CIESC Journal ›› 2025, Vol. 76 ›› Issue (3): 1018-1028.DOI: 10.11949/0438-1157.20240961

• Fluid dynamics and transport phenomena • Previous Articles Next Articles

Yiming ZHANG1( ), Peng YANG3, Xianbing JI1,2(

), Peng YANG3, Xianbing JI1,2( ), Jixing REN1, Lei ZHANG1, Zheng MIAO1,2

), Jixing REN1, Lei ZHANG1, Zheng MIAO1,2

Received:2024-08-27

Revised:2024-10-02

Online:2025-03-28

Published:2025-03-25

Contact:

Xianbing JI

张亦鸣1( ), 杨鹏3, 纪献兵1,2(

), 杨鹏3, 纪献兵1,2( ), 任纪星1, 张磊1, 苗政1,2

), 任纪星1, 张磊1, 苗政1,2

通讯作者:

纪献兵

作者简介:张亦鸣(2000—),男,硕士研究生,zym13811103752@163.com

基金资助:CLC Number:

Yiming ZHANG, Peng YANG, Xianbing JI, Jixing REN, Lei ZHANG, Zheng MIAO. Thermal performance of multi-loop flat loop heat pipes[J]. CIESC Journal, 2025, 76(3): 1018-1028.

张亦鸣, 杨鹏, 纪献兵, 任纪星, 张磊, 苗政. 多回路平板式环路热管热性能[J]. 化工学报, 2025, 76(3): 1018-1028.

Add to citation manager EndNote|Ris|BibTeX

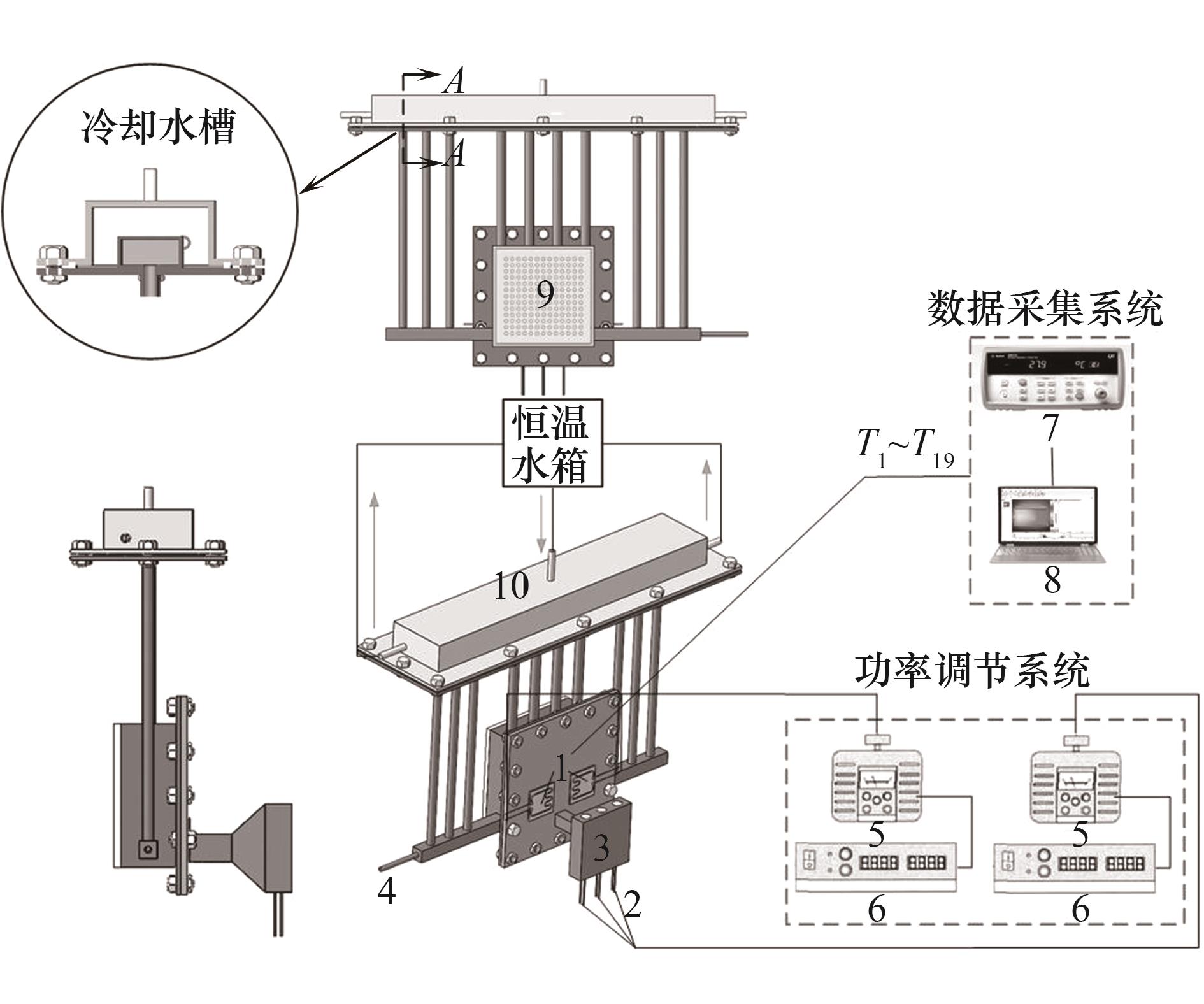

Fig.1 Experimental system1—steel based heating sheet; 2—heating rod; 3—heating copper; 4—liquid injection pipe; 5—voltage regulator; 6—power display; 7—data acquisition instrument; 8—computer; 9—evaporator; 10—condenser

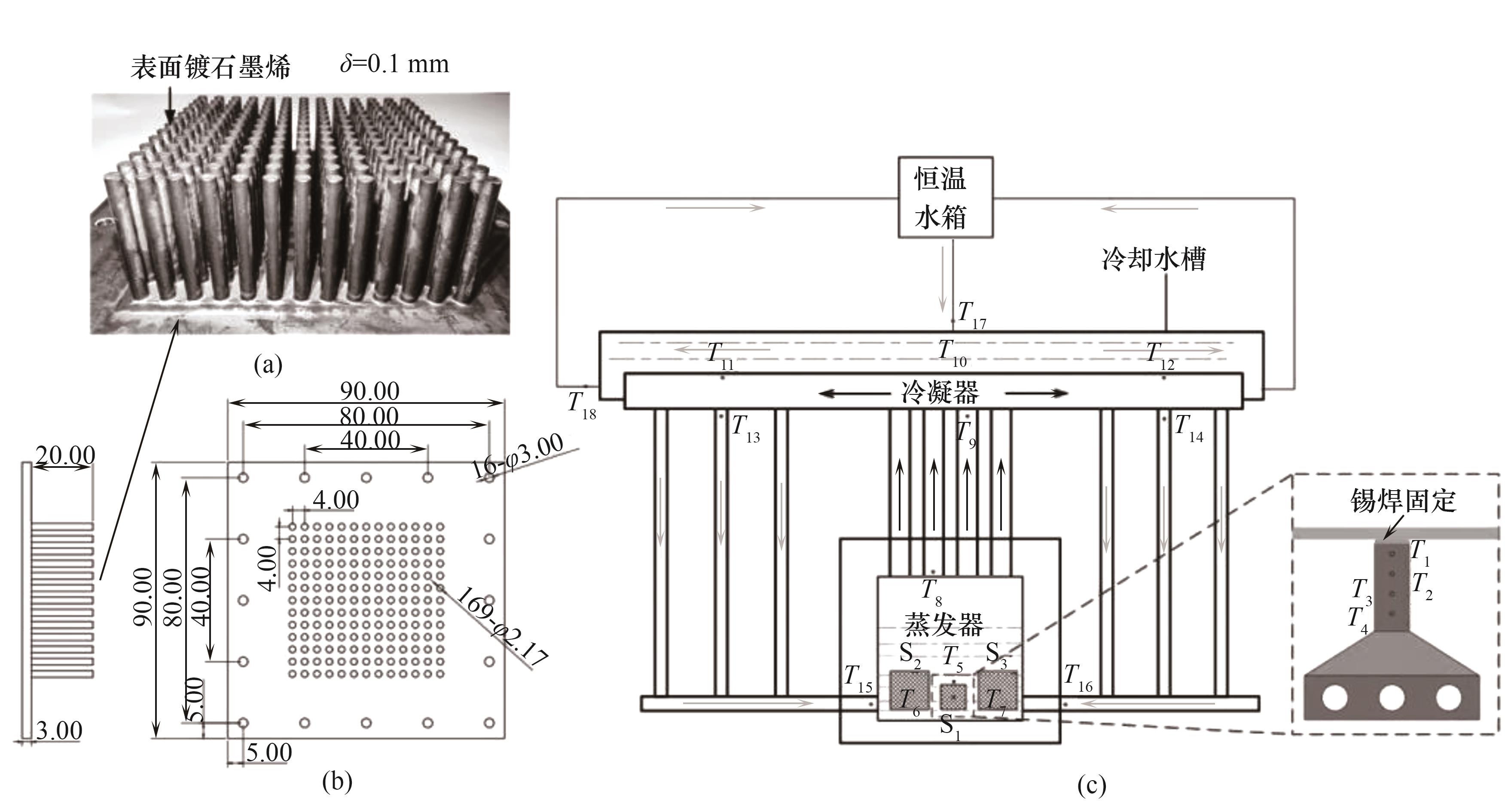

| 部件 | 参数 | 数值 |

|---|---|---|

| 蒸发器 | 腔体尺寸 | 65.0 mm×65.0 mm×25.0 mm;δ=2.0 mm |

| 加热面 | 90.0 mm×90.0 mm×2.0 mm | |

| 铜肋针 | φ=2.17 mm;d=4.0 mm;h=20.0 mm | |

| 顶盖(石英玻璃) | 65.0 mm×65.0 mm×3.0 mm | |

| 蒸气通道 | 长 内/外径 | 78.0 mm 5.0 mm/6.0 mm |

| 液体通道 | 长 内/外径 | 130.0 mm 4.0 mm/5.0 mm |

| 冷凝器 | 腔体尺寸 | 200.0 mm×20.0 mm×10.0 mm;δ=1.5 mm |

Table 1 Loop heat pipe and pin-fin structure parameters

| 部件 | 参数 | 数值 |

|---|---|---|

| 蒸发器 | 腔体尺寸 | 65.0 mm×65.0 mm×25.0 mm;δ=2.0 mm |

| 加热面 | 90.0 mm×90.0 mm×2.0 mm | |

| 铜肋针 | φ=2.17 mm;d=4.0 mm;h=20.0 mm | |

| 顶盖(石英玻璃) | 65.0 mm×65.0 mm×3.0 mm | |

| 蒸气通道 | 长 内/外径 | 78.0 mm 5.0 mm/6.0 mm |

| 液体通道 | 长 内/外径 | 130.0 mm 4.0 mm/5.0 mm |

| 冷凝器 | 腔体尺寸 | 200.0 mm×20.0 mm×10.0 mm;δ=1.5 mm |

Fig.2 (a) Physical diagram of pin-fin evaporation base plate; (b) Structure diagram of pin-fin evaporation base plate; (c) Working principle and thermocouple distribution

| 工质 | 常压下沸点/℃ | 汽化潜热/(kJ/kg) | 热导率/(W/(m∙K)) | 表面张力/(mN/m) | 黏度/(mPa·s) |

|---|---|---|---|---|---|

| FCM-47 | 49.0 | 121.7 | 0.221 | 12.20 | 1.2 |

| 无水乙醇 | 78.2 | 962.5 | 0.1625 | 22.40 | 1.2 |

| 去离子水 | 100.0 | 2257.2 | 0.614 | 71.97 | 1.00 |

| 丙酮 | 57.0 | 520.6 | 0.1514 | 18.80 | 0.31 |

| R1233zd | 18.7 | 183.5 | 0.0769 | 15.10 | 0.47 |

Table 2 Physical property parameters of working fluid

| 工质 | 常压下沸点/℃ | 汽化潜热/(kJ/kg) | 热导率/(W/(m∙K)) | 表面张力/(mN/m) | 黏度/(mPa·s) |

|---|---|---|---|---|---|

| FCM-47 | 49.0 | 121.7 | 0.221 | 12.20 | 1.2 |

| 无水乙醇 | 78.2 | 962.5 | 0.1625 | 22.40 | 1.2 |

| 去离子水 | 100.0 | 2257.2 | 0.614 | 71.97 | 1.00 |

| 丙酮 | 57.0 | 520.6 | 0.1514 | 18.80 | 0.31 |

| R1233zd | 18.7 | 183.5 | 0.0769 | 15.10 | 0.47 |

| 1 | Li J, Zhou G H, Tian T, et al. A new cooling strategy for edge computing servers using compact looped heat pipe[J]. Applied Thermal Engineering, 2021, 187: 116599. |

| 2 | Zhang K, Zhang Y W, Liu J X, et al. Recent advancements on thermal management and evaluation for data centers[J]. Applied Thermal Engineering, 2018, 142: 215-231. |

| 3 | Chen G, Jia M Z, Zhang S W, et al. Pool boiling enhancement of novel interconnected microchannels with reentrant cavities for high-power electronics cooling[J]. International Journal of Heat and Mass Transfer, 2020, 156: 119836. |

| 4 | 杨世铭, 陶文铨. 传热学[M]. 4版. 北京: 高等教育出版社, 2006. |

| Yang S M, Tao W Q. Heat Transfer[M]. 4th ed. Beijing: Higher Education Press, 2006. | |

| 5 | Zhang Y H. Experimental study on working characteristics of loop heat pipe[J]. Science and Technology Innovation Guide, 2016, 13(16): 43-44. |

| 6 | 黄洁, 王乃华, 程林. 环路热管启动特性模拟[J]. 化工学报, 2014, 65(S1): 297-302. |

| Huang J, Wang N H, Cheng L. Simulation of start-up characteristics of loop heat pipe[J]. CIESC Journal, 2014, 65(S1): 297-302. | |

| 7 | Tang H, Tang Y, Wan Z P, et al. Review of applications and developments of ultra-thin micro heat pipes for electronic cooling[J]. Applied Energy, 2018, 223: 383-400. |

| 8 | Bastakoti D, Zhang H N, Li D, et al. An overview on the developing trend of pulsating heat pipe and its performance[J]. Applied Thermal Engineering, 2018, 141: 305-332. |

| 9 | Anand A R, Jaiswal A, Ambirajan A, et al. Experimental studies on a miniature loop heat pipe with flat evaporator with various working fluids[J]. Applied Thermal Engineering, 2018, 144: 495-503. |

| 10 | Zhao T Y, Ma Z Y, Zhang Z K, et al. Experimental investigation of a loop heat pipe with a flat evaporator and cupric oxide nanofluids as working fluid[J]. Energy Reports, 2021, 7: 7693-7703. |

| 11 | Gai D X, Liu Z C, Liu W, et al. Experimental investigation of temperature oscillation in miniature loop heat pipe[C]//AIP Conference Proceedings. AIP, 2010, 1207(1): 465-470. |

| 12 | 孙志坚. 电子器件回路型热管散热器的数值模拟与试验研究[D]. 杭州: 浙江大学, 2007. |

| Sun Z J. Numerical simulation and experimental study on loop heat pipe radiator for electronic devices[D]. Hangzhou: Zhejiang University, 2007. | |

| 13 | Tsai T E, Wu H H, Chang C C, et al. Two-phase closed thermosyphon vapor-chamber system for electronic cooling[J]. International Communications in Heat and Mass Transfer, 2010, 37(5): 484-489. |

| 14 | 田亚玲, 张海南, 徐洪波, 等. 紧凑型平板环路热管实验研究[J]. 化工学报, 2021, 72(6): 3288-3295. |

| Tian Y L, Zhang H N, Xu H B, et al. Experimental study on compact plate loop heat pipe[J]. CIESC Journal, 2021, 72(6): 3288-3295. | |

| 15 | Zhou W, Ling W S, Duan L, et al. Development and tests of loop heat pipe with multi-layer metal foams as wick structure[J]. Applied Thermal Engineering, 2016, 94: 324-330. |

| 16 | 陈曦, 林毅, 邵帅. 倾角及加热功率对乙烷脉动热管传热性能的影响[J]. 化工学报, 2019, 70(4): 1383-1389. |

| Chen X, Lin Y, Shao S. Influences of inclination angle and heating power on heat transfer performance of ethane pulsating heat pipe[J]. CIESC Journal, 2019, 70(4): 1383-1389. | |

| 17 | 龙延, 魏进家, 吕虓. 不同倾角下平板型环路热管的实验研究[J]. 西安交通大学学报, 2013, 47(5): 38-43. |

| Long Y, Wei J J, Lü X. Experimental study on loop heat pipe with flat evaporator at different tilt angles[J]. Journal of Xi’an Jiaotong University, 2013, 47(5): 38-43. | |

| 18 | Hong S H, Zhang X Q, Tang Y L, et al. Experiment research on the effect of the evaporator’s configuration design of an innovative ultra-thin looped heat pipe[J]. International Journal of Heat and Mass Transfer, 2016, 92: 497-506. |

| 19 | Xu J Y, Wang Z Y, Xu H, et al. Experimental research on the heat performance of a flat copper-water loop heat pipe with different inventories[J]. Experimental Thermal and Fluid Science, 2017, 84: 110-119. |

| 20 | Solomon A B, Mahto A K, Joy R C, et al. Application of bio-wick in compact loop heat pipe[J]. Applied Thermal Engineering, 2020, 169: 114927. |

| 21 | Boo J H, Chung W B. Thermal performance of a loop heat pipe having polypropylene wick in a flat evaporator[C]//Heat Transfer: Volume 4. San Francisco, California, USA: ASMEDC, 2005: 473-478. |

| 22 | 曲燕, 张坤峰. 环路热管双孔径分布毛细结构的研究进展[J]. 粉末冶金工业, 2014, 24(3): 48-55. |

| Qu Y, Zhang K F. Review of bi-porous wick structure for loop heat pipe[J]. Powder Metallurgy Industry, 2014, 24(3): 48-55. | |

| 23 | 张畅, 谢荣建, 张添, 等. 液氮温区平板蒸发器环路热管实验研究[J]. 北京航空航天大学学报, 2019, 45(6): 1211-1217. |

| Zhang C, Xie R J, Zhang T, et al. Experimental study on a liquid nitrogen temperature region loop heat pipe with flat evaporator[J]. Journal of Beijing University of Aeronautics and Astronautics, 2019, 45(6): 1211-1217. | |

| 24 | Mizutani T, Watanabe N, Aso S, et al. Experimental and analytical investigation of a 0.3-mm-thick loop heat pipe for 10 W-class heat dissipation[J]. International Journal of Heat and Mass Transfer, 2022, 193: 122950. |

| 25 | 郭浩. 热管内气液相分离及传热性能实验研究[D]. 北京: 华北电力大学, 2021. |

| Guo H. Experimental study on gas-liquid separation and heat transfer performance in heat pipe[D]. Beijing: North China Electric Power University, 2021. | |

| 26 | 顾孝烈, 鲍峰, 程效军. 测量学[M]. 3版. 上海: 同济大学出版社, 2006. |

| Gu X L, Bao F, Cheng X J. Elementary Surveying[M]. 3rd ed. Shanghai: Tongji University Press, 2006. | |

| 27 | Yan L P, Zhang P, Xu H, et al. Visualization of thermo-hydrodynamic behavior in flat-plate pulsating heat pipe with HFE-347[J]. Journal of Thermal Science, 2021, 30(3): 926-938. |

| 28 | Xing M B, Wang R X, Xu R J. Experimental study on thermal performance of a pulsating heat pipe with surfactant aqueous solution[J]. International Journal of Heat and Mass Transfer, 2018, 127: 903-909. |

| 29 | Su Z P, Hu Y X, Zheng S B, et al. Recent advances in visualization of pulsating heat pipes: a review[J]. Applied Thermal Engineering, 2023, 221: 119867. |

| 30 | Fritz W. Maximum volume of vapor bubbles[J]. Physics, 1935, 36: 379-388. |

| 31 | 杨洪海. 闭式回路脉动热管运行性能的研究[D]. 上海: 东华大学, 2006. |

| Yang H H. Investigations of the operational performance of closed loop pulsating heat pipes[D]. Shanghai: Donghua University, 2006. |

| [1] | Junbing XIAO, Bo ZOU, Jiandi REN, Changhui LIU, Chuankun JIA. Research on heat storage performance of chloride composite molten salt based on phase diagram analysis [J]. CIESC Journal, 2025, 76(3): 963-974. |

| [2] | Ke LI, Biping XIN, Jian WEN. Sequential quadratic programming optimization of continuous variable density multi-layer insulation coupled with vapor cooled shield in liquid hydrogen storage tank [J]. CIESC Journal, 2025, 76(3): 985-994. |

| [3] | Yanfang YU, Puyu ZHANG, Huibo MENG, Wen SUN, Wen LI, Wenlong QIAO, Mengqiong ZHANG. Experimental study on heat transfer and turbulent fluctuation characteristics of biomimetic conch static mixer [J]. CIESC Journal, 2025, 76(3): 1040-1049. |

| [4] | Lyusheng ZHANG, Zhihong WANG, Qing LIU, Xuewen LI, Renmin TAN. Research progress in carbon dioxide capture using liquid-liquid phase change absorbents [J]. CIESC Journal, 2025, 76(3): 933-950. |

| [5] | Junbing XIAO, Xiangyu ZHONG, Jiandi REN, Fangfang ZHONG, Changhui LIU, Chuankun JIA. Research on the heat storage properties of stearic acid phase change materials enhanced by bio-carbon materials [J]. CIESC Journal, 2025, 76(3): 1312-1322. |

| [6] | Haochen TIAN, Zhixian MA, Zhihao WANG. Film condensation heat transfer characteristics of R1234ze(E) on a horizontal three-dimensional finned tube [J]. CIESC Journal, 2025, 76(3): 975-984. |

| [7] | Qin SUN, Guoqing ZHOU, Wanling ZHAI, Shan GAO, Qianqian LUO, Jian QU. Heat transfer characteristics of topology optimized channel flat-plate pulsating heat pipe under local multiple heat sources [J]. CIESC Journal, 2025, 76(3): 1006-1017. |

| [8] | Xiankai ZHANG, Boyu WANG, Yali GUO, Shengqiang SHEN. Calculation and analysis of thermal performance of horizontal circular tube falling film evaporative condenser [J]. CIESC Journal, 2025, 76(3): 995-1005. |

| [9] | Yan LI, Hongli GUO, Guoqing SU, Jianwen ZHANG. Gas-liquid two-phase flow and erosion-corrosion in air cooler of hydrogenation unit [J]. CIESC Journal, 2025, 76(1): 141-150. |

| [10] | Hanbin WANG, Shuai HU, Fenglei BI, Junsen LI, Laibin HE. Desorption performance analysis of a metal hydride reactor with novel corrugated fins based on finite element method [J]. CIESC Journal, 2025, 76(1): 221-230. |

| [11] | Han CHEN, Chang CAI, Hong LIU, Hongchao YIN. Experimental investigation on spray cooling heat transfer enhancement by n-pentanol additive [J]. CIESC Journal, 2025, 76(1): 131-140. |

| [12] | Ping LIU, Yusheng QIU, Shijing LI, Ruiqi SUN, Chen SHEN. Heat transfer and flow characteristics of nanofluids in microchannels [J]. CIESC Journal, 2025, 76(1): 184-197. |

| [13] | Haidong LI, Qiqi ZHANG, Lu YANG, Naeem AKRAM, Chenglin CHANG, Wenlong MO, Weifeng SHEN. Detailed design of shell-and-tube heat exchanger using intelligent evolutionary algorithms [J]. CIESC Journal, 2025, 76(1): 241-255. |

| [14] | Xinyu DONG, Longfei BIAN, Yiyi YANG, Yuxuan ZHANG, Lu LIU, Teng WANG. Study on flow and heat transfer mechanism of supercritical CO2 in inclined upward tube under cooling conditions [J]. CIESC Journal, 2024, 75(S1): 195-205. |

| [15] | Su TANG, Zi'ao ZHENG, Hanze WEI, Xiaoling XU, Xiaoqiang ZHAI. Preparation and thermal conductivity reinforcement of PMMA/PEG600/CNT composite shaped phase change materials [J]. CIESC Journal, 2024, 75(S1): 309-320. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||