)3-H2BDC-H2O and its hydrogen-storage behavior[J]. Microporous and Mesoporous Materials, 2010, 130(1/2/3): 174-179. |

| 29 | Zhao T, Li S H, Shen L, et al. The sized controlled synthesis of MIL-101(Cr) with enhanced CO2 adsorption property[J]. Inorganic Chemistry Communications, 2018, 96: 47-51. |

| 30 | Zhao T, Jeremias F, Boldog I, et al. High-yield, fluoride-free and large-scale synthesis of MIL-101(Cr)[J]. Dalton Transactions, 2015, 44(38): 16791-16801. |

| 31 | Zhao H Z, Li Q W, Wang Z Y, et al. Synthesis of MIL-101(Cr) and its water adsorption performance[J]. Microporous and Mesoporous Materials, 2020, 297: 110044. |

| 32 | Keshta B E, Yu H J, Wang L, et al. Cost-effective synthesis of MIL-101(Cr) from recyclable wastes and composite with polyaniline as an ion-to-electron transducer for potentiometric Pb2+ sensing[J]. Chemical Engineering Journal, 2024, 485: 150049. |

| 33 | Leng K Y, Sun Y Y, Li X L, et al. Rapid synthesis of metal-organic frameworks MIL-101(Cr) without the addition of solvent and hydrofluoric acid[J]. Crystal Growth & Design, 2016, 16(3): 1168-1171. |

| 34 | Bromberg L, Diao Y, Wu H M, et al. Chromium(Ⅲ) terephthalate metal organic framework (MIL-101): HF-free synthesis, structure, polyoxometalate composites, and catalytic properties[J]. Chemistry of Materials, 2012, 24(9): 1664-1675. |

| 35 | Liu Z N, Shi X L, Wei B L, et al. Preparation of MIL-53(Cr) and MIL-101(Cr)/reduced graphene oxide/polyaniline composites for Cr(Ⅵ) adsorption[J]. Journal of Porous Materials, 2025, 32(1): 353-364. |

| 36 | Teymouri N, Khoshnavazi R, Molaei S, et al. Keggin trimetallo-POM@MIL-101(Cr), synthesis, characterization and catalytic applications[J]. Catalysis Letters, 2025, 155(2): 61. |

| 37 | 安昊天, 韩章烨, 陆慕瑶, 等. 推进MOF产业化应用: 宏量制备与成型[J]. 化工学报, 2025, 76(5): 2011-2025. |

| An H T, Han Z Y, Lu M Y, et al. Promoting industrial application of MOF: scale-up preparation and shaping[J]. CIESC Journal, 2025, 76(5): 2011-2025. | |

| 38 | 孙丽媛, 张亚飞, 巩雁军. 微孔-微孔复合分子筛的结构特征及应用[J]. 物理化学学报, 2016, 32(5): 1105-1122. |

| Sun L Y, Zhang Y F, Gong Y J. Structural features and application of micro-microporous composite zeolites[J]. Acta Physico-Chimica Sinica, 2016, 32(5): 1105-1122. | |

| 39 | Hong L W, Zang J Z, Li B, et al. Research progress on the synthesis of nanosized and hierarchical beta zeolites[J]. Inorganics, 2023, 11(5): 214. |

| 40 | Seman N, Tarmizi Z I, Ali R R, et al. Preparation method of titanium dioxide nanoparticles and its application: an update[J]. IOP Conference Series: Earth and Environmental Science, 2022, 1091(1): 10. |

| 41 | 张密林, 丁立国, 景晓燕, 等. 纳米二氧化硅的制备、改性与应用研究进展[J]. 应用科技, 2004, 31(6): 64-66. |

| Zhang M L, Ding L G, Jing X Y, et al. Preparation, modification and application of nanoscale SiO2 [J]. Applied Science and Technology, 2004, 31(6): 64-66. | |

| 42 | 蔡靖, 林聪. 纳米材料与无机絮凝剂的复配絮凝实验研究[J]. 化工技术与开发, 2010, 39(2): 40-42. |

| Cai J, Lin C. Flocculation experiment of nano-material complicated with inorganic flocculants[J]. Technology & Development of Chemical Industry, 2010, 39(2): 40-42. | |

| 43 | Li Y L, Xu Z T, Wang W X. Effective flocculation of harmful algae Microcystis aeruginosa by nanoscale metal-organic framework NH2-MIL-101(Cr)[J]. Chemical Engineering Journal, 2022, 433: 134584. |

| 44 | Shao Y M, Fan X F, Wang S S, et al. Insights into adsorption and diffusion of CO2, CH4 and their mixture in MIL-101(Cr) via molecular simulation[J]. Chemical Engineering Journal, 2024, 480: 148215. |

| [1] | Zibo YANG, Youfa WANG, Hansong YUE, Shuangjie YUAN, Fujiang GENG, Qingqing LI, De AO, Bin LI, Mao YE, Zhenjie GU, Zhihua QIAO. Recent progress of MOF glasses based gas separation membrane [J]. CIESC Journal, 2025, 76(5): 2158-2168. |

| [2] | Yaohui ZHANG, Yujie BAN, Weishen YANG. Vapor-phase synthesis and post-synthetic modification of metal-organic framework membranes [J]. CIESC Journal, 2025, 76(5): 2070-2086. |

| [3] | Dong GU, Xingjian PI, Die ZHANG, Ying ZHANG. Construction and H2/CO2 separation performance evaluation of CAU-1/PI mixed matrix membrane with different nanoparticle sizes [J]. CIESC Journal, 2025, 76(5): 2410-2418. |

| [4] | Haotian AN, Zhangye HAN, Muyao LU, Awu ZHOU, Jianrong LI. Promoting industrial application of MOF: scale-up preparation and shaping [J]. CIESC Journal, 2025, 76(5): 2011-2025. |

| [5] | Yinjie ZHOU, Sibei JI, Songyang HE, Xu JI, Ge HE. Machine learning-assisted high-throughput screening approach for CO2 separation from CO2-rich natural gas using metal-organic frameworks [J]. CIESC Journal, 2025, 76(3): 1093-1101. |

| [6] | Yanhui DAI, Qizhao XIONG, Qiang FANG, Dongxiao YANG, Yi WANG, Yang CHEN, Jinping LI, Libo LI. In situ steam-assisted method for one-step synthesis of hierarchically porous Cu-BTC [J]. CIESC Journal, 2024, 75(9): 3329-3337. |

| [7] | Ying LIU, Fang ZHENG, Qiwei YANG, Zhiguo ZHANG, Qilong REN, Zongbi BAO. Recent progress in adsorption and separation of xylene isomers [J]. CIESC Journal, 2024, 75(4): 1081-1095. |

| [8] | Xue’an LIU, Liyi TANG, Jian QIN, Dajiang TANG, Zhangfa TONG, Huiying QU. Preparation of carbon nanotube bridged porous carbon by Ni/Co-ZIF-8 pyrolysis and its application to supercapacitors [J]. CIESC Journal, 2022, 73(7): 3287-3297. |

| [9] | Heng MAO, Yue WANG, Sen WANG, Weimin LIU, Jing LYU, Fuxue CHEN, Zhiping ZHAO. APTES-modified ZIF-L/PEBA mixed matrix membranes for enhancing phenol perm-selective pervaporation [J]. CIESC Journal, 2022, 73(3): 1389-1402. |

| [10] | Chenxu GENG, Yuxiu SUN, Hongliang HUANG, Xiangyu GUO, Zhihua QIAO, Chongli ZHONG. Mechanochemically synthesized small sized MOF fillers assisted for highly efficient CO2 separation [J]. CIESC Journal, 2021, 72(9): 4750-4758. |

| [11] | WANG Jiexiang, LI Hongguo, YE Songshou, ZHENG Jinbao, CHEN Binghui. Halogen-rich zinc-adeninate framework construction and its catalytic performance on CO2 cycloaddition without cocatalyst [J]. CIESC Journal, 2021, 72(7): 3686-3695. |

| [12] | HAN Xiao,CHEN Yuting,SU Baogen,BAO Zongbi,ZHANG Zhiguo,YANG Yiwen,REN Qilong,YANG Qiwei. Advances in adsorbents for hexane isomers separation [J]. CIESC Journal, 2021, 72(7): 3445-3465. |

| [13] | CHEN Rundao, ZHENG Fang, GUO Lidong, YANG Qiwei, ZHANG Zhiguo, YANG Yiwen, REN Qilong, BAO Zongbi. Advancements in adsorption separation of Xe/Kr noble gases [J]. CIESC Journal, 2021, 72(1): 14-26. |

| [14] | Puxu LIU, Chaohui HE, Libo LI, Jinping LI. Stable mixed metal-organic framework for efficient C2H6/C2H4 separation [J]. CIESC Journal, 2020, 71(9): 4211-4218. |

| [15] | Tong YANG, Xiaobo HE, Fengxiang YIN. Preparation of M-MOF-74 (M = Ni, Co, Zn) and its performance in electrocatalytic synthesis of ammonia [J]. CIESC Journal, 2020, 71(6): 2857-2870. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||