CIESC Journal ›› 2025, Vol. 76 ›› Issue (8): 4061-4070.DOI: 10.11949/0438-1157.20250068

• Catalysis, kinetics and reactors • Previous Articles Next Articles

Min YANG1,2( ), Xinwei DUAN1,2, Junhong WU1,2, Jie MI1,2, Jiancheng WANG1,2,3, Mengmeng WU1,2(

), Xinwei DUAN1,2, Junhong WU1,2, Jie MI1,2, Jiancheng WANG1,2,3, Mengmeng WU1,2( )

)

Received:2025-01-16

Revised:2025-02-24

Online:2025-09-17

Published:2025-08-25

Contact:

Mengmeng WU

杨敏1,2( ), 段新伟1,2, 吴俊宏1,2, 米杰1,2, 王建成1,2,3, 武蒙蒙1,2(

), 段新伟1,2, 吴俊宏1,2, 米杰1,2, 王建成1,2,3, 武蒙蒙1,2( )

)

通讯作者:

武蒙蒙

作者简介:杨敏(1999—),女,硕士研究生,yangmin990603@163.com

基金资助:CLC Number:

Min YANG, Xinwei DUAN, Junhong WU, Jie MI, Jiancheng WANG, Mengmeng WU. COS catalyzed hydrolysis performance and deactivation mechanism of Sm2O3/γ-Al2O3 catalysts[J]. CIESC Journal, 2025, 76(8): 4061-4070.

杨敏, 段新伟, 吴俊宏, 米杰, 王建成, 武蒙蒙. Sm2O3/γ-Al2O3催化剂的COS催化水解性能及失活机制[J]. 化工学报, 2025, 76(8): 4061-4070.

Add to citation manager EndNote|Ris|BibTeX

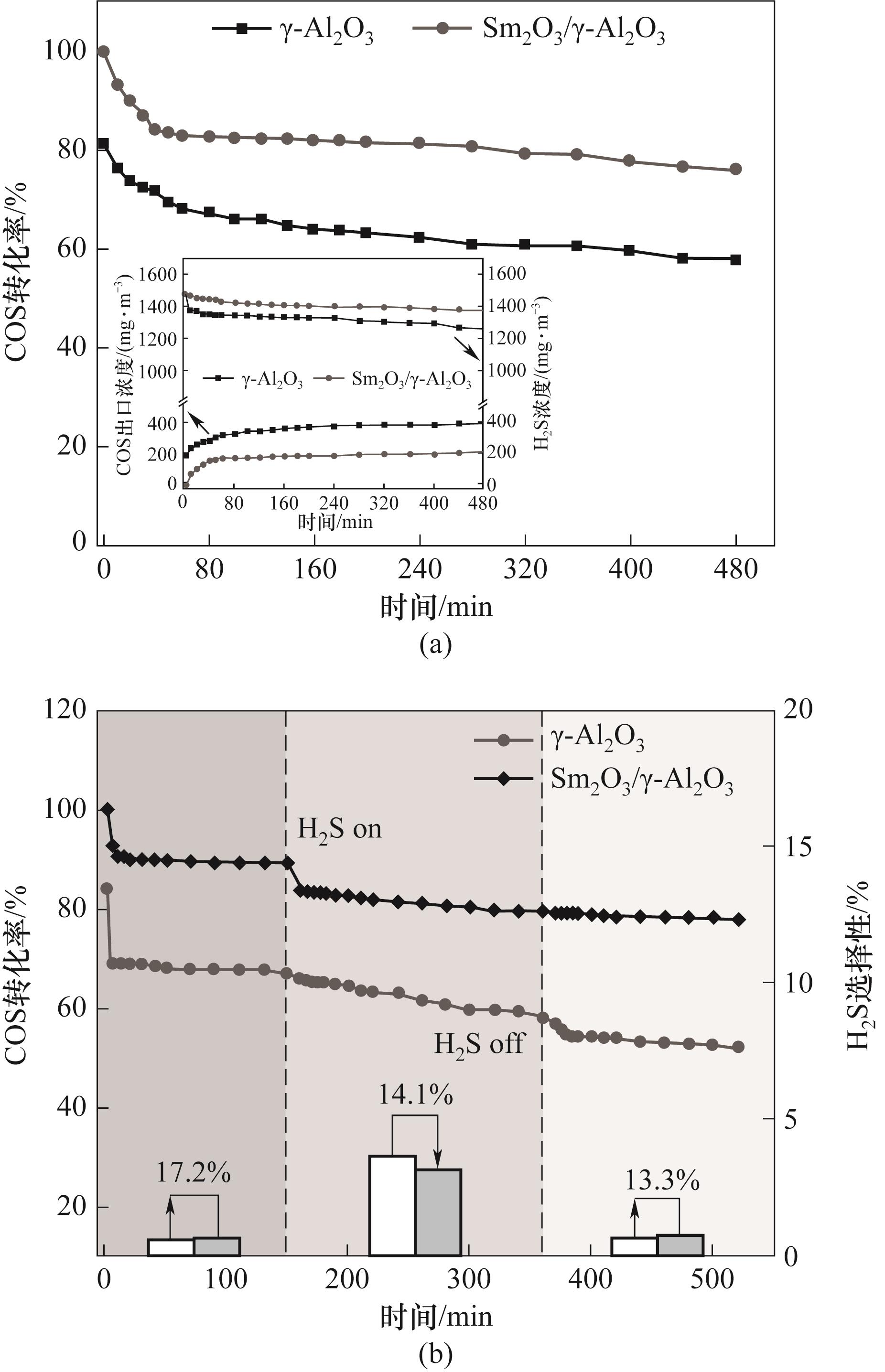

Fig.3 COS conversion and H2S concentration at the outlet as a function of COS concentration under constant CO2 (a) and effect of CO2 on COS conversion in transient experiments (b)(70℃,200 ml·min-1,1000 mg·m-3 COS,3% H2O,0.5% O2,5% CO2,N2 balance)

Fig.4 COS conversion and H2S concentration at the outlet as a function of COS concentration under constant H2S (a) and effect of H2S on COS conversion in transient experiments (b)

| 反应条件 | γ-Al2O3 | Sm2O3/γ-Al2O3 | ||||

|---|---|---|---|---|---|---|

| 比表面积/(m2·g-1) | 孔体积/(cm3·g-1) | 平均孔径/nm | 比表面积/(m2·g-1) | 孔体积/(cm3·g-1) | 平均孔径/nm | |

| fresh | 141.2 | 1.2 | 33.5 | 121.5 | 0.5 | 16.2 |

| used(O2) | 141.2 | 0.5 | 15.1 | 124.6 | 0.5 | 15.9 |

| used(O2+CO2) | 133.9 | 0.5 | 15.3 | 121.1 | 0.5 | 16.5 |

| used(O2+H2S) | 112.0 | 0.5 | 16.6 | 113.9 | 0.5 | 16.8 |

| used(O2+CO2+H2S) | 134.3 | 0.5 | 15.4 | 120.1 | 0.5 | 16.7 |

Table 1 Pore structure parameters of γ-Al2O3 and Sm2O3/γ-Al2O3 catalysts before and after COS catalysis under different gas compositions

| 反应条件 | γ-Al2O3 | Sm2O3/γ-Al2O3 | ||||

|---|---|---|---|---|---|---|

| 比表面积/(m2·g-1) | 孔体积/(cm3·g-1) | 平均孔径/nm | 比表面积/(m2·g-1) | 孔体积/(cm3·g-1) | 平均孔径/nm | |

| fresh | 141.2 | 1.2 | 33.5 | 121.5 | 0.5 | 16.2 |

| used(O2) | 141.2 | 0.5 | 15.1 | 124.6 | 0.5 | 15.9 |

| used(O2+CO2) | 133.9 | 0.5 | 15.3 | 121.1 | 0.5 | 16.5 |

| used(O2+H2S) | 112.0 | 0.5 | 16.6 | 113.9 | 0.5 | 16.8 |

| used(O2+CO2+H2S) | 134.3 | 0.5 | 15.4 | 120.1 | 0.5 | 16.7 |

| [1] | 刘臻, 次东辉, 方薪晖, 等. 基于含碳废弃物与煤共气化的碳循环概念及碳减排潜力分析[J]. 洁净煤技术, 2022, 28(2): 130-136. |

| Liu Z, Ci D H, Fang X H, et al. Concept of carbon cycle based on co-gasification of carbon containing waste and coal and analysis of carbon emission reduction potential[J]. Clean Coal Technology, 2022, 28(2): 130-136. | |

| [2] | 周守毅. 钢铁企业副产煤气中硫化物的测定[J]. 环境科学与技术, 2017, 40(S1): 252-254. |

| Zhou S Y. Determiningsulfur compound in by-product gas of iron and steel enterprises[J]. Environmental Science & Technology, 2017, 40(S1): 252-254. | |

| [3] | Cao R, Ning P, Wang X Q, et al. Low-temperature hydrolysis of carbonyl sulfide in blast furnace gas using Al2O3-based catalysts with high oxidation resistance[J]. Fuel, 2022, 310: 122295. |

| [4] | Yang D D, Chen G M, Fu J M, et al. The mitigation performance of ventilation on the accident consequences of H2S-containing natural gas release[J]. Process Safety and Environmental Protection, 2021, 148: 1327-1336. |

| [5] | 范健, 雷军. COS脱除技术进展[J]. 安徽化工, 2007, 33(4): 3-5. |

| Fan J, Lei J. Technique development of COS removal[J]. Anhui Chemical Industry, 2007, 33(4): 3-5. | |

| [6] | 王明飞, 陈鹏, 陶雷, 等. 有机硫水解催化剂研究进展[J]. 材料导报, 2022, 36(17): 40-48. |

| Wang M F, Chen P, Tao L, et al. Research progress of organic sulfur hydrolysis catalyst[J]. Materials Reports, 2022, 36(17): 40-48. | |

| [7] | 孙万堂. 助剂改性钴钼加氢脱硫催化剂制备过程研究[D]. 青岛: 青岛科技大学, 2016. |

| Sun W T. Additives modification process research of CoMo/ γ - A l 2 O 3 hydrodesulfurization catalyst[D]. Qingdao: Qingdao University of Science and Technology, 2016. | |

| [8] | 杨晨, 赖君玲, 罗根祥. 羰基硫水解催化剂研究进展[J]. 当代化工, 2015, 44(10): 2352-2354. |

| Yang C, Lai J L, Luo G X. Research progress of carbonyl sulfide hydrolysis catalysts[J]. Contemporary Chemical Industry, 2015, 44(10): 2352-2354. | |

| [9] | 王冠, 孙同华, 张宏波, 等. 催化水解法低温脱除煤气中羰基硫的研究[J]. 现代化工, 2014, 34(1): 60-63. |

| Wang G, Sun T H, Zhang H B, et al. Carbonyl sulfide gas removal by catalytic hydrolysis in low temperature[J]. Modern Chemical Industry, 2014 34(1): 60-63. | |

| [10] | 李春虎, 郭汉贤, 谈世韶. 碱改性γ-Al2O3催化剂表面碱强度分布与COS水解活性的研究[J]. 分子催化, 1994, 8(4): 305-312. |

| Li C H, Guo H X, Tan S S. Study on the alkalized γ-Al2O3 catalyst for its base strength distribution and catalytic activity[J]. Journal of Molecular Catalysis(China), 1994, 8(4): 305-312. | |

| [11] | Rhodes C, Riddel S A, West J, et al. The low-temperature hydrolysis of carbonyl sulfide and carbon disulfide: a review[J]. Catalysis Today, 2000, 59(3/4): 443-464. |

| [12] | Li H F, Su S, Peng Y, et al. Effect of La-modified supporter on H2S removal performance of Mn/La/Al2O3 sorbent in a reducing atmosphere[J]. Industrial & Engineering Chemistry Research, 2019, 58(19): 8260-8270. |

| [13] | Zhang Y Q, Xiao Z B, Ma J X. Hydrolysis of carbonyl sulfide over rare earth oxysulfides[J]. Applied Catalysis B: Environmental, 2004, 48(1): 57-63. |

| [14] | Gao P T, Li Y R, Lin Y T, et al. Promoting effect of Fe/La loading on γ-Al2O3 catalyst for hydrolysis of carbonyl sulfur[J]. Environmental Science and Pollution Research, 2022, 29(56): 84166-84179. |

| [15] | 曹强, 李玉然, 王斌, 等. γ-Al2O3基COS水解催化剂在含HCl气氛的失活机理[J]. 环境工程, 2023, 41(12): 182-189. |

| Cao Q, Li Y R, Wang B, et al. Deactivation mechanism of γ-Al2O3 based catalysts for the catalytic hydrolysis of carbonyl sulfide in presence of HCl[J]. Environmental Engineering, 2023, 41(12): 182-189. | |

| [16] | 高志华, 阴丽华, 李春虎, 等. 纳米α-FeOOH催化剂一段法脱除COS和H2S性能的研究[J]. 燃料化学学报, 2003, 31(3): 249-253. |

| Gao Z H, Yin L H, Li C H, et al. Study on simultaneous removal of COS and H2S by using α-FeOOH nanoparticle[J]. Journal of Fuel Chemistry and Technology, 2003, 31(3): 249-253. | |

| [17] | Tong S, Dalla Lana I G, Chuang K T. Kinetic modelling of the hydrolysis of carbonyl sulfide catalyzed by either titania or alumina[J]. The Canadian Journal of Chemical Engineering, 1993, 71(3): 392-400. |

| [18] | 谈世韶, 王辉, 李春虎, 等. 高浓度二氧化碳气体中羰基硫的水解脱除[J]. 化肥工业, 1991, 18(2): 26-29, 53. |

| Tan S S, Wang H, Li C H, et al. Hydrolytic of carbonyl sulfide in high concentration carbon dioxide gas[J]. Journal of Chemical Fertilizer Industry, 1991, 18(2): 26-29, 53. | |

| [19] | 王国兴, 黄新伟, 叶敬东, 等. T504型常温COS水解催化剂的研制[J]. 湖北化工, 1995, 12(1): 24-28. |

| Wang G X, Huang X W, Ye J D, et al. Development of T504 type catalyst for hydrolysis of COS at room temperature[J]. Hubei Chemical Industry, 1995, 12(1): 24-28. | |

| [20] | 张青林, 郭汉贤. γ-Al2O3催化剂上羰基硫的水解动力学[J]. 催化学报, 1988, 9(1): 14-24. |

| Zhang Q L, Guo H X. Kinetics of the hydrolysis of carbonyl sulfide over γ-Al2O3 catalysts at lower temperature[J]. Chinese Journal of Catalysis, 1988, 9(1): 14-24. | |

| [21] | Lei G C, Zheng Y, Cao Y N, et al. Deactivation mechanism of COS hydrolysis over potassium modified alumina[J]. Acta Physico Chimica Sinica, 2023, 39(9): 2210038. |

| [22] | Thommes M, Kaneko K, Neimark A V, et al. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report)[J]. Pure and Applied Chemistry, 2015, 87(9/10): 1051-1069. |

| [23] | Meng Y, Gu D, Zhang F Q, et al. Ordered mesoporous polymers and homologous carbon frameworks: amphiphilic surfactant templating and direct transformation[J]. Angewandte Chemie International Edition, 2005, 44(43): 7053-7059. |

| [24] | Pan F, Lu X C, Wang T Z, et al. Synthesis of large-mesoporous γ-Al2O3 from coal-series kaolin at room temperature[J]. Materials Letters, 2013, 91: 136-138. |

| [25] | Taherian Z, Shahed Gharahshiran V, Khataee A, et al. Anti-coking freeze-dried NiMgAl catalysts for dry and steam reforming of methane[J]. Journal of Industrial and Engineering Chemistry, 2021, 103: 187-194. |

| [26] | Zhang M, Zhang J F, Zhou Z L, et al. Effects of the surface adsorbed oxygen species tuned by rare-earth metal doping on dry reforming of methane over Ni/ZrO2 catalyst[J]. Applied Catalysis B: Environmental, 2020, 264: 118522. |

| [27] | 魏征, 张鑫, 张凤莲, 等. 镁铝水滑石衍生复合氧化物的COS水解性能[J]. 环境科学, 2019, 40(10): 4423-4430. |

| Wei Z, Zhang X, Zhang F L, et al. Hydrolysis of COS over MgAl mixed oxides derived from hydrotalcites[J]. Environmental Science, 2019, 40(10): 4423-4430. | |

| [28] | Yang S Q, He J P, Zhang N, et al. Effect of rare-earth element modification on the performance of Cu/ZnAl catalysts derived from hydrotalcite precursor in methanol steam reforming[J]. Journal of Fuel Chemistry and Technology, 2018, 46(2): 179-188. |

| [29] | Wang J W, Xie H, Shu D B, et al. The promotion of NH3-SCR performance and its mechanism on Sm modified birnessite[J]. Fuel, 2024, 356: 129604. |

| [30] | Dong X S, Li F, Zhao N, et al. A study on the order of calcination and liquid reduction over Cu-based catalyst for synthesis of methanol from CO2/H2 [J]. Catalysis Letters, 2017, 147: 1235-1242. |

| [31] | Zhao S Z, Yi H H, Tang X L, et al. The hydrolysis of carbonyl sulfide at low temperature: a review[J]. The Scientific World Journal, 2013(1): 739501. |

| [32] | 蒋慧敏. 分子筛吸附脱除焦炉煤气中羰基硫和硫化氢性能及机理研究[D]. 太原: 太原理工大学, 2021. |

| Jiang H M. Study on performance and mechanism of adsorption and removal of carbonyl sulfur and hydrogen sulfide from coke oven gas by molecular sieve[D]. Taiyuan: Taiyuan University of Technology, 2021. | |

| [33] | 臧丽莉. Al2O3表面吸附小分子的第一性原理研究[D]. 福州: 福州大学, 2011. |

| Zang L L. First-principles study on adsorption of small molecules on Al2O3 surface[D]. Fuzhou: Fuzhou University, 2011. | |

| [34] | Chupas P J, Chapman K W, Halder G J. Elucidating the structure of surface acid sites on γ-Al2O3 [J]. Journal of the American Chemical Society, 2011, 133(22): 8522-8524. |

| [35] | Zhang X, Qiu X Y, Wang R. Enabling catalysts for carbonyl sulfide hydrolysis[J]. Catalysts, 2024, 14(12): 952. |

| [36] | Cao Q, Lin Y T, Li Y R, et al. Hydrolysis of carbonyl sulfide in blast furnace gas using alkali metal-modified γ-Al2O3 catalysts with high sulfur resistance[J]. ACS Omega, 2023, 8(39): 35608-35618. |

| [37] | Zi S Y, Li K, Wang X Q, et al. Influence of surface basic sites and oxygen vacancies on the performance of metal-modified rod-like ceria catalysts for low-temperature hydrolysis of carbonyl sulfide[J]. Chemistry—An Asian Journal, 2024, 19(21): e202400235. |

| [1] | Dongling XU, Yue MA, Lu GONG, Guili MA, Jinke WANG, Fengzhi GUO, Haolun WANG, Sijia LI, Shuyuan LI, Changtao YUE. Co-pyrolysis study of oil shale and bituminous coal in fixed fluidized bed reactor [J]. CIESC Journal, 2025, 76(4): 1742-1753. |

| [2] | Longlong WANG, Zhifeng QIN, Hongyan BAN, Naizhen LI, Zhenyi DU, Feng YU, Zhiqiang ZHAI, Qiongxiao WU. Optimization of Al2O3 support pore structure: enhancing the hydrodesulfurization performance of FeMo/Al2O3 catalyst in coke oven gas [J]. CIESC Journal, 2024, 75(10): 3623-3638. |

| [3] | Feifei YANG, Shixi ZHAO, Wei ZHOU, Zhonghai NI. Sn doped In2O3 catalyst for selective hydrogenation of CO2 to methanol [J]. CIESC Journal, 2023, 74(8): 3366-3374. |

| [4] | Chen HAN, Youmin SITU, Bin ZHU, Jianliang XU, Xiaolei GUO, Haifeng LIU. Study of reaction and flow characteristics in multi-nozzle pulverized coal gasifier with co-processing of wastewater [J]. CIESC Journal, 2023, 74(8): 3266-3278. |

| [5] | Yongquan ZHANG, Weiwei XUAN. Mechanism of alkali metal/(FeO+CaO+MgO) influence on the structure and viscosity of silicate ash slag [J]. CIESC Journal, 2023, 74(4): 1764-1771. |

| [6] | Tianhao BAI, Xiaowen WANG, Mengzi YANG, Xinwei DUAN, Jie MI, Mengmeng WU. Study on release and inhibition behavior of COS during high-temperature gas desulfurization process using Zn-based oxide derived from hydrotalcite [J]. CIESC Journal, 2023, 74(4): 1772-1780. |

| [7] | Peng QIU, Yang HAN, Jianliang XU, Fuchen WANG, Zhenghua DAI. Study of EDC parameters for predicting entrained flow coal gasification [J]. CIESC Journal, 2023, 74(1): 428-437. |

| [8] | Wenhua DAI, Zhong XIN. Effect of Si-doped Cu/ZrO2 on the performance of catalysts for CO2 hydrogenation to methanol [J]. CIESC Journal, 2022, 73(8): 3586-3596. |

| [9] | Lianfeng ZHU, Chao WANG, Mengjuan ZHANG, Fangzheng LIU, Xin JIA, Ping AN, Guangwen XU, Zhennan HAN. Fluidized bed two-stage gasification of coal with steam/O2 for production of low-tar syngas [J]. CIESC Journal, 2022, 73(8): 3720-3730. |

| [10] | Wenli GAO, Zhong XIN. Research on promotion of Fe in Ni/SBA-16 catalyzing CO methanation at low temperature [J]. CIESC Journal, 2022, 73(1): 241-254. |

| [11] | Yuming ZHANG, Lifeng WAN, Juntao GUAN, Haipeng SONG, Hang YANG, Shiqiu GAO. Fundamental study on the fluid coking behavior of Dagang oil slurry and preparation of aromatic-rich oil [J]. CIESC Journal, 2021, 72(8): 4325-4335. |

| [12] | Xiaobo FENG, Tianlong LIU, Xiaoyan ZHAO, Jingpei CAO. Advance in ethanol synthesis from syngas via carbonylation of dimethyl ether and hydrogenation of methyl acetate [J]. CIESC Journal, 2021, 72(8): 3958-3967. |

| [13] | TAN Khangwei, XIONG Wenting, FU Jile, CHEN Binghui. Preparation and catalytic performance of Ru-Co/SiC catalysts for the synthesis of heavy hydrocarbons from syngas by Fischer-Tropsch reaction [J]. CIESC Journal, 2021, 72(7): 3648-3657. |

| [14] | ZHANG Yuming, JI Dexin, ZHU Hanwen, WAN Lifeng, ZHANG Wei, WEN Hongyan, YUE Junrong. Reaction kinetics of naphthalene cracking into small molecule gas in a micro fluidized bed [J]. CIESC Journal, 2021, 72(5): 2604-2615. |

| [15] | ZHOU Ye, XIAO Huixia, WANG Yifei, YU Guangsuo. Study on improving slurryability of lignite based on coal blending and surface modification [J]. CIESC Journal, 2021, 72(4): 2233-2240. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||