CIESC Journal ›› 2024, Vol. 75 ›› Issue (11): 4264-4273.DOI: 10.11949/0438-1157.20241148

• Catalysis, kinetics and reactors • Previous Articles Next Articles

Lin ZHOU( ), Bin YE, Xinyi SUN, Lingxin KONG, Yan XU, Yujun ZHAO(

), Bin YE, Xinyi SUN, Lingxin KONG, Yan XU, Yujun ZHAO( )

)

Received:2024-10-17

Revised:2024-11-19

Online:2024-12-26

Published:2024-11-25

Contact:

Yujun ZHAO

通讯作者:

赵玉军

作者简介:周琳(2001—),女,硕士研究生,zhou_linlin518@tju.edu.cn

CLC Number:

Lin ZHOU, Bin YE, Xinyi SUN, Lingxin KONG, Yan XU, Yujun ZHAO. Study on the catalytic hydrogenation of maleic anhydride by mesoporous carbon-supported Ni catalyst[J]. CIESC Journal, 2024, 75(11): 4264-4273.

周琳, 叶斌, 孙心怡, 孔令鑫, 徐艳, 赵玉军. 介孔碳负载Ni催化剂催化顺酐加氢反应研究[J]. 化工学报, 2024, 75(11): 4264-4273.

Add to citation manager EndNote|Ris|BibTeX

| 催化剂 | 反应 温度/℃ | 氢气 压力/MPa | MA 转化率/% | SA 选择性/% |

|---|---|---|---|---|

| 40Ni/MC | 30 | 1 | 20.8 | 100.0 |

| 60 | 1 | 80.1 | 100.0 | |

| 90 | 1 | 100.0 | 100.0 | |

| 60 | 2 | 86.9 | 100.0 | |

| 60 | 3 | 89.1 | 100.0 | |

| 60 | 4 | 96.5 | 100.0 |

Table 1 Effect of reaction temperature and hydrogen pressure on the hydrogenation performance of maleic anhydride

| 催化剂 | 反应 温度/℃ | 氢气 压力/MPa | MA 转化率/% | SA 选择性/% |

|---|---|---|---|---|

| 40Ni/MC | 30 | 1 | 20.8 | 100.0 |

| 60 | 1 | 80.1 | 100.0 | |

| 90 | 1 | 100.0 | 100.0 | |

| 60 | 2 | 86.9 | 100.0 | |

| 60 | 3 | 89.1 | 100.0 | |

| 60 | 4 | 96.5 | 100.0 |

| 理论镍负载量/%(质量) | ICP-OES测定镍负载量/%(质量) |

|---|---|

| 10 | 9.9 |

| 20 | 20.4 |

| 30 | 29.8 |

| 40 | 39.4 |

| 50 | 50.2 |

Table 2 The real Ni loadings of the catalysts from the results of ICP-OES

| 理论镍负载量/%(质量) | ICP-OES测定镍负载量/%(质量) |

|---|---|

| 10 | 9.9 |

| 20 | 20.4 |

| 30 | 29.8 |

| 40 | 39.4 |

| 50 | 50.2 |

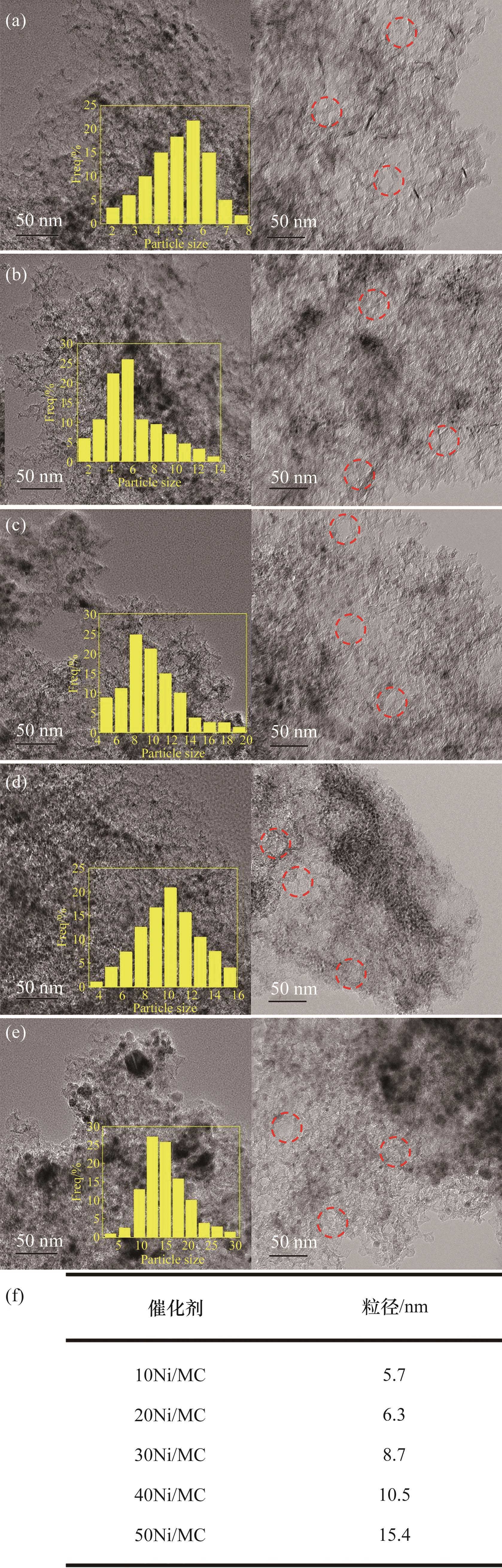

Fig.6 TEM images of catalysts with different nickel loadings (a) 10Ni/MC; (b) 20Ni/MC; (c) 30Ni/MC; (d) 40Ni/MC; (e) 50Ni/MC; (f) average particle size of yNi/MC catalysts

| Catalyst | SBET①/ (m2/g) | Vpore①/ (cm3/g) | Dpore①/nm | Metal dispersion②/% |

|---|---|---|---|---|

| MC | 974 | 3.4 | 11.8 | — |

| 10Ni/MC | 905 | 1.8 | 8.2 | 7.5 |

| 20Ni/MC | 825 | 1.6 | 8.3 | 6.8 |

| 30Ni/MC | 718 | 1.5 | 8.5 | 5.5 |

| 40Ni/MC | 654 | 1.4 | 8.8 | 4.3 |

| 50Ni/MC | 560 | 1.2 | 8.9 | 3.7 |

Table 3 Textural properties of Ni/MC catalysts with different content of Ni

| Catalyst | SBET①/ (m2/g) | Vpore①/ (cm3/g) | Dpore①/nm | Metal dispersion②/% |

|---|---|---|---|---|

| MC | 974 | 3.4 | 11.8 | — |

| 10Ni/MC | 905 | 1.8 | 8.2 | 7.5 |

| 20Ni/MC | 825 | 1.6 | 8.3 | 6.8 |

| 30Ni/MC | 718 | 1.5 | 8.5 | 5.5 |

| 40Ni/MC | 654 | 1.4 | 8.8 | 4.3 |

| 50Ni/MC | 560 | 1.2 | 8.9 | 3.7 |

| Catalyst | Temperature/℃ | Peak area×103 | ||

|---|---|---|---|---|

| α | β | α | β | |

| MC | — | 491.9 | — | 102.9 |

| 10Ni/MC | 246.2 | 492.7 | 3.5 | 134.1 |

| 20Ni/MC | 234.3 | 500.9 | 10.5 | 158.4 |

| 30Ni/MC | 243.0 | 495.6 | 19.7 | 196.2 |

| 40Ni/MC | 223.7 | 492.3 | 23.0 | 228.7 |

| 50Ni/MC | 213.4 | 494.0 | 17.9 | 254.7 |

Table 4 H2-TPR curve fitting results of catalysts with different nickel loads

| Catalyst | Temperature/℃ | Peak area×103 | ||

|---|---|---|---|---|

| α | β | α | β | |

| MC | — | 491.9 | — | 102.9 |

| 10Ni/MC | 246.2 | 492.7 | 3.5 | 134.1 |

| 20Ni/MC | 234.3 | 500.9 | 10.5 | 158.4 |

| 30Ni/MC | 243.0 | 495.6 | 19.7 | 196.2 |

| 40Ni/MC | 223.7 | 492.3 | 23.0 | 228.7 |

| 50Ni/MC | 213.4 | 494.0 | 17.9 | 254.7 |

| Catalyst | Temperature/℃ | Peak area | ||||

|---|---|---|---|---|---|---|

| α | β | γ | α | β | γ | |

| 20Ni/MC | 112.6 | 259.1 | 377.8 | 8.5 | 13.5 | 15.5 |

| 30Ni/MC | 114.3 | 263.1 | 378.0 | 14.4 | 27.8 | 34.3 |

| 40Ni/MC | 114.4 | 263.2 | 382.2 | 21.6 | 26.8 | 30.9 |

| 50Ni/MC | 116.7 | 271.8 | 378.5 | 20.3 | 41.3 | 63.4 |

Table 5 C2H4-TPD curve fitting results of catalysts with different nickel loads

| Catalyst | Temperature/℃ | Peak area | ||||

|---|---|---|---|---|---|---|

| α | β | γ | α | β | γ | |

| 20Ni/MC | 112.6 | 259.1 | 377.8 | 8.5 | 13.5 | 15.5 |

| 30Ni/MC | 114.3 | 263.1 | 378.0 | 14.4 | 27.8 | 34.3 |

| 40Ni/MC | 114.4 | 263.2 | 382.2 | 21.6 | 26.8 | 30.9 |

| 50Ni/MC | 116.7 | 271.8 | 378.5 | 20.3 | 41.3 | 63.4 |

| Catalyst | Temperature/℃ | Peak area | ||

|---|---|---|---|---|

| α | β | α | β | |

| MC | 111.8 | 472.6 | — | — |

| 10Ni/MC | 93.3 | 475.0 | 240.8 | 2694.5 |

| 20Ni/MC | 127.7 | 484.2 | 489.6 | 2502.6 |

| 30Ni/MC | 126.4 | 504.4 | 509.1 | 3090.5 |

| 40Ni/MC | 114.9 | 494.6 | 534.8 | 3701.3 |

| 50Ni/MC | 114.2 | 521.1 | 519.8 | 3852.4 |

Table 6 H2-TPD curve fitting results of catalysts with different nickel loads

| Catalyst | Temperature/℃ | Peak area | ||

|---|---|---|---|---|

| α | β | α | β | |

| MC | 111.8 | 472.6 | — | — |

| 10Ni/MC | 93.3 | 475.0 | 240.8 | 2694.5 |

| 20Ni/MC | 127.7 | 484.2 | 489.6 | 2502.6 |

| 30Ni/MC | 126.4 | 504.4 | 509.1 | 3090.5 |

| 40Ni/MC | 114.9 | 494.6 | 534.8 | 3701.3 |

| 50Ni/MC | 114.2 | 521.1 | 519.8 | 3852.4 |

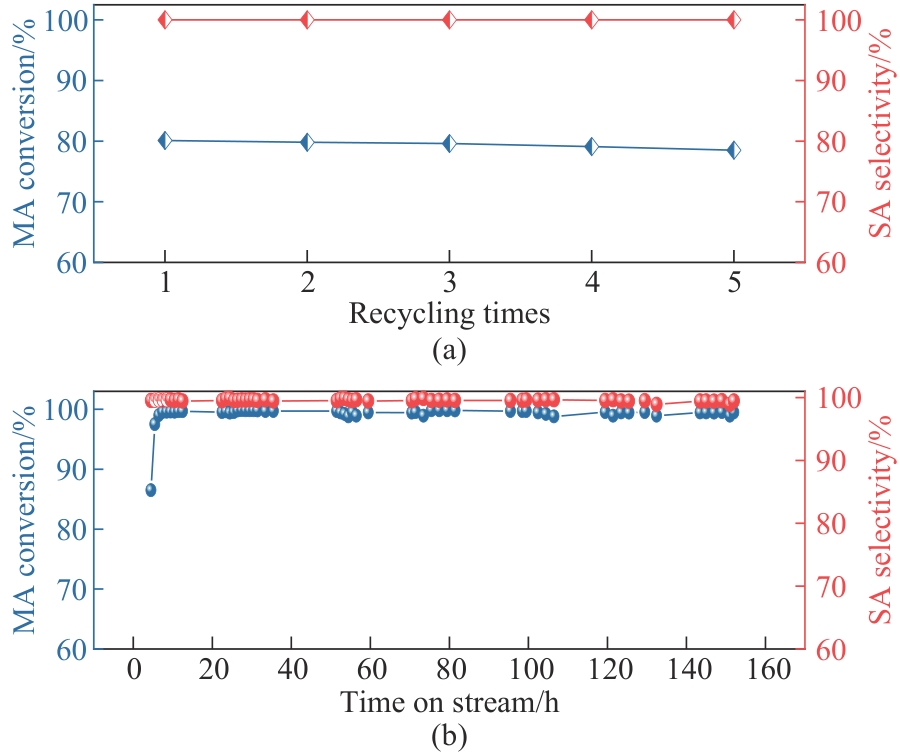

Fig.11 (a) Performances of 40Ni/MC catalyst in batch kettle reactor (reaction conditions: 60℃, 1 MPa, WHSV 8.3 h-1); (b) Performances of 40Ni/MC catalyst in fixed bed reactor (reaction conditions: 60℃, 1 MPa, WHSV 2 h-1, H2/MA=20)

| 1 | 安思源, 朱晶莹, 卢滇楠, 等. 酶催化合成高分子量聚丁二酸丁二醇酯(PBS)及其材料特性[J]. 化工学报, 2013, 64(5): 1855-1861. |

| An S Y, Zhu J Y, Lu D N, et al. Lipase-catalyzed synthesis and characterization of high-molecular-weight PBS[J]. CIESC Journal, 2013, 64(5): 1855-1861. | |

| 2 | Cukalovic A, Stevens C V. Feasibility of production methods for succinic acid derivatives: a marriage of renewable resources and chemical technology[J]. Biofuels, Bioproducts and Biorefining, 2008, 2(6): 505-529. |

| 3 | 陈建兵, 廖克俭, 佟明友, 等. 顺酐加氢制备丁二酸酐的研究[J]. 石油化工高等学校学报, 2010, 23(4): 29-32. |

| Chen J B, Liao K J, Tong M Y, et al. Maleic anhydride hydrogenated to succinic anhydride[J]. Journal of Petrochemical Universities, 2010, 23(4): 29-32. | |

| 4 | 钟驭涛, 尚长宇, 王言东, 等. 利用酵母细胞工厂合成丁二酸的研究进展[J]. 生物工程学报, 2024, 40(8): 2644-2665. |

| Zhong Y T, Shang C Y, Wang Y D, et al. Advances in synthesis of succinic acid using yeast cell factories[J]. Chinese Journal of Biotechnology, 2024, 40(8): 2644-2665. | |

| 5 | Pallassana V, Neurock M. First-principles periodic density functional study of the hydrogenation of maleic anhydride to succinic anhydride over palladium(111)[J]. The Journal of Physical Chemistry B, 2000, 104(40): 9449-9459. |

| 6 | Wang C L, Zhang Y, Li H T, et al. Ni@C nanocatalysts for the highly efficient hydrogenation of maleic anhydride to γ-butyrolactone[J]. Molecular Catalysis, 2024, 556: 113866. |

| 7 | 房畅, 吕清林, 韩冰, 等. 顺酐加氢催化剂的研究进展[J]. 石油化工, 2023, 52(5): 720-727. |

| Fang C, Lyu Q L, Han B, et al. Research progress of maleic anhydride hydrogenation catalyst[J]. Petrochemical Technology, 2023, 52(5): 720-727. | |

| 8 | 黄国强. 负载型镍基催化剂的制备及加氢性能研究[D]. 西安: 西安石油大学, 2021. |

| Huang G Q. Preparation and hydrogenation performance of supported nickel-based catalyst[D]. Xi'an: Xi'an Shiyou University, 2021. | |

| 9 | Chen M R, Meng X, Liu N W, et al. Low supported nickel-cobalt catalyst for hydrogenation of maleic anhydride[J]. Fuel, 2023, 331: 125520. |

| 10 | 梁旭, 李丰, 魏灵朝, 等. 顺酐加氢连续生产丁二酸酐中试工艺研究[J]. 化学与生物工程, 2018, 35(10): 56-59. |

| Liang X, Li F, Wei L C, et al. Pilot process of continuous production of succinic anhydride by hydrogenation of maleic anhydride[J]. Chemistry & Bioengineering, 2018, 35(10): 56-59. | |

| 11 | Cai J X, Zhu J X, Zuo L, et al. Effect of surface acidity/basicity on the selective hydrogenation of maleic anhydride to succinic anhydride over supported nickel catalysts[J]. Catalysis Communications, 2018, 110: 93-96. |

| 12 | Zhao Y X, Qin X Q, Hou X C, et al. Preparation, characterization and properties of selective hydrogenation on Ni-based catalysts[J]. Acta Physico-Chimica Sinica, 2003, 19(5): 450-454. |

| 13 | Tian F P, Zhang M J, Zhang X C, et al. Porous carbon-encapsulated Ni nanocatalysts for selective catalytic hydrogenation of cinnamaldehyde to hydrocinnamaldehyde[J]. Journal of Materials Science, 2022, 57(5): 3168-3182. |

| 14 | Zhou Y F, Chen Q L, Wang Q, et al. Selective hydrogenation of maleic anhydride to succinic anhydride over nickel catalyst supported on carbon microspheres[J]. China Petroleum Processing & Petrochemical Technology, 2021, 23(4): 75-82. |

| 15 | Wang Y, Sang S Y, Zhu W, et al. CuNi@C catalysts with high activity derived from metal-organic frameworks precursor for conversion of furfural to cyclopentanone[J]. Chemical Engineering Journal, 2016, 299: 104-111. |

| 16 | 姚雅琪. 凝聚相脂肪酸酯加氢铜基催化剂的制备与调控[D]. 天津: 天津大学, 2020. |

| Yao Y Q. Preparation and regulation of copper-based catalyst for hydrogenation of fatty acid esters in condensed phase[D]. Tianjin: Tianjin University, 2020. | |

| 17 | 曹萌. 草酸酯加氢制乙醇负载型铁基催化剂的研究[D]. 天津: 天津大学, 2022. |

| Cao M. Study on supported iron-based catalyst for hydrogenation of oxalate to ethanol[D]. Tianjin: Tianjin University, 2022. | |

| 18 | 杨文龙, 赵玉军, 王胜平, 等. 铜硅催化剂中层状硅酸铜的形成过程[J]. 化学工业与工程, 2016, 33(1): 1-5. |

| Yang W L, Zhao Y J, Wang S P, et al. Formation of copper phyllosilicate in silica supported copper catalyst[J]. Chemical Industry and Engineering, 2016, 33(1): 1-5. | |

| 19 | Tan J J, Xia X L, Cui J L, et al. Efficient tuning of surface nickel species of the Ni-phyllosilicate catalyst for the hydrogenation of maleic anhydride[J]. The Journal of Physical Chemistry C, 2019, 123(15): 9779-9787. |

| 20 | Sheng Q, Wang Y Y, Zhang P F, et al. Highly dispersed Ni on defective carbon with metal-support interaction for efficient and selective cinnamaldehyde hydrogenation[J]. Applied Surface Science, 2024, 666: 160369. |

| 21 | Campisi S, Chan-Thaw C E, Villa A. Understanding heteroatom-mediated metal-support interactions in functionalized carbons: a perspective review[J]. Applied Sciences, 2018, 8(7): 1159. |

| 22 | Zhuang J G, Yan S Y, Zhang P, et al. Regulating the states of Ni species by controlling the silanols of MCM-41 support to promote the hydrogenation of maleic anhydride[J]. Fuel, 2023, 335: 127030. |

| 23 | 张因, 赵丽丽, 张鸿喜, 等. 载体对镍基催化剂顺酐液相加氢性能的影响[J]. 化工学报, 2015, 66(7): 2505-2513. |

| Zhang Y, Zhao L L, Zhang H X, et al. Effect of support on catalytic performance of nickel-based catalysts used for liquid phase hydrogenation of maleic anhydride[J]. CIESC Journal, 2015, 66(7): 2505-2513. | |

| 24 | Li P F, Huang H J, Wang Z, et al. Reductive amination of n-hexanol to n-hexylamine over Ni-Ce/γ-Al2O3 catalysts[J]. Frontiers of Chemical Science and Engineering, 2023, 17(1): 82-92. |

| 25 | Feng Y H, Yin H B, Wang A L, et al. Selective hydrogenation of maleic anhydride to succinic anhydride catalyzed by metallic nickel catalysts[J]. Applied Catalysis A: General, 2012, 425: 205-212. |

| 26 | Regenhardt S A, Meyer C I, Garetto T F, et al. Selective gas phase hydrogenation of maleic anhydride over Ni-supported catalysts: effect of support on the catalytic performance[J]. Applied Catalysis A: General, 2012, 449: 81-87. |

| 27 | Choy J H, Yoon J B, Jung H, et al. Structural evolution of SiO2-ZrO2 nano-sol intercalated clays upon pillaring reaction[J]. Journal of Materials Chemistry, 2003, 13(3): 557-562. |

| 28 | Baldovino-Medrano V G, Niño-Celis V, Isaacs Giraldo R. Systematic analysis of the nitrogen adsorption-desorption isotherms recorded for a series of materials based on microporous-mesoporous amorphous aluminosilicates using classical methods[J]. Journal of Chemical & Engineering Data, 2023, 68(9): 2512-2528. |

| 29 | Meyer C I, Regenhardt S A, Bertone M E, et al. Gas-phase maleic anhydride hydrogenation over Ni/SiO2-Al2O3 catalysts: effect of metal loading[J]. Catalysis Letters, 2013, 143(10): 1067-1073. |

| 30 | Molina-Sabio M, Rodrı́guez-Reinoso F. Role of chemical activation in the development of carbon porosity[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2004, 241(1/2/3): 15-25. |

| 31 | Gao B Y, Huang H J, Rehman M U, et al. Amination of n-hexanol to n-hexylamine over Ru-Ni bimetallic catalyst [J]. Journal of Chemical Technology & Biotechnology, 2024. doi: 10.1002/jctb.7751 . |

| 32 | Pham-Huu C, Ledoux M J. Carbon nanomaterials with controlled macroscopic shapes as new catalytic materials[J]. Topics in Catalysis, 2006, 40(1): 49-63. |

| 33 | Fúnez A, De Lucas A, Sánchez P, et al. Hydroisomerization in liquid phase of a refinery naphtha stream over Pt-Ni/H-beta zeolite catalysts[J]. Chemical Engineering Journal, 2008, 136(2/3): 267-275. |

| 34 | Byun M Y, Lee M S. Pt supported on hierarchical porous carbon for furfural hydrogenation[J]. Journal of Industrial and Engineering Chemistry, 2021, 104: 406-415. |

| 35 | Fu Y, Devred F, Eloy P, et al. The effect of Ni particle size and carbon support on catalytic activity for glucose hydrogenation reaction[J]. Applied Catalysis A: General, 2022, 644: 118833. |

| 36 | Dasari M A, Kiatsimkul P P, Sutterlin W R, et al. Low-pressure hydrogenolysis of glycerol to propylene glycol[J]. Applied Catalysis A: General, 2005, 281(1/2): 225-231. |

| 37 | 李波, 鲍世宁, 曹培林. 乙烯和乙炔基在Ni(110)表面上吸附结构的研究[J]. 物理学报, 2005, 54(12): 5784. |

| Li B, Bao S N, Cao P L. Adsorption geometry of C2H4 and C2H on Ni(110) surface[J]. Acta Physica Sinica, 2005, 54(12): 5784. | |

| 38 | Li B, Bao S N, Zhuang Y Y, et al. The adsorption geometry of ethylene on the Ni (110) surface[J]. Acta Physica Sinica, 2003, 52(1): 202. |

| 39 | Lv S S, Liu X J, Shen X J. A simulated-TPD study of H2 desorption on metal surfaces[J]. Surface Science, 2022, 718: 122015. |

| 40 | Lueking A D, Yang R T. Hydrogen spillover to enhance hydrogen storage—study of the effect of carbon physicochemical properties[J]. Applied Catalysis A: General, 2004, 265(2): 259-268. |

| 41 | Zea H, Lester K, Datye A K, et al. The influence of Pd-Ag catalyst restructuring on the activation energy for ethylene hydrogenation in ethylene-acetylene mixtures[J]. Applied Catalysis A: General, 2005, 282(1/2): 237-245. |

| 42 | Neurock M, Pallassana V, van Santen R A. The importance of transient states at higher coverages in catalytic reactions[J]. Journal of the American Chemical Society, 2000, 122(6): 1150-1153. |

| 43 | Filhol J S, Simon D, Sautet P. Ethylene adsorption and coadsorption with H on Pd(110) from first principles[J]. The Journal of Physical Chemistry B, 2003, 107(7): 1604-1615. |

| 44 | Tan Y C, Abu Bakar N H H, Tan W L, et al. Hydrogenation of liquid styrene by alumina supported nickel catalysts: comparison between classical and non-classical methods[J]. IOP Conference Series: Materials Science and Engineering, 2016, 133: 012017. |

| 45 | Chen S, Miao C X, Luo Y, et al. Study of catalytic hydrodeoxygenation performance of Ni catalysts: effects of prepared method[J]. Renewable Energy, 2018, 115: 1109-1117. |

| [1] | Yanlin CHEN, Aiguo ZHOU, Jiale ZHENG, Chuanruo YANG, Tianshu GE. Effects of support materials on amine-impregnated DAC adsorbents [J]. CIESC Journal, 2024, 75(S1): 217-222. |

| [2] | Meilin SHI, Lianda ZHAO, Xingjian DENG, Jingsong WANG, Haibin ZUO, Qingguo XUE. Research progress on catalytic methane reforming process [J]. CIESC Journal, 2024, 75(S1): 25-39. |

| [3] | Ji LI, Jianlin WANG, Rui HE, Xinjie ZHOU, Wen WANG, Liqiang ZHAO. DBSVDD-RVR based online soft sensing for quality variables in multimode batch processes [J]. CIESC Journal, 2024, 75(9): 3231-3241. |

| [4] | Yachao LIU, Xiaojie TAN, Xudong LI, Rui WANG, Hui WANG, Xuan HAN, Qingshan ZHAO. Synthesis of efficient cobalt carbonate nanosheets based on DES for oxygen evolution reaction [J]. CIESC Journal, 2024, 75(9): 3320-3328. |

| [5] | Mengting ZHANG, Shulin WANG, Xi SANG, Xinghao YUAN, Gang XU. Artificial Cu-TM1459 metalloenzyme catalyzes asymmetric Michael addition reaction [J]. CIESC Journal, 2024, 75(9): 3255-3265. |

| [6] | Ran WANG, Huan WANG, Xiaoyun XIONG, Huimin GUAN, Yunfeng ZHENG, Cailin CHEN, Yucai QIN, Lijuan SONG. Visual analysis of mass transfer enhanced active site utilization efficiency of FCC catalyst [J]. CIESC Journal, 2024, 75(9): 3198-3209. |

| [7] | Jingyu WANG, Jia LIU, Jixiang XU, Lei WANG. Synthesis of lamellar PtZn@Silicalite-1 zeolite and its catalytic properties for propane dehydrogenation [J]. CIESC Journal, 2024, 75(9): 3188-3197. |

| [8] | Dezheng HU, Rong WANG, Shidong WANG, Wenfei YANG, Hongwei ZHANG, Pei YUAN. Construction of amorphous NiP@γ-Al2O3 catalyst rich in Ni δ+ for petroleum resin hydrogenation with enhanced hydrogenation and desulfurization activity [J]. CIESC Journal, 2024, 75(9): 3152-3162. |

| [9] | Shuzhen WANG, Yuting WANG, Mengxi MA, Wei ZHANG, Jiangnan XIANG, Haiying LU, Yan WANG, Binbin FAN, Jiajun ZHENG, Weijiong DAI, Ruifeng LI. Synthesis of ZSM-22 molecular sieve by two-step crystallization and its hydroisomerization performance [J]. CIESC Journal, 2024, 75(9): 3176-3187. |

| [10] | Shaojun DOU, Liang HAO. Mesoscale simulation of coupled gas charge transfer process in PEMFC catalyst layer [J]. CIESC Journal, 2024, 75(8): 3002-3010. |

| [11] | Li LUO, Wenyao CHEN, Jing ZHANG, Gang QIAN, Xinggui ZHOU, Xuezhi DUAN. Alumina structure and surface property regulation for catalyzing methanol dehydration to dimethyl ether [J]. CIESC Journal, 2024, 75(7): 2522-2532. |

| [12] | Yin WANG, Pengfei CHU, Hu LIU, Jing LYU, Shouying HUANG, Shengping WANG, Xinbin MA. Influence of aluminum sol with different pH on performance of shaped mordenite catalyst for dimethyl ether carbonylation [J]. CIESC Journal, 2024, 75(7): 2533-2543. |

| [13] | Lu YANG, Congcong LIU, Tongtong MENG, Boyuan ZHANG, Tengfei YANG, Wen’an DENG, Xiaobin WANG. Hydrogenation and coke-suppression performance of dispersed catalyst in coal/heavy oil co-processing reactions [J]. CIESC Journal, 2024, 75(7): 2556-2564. |

| [14] | Xusheng LIU, Zeyang LI, Yusen YANG, Min WEI. Research progress on electrocatalytic carbon dioxide reduction to gaseous products [J]. CIESC Journal, 2024, 75(7): 2385-2408. |

| [15] | Han ZHANG, Shuning ZHANG, Ke LIU, Guanlong DENG. Particle size prediction of cobalt oxalate synthesis process based on slow feature analysis and least squares support vector regression [J]. CIESC Journal, 2024, 75(6): 2313-2321. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||