化工学报 ›› 2019, Vol. 70 ›› Issue (9): 3553-3564.DOI: 10.11949/0438-1157.20190179

收稿日期:2019-03-03

修回日期:2019-05-24

出版日期:2019-09-05

发布日期:2019-09-05

通讯作者:

闫霆,潘卫国

作者简介:吴韶飞(1993—),男,硕士研究生,基金资助:

Shaofei WU( ),Ting YAN(

),Ting YAN( ),Zihan KUAI,Weiguo PAN(

),Zihan KUAI,Weiguo PAN( )

)

Received:2019-03-03

Revised:2019-05-24

Online:2019-09-05

Published:2019-09-05

Contact:

Ting YAN,Weiguo PAN

摘要:

采用棕榈酸(palmitic acid, PA)作为相变材料,膨胀石墨(expanded graphite, EG)作为添加基质,通过“熔融共混-凝固定形”工艺制备了PA/EG定形复合相变材料以提高相变材料的综合性能。预测并制备了21种不同配比的定形复合相变材料,对其形貌结构和孔隙率进行了微观表征与理论分析,并在此基础上对样品进行了传热性能分析、热物性测试、热稳定性研究和储热性能分析。SEM形貌分析显示所使用工艺可使棕榈酸能较好地被吸附于膨胀石墨的孔隙结构并使之均匀分布;DSC测试结果表明定形复合相变材料[70%(质量) PA]的焓值为193.01 J/g,纯PA的焓值为275.35 J/g,对应于熔点分别为61.08℃和59.53℃。EG的添加,可有效提高相变材料的热导率。当样品密度为900 kg/m3,EG含量为30%(质量)时,定形复合相变材料的热导率为14.09 W/(m·K),相比于纯PA[0.162 W/(m·K)]提高约87倍;对制备的样品进行50次循环稳定性实验,EG含量为24%(质量)和30%(质量)的样品形态均未出现明显变化,表现出良好的充放热循环稳定性。

中图分类号:

吴韶飞, 闫霆, 蒯子函, 潘卫国. 高导热膨胀石墨/棕榈酸定形复合相变材料的制备及储热性能研究[J]. 化工学报, 2019, 70(9): 3553-3564.

Shaofei WU, Ting YAN, Zihan KUAI, Weiguo PAN. Preparation and thermal energy storage properties of high heat conduction expanded graphite/palmitic acid form-stable phase change materials[J]. CIESC Journal, 2019, 70(9): 3553-3564.

| 方块密度/(kg/m3) | EG/%(mass) | 质量/g | 密度/(kg/m3) | 样品序号 |

|---|---|---|---|---|

| 600 | 6 | 38.977 | 609 | S1 |

| 12 | 50.940 | 596 | S2 | |

| 18 | 38.076 | 595 | S3 | |

| 24 | 38.339 | 599 | S4 | |

| 30 | 38.001 | 594 | S5 | |

| 700 | 6 | 44.530 | 696 | S6 |

| 12 | 44.539 | 696 | S7 | |

| 18 | 44.596 | 697 | S8 | |

| 24 | 44.679 | 698 | S9 | |

| 30 | 44.730 | 699 | S10 | |

| 800 | 6 | 50.940 | 796 | S11 |

| 12 | 50.840 | 794 | S12 | |

| 18 | 51.095 | 798 | S13 | |

| 24 | 51.098 | 798 | S14 | |

| 30 | 51.138 | 799 | S15 | |

| 900 | 6 | — | — | — |

| 12 | 57.485 | 898 | S16 | |

| 18 | 57.429 | 897 | S17 | |

| 24 | 57.487 | 898 | S18 | |

| 30 | 57.252 | 895 | S19 | |

| 1000 | 6 | — | — | — |

| 12 | — | — | — | |

| 18 | — | — | — | |

| 24 | 63.847 | 998 | S20 | |

| 30 | 63.620 | 994 | S21 |

表1 不同质量分数的EG和不同密度的PA/EG定形复合相变储热材料样品配比

Table1 PA/EG form-stable composite PCMs sample with different mass fractions of EG and different densities

| 方块密度/(kg/m3) | EG/%(mass) | 质量/g | 密度/(kg/m3) | 样品序号 |

|---|---|---|---|---|

| 600 | 6 | 38.977 | 609 | S1 |

| 12 | 50.940 | 596 | S2 | |

| 18 | 38.076 | 595 | S3 | |

| 24 | 38.339 | 599 | S4 | |

| 30 | 38.001 | 594 | S5 | |

| 700 | 6 | 44.530 | 696 | S6 |

| 12 | 44.539 | 696 | S7 | |

| 18 | 44.596 | 697 | S8 | |

| 24 | 44.679 | 698 | S9 | |

| 30 | 44.730 | 699 | S10 | |

| 800 | 6 | 50.940 | 796 | S11 |

| 12 | 50.840 | 794 | S12 | |

| 18 | 51.095 | 798 | S13 | |

| 24 | 51.098 | 798 | S14 | |

| 30 | 51.138 | 799 | S15 | |

| 900 | 6 | — | — | — |

| 12 | 57.485 | 898 | S16 | |

| 18 | 57.429 | 897 | S17 | |

| 24 | 57.487 | 898 | S18 | |

| 30 | 57.252 | 895 | S19 | |

| 1000 | 6 | — | — | — |

| 12 | — | — | — | |

| 18 | — | — | — | |

| 24 | 63.847 | 998 | S20 | |

| 30 | 63.620 | 994 | S21 |

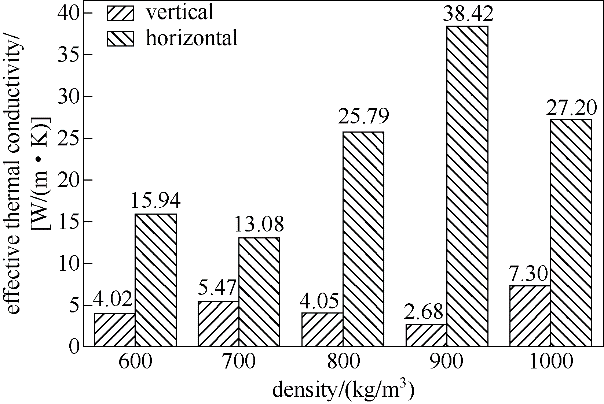

图10 EG含量为30%时PA/EG定形复合材料样品水平和垂直方向的热导率随样品密度的变化

Fig.10 Changes in horizontal and vertical thermal conductivity of PA/EG form-stable composite samples with sample density when content of EG is 30%(mass)

| 1 | Huang X , Alva G , Liu L . et al. Microstructure and thermal properties of cetyl alcohol/high density polyethylene composite phase change materials with carbon fiber as shape-stabilized thermal storage materials [J]. Applied Energy, 2017, 200: 19-27. |

| 2 | Kant K , Shukla A , Sharma A . Advancement in phase change materials for thermal energy storage applications [J]. Solar Energy Materials and Solar Cells, 2017, 172: 82-92. |

| 3 | Chandel S S , Agarwal T . Review of current state of research on energy storage, toxicity, health hazards and commercialization of phase changing materials [J]. Renewable and Sustainable Energy Reviews, 2017, 67: 581-596. |

| 4 | Tang Y , Jia Y , Alva G , et al . Synthesis, characterization and properties of palmitic acid/high density polyethylene/graphene nanoplatelets composites as form-stable phase change materials [J]. Solar Energy Materials and Solar Cells, 2016, 155: 421-429. |

| 5 | Lin Y , Zhu C , Alva G , et al . Palmitic acid/polyvinyl butyral/expanded graphite composites as form-stable phase change materials for solar thermal energy storage [J]. Applied Energy, 2018, 228:1801-1809. |

| 6 | Cárdenas B , León N . High temperature latent heat thermal energy storage: phase change materials, design considerations and performance enhancement techniques [J]. Renewable and Sustainable Energy Reviews, 2013, 27: 724-737. |

| 7 | Atinafu D G , Dong W , Huang X , et al . Introduction of organic-organic eutectic PCM in mesoporous N-doped carbons for enhanced thermal conductivity and energy storage capacity [J]. Applied Energy, 2018, 211: 1203-1215. |

| 8 | Ma G , Liu S , Xie S , et al . Binary eutectic mixtures of stearic acid- n-butyramide/n-octanamide as phase change materials for low temperature solar heat storage [J]. Applied Thermal Engineering, 2017, 111: 1052-1059. |

| 9 | Tay N H S , Liu M , Belusko M , et al . Review on transportable phase change material in thermal energy storage systems [J]. Renewable and Sustainable Energy Reviews, 2017, 75: 264-277. |

| 10 | Lin Y , Jia Y , Alva G , et al . Review on thermal conductivity enhancement, thermal properties and applications of phase change materials in thermal energy storage [J]. Renewable and Sustainable Energy Reviews, 2018, 82: 2730-2742. |

| 11 | Khan M A , Saidur R , Al-Sulaiman F A . A review for phase change materials (PCMs) in solar absorption refrigeration systems [J]. Renewable and Sustainable Energy Reviews, 2017, 76: 105-137. |

| 12 | Alva G , Liu L , Huang X , et al . Thermal energy storage materials and systems for solar energy applications[J]. Renewable and Sustainable Energy Reviews, 2017, 68: 693-706. |

| 13 | Souayfane F , Fardoun F , Biwole P H . Phase change materials (PCM) for cooling applications in buildings: a review [J]. Energy and Buildings [J]. 2016, 129: 396-431. |

| 14 | Miró L , Gasia J , Cabeza L F . Thermal energy storage (TES) for industrial waste heat (IWH) recovery: a review [J]. Applied Energy, 2016, 179: 284-301. |

| 15 | Cao R R , Li X , Chen S , et al . Fabrication and characterization of novel shape-stabilized synergistic phase change materials based on PHDA/GO composites [J]. Energy, 2017, 138: 157-166. |

| 16 | Xu Y , Li M J , Zheng Z J , et al . Melting performance enhancement of phase change material by a limited amount of metal foam: configurational optimization and economic assessment [J]. Applied Energy, 2018, 212: 868-880. |

| 17 | Wu S , Li T X , Yan T , et al . High performance form-stable expanded graphite/stearic acid composite phase change material for modular thermal energy storage [J]. International Journal of Heat and Mass Transfer, 2016, 102: 733-744. |

| 18 | Zhang Q , Luo Z , Guo Q , et al . Preparation and thermal properties of short carbon fibers/erythritol phase change materials [J]. Energy Conversion and Management, 2017, 136: 220-228. |

| 19 | Xu T , Chen Q , Huang G , et al . Preparation and thermal energy storage properties of D-mannitol/expanded graphite composite phase change material [J]. Solar Energy Materials and Solar Cells, 2016, 155: 141-146. |

| 20 | Karaipekli A , Biçer A , Sarı A , et al . Thermal characteristics of expanded perlite/paraffin composite phase change material with enhanced thermal conductivity using carbon nanotubes [J]. Energy Conversion and Management, 2017, 134: 373-381. |

| 21 | Harish S , Orejon D , Takata Y , et al . Thermal conductivity enhancement of lauric acid phase change nanocomposite with graphene nanoplatelets [J]. Applied Thermal Engineering, 2015, 80: 205-211. |

| 22 | Leng G , Qiao G , Xu G , et al . Erythritol-Vermiculite form-stable phase change materials for thermal energy storage [J]. Energy Procedia, 2017, 142: 3363-3368. |

| 23 | Lv P , Liu C , Rao Z . Experiment study on the thermal properties of paraffin/kaolin thermal energy storage form-stable phase change materials [J]. Applied Energy, 2016, 182: 475-487. |

| 24 | Lin C , Rao Z . Thermal conductivity enhancement of paraffin by adding boron nitride nanostructures: a molecular dynamics study [J]. Applied Thermal Engineering, 2017, 110: 1411-1419. |

| 25 | Babapoor A , Karimi G . Thermal properties measurement and heat storage analysis of paraffin nanoparticles composites phase change material: comparison and optimization [J]. Applied Thermal Engineering, 2015, 90: 945-951. |

| 26 | Xiao X , Zhang P , Li M . Preparation and thermal characterization of paraffin/metal foam composite phase change material [J]. Applied Energy, 2013, 112: 1357-1366. |

| 27 | Zheng H , Wang C , Liu Q , et al . Thermal performance of copper foam/paraffin composite phase change material [J]. Energy Conversion and Management, 2018, 157: 372-381. |

| 28 | Zhang H , Gao X , Chen C , et al . A capric-palmitic-stearic acid ternary eutectic mixture/expanded graphite composite phase change material for thermal energy storage [J]. Composites Part A: Applied Science and Manufacturing, 2016, 87: 138-145. |

| 29 | Tang Y , Su D , Huang X , et al . Synthesis and thermal properties of the MA/HDPE composites with nano-additives as form-stable PCM with improved thermal conductivity [J]. Applied Energy, 2016, 180: 116-129. |

| 30 | Li Y L , Li J H , Feng W W , et al . Design and preparation of the phase change materials paraffin/porous Al2O3@graphite foams with enhanced heat storage capacity and thermal conductivity [J]. ACS Sustainable Chemistry & Engineering, 2017, 5: 7594-7603. |

| 31 | Yang J , Qi G Q , Liu Y , et al . Hybrid graphene aerogels/phase change material composites: thermal conductivity, shape-stabilization and light-to-thermal energy storage [J]. Carbon, 2016, 100: 693-702. |

| 32 | Wang J , Huang X , Gao H , et al . Construction of CNT@Cr-MIL-101-NH2 hybrid composite for shape-stabilized phase change materials with enhanced thermal conductivity [J]. Chemical Engineering Journal, 2018, 350: 164-172. |

| 33 | Liang W , Zhang G , Sun H , et al . Graphene-nickel/n -carboxylic acids composites as form-stable phase change materials for thermal energy storage [J]. Solar Energy Materials and Solar Cells, 2015, 132: 425-430. |

| 34 | Zhai T Y , Li T X , Wu S , et al . Preparation and thermal performance of form-stable expanded graphite/stearic acid composite phase change materials with high thermal conductivity [J]. Chinese Science Bulletin, 2017, 63(7): 674-683. |

| 35 | 仵斯, 李廷贤, 闫霆, 等 . 高性能定形复合相变储能材料的制备及热性能[J]. 化工学报, 2015, 66 (12): 5127-5134. |

| Wu S , Li T X , Yan T , et al . Preparation and thermal properties of high performance shape-stabilized phase change composites using stearic acid and expanded graphite [J]. CIESC Journal, 2015, 66 (12): 5127-5134. | |

| 36 | 向欢欢 . 三水合乙酸钠复合相变储热材料的制备与热物性研究 [D]. 广州: 广东工业大学, 2016. |

| Xiang H H . Preparation and thermal performance research of sodium acetate trihydrate composite phase change heat storage material [D]. Guangzhou: Guangdong University of Technology, 2016. | |

| 37 | 秦盟盟 . 碳复合材料的微观结构调控及性能研究 [D]. 天津: 天津大学, 2017. |

| Qin M M . Carbon-based composites with high thermal and mechanical properties by controlling their microstructures [D]. Tianjin: Tianjin University, 2017. | |

| 38 | Wang T , Wang S , Wu W . Experimental study on effective thermal conductivity of microcapsules based phase change composites [J]. International Journal of Heat and Mass Transfer, 2017, 109: 930-937. |

| [1] | 吴延鹏, 刘乾隆, 田东民, 陈凤君. 相变材料与热管耦合的电子器件热管理研究进展[J]. 化工学报, 2023, 74(S1): 25-31. |

| [2] | 吴文涛, 褚良永, 张玲洁, 谭伟民, 沈丽明, 暴宁钟. 腰果酚生物基自愈合微胶囊的高效制备工艺研究[J]. 化工学报, 2023, 74(7): 3103-3115. |

| [3] | 王志龙, 杨烨, 赵真真, 田涛, 赵桐, 崔亚辉. 搅拌时间和混合顺序对锂离子电池正极浆料分散特性的影响[J]. 化工学报, 2023, 74(7): 3127-3138. |

| [4] | 李振, 张博, 王丽伟. PEG-EG固-固相变材料的制备和性能研究[J]. 化工学报, 2023, 74(6): 2680-2688. |

| [5] | 朱风, 陈凯琳, 黄小凤, 鲍银珠, 李文斌, 刘嘉鑫, 吴玮强, 高王伟. KOH改性电石渣脱除羰基硫的性能研究[J]. 化工学报, 2023, 74(6): 2668-2679. |

| [6] | 吴学红, 栾林林, 陈亚南, 赵敏, 吕财, 刘勇. 可降解柔性相变薄膜的制备及其热性能[J]. 化工学报, 2023, 74(4): 1818-1826. |

| [7] | 张雪婷, 胡激江, 赵晶, 李伯耿. 高分子量聚丙二醇在微通道反应器中的制备[J]. 化工学报, 2023, 74(3): 1343-1351. |

| [8] | 靳志远, 单国荣, 潘鹏举. AM/AMPS/SSS三元共聚物的制备及耐温耐盐性能[J]. 化工学报, 2023, 74(2): 916-923. |

| [9] | 杜江龙, 杨雯棋, 黄凯, 练成, 刘洪来. 复合相变材料/空冷复合式锂离子电池模块散热性能[J]. 化工学报, 2023, 74(2): 674-689. |

| [10] | 张浩, 王子悦, 程钰洁, 何晓辉, 纪红兵. 单原子催化剂规模化制备的研究进展[J]. 化工学报, 2023, 74(1): 276-289. |

| [11] | 刘佳宁, 马嘉浩, 张军营, 程珏. 顺序双重热固化的硫醇-丙烯酸酯-环氧树脂三维网络的构建及性能[J]. 化工学报, 2022, 73(9): 4173-4186. |

| [12] | 李承威, 骆华勇, 张铭轩, 廖鹏, 方茜, 荣宏伟, 王竞茵. 氢氧化镧交联壳聚糖微球的微流控制备及其除磷性能[J]. 化工学报, 2022, 73(9): 3929-3939. |

| [13] | 钟磊, 邱学青, 张文礼. 木质素衍生炭在碱金属离子电池负极中的研究进展[J]. 化工学报, 2022, 73(8): 3369-3380. |

| [14] | 高端辉, 肖卫强, 高峰, 夏倩, 汪曼秋, 卢昕博, 詹晓力, 张庆华. 聚酰亚胺基气凝胶材料的制备与应用[J]. 化工学报, 2022, 73(7): 2757-2773. |

| [15] | 宋超宇, 熊亚选, 张金花, 金宇贺, 药晨华, 王辉祥, 丁玉龙. 污泥焚烧炉渣基定型复合相变储热材料的制备和性能[J]. 化工学报, 2022, 73(5): 2279-2287. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号