CIESC Journal ›› 2019, Vol. 70 ›› Issue (4): 1446-1454.DOI: 10.11949/j.issn.0438-1157.20181257

• Separation engineering • Previous Articles Next Articles

Jianglin WU1( ),Zhaohui ZHANG1,2(

),Zhaohui ZHANG1,2( ),Liang WANG1,2,Bin ZHAO1,2,Tengfei LI1,Mengmeng CHEN1

),Liang WANG1,2,Bin ZHAO1,2,Tengfei LI1,Mengmeng CHEN1

Received:2018-10-24

Revised:2018-12-18

Online:2019-04-05

Published:2019-04-05

Contact:

Zhaohui ZHANG

吴降麟1( ),张朝晖1,2(

),张朝晖1,2( ),王亮1,2,赵斌1,2,李腾飞1,陈萌萌1

),王亮1,2,赵斌1,2,李腾飞1,陈萌萌1

通讯作者:

张朝晖

作者简介:<named-content content-type="corresp-name">吴降麟</named-content>(1992—),男,硕士研究生,<email>wujianglin999@126.com</email>|张朝晖(1974—),女,博士,副教授,<email>zzh7448@126.com</email>

基金资助:CLC Number:

Jianglin WU, Zhaohui ZHANG, Liang WANG, Bin ZHAO, Tengfei LI, Mengmeng CHEN. Analysis of anti-fouling performance of wider spacer RO membrane module[J]. CIESC Journal, 2019, 70(4): 1446-1454.

吴降麟, 张朝晖, 王亮, 赵斌, 李腾飞, 陈萌萌. 宽流道反渗透膜元件抗污染性能分析[J]. 化工学报, 2019, 70(4): 1446-1454.

Add to citation manager EndNote|Ris|BibTeX

URL: https://hgxb.cip.com.cn/EN/10.11949/j.issn.0438-1157.20181257

| Sample | Membrane module type | Channel width/mil | Spacer orientation | Membrane material | Membrane area/m2 | Rejection rate of Na2SO4 | Pure water flux/(L/(m2·h)) |

|---|---|---|---|---|---|---|---|

| 20 mil-40° | LE-2521 | 20 | 40° | polyamide | 1.3935 | ≥99% | ≥50 |

| 30 mil-40° | LE-2521 | 30 | 40° | polyamide | 1.3935 | ≥99% | ≥50 |

| 40 mil-40° | LE-2521 | 40 | 40° | polyamide | 1.3935 | ≥99% | ≥50 |

| 40 mil-45° | LE-2521 | 40 | 45° | polyamide | 1.3935 | ≥99% | ≥50 |

Table 1 Parameters of reverse osmosis membrane module

| Sample | Membrane module type | Channel width/mil | Spacer orientation | Membrane material | Membrane area/m2 | Rejection rate of Na2SO4 | Pure water flux/(L/(m2·h)) |

|---|---|---|---|---|---|---|---|

| 20 mil-40° | LE-2521 | 20 | 40° | polyamide | 1.3935 | ≥99% | ≥50 |

| 30 mil-40° | LE-2521 | 30 | 40° | polyamide | 1.3935 | ≥99% | ≥50 |

| 40 mil-40° | LE-2521 | 40 | 40° | polyamide | 1.3935 | ≥99% | ≥50 |

| 40 mil-45° | LE-2521 | 40 | 45° | polyamide | 1.3935 | ≥99% | ≥50 |

Fig.2 Membrane specific flux decay curves of different reverse osmosis modules(operation pressure 1.5 MPa; active blue concentration 200 mg/L; conductivity 8.32 mS/cm; recovery rate 20%)

Fig.3 Variation of membrane flux before and after low pressure flushing(operation pressure 1.5 MPa; active blue concentration 200 mg/L; conductivity 8.32 mS/cm; recovery rate 20%)

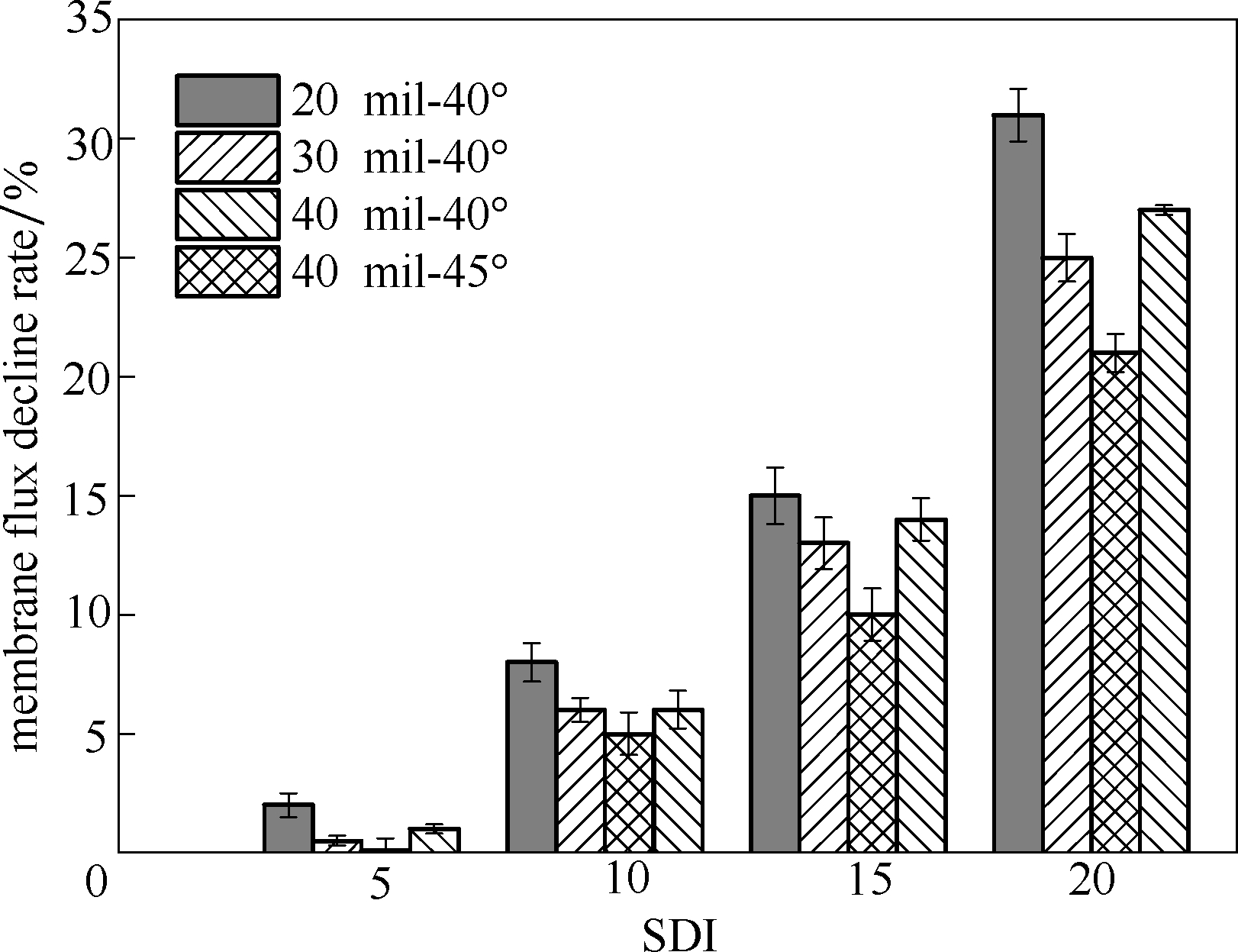

Fig.4 Effect of influent water quality on membrane performance(operation pressure 1.5 MPa; active blue concentration 0.2—200 mg/L; conductivity 0.112—8.32 mS/cm; recovery rate 20%)

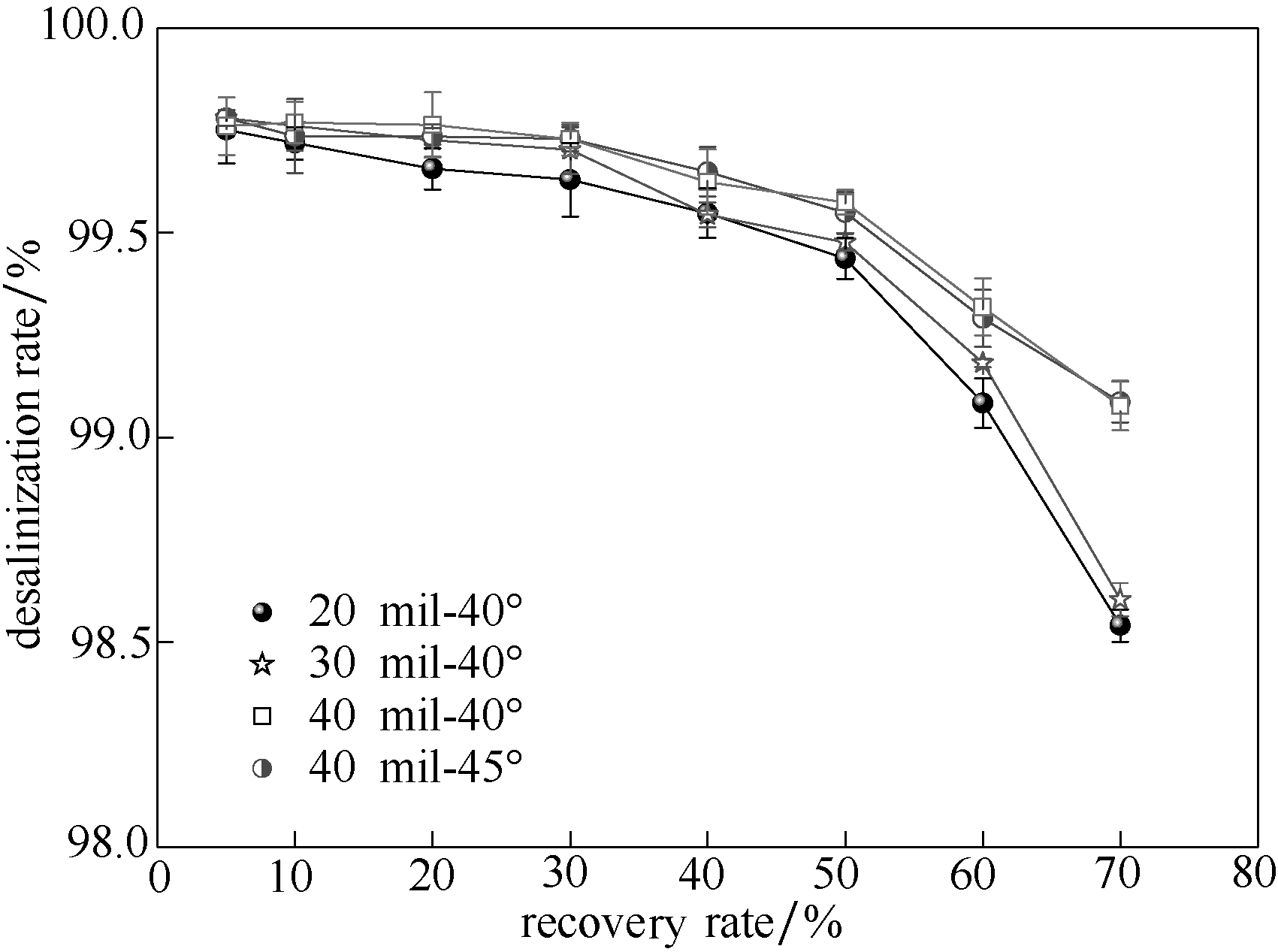

Fig.5 Relation curve of desalination rate and recovery rate(operation pressure 1.5 MPa; active blue concentration 200 mg/L; conductivity 8.32 mS/cm; recovery rate 20%)

Fig.6 Trade-off diagram of reverse osmosis membrane with different specifications(operation pressure 1.5 MPa; active blue concentration 200 mg/L; conductivity 8.32 mS/cm; recovery rate 10%—60%)

Fig.7 Variation of operation pressure of reverse osmosis membrane module with water flux growth(operation pressure 1.5 MPa; active blue concentration 200 mg/L; conductivity 8.32 mS/cm; recovery rate 20%)

| 1 | JooS H, TanselB. Novel technologies for reverse osmosis concentrate treatment: a review[J]. Journal of Environmental Management, 2015, 150: 322-335. |

| 2 | QiS, WangR, ChaitraG K M, et al. Aquaporin-based biomimetic reverse osmosis membranes: stability and long term performance[J]. Journal of Membrane Science, 2016, 508: 94-103. |

| 3 | JiangS, LiY, LadewigB P. A review of reverse osmosis membrane fouling and control strategies[J]. Science of the Total Environment, 2017, 595: 567-583. |

| 4 | SafarpourM, KhataeeA, VatanpourV. Thin film nanocomposite reverse osmosis membrane modified by reduced graphene oxide/TiO2 with improved desalination performance[J]. Journal of Membrane Science, 2015, 489(5): 43-54. |

| 5 | AsadollahiM, BastaniD, MusaviS A. Enhancement of surface properties and performance of reverse osmosis membranes after surface modification: a review[J]. Desalination, 2017, 420: 330-383. |

| 6 | PiyadasaC, RidgwayH F, YeagerT R, et al. The application of electromagnetic fields to the control of the scaling and biofouling of reverse osmosis membranes—a review[J]. Desalination, 2017, 418: 19-34. |

| 7 | TiradoM L M, BassM, PiatkovskyM, et al. Assessing biofouling resistance of a polyamide reverse osmosis membrane surface-modified with a zwitterionic polymer[J]. Journal of Membrane Science, 2016, 520: 490-498. |

| 8 | 祝敏, 沈广录, 黄洪伟, 等. 宽流道反渗透膜耐污染性分析及其在电厂的应用[J]. 工业水处理, 2017, 37(3): 110-112. |

| ZhuM, ShenG L, HuangH W, et al. Pollution-resistant analysis of wider spacer RO membrane and its application in power plants[J]. Industrial Water Treatment, 2017, 37(3): 110-112. | |

| 9 | HuiY, YangB Q, YangJ M, et al. Bioevaporation treatment of concentrated landfill leachate from two-stage DTRO[J]. China Environmental Science, 2017, 37(9): 3437-3445. |

| 10 | KavianipourO, IngramG D, VuthaluruH B. Investigation into the effectiveness of feed spacer configurations for reverse osmosis membrane modules using Computational Fluid Dynamics[J]. Journal of Membrane Science, 2017, 526: 156-171. |

| 11 | GongH, YanZ, LiangK Q, et al. Concentrating process of liquid digestate by disk tube-reverse osmosis system[J]. Desalination, 2013, 326(10): 30-36. |

| 12 | ZuoJ, SongY, WangJ. Application of DTRO technology in the treatment of landfill leachate[J]. Membrane Science & Technology, 2011, 31(2): 110-115. |

| 13 | 杨庆峰. 卷式反渗透膜器浓水侧流道缺陷诊断[J]. 化工学报, 2006, 57(6): 1319-1322. |

| YangQ F. Diagnosis of membrane passage defects for reverse osmosis spiral wound membrane module[J]. Journal of Chemical Industry and Engineering(China), 2006, 57(6): 1319-1322. | |

| 14 | GeiseG M, ParkH B, SagleA C, et al. Water permeability and water/salt selectivity tradeoff in polymers for desalination[J]. Journal of Membrane Science, 2011, 369(1): 130-138. |

| 15 | YangZ, ZhouZ W, GuoH, et al. Tannic acid/Fe3+ nanoscaffold for interfacial polymerization: toward enhanced nanofiltration performance[J]. Environ. Sci. Technol., 2018, 52(16): 9341-9349. |

| 16 | TanZ, ChenS, PengX, et al. Polyamide membranes with nanoscale turing structures for water purification[J]. Science, 2018, 360(6388): 518-521. |

| 17 | AraújoP A, KruithofJ C, LoosdrechtM C M V, et al. The potential of standard and modified feed spacers for biofouling control[J]. Journal of Membrane Science, 2012, 403/404(404): 58-70. |

| 18 | MajamaaK, AertsP E M, GrootC, et al. Industrial water reuse with integrated membrane system increases the sustainability of the chemical manufacturing[J]. Desalination & Water Treatment, 2010, 18(1/2/3): 17-23. |

| 19 | HaidariA H, HeijmanS G J, van der MeerW G J. Optimal design of spacers in reverse osmosis[J]. Separation and Purification Technology, 2018, 192: 441-456. |

| 20 | CostaA R D, FaneA G, WileyD E. Spacer characterization and pressure drop modelling in spacer-filled channels for ultrafiltration[J]. Journal of Membrane Science, 1994, 87(1/2): 79-98. |

| 21 | DarbyR, DarbyR, ChhabraR P. Chemical Engineering Fluid Mechanics, Revised and Expanded[M]. New York: Marcel Dekker Inc., 2001: 330-358. |

| 22 | HoekE M V, KimA S, ElimelechM. Influence of crossflow membrane filter geometry and shear rate on colloidal fouling in reverse osmosis and nanofiltration separations[J]. Environmental Engineering Science, 2002, 19(6): 357-372. |

| 23 | CostaA R D, FaneA G, FellC J D, et al. Optimal channel spacer design for ultrafiltration[J]. Journal of Membrane Science, 1991, 62(3): 275-291. |

| 24 | Fimbres-WeihsG A, WileyD E. Numerical study of mass transfer in three-dimensional spacer-filled narrow channels with steady flow[J]. Journal of Membrane Science, 2007, 306(1): 228-243. |

| 25 | NealP R, LiH, FaneA G, et al. The effect of filament orientation on critical flux and particle deposition in spacer-filled channels[J]. Journal of Membrane Science, 2003, 214(2): 165-178. |

| 26 | AraújoP A, MillerD J, CorreiaP B, et al. Impact of feed spacer and membrane modification by hydrophilic, bactericidal and biocidal coating on biofouling control[J]. Desalination, 2012, 295(6): 1-10. |

| 27 | ChapmanR G, OstuniE, LiangM N, et al. Polymeric thin films that resist the adsorption of proteins and the adhesion of bacteria[J]. Langmuir, 2001, 17(4): 1225-1233. |

| 28 | BrzozowskaA M, SpruijtE, KeizerA D, et al. On the stability of the polymer brushes formed by adsorption of Ionomer Complexes on hydrophilic and hydrophobic surfaces[J]. Journal of Colloid & Interface Science, 2011, 353(2): 380-391. |

| 29 | AhmadA L, LauK K, BakarM Z A, et al. Integrated CFD simulation of concentration polarization in narrow membrane channel[J]. Computers & Chemical Engineering, 2005, 29(10): 2087-2095. |

| 30 | AmokraneM, SadaouiD, DudeckM, et al. New spacer designs for the performance improvement of the zigzag spacer configuration in spiral-wound membrane modules[J]. Desalination & Water Treatment, 2016, 57(12): 5266-5274. |

| [1] | Zhewen CHEN, Junjie WEI, Yuming ZHANG. System integration and energy conversion mechanism of the power technology with integrated supercritical water gasification of coal and SOFC [J]. CIESC Journal, 2023, 74(9): 3888-3902. |

| [2] | Cong QI, Zi DING, Jie YU, Maoqing TANG, Lin LIANG. Study on solar thermoelectric power generation characteristics based on selective absorption nanofilm [J]. CIESC Journal, 2023, 74(9): 3921-3930. |

| [3] | Zhaolun WEN, Peirui LI, Zhonglin ZHANG, Xiao DU, Qiwang HOU, Yegang LIU, Xiaogang HAO, Guoqing GUAN. Design and optimization of cryogenic air separation process with dividing wall column based on self-heat regeneration [J]. CIESC Journal, 2023, 74(7): 2988-2998. |

| [4] | Jinbo JIANG, Xin PENG, Wenxuan XU, Rixiu MEN, Chang LIU, Xudong PENG. Study on leakage characteristics and parameter influence of pump-out spiral groove oil-gas seal [J]. CIESC Journal, 2023, 74(6): 2538-2554. |

| [5] | Shanghao LIU, Shengkun JIA, Yiqing LUO, Xigang YUAN. Optimization of ternary-distillation sequence based on gradient boosting decision tree [J]. CIESC Journal, 2023, 74(5): 2075-2087. |

| [6] | Bimao ZHOU, Shisen XU, Xiaoxiao WANG, Gang LIU, Xiaoyu LI, Yongqiang REN, Houzhang TAN. Effect of burner bias angle on distribution characteristics of gasifier slag layer [J]. CIESC Journal, 2023, 74(5): 1939-1949. |

| [7] | Jiyuan LI, Jinwang LI, Liuwei ZHOU. Heat transfer performance of cold plates with different turbulence structures [J]. CIESC Journal, 2023, 74(4): 1474-1488. |

| [8] | Wenxuan XU, Jinbo JIANG, Xin PENG, Rixiu MEN, Chang LIU, Xudong PENG. Comparative study on leakage and film-forming characteristics of oil-gas seal with three-typical groove in a wide speed range [J]. CIESC Journal, 2023, 74(4): 1660-1679. |

| [9] | Siqi WANG, Tianyu GU, Xianfu CHEN, Tong WANG, Jia LI, Wei KE, Xiaofeng LI, Yiqun FAN. Study on separation characteristics and membrane fouling mechanism of ceramic membrane for clarification of Eucommia ulmoides leaves extract [J]. CIESC Journal, 2023, 74(3): 1113-1125. |

| [10] | Junxian CHEN, Zhongli JI, Yu ZHAO, Qian ZHANG, Yan ZHOU, Meng LIU, Zhen LIU. Study on online detection method of particulate matter in natural gas pipeline based on microwave technology [J]. CIESC Journal, 2023, 74(3): 1042-1053. |

| [11] | Jinjia WEI, Lei LIU, Xiaoping YANG. Research progress of loop heat pipes for heat dissipation of high-heat-flux electronic devices [J]. CIESC Journal, 2023, 74(1): 60-73. |

| [12] | Peng WEI, Jun CHEN, Zhiguo WANG, Fei LIU. Improved productivity strategy of simulated moving bed based on binary-partial-discard [J]. CIESC Journal, 2022, 73(7): 3099-3108. |

| [13] | Taoyan ZHAO, Jiangtao CAO, Ping LI, Lin FENG, Yu SHANG. Application of interval type-2 fuzzy immune PID controller to temperature control system for uncatalysed oxidation of cyclohexane [J]. CIESC Journal, 2022, 73(7): 3166-3173. |

| [14] | Jing WAN, Lin ZHANG, Yachao FAN, Xiemin LIU, Peicheng LUO, Feng ZHANG, Zhibing ZHANG. Bioreactor scale-up simulation and experimental study based on mesoscale PBM model [J]. CIESC Journal, 2022, 73(6): 2698-2707. |

| [15] | Xin ZHANG, Li ZHOU, Shihui WANG, Xu JI, Kexin BI. Integrated optimization of refinery hydrogen networks with crude oil properties fluctuations [J]. CIESC Journal, 2022, 73(4): 1631-1646. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||