化工学报 ›› 2020, Vol. 71 ›› Issue (4): 1734-1743.DOI: 10.11949/0438-1157.20190903

收稿日期:2019-08-06

修回日期:2019-10-28

出版日期:2020-04-05

发布日期:2020-04-05

通讯作者:

江锦波

作者简介:车健(1994—),男,硕士研究生,基金资助:

Jian CHE( ),Jinbo JIANG(

),Jinbo JIANG( ),Jiyun LI,Xudong PENG,Yi MA,Yuming WANG

),Jiyun LI,Xudong PENG,Yi MA,Yuming WANG

Received:2019-08-06

Revised:2019-10-28

Online:2020-04-05

Published:2020-04-05

Contact:

Jinbo JIANG

摘要:

以径向单列和多列小孔节流静压干气密封为研究对象,采用湍流大涡模拟方法分析了节流孔位置和气膜厚度对单列小孔节流静压干气密封开启力、气膜刚度和泄漏率等稳态性能的影响,对比分析了不同节流孔径向出气模式和周向排布对径向多列节流静压干气密封稳态性能的影响,获得了不同膜厚条件下最佳的节流孔出气模式,在此基础上提出一种出气模式在线可调的新型静压干气密封结构。结果表明:相较于经典单列节流静压干气密封,小膜厚时(膜厚<10 μm)径向上、下游同时开孔的多列节流静压干气密封,以及大膜厚时(膜厚>10 μm)径向上、中、下游同时开孔的多列节流静压干气密封开启力和气膜刚度显著提高,最大增幅分别达到15%和25%;通过选取合理的节流孔出气模式可满足不同条件下静压干气密封高气膜承载能力、低泄漏率和低耗气量的性能需求。

中图分类号:

车健, 江锦波, 李纪云, 彭旭东, 马艺, 王玉明. 节流孔出气模式对静压干气密封稳态性能影响[J]. 化工学报, 2020, 71(4): 1734-1743.

Jian CHE, Jinbo JIANG, Jiyun LI, Xudong PENG, Yi MA, Yuming WANG. Effect of orifice exhaust mode on steady performance of hydrostatic dry gas seal[J]. CIESC Journal, 2020, 71(4): 1734-1743.

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| 密封端面内径ri/mm | 29.5 | 均压槽深度hd/mm | 0.05 |

| 密封端面外径ro/mm | 36.5 | 节流孔个数N | 12 |

| 节流孔位置半径r/mm | 33.0 | 气膜厚度h/μm | 12 |

| 节流孔直径d/mm | 0.2 | 密封外径压力po/MPa | 0.3 |

| 节流孔长度l/mm | 0.5 | 密封内径压力pi/MPa | 0.1 |

| 均压槽宽度w/mm | 1.0 | 节流气压力ps/MPa | 0.5 |

表1 静压干气密封初始计算参数

Table 1 Initial calculation parameters of hydrostatic dry gas seal

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| 密封端面内径ri/mm | 29.5 | 均压槽深度hd/mm | 0.05 |

| 密封端面外径ro/mm | 36.5 | 节流孔个数N | 12 |

| 节流孔位置半径r/mm | 33.0 | 气膜厚度h/μm | 12 |

| 节流孔直径d/mm | 0.2 | 密封外径压力po/MPa | 0.3 |

| 节流孔长度l/mm | 0.5 | 密封内径压力pi/MPa | 0.1 |

| 均压槽宽度w/mm | 1.0 | 节流气压力ps/MPa | 0.5 |

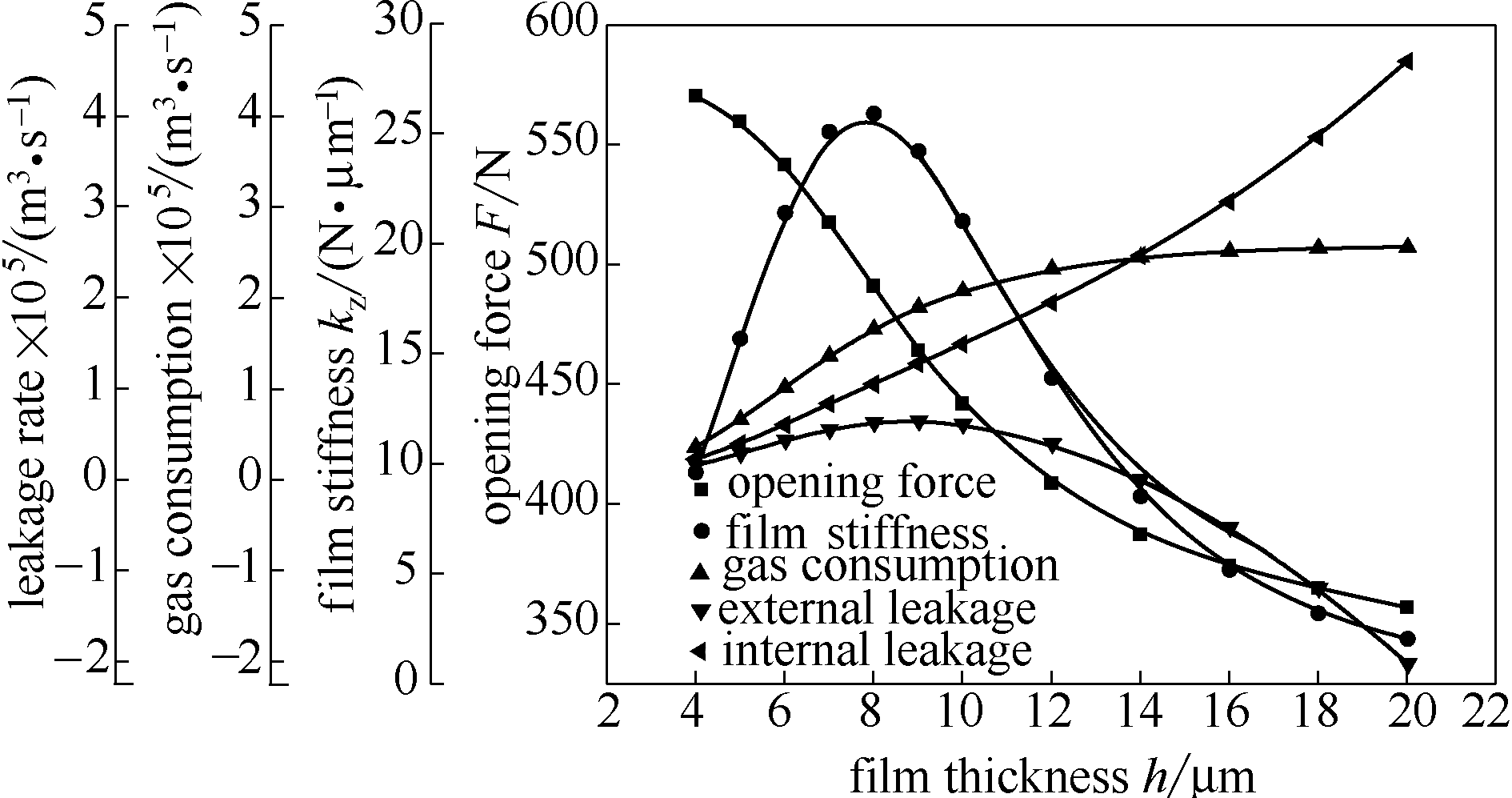

图5 经典小孔节流静压干气密封稳态性能参数随气膜厚度变化规律

Fig.5 Influence of film thickness on steady-state performance of hydrostatic dry gas seal with normal orifice-type restrictor

| 1 | Fujiwara S, Fuse T. Advanced aerostatic dry gas seal[C]//16th International Conference on Fluid Sealing. BHR Group 2000 Fluid Sealing, 2000:483-499. |

| 2 | 刘墩, 刘育华, 陈世杰. 静压气体润滑[M]. 哈尔滨:哈尔滨工业大学出版社, 1990. |

| Liu D, Liu Y H, Chen S J. Aerostatic Gas Lubrication[M]. Harbin: Harbin Institue of Technology Press, 1990. | |

| 3 | Cheng H S, Chow C Y, Wilcock D F. Behavior of hydrostatic and hydrodynamic noncontacting face seals[J]. ASME Journal of Tribology, 1967, 90(2): 521-519. |

| 4 | Stolarski T A, Xue Y. Performance study of a back-depression mechanical dry gas seal [J]. Proceedings of the IMechE, Part J. Journal of Engineering Tribology, 1998, 212(4): 279-290. |

| 5 | Xu H J, Song P Y. Influence of the groove width on the aerostatic dry gas seal [J]. Applied Mechanics and Materials, 2013, 365/366: 318-322. |

| 6 | 许恒杰, 宋鹏云, 余建平. 静压气体润滑机械密封性能分析[J]. 润滑与密封, 2013, 38(8): 41-45. |

| Xu H J, Song P Y, Yu J P. Analysis on the seal performance of aerostatic gas lubricating mechanical seal [J]. Lubrication Engineering, 2013, 38(8): 41-45. | |

| 7 | 管羽刚, 贾祥际, 王东生. 静压干气密封特性研究及节流孔参数优化方法探讨[J]. 化工设备与管道, 2019, 56(2): 53-59. |

| Guan Y G, Jia X J, Wang D S. Study of seal performance of static dry gas and discussion of parameter optimization method for orifice [J]. Process Equipment & Piping, 2019, 56(2): 53-59. | |

| 8 | Li S X, Zhu L, Cai J N, et al. Study on hydrostatic gas lubricated non-contacting mechanical seal[J]. High Technology Letters, 2012, 18(4): 433-440. |

| 9 | 扈中平, 李双喜, 蔡纪宁, 等. 自加压式动静压混合式气体润滑密封的性能分析[J]. 润滑与密封, 2011, 36(4): 48-52, 86. |

| Hu Z P, Li S X, Cai J N, et al. Study on self-pressurized hydrostatic-dynamic hybrid lubricaiton gas seal[J]. Lubrication Engineering, 2011, 36(4): 48-52, 86. | |

| 10 | 李双喜, 张树强, 蔡纪宁, 等. 动静压混合式气体密封的特性分析[J]. 摩擦学学报, 2011, 31(5): 457-466. |

| Li S X, Zhang S Q, Cai J N, et al. Performance study of dynamic-hydrostatic hybrid gas seal[J]. Tribology, 2011, 31(5): 457-466. | |

| 11 | 金朝旭, 李双喜, 蔡纪宁, 等. 可调控型气膜润滑密封静压结构参数优化[J]. 化工学报, 2015, 66(4):1425-1433. |

| Jin Z X, Li S X, Cai J N, et al. Hydrostatic structural parameters optimization of regulatable gas lubricated seal[J]. CIESC Journal, 2015, 66(4): 1425-1433. | |

| 12 | 刘雨川, 徐万孚, 陈国林, 等. 端面气膜密封的高性能端面结构[J]. 航空学报, 2000, 21(2): 187-190. |

| Liu Y C, Xu W F, Chen G L, et al. Face configuration with high performance for gas film face seal[J]. Acta Aeronautica et Astronautical Sinica, 2000, 21(2): 187-190. | |

| 13 | 赵艳凤, 彭旭东, 江锦波, 等. 均压槽结构形状对静压干气密封性能影响分析[J]. 摩擦学学报, 2017, 37(5): 677-685. |

| Zhao Y F, Peng X D, Jiang J B, et al. Influence of the pressure-equalizing groove on the seal performance of hydrostatic dry gas seal[J]. Tribology, 2017, 37(5): 677-685. | |

| 14 | 许恒杰, 宋鹏云. 三自由度微扰下的静压干气密封动态特性分析[J]. 排灌机械工程学报, 2017, 35(1): 56-64. |

| Xu H J, Song P Y. Analysis on dynamic characteristics of aerostatic dry gas seals with three degrees of freedom perturbation[J]. Journal of Drainage and Irrigation Machinery Engineering, 2017, 35(1): 56-64. | |

| 15 | 张树强, 李双喜, 蔡纪宁, 等. 动静压混合式气体密封追随性及主动调控振动特性数值分析[J]. 航空学报, 2012, 33(7): 1336-1346. |

| Zhang S Q, Li S X, Cai J N, et al. Numerical analysis for the tracking property and active regulation vibration characteristics of dynamic-hydrostatic hybrid gas seals[J]. Acta Aeronautica et Astronautical Sinica, 2012, 33(7): 1336-1346. | |

| 16 | 尹源, 刘向峰, 丛国辉, 等. 外加压静压型机械密封均压槽设计对动态性能的影响[J]. 流体机械, 2017, 45(4): 15-21. |

| Yin Y, Liu X F, Cong G H, et al. Influence of equalizing grooves design for externally pressurized hydrostatic mechanical seal on dynamic performance[J]. Fluid Machinery, 2017, 45(4): 15-21. | |

| 17 | Zhu J, Chen H, Chen X. Large eddy simulation of vortex shedding and pressure fluctuation in aerostatic bearings[J]. Journal of Fluids and Structures, 2013, 40:42-51. |

| 18 | Li Y T, Han D. Influences of the geometrical parameters of aerostatic thrust bearing with pocketed orifice-type restrictor on its performance[J]. Tribology International, 2007, 40(7):1120-1126. |

| 19 | Chen X D, He X. The effect of the recess shape on performance analysis of the gas-lubricated bearing in optical lithography [J]. Tribology International, 2006, 39(11): 1336-1341. |

| 20 | Chen X D, Chen H, Luo X, et al. Air vortices and nano-vibration of aerostatic bearings[J]. Tribology Letters, 2011, 42(2): 179-183. |

| 21 | 李运堂, 蔺应晓, 朱红霞, 等. 基于大涡模拟静压气体推力轴承微幅自激振动特性分析[J]. 机械工程学报, 2013, 49(13): 56-62. |

| Li Y T, Lin Y X, Zhu H X, et al. Analysis of the micro self-vibration of aerostatic thrust bearing based on large eddy simulation[J]. Journal of Mechanical Engineering, 2013, 49(13): 56-62. | |

| 22 | Li Y T, Lin Y X, Zhu H X, et al. Research on the gas pressure fluctuation characteristics inside an aerostatic thrust bearing with a pocketed orifice-type restrictor[J]. Tribology Transactions, 2014, 57(1):28-35. |

| 23 | Belforte G, Raparelli T, Viktorov V, et al. Discharge coefficients of orifice-type restrictor for aerostatic bearings[J]. Tribology International, 2007, 40: 512-521. |

| 24 | Belforte G, Raparelli T, Trivella A, et al. CFD analysis of a simple orifice-type feeding system for aerostatic bearings[J]. Tribology Letters, 2015, 58(2):25. |

| 25 | Huang M, Xu Q, Li M, et al. A calculation method on the performance analysis of the thrust aerostatic bearing with vacuum pre-load[J]. Tribology International, 2017, 110:125-130. |

| 26 | Lai T H, Chang T Y, Yang Y L, et al. Parameters design of a membrane-type restrictor with single-pad hydrostatic bearing to achieve high static stiffness[J]. Tribology International, 2017, 107:206-212. |

| 27 | Jin Z X, Li S X, Cai J N, et al. Optimizing on hydrostatic structural parameters for regulatable dry gas seal based on central composite design test[J]. Industrial Lubrication and Tribology, 2016, 68(1):99-105. |

| 28 | Yoshimoto S, Suganuma N, Yagi K, et al. Numerical calculations of pressure distribution in the bearing clearance of circular aerostatic thrust bearings with a single air supply inlet[J]. ASME Journal of Tribology, 2007, 179(2): 384-390. |

| 29 | Ma W, Cui J W, Liu Y M, et al. Improving the pneumatic stability of aerostatic thrust bearing with recess using damping orifices[J]. Tribology International, 2016, 103: 281-288. |

| 30 | Al-Bender F. On the modeling of the dynamic characteristics of aerostatic bearing films from stability analysis to active compensation[J]. Precision Engineering, 2009, 33: 117 -126. |

| 31 | Aoyama T, Kakinuma Y, Kobayashi Y. Numerical and experimental analysis for the small vibration of aerostatic guideways[J]. CIRP Annals, 2006, 55(1):419-422. |

| [1] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [2] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [3] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [4] | 叶展羽, 山訸, 徐震原. 用于太阳能蒸发的折纸式蒸发器性能仿真[J]. 化工学报, 2023, 74(S1): 132-140. |

| [5] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [6] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [7] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [8] | 温凯杰, 郭力, 夏诏杰, 陈建华. 一种耦合CFD与深度学习的气固快速模拟方法[J]. 化工学报, 2023, 74(9): 3775-3785. |

| [9] | 程小松, 殷勇高, 车春文. 不同工质在溶液除湿真空再生系统中的性能对比[J]. 化工学报, 2023, 74(8): 3494-3501. |

| [10] | 刘文竹, 云和明, 王宝雪, 胡明哲, 仲崇龙. 基于场协同和 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. 耗散的微通道拓扑优化研究[J]. 化工学报, 2023, 74(8): 3329-3341. |

| [11] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [12] | 岳林静, 廖艺涵, 薛源, 李雪洁, 李玉星, 刘翠伟. 凹坑缺陷对厚孔板喉部空化流动特性影响研究[J]. 化工学报, 2023, 74(8): 3292-3308. |

| [13] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [14] | 韩晨, 司徒友珉, 朱斌, 许建良, 郭晓镭, 刘海峰. 协同处理废液的多喷嘴粉煤气化炉内反应流动研究[J]. 化工学报, 2023, 74(8): 3266-3278. |

| [15] | 汪林正, 陆俞冰, 张睿智, 罗永浩. 基于分子动力学模拟的VOCs热氧化特性分析[J]. 化工学报, 2023, 74(8): 3242-3255. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号