CIESC Journal ›› 2024, Vol. 75 ›› Issue (1): 268-278.DOI: 10.11949/0438-1157.20231132

• Fluid dynamics and transport phenomena • Previous Articles Next Articles

Yao ZHOU1( ), Xiaoping YANG2(

), Xiaoping YANG2( ), Yicheng NI2, Jiping LIU1, Jinjia WEI2,3, Junjie YAN3

), Yicheng NI2, Jiping LIU1, Jinjia WEI2,3, Junjie YAN3

Received:2023-11-06

Revised:2023-12-17

Online:2024-03-11

Published:2024-01-25

Contact:

Xiaoping YANG

周尧1( ), 杨小平2(

), 杨小平2( ), 倪一程2, 刘继平1, 魏进家2,3, 严俊杰3

), 倪一程2, 刘继平1, 魏进家2,3, 严俊杰3

通讯作者:

杨小平

作者简介:周尧(1994—),男,博士研究生,foreverzy@stu.xjtu.edu.cn

基金资助:CLC Number:

Yao ZHOU, Xiaoping YANG, Yicheng NI, Jiping LIU, Jinjia WEI, Junjie YAN. Numerical simulation of two-phase steam ejector applied in novel loop heat pipe[J]. CIESC Journal, 2024, 75(1): 268-278.

周尧, 杨小平, 倪一程, 刘继平, 魏进家, 严俊杰. 应用于新型环路热管的两相引射器数值模拟[J]. 化工学报, 2024, 75(1): 268-278.

Add to citation manager EndNote|Ris|BibTeX

Fig.1 Schematic diagram of novel LHP system coupled with two-phase steam ejector1—evaporator; 2—vapor line; 3—two-phase steam ejector; 4—liquid line Ⅰ; 5—cooler Ⅰ; 6—liquid line Ⅱ; 7—cooler Ⅱ

| 几何参数及边界条件 | 结构1 | 结构2 | 结构3 | 结构4 |

|---|---|---|---|---|

| 蒸汽喷嘴喉部直径, dst/mm | 1.24 | 1.24 | 1.24 | 1.24 |

| 蒸汽喷嘴出口直径, dso/mm | 1.5 | 1.5 | 1.5 | 1.5 |

| 混合腔入口直径, dmi/mm | 2.8 | 2.8 | 2.8 | 2.8 |

| 喉部直径, dm/mm | 1.8 | 1.8 | 1.8 | 1.8 |

| 混合腔长度, lm/mm | 13 | 11 | 9 | 7 |

| 喉部长度, lt/mm | 2 | 2 | 2 | 2 |

| 扩散段出口直径, dd/mm | 4 | 4 | 4 | 4 |

| 蒸汽喷嘴壁面厚度, δ/mm | 0.25 | 0.25 | 0.25 | 0.25 |

| 蒸汽入口压力, ps/kPa | 60~167 | 149 | 149 | 149 |

| 蒸汽喷嘴喉部质量流率, Gs/(kg/(m2·s)) | 95~257 | 232 | 232 | 232 |

| 蒸汽入口温度, Ts/℃ | 85.9~115 | 111 | 111 | 111 |

| 水喷嘴出口质量流率, Gw/(kg/(m2·s)) | 830~2238 | 2020 | 2020 | 2020 |

| 水喷嘴入口温度, Tw/℃ | 5~55 | 5~55 | 2~55 | 2~55 |

| 出口背压, pb/kPa | 40~129 | 79~114 | 89~113 | 91~105 |

Table 1 Geometry dimensions and boundary conditions of two-phase steam ejector

| 几何参数及边界条件 | 结构1 | 结构2 | 结构3 | 结构4 |

|---|---|---|---|---|

| 蒸汽喷嘴喉部直径, dst/mm | 1.24 | 1.24 | 1.24 | 1.24 |

| 蒸汽喷嘴出口直径, dso/mm | 1.5 | 1.5 | 1.5 | 1.5 |

| 混合腔入口直径, dmi/mm | 2.8 | 2.8 | 2.8 | 2.8 |

| 喉部直径, dm/mm | 1.8 | 1.8 | 1.8 | 1.8 |

| 混合腔长度, lm/mm | 13 | 11 | 9 | 7 |

| 喉部长度, lt/mm | 2 | 2 | 2 | 2 |

| 扩散段出口直径, dd/mm | 4 | 4 | 4 | 4 |

| 蒸汽喷嘴壁面厚度, δ/mm | 0.25 | 0.25 | 0.25 | 0.25 |

| 蒸汽入口压力, ps/kPa | 60~167 | 149 | 149 | 149 |

| 蒸汽喷嘴喉部质量流率, Gs/(kg/(m2·s)) | 95~257 | 232 | 232 | 232 |

| 蒸汽入口温度, Ts/℃ | 85.9~115 | 111 | 111 | 111 |

| 水喷嘴出口质量流率, Gw/(kg/(m2·s)) | 830~2238 | 2020 | 2020 | 2020 |

| 水喷嘴入口温度, Tw/℃ | 5~55 | 5~55 | 2~55 | 2~55 |

| 出口背压, pb/kPa | 40~129 | 79~114 | 89~113 | 91~105 |

| 加热功率Q/W | 蒸发热量Qevap/W | 加热性能ΔT | 蒸汽入口压力ps | ||||

|---|---|---|---|---|---|---|---|

| 实验值/℃ | 模拟值/℃ | 相对误差/% | 实验值/kPa | 模拟值/ kPa | 相对误差/% | ||

| 450 | 343 | 31.0 | 30.1 | 0.32 | 69.9 | 71.3 | -2.0 |

| 550 | 430 | 37.7 | 35.7 | 0.64 | 87.7 | 89.5 | -2.1 |

Table 2 Comparison of steady-state data between experiment[16] and numerical simulation in two-phase ejector

| 加热功率Q/W | 蒸发热量Qevap/W | 加热性能ΔT | 蒸汽入口压力ps | ||||

|---|---|---|---|---|---|---|---|

| 实验值/℃ | 模拟值/℃ | 相对误差/% | 实验值/kPa | 模拟值/ kPa | 相对误差/% | ||

| 450 | 343 | 31.0 | 30.1 | 0.32 | 69.9 | 71.3 | -2.0 |

| 550 | 430 | 37.7 | 35.7 | 0.64 | 87.7 | 89.5 | -2.1 |

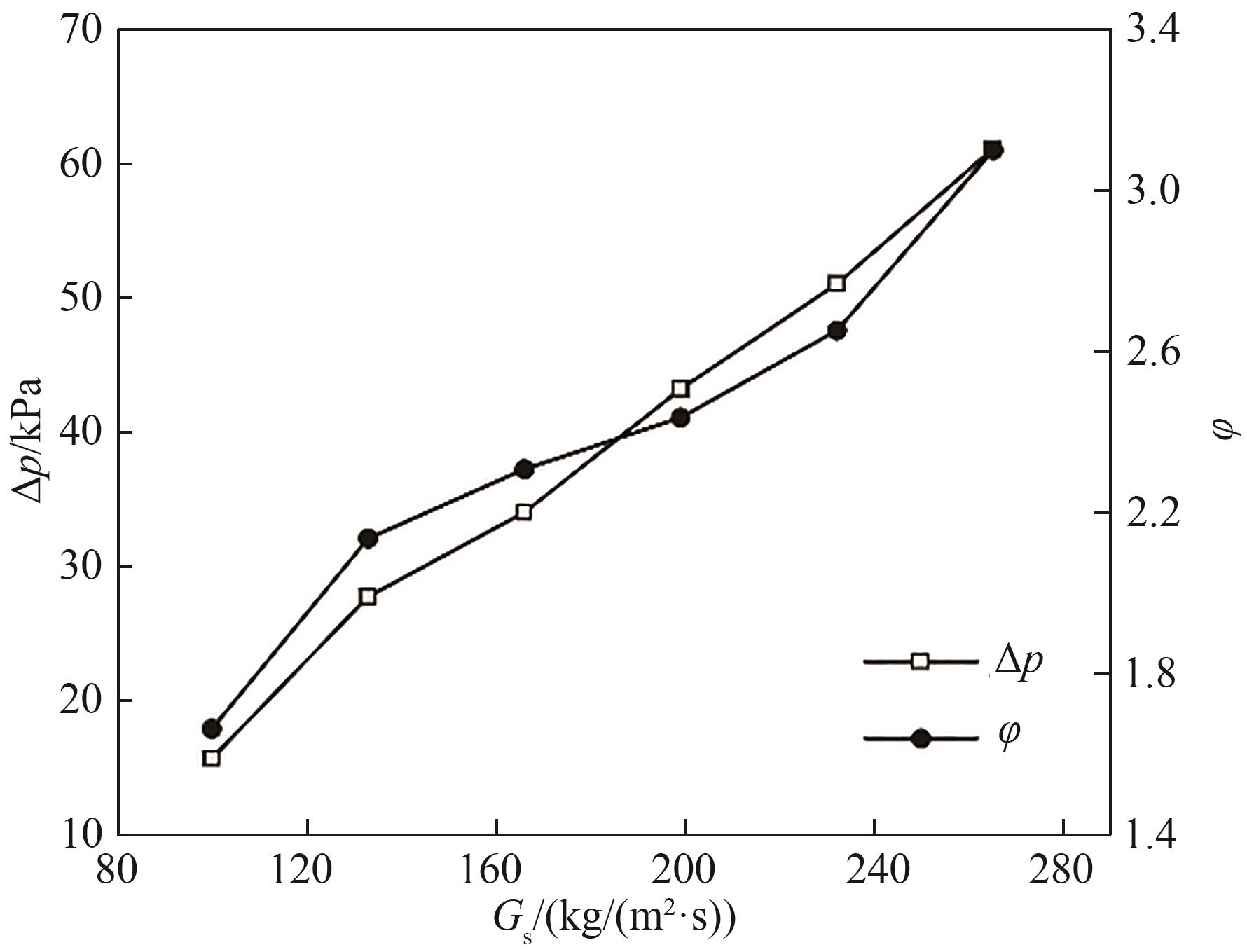

Fig.13 Pressure difference and pressure ratio between two sides of condensation shockwave at maximum discharge pressure and different steam mass flow rates

Fig.14 Pressure difference and pressure ratio between two sides of condensation shockwave at maximum discharge pressure and different water temperature

| 1 | 魏进家, 刘蕾, 杨小平. 面向高热流电子器件散热的环路热管研究进展[J]. 化工学报, 2023, 74(1): 60-73. |

| Wei J J, Liu L, Yang X P. Research progress of loop heat pipes for heat dissipation of high-heat-flux electronic devices[J]. CIESC Journal, 2023, 74(1): 60-73. | |

| 2 | Su Q, Chang S N, Zhao Y Y, et al. A review of loop heat pipes for aircraft anti-icing applications[J]. Applied Thermal Engineering, 2018, 130: 528-540. |

| 3 | Beygzadeh V, Khalilarya S, Mirzaee I. Thermodynamic comparison of two novel combined systems based on solar loop heat pipe evaporator[J]. Energy, 2020, 206: 118145. |

| 4 | Mueller C, Tsvetkov P. A review of heat-pipe modeling and simulation approaches in nuclear systems design and analysis[J]. Annals of Nuclear Energy, 2021, 160: 108393. |

| 5 | Adachi T, Fujita K, Nagai H. Numerical study of temperature oscillation in loop heat pipe[J]. Applied Thermal Engineering, 2019, 163: 114281. |

| 6 | Bai L Z, Tao Y B, Guo Y D, et al. Startup characteristics of a dual compensation chamber loop heat pipe with an extended bayonet tube[J]. International Journal of Heat and Mass Transfer, 2020, 148: 119066. |

| 7 | Chen X T, Qi C, Wang W, et al. Heat transfer limit resulting from heat leak in a cryogenic loop heat pipe[J]. Applied Thermal Engineering, 2021, 184: 116280. |

| 8 | Ji X B, Wang Y, Xu J L, et al. Experimental study of heat transfer and start-up of loop heat pipe with multiscale porous wicks[J]. Applied Thermal Engineering, 2017, 117: 782-798. |

| 9 | 熊康宁, 吴伟, 汪双凤. 平板形蒸发器环路热管的研究进展[J]. 化工进展, 2021, 40(10): 5388-5402. |

| Xiong K N, Wu W, Wang S F. Research and development of loop heat pipe with flat evaporator[J]. Chemical Industry and Engineering Progress, 2021, 40(10): 5388-5402. | |

| 10 | 王野, 纪献兵, 郑晓欢, 等. 多尺度复合毛细芯环路热管的传热特性[J]. 化工学报, 2015, 66(6): 2055-2061. |

| Wang Y, Ji X B, Zheng X H, et al. Heat transfer characteristics of loop heat pipe with modulated composite porous wick[J]. CIESC Journal, 2015, 66(6): 2055-2061. | |

| 11 | Li X Q, Zhu K, Li H L, et al. Performance comparison regarding loop heat pipes with different evaporator structures[J]. International Journal of Thermal Sciences, 2019, 136: 86-95. |

| 12 | Setyawan I, Putra N, Hakim I I. Experimental investigation of the operating characteristics of a hybrid loop heat pipe using pump assistance[J]. Applied Thermal Engineering, 2018, 130: 10-16. |

| 13 | Zhang H, Jiang C, Zhang Z K, et al. A study on thermal performance of a pump-assisted loop heat pipe with ammonia as working fluid[J]. Applied Thermal Engineering, 2020, 175: 115342. |

| 14 | 莫冬传, 邹冠生, 丁楠, 等. 双通道平板型环路热管的传热特性[J]. 化工学报, 2012, 63(S1): 114-118. |

| Mo D C, Zou G S, Ding N, et al. Heat transfer characteristics of flat loop heat pipe with bi-transport loops[J]. CIESC Journal, 2012, 63(S1): 114-118. | |

| 15 | Boo J H, Jung E G. Bypass line assisted start-up of a loop heat pipe with a flat evaporator[J]. Journal of Mechanical Science and Technology, 2009, 23(6): 1613-1619. |

| 16 | Liu L, Yang X P, Yuan B, et al. Experimental study of a novel loop heat pipe with a vapor-driven jet injector[J]. International Journal of Heat and Mass Transfer, 2021, 164: 120518. |

| 17 | 刘蕾, 袁博, 崔晨乙, 等. 耦合引射器和沸腾池的环路热管传热特性研究[J]. 西安交通大学学报, 2022, 56(7): 19-26. |

| Liu L, Yuan B, Cui C Y, et al. Heat transfer characteristics of loop heat pipe with injector and boiling pool[J]. Journal of Xi'an Jiaotong University, 2022, 56(7): 19-26. | |

| 18 | Liu L, Yang X P, Yuan B, et al. Investigation of temperature oscillations in a novel loop heat pipe with a vapor-driven jet injector[J]. International Journal of Heat and Mass Transfer, 2021, 179: 121672. |

| 19 | Yan J J, Shao S F, Liu J P, et al. Experiment and analysis on performance of steam-driven jet injector for district-heating system[J]. Applied Thermal Engineering, 2005, 25(8/9): 1153-1167. |

| 20 | Takeya Y, Miwa S, Hibiki T, et al. Application of steam injector to improved safety of light water reactors[J]. Progress in Nuclear Energy, 2015, 78: 80-100. |

| 21 | Chen J Y, Jarall S, Havtun H, et al. A review on versatile ejector applications in refrigeration systems[J]. Renewable and Sustainable Energy Reviews, 2015, 49: 67-90. |

| 22 | Zhang Y, Qu X H, Zhang G M, et al. Effect of non-condensable gas on the performance of steam-water ejector in a trigeneration system for hydrogen production: an experimental and numerical study[J]. International Journal of Hydrogen Energy, 2020, 45(39): 20266-20281. |

| 23 | Cattadori G, Galbiati L, Mazzocchi L, et al. A single-stage high pressure steam injector for next generation reactors: test results and analysis[J]. International Journal of Multiphase Flow, 1995, 21(4): 591-606. |

| 24 | Kwidzinski R. Experimental investigation of condensation wave structure in steam-water injector[J]. International Journal of Heat and Mass Transfer, 2015, 91: 594-601. |

| 25 | Grolmes M. Steam-water condensing-injector performance analysis with supersonic inlet vapor and convergent condensing section[D]. Argonne, IL, USA: University of University of Notre Dame, 1968. |

| 26 | Miwa S, Endo H, Moribe T, et al. Investigation of the supersonic steam injector operation mode[J]. Nuclear Engineering and Design, 2018, 334: 57-65. |

| 27 | Miwa S, Xu Y F, Hibiki T, et al. Pressure elevation of high-performance steam-water condensing-injector[J]. International Journal of Heat and Mass Transfer, 2021, 170: 120971. |

| 28 | Narayanan J K, Roy A, Ghosh P. Computational fluid dynamics studies on unstable oscillatory direct contact condensation of subsonic steam jets in water cross-flow[J]. Journal of Heat Transfer, 2020, 142(5): 051601. |

| 29 | Končar B, Mavko B. Modelling of low-pressure subcooled flow boiling using the RELAP5 code[J]. Nuclear Engineering and Design, 2003, 220(3): 255-273. |

| 30 | Zhou Y, Yang X P, Fu P F, et al. Numerical investigation on submerged steam jet condensation in subcooled water flow in a restricted channel with the presence of non-condensable gas[J]. International Journal of Thermal Sciences, 2021, 170: 107122. |

| 31 | Zhou Y, Liu J P, Mo Y L, et al. Numerical simulation on the direct contact condensation in a steam-water two-phase ejector with non-condensable gas[J]. International Journal of Thermal Sciences, 2023, 185: 108030. |

| 32 | Chen X B, Tian M C, Qu X H, et al. Numerical investigation on the interfacial characteristics of steam jet condensation in subcooled water flow in a restricted channel[J]. International Journal of Heat and Mass Transfer, 2019, 137: 908-921. |

| 33 | Xu Q, Liang L, She Y L, et al. Numerical investigation on thermal hydraulic characteristics of steam jet condensation in subcooled water flow in pipes[J]. International Journal of Heat and Mass Transfer, 2022, 184: 122277. |

| 34 | Hughmark G A. Mass and heat transfer from rigid spheres[J]. AIChE Journal, 1967, 13(6): 1219-1221. |

| 35 | Lopez de Bertodano M A. Two fluid model for two-phase turbulent jets[J]. Nuclear Engineering and Design, 1998, 179(1): 65-74. |

| 36 | Shah A, Chughtai I R, Inayat M H. Experimental and numerical analysis of steam jet pump[J]. International Journal of Multiphase Flow, 2011, 37(10): 1305-1314. |

| 37 | Ma H J, Zhao H X, Wang L, et al. Modeling and investigation of a steam-water injector[J]. Energy Conversion and Management, 2017, 151: 170-178. |

| 38 | Radovskii I S. Speed of sound in two-phase vapor-liquid systems[J]. Journal of Applied Mechanics and Technical Physics, 1970, 11(5): 778-784. |

| 39 | Kieffer S W. Sound speed in liquid-gas mixtures: water-air and water-steam[J]. Journal of Geophysical Research, 1977, 82(20): 2895-2904. |

| [1] | Bidan ZHAO, Yiyang DAI, Junwu WANG, Yongmin ZHANG. CFD-DEM-IBM simulation on force characteristic on inclined-surface baffles in fluidized beds [J]. CIESC Journal, 2024, 75(1): 255-267. |

| [2] | Yizhou CUI, Chengxiang LI, Linxiao ZHAI, Shuyu LIU, Xiaogang SHI, Jinsen GAO, Xingying LAN. Comparative study on the flow and mass transfer characteristics of sub-millimeter bubbles and conventional bubbles in gas-liquid two-phase flow [J]. CIESC Journal, 2024, 75(1): 197-210. |

| [3] | Junnan WANG, Chengxiang HE, Zhongdong WANG, Chunying ZHU, Youguang MA, Taotao FU. Numerical simulation of homogeneous mixing in T-junction micromixers [J]. CIESC Journal, 2024, 75(1): 242-254. |

| [4] | Xiaoyang LI, Dong LI, Minglei TAO, Zhifu ZHOU, Lingyi ZHANG, Lizheng SU, Tianning ZHANG, Zhi LI, Bin CHEN. Experimental study on heat transfer characteristics of multi nozzle spray cooling surface [J]. CIESC Journal, 2024, 75(1): 231-241. |

| [5] | Yijiang WANG, Li SUN, Menghan LIU, Jinhong YANG, Guoyuan WANG. Optimization on parameter of plate-fin-and-tube air cooler in mines based on response surface method [J]. CIESC Journal, 2024, 75(1): 279-291. |

| [6] | Shaohua ZHOU, Feilong ZHAN, Guoliang DING, Hao ZHANG, Yanpo SHAO, Yantao LIU, Zheming GAO. Experimental study of flow noise in short tube throttle valve and noise reduction measures [J]. CIESC Journal, 2023, 74(S1): 113-121. |

| [7] | Wei SU, Dongxu MA, Xu JIN, Zhongyan LIU, Xiaosong ZHANG. Visual experimental study on effect of surface wettability on frost propagation characteristics [J]. CIESC Journal, 2023, 74(S1): 122-131. |

| [8] | Zhanyu YE, He SHAN, Zhenyuan XU. Performance simulation of paper folding-like evaporator for solar evaporation systems [J]. CIESC Journal, 2023, 74(S1): 132-140. |

| [9] | Shuangxing ZHANG, Fangchen LIU, Yifei ZHANG, Wenjing DU. Experimental study on phase change heat storage and release performance of R-134a pulsating heat pipe [J]. CIESC Journal, 2023, 74(S1): 165-171. |

| [10] | Yifei ZHANG, Fangchen LIU, Shuangxing ZHANG, Wenjing DU. Performance analysis of printed circuit heat exchanger for supercritical carbon dioxide [J]. CIESC Journal, 2023, 74(S1): 183-190. |

| [11] | Aiqiang CHEN, Yanqi DAI, Yue LIU, Bin LIU, Hanming WU. Influence of substrate temperature on HFE7100 droplet evaporation process [J]. CIESC Journal, 2023, 74(S1): 191-197. |

| [12] | Mingxi LIU, Yanpeng WU. Simulation analysis of effect of diameter and length of light pipes on heat transfer [J]. CIESC Journal, 2023, 74(S1): 206-212. |

| [13] | Zhiguo WANG, Meng XUE, Yushuang DONG, Tianzhen ZHANG, Xiaokai QIN, Qiang HAN. Numerical simulation and analysis of geothermal rock mass heat flow coupling based on fracture roughness characterization method [J]. CIESC Journal, 2023, 74(S1): 223-234. |

| [14] | Jiahao SONG, Wen WANG. Study on coupling operation characteristics of Stirling engine and high temperature heat pipe [J]. CIESC Journal, 2023, 74(S1): 287-294. |

| [15] | Siyu ZHANG, Yonggao YIN, Pengqi JIA, Wei YE. Study on seasonal thermal energy storage characteristics of double U-shaped buried pipe group [J]. CIESC Journal, 2023, 74(S1): 295-301. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||