CIESC Journal ›› 2025, Vol. 76 ›› Issue (3): 995-1005.DOI: 10.11949/0438-1157.20240941

• Fluid dynamics and transport phenomena • Previous Articles Next Articles

Xiankai ZHANG( ), Boyu WANG, Yali GUO, Shengqiang SHEN(

), Boyu WANG, Yali GUO, Shengqiang SHEN( )

)

Received:2024-08-20

Revised:2024-10-22

Online:2025-03-28

Published:2025-03-25

Contact:

Shengqiang SHEN

通讯作者:

沈胜强

作者简介:张先开(2001—),男,硕士研究生,17752950696@163.com

基金资助:CLC Number:

Xiankai ZHANG, Boyu WANG, Yali GUO, Shengqiang SHEN. Calculation and analysis of thermal performance of horizontal circular tube falling film evaporative condenser[J]. CIESC Journal, 2025, 76(3): 995-1005.

张先开, 王博宇, 郭亚丽, 沈胜强. 水平圆管降膜蒸发式冷凝器热力性能计算分析[J]. 化工学报, 2025, 76(3): 995-1005.

Add to citation manager EndNote|Ris|BibTeX

| 管轴向 长度/m | 迎风面 长度/m | 迎风面 宽度/m | 管间距 | 管列数 | 管程数 |

|---|---|---|---|---|---|

| 0.288 | 0.3 | 0.18 | 1.6D | 5 | 6 |

Table 1 Structural parameters

| 管轴向 长度/m | 迎风面 长度/m | 迎风面 宽度/m | 管间距 | 管列数 | 管程数 |

|---|---|---|---|---|---|

| 0.288 | 0.3 | 0.18 | 1.6D | 5 | 6 |

| 冷凝温度/℃ | 进口空气干球温度/℃ | 进口空气湿度/% | 喷淋水温度/℃ |

|---|---|---|---|

| 26 | 20 | 60 | 25 |

Table 2 Operating parameters

| 冷凝温度/℃ | 进口空气干球温度/℃ | 进口空气湿度/% | 喷淋水温度/℃ |

|---|---|---|---|

| 26 | 20 | 60 | 25 |

| 冷凝温度/℃ | 进口空气 干球温度/℃ | 进口空气 湿球温度/℃ | 喷淋水温度/℃ |

|---|---|---|---|

| 36 | 31 | 25 | 25 |

Table 3 Operating conditions

| 冷凝温度/℃ | 进口空气 干球温度/℃ | 进口空气 湿球温度/℃ | 喷淋水温度/℃ |

|---|---|---|---|

| 36 | 31 | 25 | 25 |

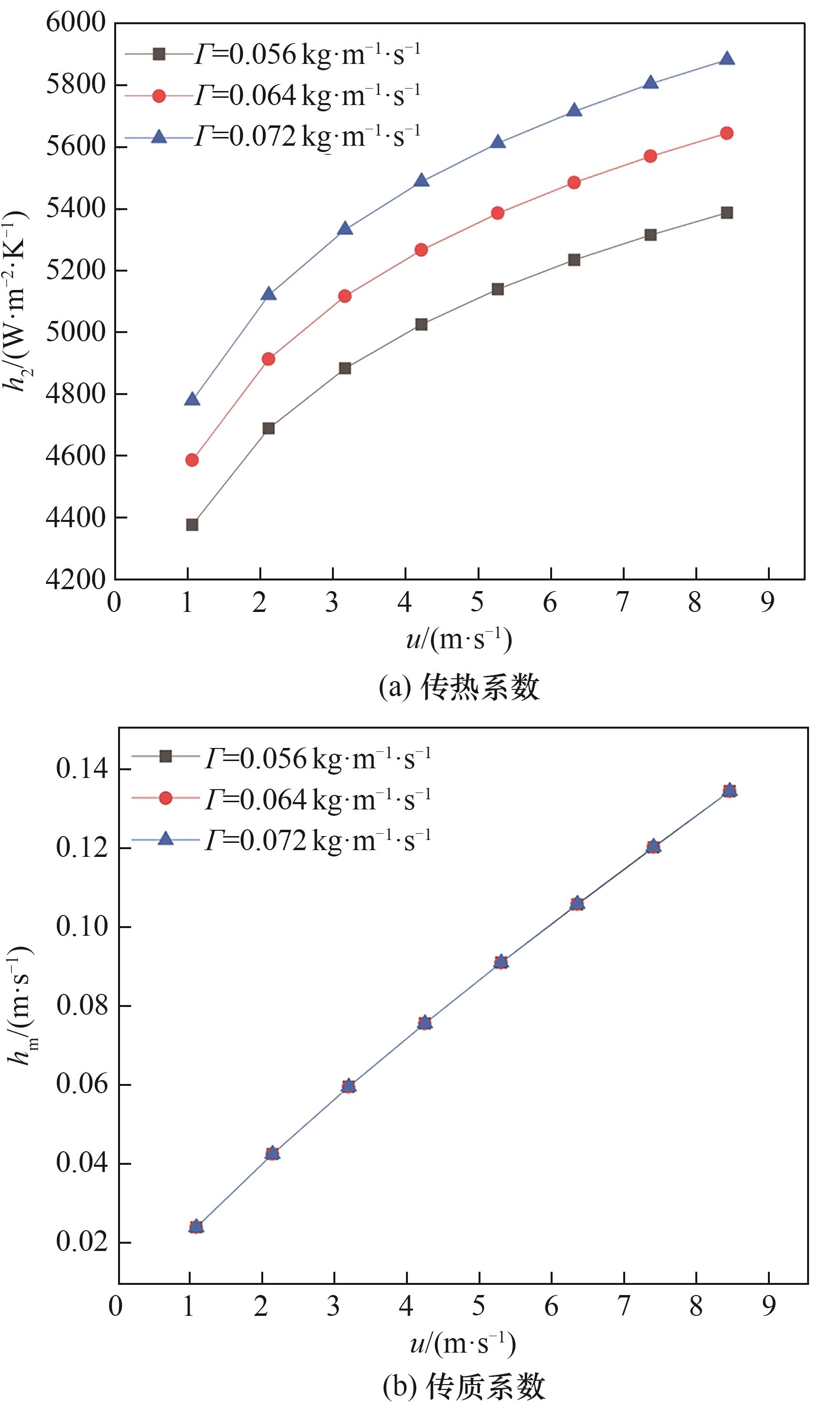

Fig.5 The variation curve of heat transfer coefficient and mass transfer coefficient of outer tube wall and water film with head-on wind speed at different spray densities

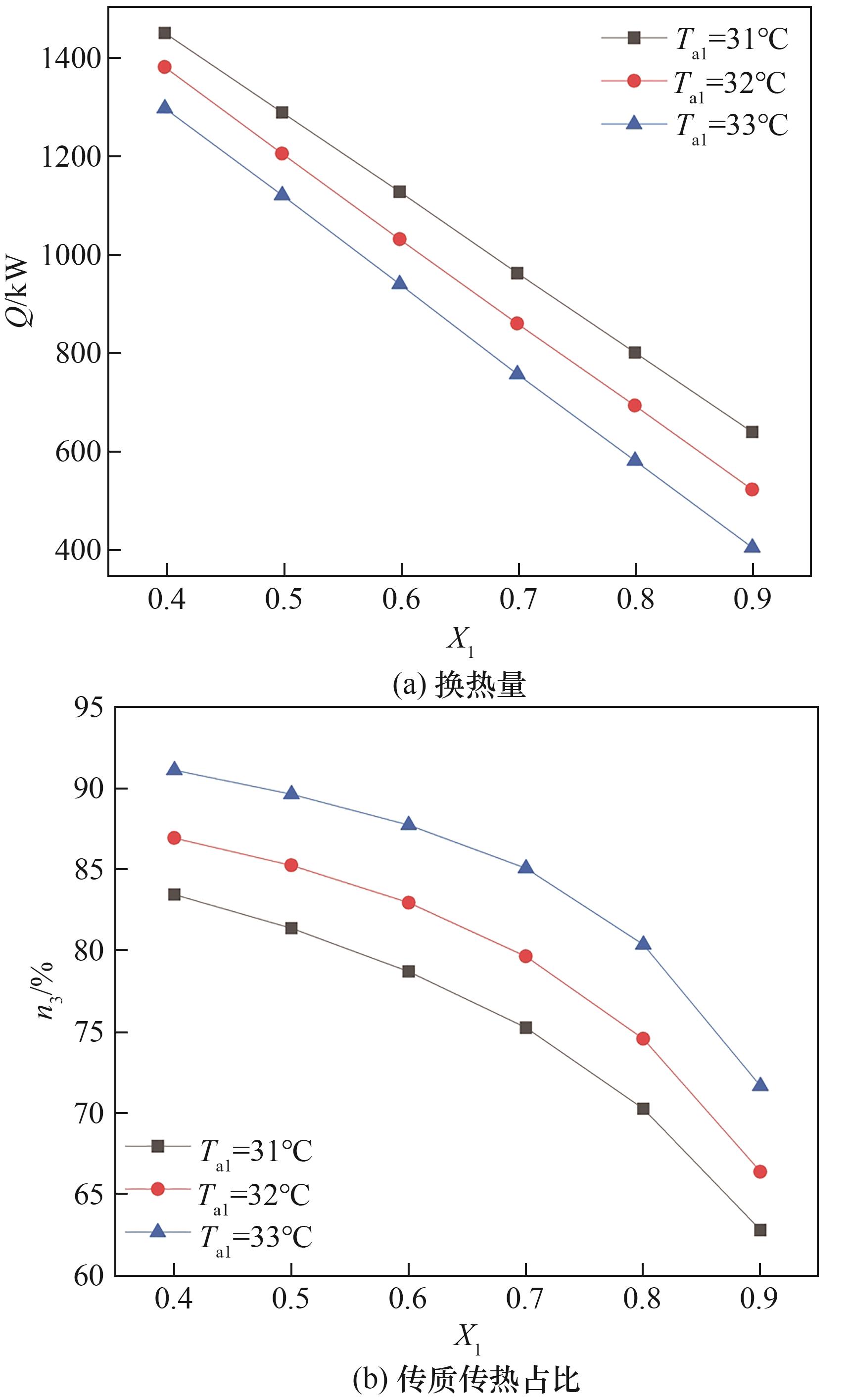

Fig.13 The change curve of the heat transfer and mass transfer heat ratio with the relative humidity of the environment at different dry bulb temperatures

| 1 | Shah M M. A general correlation for heat transfer during film condensation inside pipes[J]. International Journal of Heat and Mass Transfer, 1979, 22(4): 547-556. |

| 2 | Bazán F S V, Bedin L, Bozzoli F. New methods for numerical estimation of convective heat transfer coefficient in circular ducts[J]. International Journal of Thermal Sciences, 2019, 139: 387-402. |

| 3 | 赵允玉. 水平管内凝结传热与流动阻力的耦合影响研究[D]. 北京: 华北电力大学, 2011. |

| Zhao Y Y. Research of heat transfer and flow resistance coupling effect during condensation in horizontal tube[D]. Beijing: North China Electric Power University, 2011. | |

| 4 | Cavallini A, Col D D, Doretti L, et al. Condensation in horizontal smooth tubes: a new heat transfer model for heat exchanger design[J]. Heat Transfer Engineering, 2006, 27(8): 31-38. |

| 5 | Dorao C A, Fernandino M. Simple and general correlation for heat transfer during flow condensation inside plain pipes[J]. International Journal of Heat and Mass Transfer, 2018, 122: 290-305. |

| 6 | Zhu X J, Chen S, Shen S Q, et al. Experimental study on the heat and mass transfer characteristics of air-water two-phase flow in an evaporative condenser with a horizontal elliptical tube bundle[J]. Applied Thermal Engineering, 2020, 168: 114825. |

| 7 | 任显龙. 横管降膜蒸发传热实验研究[D]. 大连: 大连理工大学, 2009. |

| Ren X L. Experimental investigation on heat transfer of horizontal-tube falling film evaporation[D]. Dalian: Dalian University of Technology, 2009. | |

| 8 | Liu Z H, Zhu Q Z, Chen Y M. Evaporation heat transfer of falling water film on a horizontal tube bundle[J]. Heat Transfer-Asian Research, 2002, 31(1): 42-55. |

| 9 | 沈胜强, 陈学, 牟兴森, 等. 管间距对水平管降膜蒸发流动形态和传热的影响[J]. 哈尔滨工程大学学报, 2014, 35(12): 1492-1496. |

| Shen S Q, Chen X, Mu X S, et al. The effect of tube spacing on flow pattern and heat transfer of horizontal tube falling film evaporation[J]. Journal of Harbin Engineering University, 2014, 35(12): 1492-1496. | |

| 10 | Zhang H H, Zhou Y S. Effects of tube shape on the distribution of film thickness and heat transfer performance in falling film evaporation[J]. Heat and Mass Transfer, 2022, 58(9): 1533-1543. |

| 11 | 邱庆刚, 陈金波. 水平管降膜蒸发器管外液膜的数值模拟[J]. 动力工程学报, 2011, 31(5): 357-361, 374. |

| Qiu Q G, Chen J B. Numerical simulation of film formation on horizontal-tube falling film evaporators[J]. Journal of Chinese Society of Power Engineering, 2011, 31(5): 357-361, 374. | |

| 12 | Liu S L, Mu X S, Shen S Q, et al. Experimental study on the distribution of local heat transfer coefficient of falling film heat transfer outside horizontal tube[J]. International Journal of Heat and Mass Transfer, 2021, 170: 121031. |

| 13 | Mu X S, Shen S Q, Yang Y, et al. Experimental study of falling film evaporation heat transfer coefficient on horizontal tube[J]. Desalination and Water Treatment, 2012, 50(1/2/3): 310-316. |

| 14 | Mizushina T, Ito R, Miyashita H. Experimental study of evaporative cooler[J]. Chemical Engineering, 1967, 31(5): 469-473. |

| 15 | Parker R O, Treybal R E. The heat mass transfer characteristics of evaporative coolers[J]. AIChE Chemical Engineering Progress Symposium Series, 1962, 57(32): 138-149. |

| 16 | Heyns J A, Kröger D G. Experimental investigation into the thermal-flow performance characteristics of an evaporative cooler[J]. Applied Thermal Engineering, 2010, 30(5): 492-498. |

| 17 | 沈家龙. 蒸发式冷凝器传热传质理论分析及实验研究[D]. 广州: 华南理工大学, 2005. |

| Shen J L. Theoretical analysis and experimental study on heat and mass transfer of evaporative condenser[D]. Guangzhou: South China University of Technology, 2005. | |

| 18 | 郑伟业. 蒸发式冷却器传热传质的试验研究及数值模拟[D]. 上海: 华东理工大学, 2013. |

| Zheng W Y. Experimental investigation and numerical simulation of the heat and mass transfer in evaporative cooler[D]. Shanghai: East China University of Science and Technology, 2013. | |

| 19 | 姜永永. 水膜蒸发式空冷器传热传质研究及设计程序开发[D]. 武汉: 华中科技大学, 2014. |

| Jiang Y Y. Heat and mass transfer research of water film evaporative air cooler and design program development[D]. Wuhan: Huazhong University of Science and Technology, 2014. | |

| 20 | Fiorentino M, Starace G. The design of countercurrent evaporative condensers with the hybrid method[J]. Applied Thermal Engineering, 2018, 130: 889-898. |

| 21 | 单思宇, 谭宏博. 基于扁管的蒸发式冷凝器管外传热传质特性研究[J]. 化工学报, 2019, 70(S1): 69-78. |

| Shan S Y, Tan H B. Study on heat and mass transfer characteristics outside flat tube for evaporative condensers[J]. CIESC Journal, 2019, 70(S1): 69-78. | |

| 22 | 张梦超, 牟兴森, 沈胜强. 水平管外降膜蒸发气水对流过程换热量数值模拟分析[J]. 大连理工大学学报, 2022, 62(2): 172-178. |

| Zhang M C, Mu X S, Shen S Q. Numerical simulation analysis of heat transfer in falling film evaporation process of air-water convection outside horizontal tube[J]. Journal of Dalian University of Technology, 2022, 62(2): 172-178. | |

| 23 | 倪双全. 水平椭圆管蒸发式冷凝器传热传质实验研究[D]. 大连: 大连理工大学, 2018. |

| Ni S Q. Experimental study on heat and mass transfer of horizontal oval tube evaporative condenser[D]. Dalian: Dalian University of Technology, 2018. | |

| 24 | 李纪昌. 蒸发式凝汽器管束阻力和传热传质实验研究[D]. 大连: 大连理工大学, 2021. |

| Li J C. Experimental study on tube bundle flow resistance and heat and mass transfer of evaporative condenser[D]. Dalian: Dalian University of Technology, 2021. | |

| 25 | 蔡祖康, 夏畹, 刘焕成, 等. 蒸发式冷凝器的热力计算[J]. 制冷学报, 1989, 10(4): 1-7. |

| Cai Z K, Xia W, Liu H C, et al. Thermodynamic calculation of the evaporative condenser[J]. Journal of Refrigeration, 1989, 10(4): 1-7. | |

| 26 | 王东屏. 蒸发式冷凝器的设计[J]. 大连铁道学院学报, 1999, 20(1): 45-49. |

| Wang D P. Design of evaporative condenser[J]. Journal of Dalian Railway Institute, 1999, 20(1): 45-49. | |

| 27 | 王少为, 刘震炎. 一种蒸发式冷凝器的新型设计方法[J]. 制冷与空调, 2002, 2(4): 31-35. |

| Wang S W, Liu Z Y. A new method to design evaporative condenser[J]. Refrigeration and Air Conditioning, 2002, 2(4): 31-35. | |

| 28 | 吴金星, 尹凯杰, 潘彦凯, 等. 蒸发式冷凝器的程序化设计及参数动态分析[J]. 流体机械, 2011, 39(3): 75-79. |

| Wu J X, Yin K J, Pan Y K, et al. Programmed design and parameter dynamic analyses of evaporative condenser[J]. Fluid Machinery, 2011, 39(3): 75-79. | |

| 29 | Žukauskas A. Heat transfer from tubes in crossflow[M]//Advances in Heat Transfer. Amsterdam: Elsevier, 1972: 93-160. |

| 30 | 杨世铭, 陶文铨. 传热学[M]. 4版. 北京: 高等教育出版社, 2006. |

| Yang S M, Tao W Q. Heat Transfer[M]. 4th ed. Beijing: Higher Education Press, 2006. |

| [1] | Yiming ZHANG, Peng YANG, Xianbing JI, Jixing REN, Lei ZHANG, Zheng MIAO. Thermal performance of multi-loop flat loop heat pipes [J]. CIESC Journal, 2025, 76(3): 1018-1028. |

| [2] | Ke LI, Biping XIN, Jian WEN. Sequential quadratic programming optimization of continuous variable density multi-layer insulation coupled with vapor cooled shield in liquid hydrogen storage tank [J]. CIESC Journal, 2025, 76(3): 985-994. |

| [3] | Yanfang YU, Puyu ZHANG, Huibo MENG, Wen SUN, Wen LI, Wenlong QIAO, Mengqiong ZHANG. Experimental study on heat transfer and turbulent fluctuation characteristics of biomimetic conch static mixer [J]. CIESC Journal, 2025, 76(3): 1040-1049. |

| [4] | Lyusheng ZHANG, Zhihong WANG, Qing LIU, Xuewen LI, Renmin TAN. Research progress in carbon dioxide capture using liquid-liquid phase change absorbents [J]. CIESC Journal, 2025, 76(3): 933-950. |

| [5] | Junbing XIAO, Xiangyu ZHONG, Jiandi REN, Fangfang ZHONG, Changhui LIU, Chuankun JIA. Research on the heat storage properties of stearic acid phase change materials enhanced by bio-carbon materials [J]. CIESC Journal, 2025, 76(3): 1312-1322. |

| [6] | Haochen TIAN, Zhixian MA, Zhihao WANG. Film condensation heat transfer characteristics of R1234ze(E) on a horizontal three-dimensional finned tube [J]. CIESC Journal, 2025, 76(3): 975-984. |

| [7] | Ke QI, Di WANG, Zhe XIE, Dongsheng CHEN, Yunlong ZHOU, Lingfang SUN. Research on transient characteristics of solid oxide fuel cells considering coupling features of multiphysics fields [J]. CIESC Journal, 2025, 76(3): 1264-1274. |

| [8] | Qin SUN, Guoqing ZHOU, Wanling ZHAI, Shan GAO, Qianqian LUO, Jian QU. Heat transfer characteristics of topology optimized channel flat-plate pulsating heat pipe under local multiple heat sources [J]. CIESC Journal, 2025, 76(3): 1006-1017. |

| [9] | Junbing XIAO, Bo ZOU, Jiandi REN, Changhui LIU, Chuankun JIA. Research on heat storage performance of chloride composite molten salt based on phase diagram analysis [J]. CIESC Journal, 2025, 76(3): 963-974. |

| [10] | Nannan XIE, He CHEN, Guanghua YE, Zhongming SHU, Songbao FU, Xinggui ZHOU. Interaction of multiple impellers for gas-liquid stirred tank and optimization of their combinations [J]. CIESC Journal, 2025, 76(2): 564-575. |

| [11] | Han CHEN, Chang CAI, Hong LIU, Hongchao YIN. Experimental investigation on spray cooling heat transfer enhancement by n-pentanol additive [J]. CIESC Journal, 2025, 76(1): 131-140. |

| [12] | Ping LIU, Yusheng QIU, Shijing LI, Ruiqi SUN, Chen SHEN. Heat transfer and flow characteristics of nanofluids in microchannels [J]. CIESC Journal, 2025, 76(1): 184-197. |

| [13] | Haidong LI, Qiqi ZHANG, Lu YANG, Naeem AKRAM, Chenglin CHANG, Wenlong MO, Weifeng SHEN. Detailed design of shell-and-tube heat exchanger using intelligent evolutionary algorithms [J]. CIESC Journal, 2025, 76(1): 241-255. |

| [14] | Yan LI, Hongli GUO, Guoqing SU, Jianwen ZHANG. Gas-liquid two-phase flow and erosion-corrosion in air cooler of hydrogenation unit [J]. CIESC Journal, 2025, 76(1): 141-150. |

| [15] | Hanbin WANG, Shuai HU, Fenglei BI, Junsen LI, Laibin HE. Desorption performance analysis of a metal hydride reactor with novel corrugated fins based on finite element method [J]. CIESC Journal, 2025, 76(1): 221-230. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||