化工学报 ›› 2021, Vol. 72 ›› Issue (10): 5294-5309.DOI: 10.11949/0438-1157.20210788

收稿日期:2021-06-10

修回日期:2021-07-23

出版日期:2021-10-05

发布日期:2021-10-05

通讯作者:

江锦波

作者简介:于辰(1997—),男,硕士研究生,基金资助:

Chen YU( ),Jinbo JIANG(

),Jinbo JIANG( ),Wenjing ZHAO,Jiyun LI,Xudong PENG,Yuming WANG

),Wenjing ZHAO,Jiyun LI,Xudong PENG,Yuming WANG

Received:2021-06-10

Revised:2021-07-23

Online:2021-10-05

Published:2021-10-05

Contact:

Jinbo JIANG

摘要:

为解决现有干气密封端面型槽型线方程表征能力不强和结构参数定义体系不统一的问题,提出了一种基于径向微段组合以表征任意形状型线的广义对数螺旋槽结构模型。给出了广义对数螺旋槽结构参数定义体系,对比了不同压力和速度条件下广义螺旋槽与经典螺旋槽干气密封的开启力、气膜刚度和泄漏率等稳态性能,重点研究了广义螺旋角分布和型线周向偏转两个特征量对干气密封性能的影响,基于不同目标函数获得了广义螺旋槽的最优形状。结果表明:型槽上游侧壁型线形状对各项稳态性能参数均有显著影响,而下游侧壁型线形状仅对泄漏率和气膜刚度影响显著;经典对数螺旋槽是一种流体动静压效应很强的端面结构,单纯依靠型线优化难以使气膜承载力显著提高,不过在低压高速条件下优化广义螺旋角分布,在高压低速条件下合适设置型线周向偏转有望提高干气密封的气膜刚度和刚漏比。

中图分类号:

于辰,江锦波,赵文静,李纪云,彭旭东,王玉明. 基于微段组合的干气密封端面型槽结构模型及其参数影响[J]. 化工学报, 2021, 72(10): 5294-5309.

Chen YU,Jinbo JIANG,Wenjing ZHAO,Jiyun LI,Xudong PENG,Yuming WANG. Geometrical model of surface groove based on micro-segment combination for dry gas seal and its parameter influence[J]. CIESC Journal, 2021, 72(10): 5294-5309.

偏转角 情况 | 型槽结构 | 槽根周向夹角θg |

|---|---|---|

| θ1>0,θ2<0 |  | θh |

| θ1<0,θ2>0 |  | θh(1-|θ2|-|θ1|) |

| θ1<0,θ2<0 |  | θh(1-|θ1|) |

| θ1>0,θ2>0 |  | θh(1-|θ2|) |

表1 单向广义螺旋槽型线非连续偏转及开槽角度

Table 1 Discontinuous deflection and slotting angle of unidirectional generalized spiral groove

偏转角 情况 | 型槽结构 | 槽根周向夹角θg |

|---|---|---|

| θ1>0,θ2<0 |  | θh |

| θ1<0,θ2>0 |  | θh(1-|θ2|-|θ1|) |

| θ1<0,θ2<0 |  | θh(1-|θ1|) |

| θ1>0,θ2>0 |  | θh(1-|θ2|) |

| 几何参数 | 形状演变 | |

|---|---|---|

| 广义螺旋角分布 | 进口螺旋角β1 |  |

| 转折螺旋角β2 |  | |

| 出口螺旋角β3 |  | |

| 上游超椭圆系数n1 |  | |

| 下游超椭圆系数n2 |  | |

| 极角分布 | 迎风侧偏角系数α2 |  |

| 背风侧偏角系数α1 |  | |

表2 广义螺旋槽结构参数取值对型槽形状的影响

Table 2 The influence of generalized spiral groove structure parameters on the shape of groove

| 几何参数 | 形状演变 | |

|---|---|---|

| 广义螺旋角分布 | 进口螺旋角β1 |  |

| 转折螺旋角β2 |  | |

| 出口螺旋角β3 |  | |

| 上游超椭圆系数n1 |  | |

| 下游超椭圆系数n2 |  | |

| 极角分布 | 迎风侧偏角系数α2 |  |

| 背风侧偏角系数α1 |  | |

| 型槽类型 | 型槽图例 | 广义螺旋角分布 | 周向极角分布 | 具体参数 |

|---|---|---|---|---|

| 流道等宽槽 |  | β1=β2=β3=15°; α1=α2=0;n1=1, n2=1 | ||

| 流道渐扩槽 |  | β1=10°, β2=25°, β3=40°; α1=α2=0;n1=1, n2=1 | ||

| 流道渐缩槽 |  | β1=40°, β2=25°, β3=10°;α1=α2=0;n1=1, n2=1 | ||

| 先扩后缩槽 |  | β1=10°, β2=40°, β3=10°;α1=α2=0;n1=1, n2=1 | ||

| 先缩后扩槽 |  | β1=40°, β2=10°, β3=40°;α1=α2=0;n1=1, n2=1 | ||

| 人字槽[ |  | β1=15°, β2=90°, β3=165°;α1=α2=0;n1=0.1, n2=0.1 | ||

| 多翼槽 |  | β1=β2=β3=15°; α1=0, α2=0.5;n1=1, n2=1 | ||

表3 不同特征参数取值对应的广义螺旋槽形状

Table 3 Corresponding characteristic parameters of generalized spiral groove shape

| 型槽类型 | 型槽图例 | 广义螺旋角分布 | 周向极角分布 | 具体参数 |

|---|---|---|---|---|

| 流道等宽槽 |  | β1=β2=β3=15°; α1=α2=0;n1=1, n2=1 | ||

| 流道渐扩槽 |  | β1=10°, β2=25°, β3=40°; α1=α2=0;n1=1, n2=1 | ||

| 流道渐缩槽 |  | β1=40°, β2=25°, β3=10°;α1=α2=0;n1=1, n2=1 | ||

| 先扩后缩槽 |  | β1=10°, β2=40°, β3=10°;α1=α2=0;n1=1, n2=1 | ||

| 先缩后扩槽 |  | β1=40°, β2=10°, β3=40°;α1=α2=0;n1=1, n2=1 | ||

| 人字槽[ |  | β1=15°, β2=90°, β3=165°;α1=α2=0;n1=0.1, n2=0.1 | ||

| 多翼槽 |  | β1=β2=β3=15°; α1=0, α2=0.5;n1=1, n2=1 | ||

| 名称与单位 | 数值 | 名称与单位 | 数值 |

|---|---|---|---|

| 密封端面外径,ro /mm | 37.5 | 背风侧偏转角系数,α1 | 0 |

| 密封端面内径,ri/mm | 29.5 | 迎风侧偏转角系数,α2 | 0 |

| 螺旋槽数,Ng | 12 | 气膜厚度,h0/μm | 3.0 |

| 周向槽宽比,δ | 0.5 | 气体黏度, μ/(mPa·s) | 0.0186 |

| 径向槽长比, γ1 | 0.6 | 环境压力, pa /MPa | 0.10 |

| 上游槽长比,γ2 | 0.5 | 内径侧压力,pi /MPa | 0.10 |

| 槽深, hg/μm | 5.0 | 外径侧压力,po/MPa | 0.50 |

| 上游超椭圆系数,n1 | 1.0 | 密封端面平均线速度,v/(m·s-1) | 100 |

| 下游超椭圆系数,n2 | 1.0 |

表4 干气密封运行工况及结构参数缺省值

Table 4 Operating conditions and structural parameter default values of dry gas seal

| 名称与单位 | 数值 | 名称与单位 | 数值 |

|---|---|---|---|

| 密封端面外径,ro /mm | 37.5 | 背风侧偏转角系数,α1 | 0 |

| 密封端面内径,ri/mm | 29.5 | 迎风侧偏转角系数,α2 | 0 |

| 螺旋槽数,Ng | 12 | 气膜厚度,h0/μm | 3.0 |

| 周向槽宽比,δ | 0.5 | 气体黏度, μ/(mPa·s) | 0.0186 |

| 径向槽长比, γ1 | 0.6 | 环境压力, pa /MPa | 0.10 |

| 上游槽长比,γ2 | 0.5 | 内径侧压力,pi /MPa | 0.10 |

| 槽深, hg/μm | 5.0 | 外径侧压力,po/MPa | 0.50 |

| 上游超椭圆系数,n1 | 1.0 | 密封端面平均线速度,v/(m·s-1) | 100 |

| 下游超椭圆系数,n2 | 1.0 |

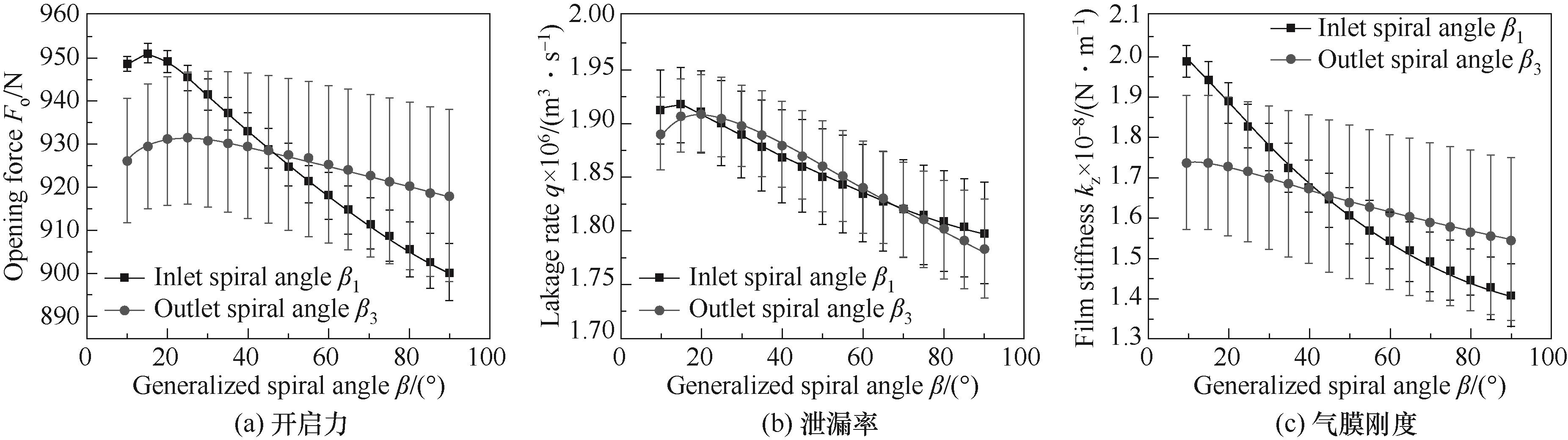

图7 进口螺旋角和出口螺旋角对干气密封稳态性能的影响(β2=30°)

Fig.7 The influence of inlet spiral angle and outlet sprial angle on the steady-state performance of dry gas seals (β2=30°)

图8 上游槽和下游槽超椭圆系数对干气密封稳态性能的影响(β1=15°、 β2=30°、 β3=45°)(β1=15°, β2=30°, β3=45°)

Fig.8 The influence of the hyperelliptic coefficient of upstream and downstream grooves on the steady-state performance of gas seals

| 密封性能 | 上游槽 | 下游槽 | ||

|---|---|---|---|---|

| β1 | n1 | β3 | n2 | |

| 开启力 Fo | 5.48% | 2.95% | 1.45% | 0.24% |

| 泄漏率 q | 6.42% | 3.21% | 6.77% | 2.33% |

| 气膜刚度 kz | 35.33% | 10.70% | 11.52% | 4.00% |

表5 不同上游槽和下游槽型线特征参数对应的性能参数均值变化率

Table 5 The sealing performance change rate corresponding to the characteristic parameters of the upstream and downstream grooves

| 密封性能 | 上游槽 | 下游槽 | ||

|---|---|---|---|---|

| β1 | n1 | β3 | n2 | |

| 开启力 Fo | 5.48% | 2.95% | 1.45% | 0.24% |

| 泄漏率 q | 6.42% | 3.21% | 6.77% | 2.33% |

| 气膜刚度 kz | 35.33% | 10.70% | 11.52% | 4.00% |

| 1 | 王玉明, 刘伟, 刘莹. 非接触式机械密封基础研究现状与展望[J]. 液压气动与密封, 2011, 31(2): 29-33. |

| Wang Y M, Liu W, Liu Y. Current research and developing trends on non-contacting mechanical seals[J]. Hydraulics Pneumatics & Seals, 2011, 31(2): 29-33. | |

| 2 | Gardner J. Rotary mechanical seal of the gap type: US3499653[P]. 1968-06-05. |

| 3 | Gabriel R P. Fundamentals of spiral groove noncontacting face seals[J]. Lubrication Engineering, 1994, 50(3): 215-224. |

| 4 | 江锦波, 徐奇超, 陈源, 等. 端面型槽广义对数螺旋线的通用模型与应用[J]. 中国机械工程, 2019, 30(22): 2661-2667. |

| Jiang J B, Xu Q C, Chen Y, et al. Universal model and applications of generalized logarithmic helix on surface grooves[J]. China Mechanical Engineering, 2019, 30(22): 2661-2667. | |

| 5 | 彭旭东, 宗聪, 江锦波. 干气密封单向螺旋槽及其衍生结构功能演变进展[J]. 化工学报, 2017, 68(4): 1271-1281. |

| Peng X D, Zong C, Jiang J B. Progress in dry gas seal performance evolution of unidirectional spiral groove and its derivative structures[J]. CIESC Journal, 2017, 68(4): 1271-1281. | |

| 6 | 彭旭东, 江锦波, 白少先, 等. 中低压干气密封螺旋槽结构参数优化[J]. 化工学报, 2014, 65(11): 4536-4542. |

| Peng X D, Jiang J B, Bai S X, et al. Structural parameter optimization of spiral groove dry gas seal under low or medium pressure[J]. CIESC Journal, 2014, 65(11): 4536-4542. | |

| 7 | 宋文博, 李双喜, 蔡纪宁. 不等深螺旋槽干气密封性能的研究[J]. 润滑与密封, 2010, 35(4): 80-84. |

| Song W B, Li S X, Cai J N. Study on the performance of dry gas seal with cone-shaped and ladder-like spiral groove[J].Lubrication Engineering, 2010, 35(4): 80-84. | |

| 8 | Shahin I, Gadala M, Alqaradawi M, et al. Three dimensional computational study for spiral dry gas seal with constant groove depth and different tapered grooves[J]. Procedia Engineering, 2013, 68: 205-212. |

| 9 | Salant R F, Homiller S J. The effects of shallow groove patterns on mechanical seal leakage[J]. Tribology Transactions, 1992, 35(1): 142-148. |

| 10 | 胡丹梅, 彭旭东, 郝木明, 等. 直线槽气体端面密封流体膜厚度的测量[J]. 润滑与密封, 2005, 30(2): 139-142. |

| Hu D M, Peng X D, Hao M M, et al. Measurement of the film thickness of the oblique line groove gas face seal[J]. Lubrication Engineering, 2005, 30(2): 139-142. | |

| 11 | 王建荣, 顾永泉, 陈弘. 圆弧槽气体润滑非接触式机械密封的特性[J]. 流体机械, 1991, 19(3): 1-6, 64. |

| Wang J R, Gu Y Q, Chen H. The performance and analysis of partally circular arc grooved machnical face gas seal[J].Fluid Machinery, 1991, 19(3): 1-6, 64. | |

| 12 | Chen Y, Jiang J B, Peng X D. Dynamic characteristics and transient sealing performance analysis of hyperelliptic curve groove dry gas seals[J]. Tribology International, 2017, 116: 217-228. |

| 13 | 徐奇超, 江锦波, 陈源, 等. 经典曲线型槽干气密封稳动态密封特性数值分析[J]. 摩擦学学报, 2018, 38(5): 584-594. |

| Xu Q C, Jiang J B, Chen Y, et al. Numerical analysis of steady-state and dynamic characteristics of typical molded line groove dry gas seals[J]. Tribology, 2018, 38(5): 584-594. | |

| 14 | Hashimoto H, Namba T. Optimization of groove geometry for a thrust air bearing according to various objective functions[J]. Journal of Tribology, 2009, 131(4): 1-10. |

| 15 | Hashimoto H, Ochiai M. Optimization of groove geometry for thrust air bearing to maximize bearing stiffness[J]. Journal of Tribology, 2008, 130(3): 031101. |

| 16 | 丁雪兴, 赵芳, 黄义仿, 等. 拟合曲线槽干气密封流场的数值模拟及分析[J]. 润滑与密封, 2013, 38(2): 35-38, 105. |

| Ding X X, Zhao F, Huang Y F, et al. Numerical simulation and analysis of flow field for dry gas seal with fitted curve groove based on tracing line[J]. Lubrication Engineering, 2013, 38(2): 35-38, 105. | |

| 17 | Shen C, Khonsari M M. Numerical optimization of texture shape for parallel surfaces under unidirectional and bidirectional sliding[J]. Tribology International, 2015, 82: 1-11. |

| 18 | 魏超, 陈国明, 栾智存, 等. 车用旋转密封件动压槽型线优化研究[J]. 北京理工大学学报, 2016, 36(1): 25-30. |

| Wei C, Chen G M, Luan Z C, et al. Optimization on the hydrodynamic groove geometry of rotary seals for automotive transmissions[J]. Transactions of Beijing Institute of Technology, 2016, 36(1): 25-30. | |

| 19 | 彭旭东, 黄莉, 白少先, 等. 雁型槽干式气体端面密封性能的数值分析[J]. 化工学报, 2010, 61(12): 3193-3199. |

| Peng X D, Huang L, Bai S X, et al. Numerical analysis of sealing performance of dry gas seal with goose-grooves[J]. CIESC Journal, 2010, 61(12): 3193-3199 | |

| 20 | 彭旭东, 刘坤, 白少先, 等. 典型螺旋槽端面干式气体密封动压开启性能[J]. 化工学报, 2013, 64(1): 326-333. |

| Peng X D, Liu K, Bai S X, et al. Dynamic opening characteristics of dry gas seals with typical types of spiral grooves[J]. CIESC Journal, 2013, 64(1): 326-333. | |

| 21 | Li Y, Song P Y, Xu H J. Performance analyses of the spiral groove dry gas seal with inner annular groove[J]. Applied Mechanics and Materials, 2013, 420: 51-55. |

| 22 | 彭旭东, 谭丽丽, 盛颂恩, 等. 带内环槽的螺旋槽干式气体端面密封的静压性能[J]. 摩擦学学报, 2008, 28(6): 507-511. |

| Peng X D, Tan L L, Sheng S E, et al. Static analysis of a spiral-groove dry gas seal with an inner annular groove[J]. Tribology, 2008, 28(6): 507-511. | |

| 23 | 彭旭东, 呼延晨龙, 白少先, 等. 基于鸟翼轮廓的干式气体密封仿生型槽设计[J] .摩擦学学报, 2012, 32(6): 563-569. |

| Peng X D, Huyan C L, Bai S X, et al. Design of a biomorphic groove dry gas seal based on bird wing outlines[J]. Tribology, 2012, 32(6): 563-569. | |

| 24 | 陶丹萍. 组合螺旋型槽干气密封泄漏特性研究[D]. 南京: 南京林业大学, 2013. |

| Tao D P. Study on the leakage characteristics of the combined spiral groove dry gas seal[D]. Nanjing: Nanjing Forestry University, 2013. |

| [1] | 丁俊华, 俞树荣, 王世鹏, 洪先志, 包鑫, 丁雪兴. 多重效应下超高速干气密封流场模拟及密封性能试验[J]. 化工学报, 2023, 74(5): 2088-2099. |

| [2] | 严如奇, 丁雪兴, 徐洁, 洪先志, 包鑫. 基于湍流模型的S-CO2干气密封流场与稳态性能分析[J]. 化工学报, 2021, 72(8): 4292-4303. |

| [3] | 孙雪剑, 宋鹏云, 毛文元, 邓强国, 许恒杰, 陈维. 考虑密封环材料属性和表面形貌干气密封启停阶段的动态接触特性分析[J]. 化工学报, 2021, 72(8): 4279-4291. |

| [4] | 江鹏, 江锦波, 彭旭东, 孟祥铠, 马艺. 传热模型对近临界工况CO2干气密封温压分布和稳态性能影响[J]. 化工学报, 2021, 72(8): 4239-4254. |

| [5] | 商浩, 陈源, 李孝禄, 王冰清, 李运堂, 彭旭东. 膜厚扰动下的非线性效应对干气密封性能影响研究[J]. 化工学报, 2021, 72(4): 2213-2222. |

| [6] | 江锦波, 滕黎明, 孟祥铠, 李纪云, 彭旭东. 基于多变量摄动的超临界CO2干气密封动态特性[J]. 化工学报, 2021, 72(4): 2190-2202. |

| [7] | 严如奇, 洪先志, 包鑫, 徐洁, 丁雪兴. 超临界二氧化碳干气密封相态分布规律与密封性能研究[J]. 化工学报, 2020, 71(8): 3681-3690. |

| [8] | 范瑜, 宋鹏云, 许恒杰. 水蒸气润滑干气密封启动过程研究[J]. 化工学报, 2020, 71(8): 3671-3680. |

| [9] | 陈维, 宋鹏云, 许恒杰, 孙雪剑. 含杂质二氧化碳实际气体干气密封性能研究[J]. 化工学报, 2020, 71(5): 2215-2229. |

| [10] | 车健, 江锦波, 李纪云, 彭旭东, 马艺, 王玉明. 节流孔出气模式对静压干气密封稳态性能影响[J]. 化工学报, 2020, 71(4): 1734-1743. |

| [11] | 沈伟, 彭旭东, 江锦波, 李纪云. 高速超临界二氧化碳干气密封实际效应影响分析[J]. 化工学报, 2019, 70(7): 2645-2659. |

| [12] | 徐奇超, 江锦波, 彭旭东, 李纪云, 王玉明. 基于遗传算法的干气密封双向槽统一模型与参数优化[J]. 化工学报, 2019, 70(3): 995-1005. |

| [13] | 胡琼, 王衍, 戴嵘, 孙见君, 郑小清. 基于有序微造型的圆弧线槽干气密封性能分析[J]. 化工学报, 2019, 70(3): 1006-1015. |

| [14] | 江锦波, 陈源, 赵文静, 李纪云, 彭旭东. 干气密封螺旋槽几何参数优选交互影响[J]. 化工学报, 2018, 69(4): 1518-1527. |

| [15] | 许恒杰, 宋鹏云, 毛文元, 邓强国, 孙雪剑. 层流状态下高压高转速二氧化碳干气密封的惯性效应分析[J]. 化工学报, 2018, 69(10): 4311-4323. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号