CIESC Journal ›› 2024, Vol. 75 ›› Issue (11): 4254-4263.DOI: 10.11949/0438-1157.20240808

• Catalysis, kinetics and reactors • Previous Articles Next Articles

Baolin HOU1( ), Ruoxi HAN1,2, Xiaodong WANG1(

), Ruoxi HAN1,2, Xiaodong WANG1( )

)

Received:2024-07-17

Revised:2024-09-25

Online:2024-12-26

Published:2024-11-25

Contact:

Baolin HOU, Xiaodong WANG

通讯作者:

侯宝林,王晓东

作者简介:侯宝林(1979—),男,博士,研究员,blhou@dicp.ac.cn

基金资助:CLC Number:

Baolin HOU, Ruoxi HAN, Xiaodong WANG. Process of monopropellant flow and catalytic decomposition reaction in micro/nano pores of catalyst[J]. CIESC Journal, 2024, 75(11): 4254-4263.

侯宝林, 韩若曦, 王晓东. 催化剂微纳孔道内液体推进剂流动与分解反应过程研究[J]. 化工学报, 2024, 75(11): 4254-4263.

Add to citation manager EndNote|Ris|BibTeX

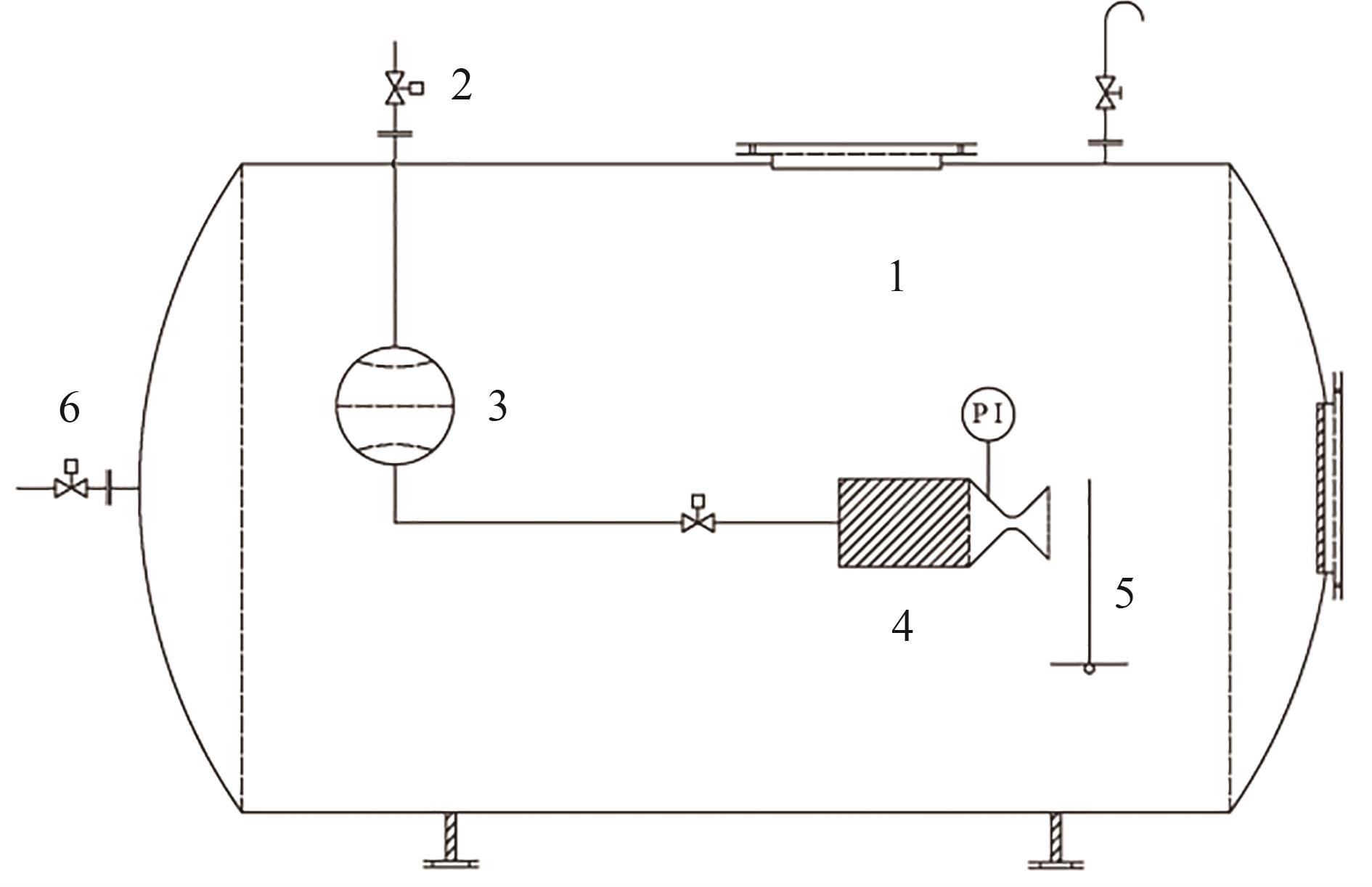

Fig.4 Schematic diagram of monopropellant thruster ignition test chamber1—vacuum chamber; 2—high pressure nitrogen valve; 3—propellant storage tank; 4—monopropellant; 5—thrust force test; 6—vacuum pump inlet

| 1 | Hwang C H, Lee S N, Baek S W, et al. Effects of catalyst bed failure on thermochemical phenomena for a hydrazine monopropellant thruster using Ir/Al2O3 catalysts[J]. Industrial & Engineering Chemistry Research, 2012, 51(15): 5382-5393. |

| 2 | Hou B L, Wang X D, Li T, et al. Steady-state behavior of liquid fuel hydrazine decomposition in packed bed[J]. AIChE Journal, 2015, 61(3): 1064-1080. |

| 3 | Spores R, Masse R, Kimbrel S, et al. GPIM AF-M315E propulsion system[C]//51st AIAA/SAE/ASEE Joint Propulsion Conference. Reston, Virginia: AIAA, 2015: 3753. |

| 4 | Chambreau S D, Popolan-Vaida D M, Kostko O, et al. Thermal and catalytic decomposition of 2-hydroxyethylhydrazine and 2-hydroxyethylhydrazinium nitrate ionic liquid[J]. The Journal of Physical Chemistry A, 2022, 126(3): 373-394. |

| 5 | Koerner M. Recent developments in aircraft emergency power[C]//35th Intersociety Energy Conversion Engineering Conference and Exhibit. Reston, Virginia: AIAA, 2000: 2802. |

| 6 | Masse R K, Glassy B A, Spores R A, et al. Hydrazine-based green monopropellant blends[C]//AIAA SCITECH 2024 Forum. Reston, Virginia: AIAA, 2024: 1619. |

| 7 | Thomas J C, Rodriguez F A, Teitge D S, et al. Lab-scale ballistic and safety property investigations of LMP-103S[J]. Combustion and Flame, 2023, 253: 112810. |

| 8 | Esparza A A, Chambreau S D, Vaghjiani G L, et al. Two-stage decomposition of 2-hydroxyethylhydrazinium nitrate (HEHN)[J]. Combustion and Flame, 2020, 220: 1-6. |

| 9 | 杨敏, 曹炳阳. 微纳通道中牛顿流体毛细流动的研究进展[J]. 科学通报, 2016, 61(14): 1574-1584. |

| Yang M, Cao B Y. Advances of capillary filling of Newtonian fluids in micro- and nanochannels[J]. Chinese Science Bulletin, 2016, 61(14): 1574-1584. | |

| 10 | Ye G H, Wang H Z, Zhou X G, et al. Optimizing catalyst pore network structure in the presence of deactivation by coking[J]. AIChE Journal, 2019, 65(10): e16687. |

| 11 | Kerr D H, Karagozian A R, Bilyeu D, et al. Nondeterministic analysis of monopropellant catalyst bed model[J]. Journal of Propulsion and Power, 2021, 37(1): 126-138. |

| 12 | Sun D C, Liu J, Xiang W B. Numerical simulation of the transient process of monopropellant rocket engines[J]. Aerospace Science and Technology, 2020, 103: 105921. |

| 13 | Hwang C H, Baek S W, Cho S J. Experimental investigation of decomposition and evaporation characteristics of HAN-based monopropellants[J]. Combustion and Flame, 2014, 161(4): 1109-1116. |

| 14 | Walls P L L, Dequidt G, Bird J C. Capillary displacement of viscous liquids[J]. Langmuir, 2016, 32(13): 3186-3190. |

| 15 | Fries N, Dreyer M. An analytic solution of capillary rise restrained by gravity[J]. Journal of Colloid and Interface Science, 2008, 320(1): 259-263. |

| 16 | Bird B R, Stewart W E, Lightfoot E N. Transport Phenomena[M]. 2nd ed. New York: John Wiley & Sons, Inc., 2002:46. |

| 17 | Levenspiel O. Chemical Reaction Engineering [M]. 3rd ed. New York: John Wiley & Sons, Inc., 1999:105. |

| 18 | Washburn E W. The dynamics of capillary flow[J]. Physical Review, 1921, 17(3): 273-283. |

| 19 | Figliuzzi B, Buie C R. Rise in optimized capillary channels[J]. Journal of Fluid Mechanics, 2013, 731: 142-161. |

| 20 | Han A P, Mondin G, Hegelbach N G, et al. Filling kinetics of liquids in nanochannels as narrow as 27 nm by capillary force[J]. Journal of Colloid and Interface Science, 2006, 293(1): 151-157. |

| 21 | Wu P K, Ramakrishnan T S, Zhang H, et al. Closed-end capillary rise—an experimental study[J]. AIChE Journal, 2020, 66(6): e16964. |

| 22 | Wood J, Gladden L F. Modelling diffusion and reaction accompanied by capillary condensation using three-dimensional pore networks (Part 1): Fickian diffusion and pseudo-first-order reaction kinetics[J]. Chemical Engineering Science, 2002, 57(15): 3033-3045. |

| 23 | Wood J, Gladden L F, Keil F J. Modelling diffusion and reaction accompanied by capillary condensation using three-dimensional pore networks (Part 2): Dusty gas model and general reaction kinetics[J]. Chemical Engineering Science, 2002, 57(15): 3047-3059. |

| 24 | 吕同富, 康兆敏, 方秀男. 数值计算方法[M]. 北京: 清华大学出版社, 2008: 281. |

| Lyu T F, Kang Z M, Fang X N. Numerical Computation Method[M]. Beijing: Tsinghua University Press, 2008: 281. | |

| 25 | Soares Neto T G, Dias F F, Cobo A J G, et al. Evolution of textural properties and performance of Ir/Al2O3 catalysts during hydrazine catalytic decomposition in a 2N satellite thruster[J]. Chemical Engineering Journal, 2011, 173(1): 220-225. |

| 26 | Heo S, Jo S, Yun Y, et al. Effect of dual-catalytic bed using two different catalyst sizes for hydrogen peroxide thruster[J]. Aerospace Science and Technology, 2018, 78: 26-32. |

| 27 | Wilhelm M, Negri M, Ciezki H, et al. Preliminary tests on thermal ignition of ADN-based liquid monopropellants[J]. Acta Astronautica, 2019, 158: 388-396. |

| 28 | Negri M, Lauck F. Hot firing tests of a novel green hypergolic propellant in a thruster[J]. Journal of Propulsion and Power, 2022, 38(3): 467-477. |

| 29 | 吴越. 应用催化基础[M]. 北京: 化学工业出版社, 2009: 243. |

| Wu Y. Basis of Applied Catalysis[M]. Beijing: Chemical Industry Press, 2009: 243. | |

| 30 | Gugulothu R, Macharla A K, Chatragadda K, et al. Catalytic decomposition mechanism of aqueous ammonium dinitramide solution elucidated by thermal and spectroscopic methods[J]. Thermochimica Acta, 2020, 686: 178544. |

| [1] | Zhengang ZHAO, Mengyao ZHOU, Dian JIN, Dacheng ZHANG. Study on direct methanol fuel cell performance modification based on foam carbon diffusion layer [J]. CIESC Journal, 2024, 75(S1): 259-266. |

| [2] | Angran ZHAO, Yongqiang HAN, Zhipeng WANG, Pengfei LI, Yawei XU, Huiling TONG. Experimental study on simultaneous desulfurization and denitrification of red mud at low temperature [J]. CIESC Journal, 2024, 75(S1): 276-282. |

| [3] | Huanjuan ZHAO, Yingxin BAO, Kang YU, Jing LIU, Xinming QIAN. Quantitative experimental study on detonation instability of multi-component [J]. CIESC Journal, 2024, 75(S1): 339-348. |

| [4] | Yan LI, Lijun ZHENG, Enyong ZHANG, Yunfei WANG. Model and experimental study of fluid permeation characteristics in a deep-water oil and gas tube [J]. CIESC Journal, 2024, 75(S1): 118-125. |

| [5] | Yong YANG, Zixuan ZU, Yukun LI, Dongliang WANG, Zongliang FAN, Huairong ZHOU. Numerical simulation of CO2 absorption by alkali liquor in T-junction cylindrical microchannels [J]. CIESC Journal, 2024, 75(S1): 135-142. |

| [6] | Yachao LIU, Xiaojie TAN, Xudong LI, Rui WANG, Hui WANG, Xuan HAN, Qingshan ZHAO. Synthesis of efficient cobalt carbonate nanosheets based on DES for oxygen evolution reaction [J]. CIESC Journal, 2024, 75(9): 3320-3328. |

| [7] | Mengting ZHANG, Shulin WANG, Xi SANG, Xinghao YUAN, Gang XU. Artificial Cu-TM1459 metalloenzyme catalyzes asymmetric Michael addition reaction [J]. CIESC Journal, 2024, 75(9): 3255-3265. |

| [8] | Ran WANG, Huan WANG, Xiaoyun XIONG, Huimin GUAN, Yunfeng ZHENG, Cailin CHEN, Yucai QIN, Lijuan SONG. Visual analysis of mass transfer enhanced active site utilization efficiency of FCC catalyst [J]. CIESC Journal, 2024, 75(9): 3198-3209. |

| [9] | Xinyi LUO, Qiang XU, Yonglu SHE, Tengfei NIE, Liejin GUO. Study on bubble dynamic characteristics and mass transfer mechanism in photoelectrochemical water splitting for hydrogen production [J]. CIESC Journal, 2024, 75(9): 3083-3093. |

| [10] | Zichi YANG, Bingqi XIE, Ruixin SHI, Hong LEI, Chen CHEN, Caijin ZHOU, Jisong ZHANG. Research progress on efficient and safe gas-liquid mass transfer and reaction processes in tube-in-tube reactor [J]. CIESC Journal, 2024, 75(9): 3011-3027. |

| [11] | Fangming LYU, Zhiming BAO, Bowen WANG, Kui JIAO. Investigation on impact of gas diffusion layer intrusion into channel on water management in fuel cell [J]. CIESC Journal, 2024, 75(8): 2929-2938. |

| [12] | Shuaiqi ZHAO, Rui ZHANG, Han HUANG, Kunpeng ZHAO, Bofeng BAI. Inhibition of water-gas shift reaction on coal gasification in supercritical water [J]. CIESC Journal, 2024, 75(8): 2960-2969. |

| [13] | Jingru HUANG, Jiaxuan CHEN, Qunfeng ZHANG, Jin RUAN, Lai ZHU, Guanghua YE, Xinggui ZHOU. Effect of ZSM-5 zeolite structure on the reaction performance of benzene alkylation: a computational study [J]. CIESC Journal, 2024, 75(7): 2544-2555. |

| [14] | Jinrui YANG, Hongfei ZHENG, Xinglong MA, Rihui JIN, Shen LIANG. Study on two-stage stacked humidification-dehumidification desalination device [J]. CIESC Journal, 2024, 75(7): 2446-2454. |

| [15] | Juan JIA, Yang YANG, Xun ZHU, Dingding YE, Rong CHEN, Qiang LIAO. Hydrogel-based drug releasing system with external electricity stimulation for wound dressing [J]. CIESC Journal, 2024, 75(7): 2700-2708. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||