化工学报 ›› 2023, Vol. 74 ›› Issue (4): 1818-1826.DOI: 10.11949/0438-1157.20221676

收稿日期:2022-12-30

修回日期:2023-03-22

出版日期:2023-04-05

发布日期:2023-06-02

通讯作者:

吴学红

作者简介:吴学红(1979—),男,博士,教授,wuxh1212@163.com

基金资助:

Xuehong WU( ), Linlin LUAN, Yanan CHEN, Min ZHAO, Cai LYU, Yong LIU

), Linlin LUAN, Yanan CHEN, Min ZHAO, Cai LYU, Yong LIU

Received:2022-12-30

Revised:2023-03-22

Online:2023-04-05

Published:2023-06-02

Contact:

Xuehong WU

摘要:

为解决相变材料易泄漏、热导率低和力学性能差的问题,以生物基可降解聚乳酸(PLA)为基底,聚乙二醇(PEG)为相变工质,改性氧化铝(Al2O3)为导热添加剂,通过溶液共混法制备PEG/PLA/Al2O3柔性相变薄膜,用于热储能。相变薄膜可任意卷曲和折叠而不发生断裂,表现出良好的柔性。对其热性能、导热性能和降解性能等进行测试,结果表明:PEG和PLA具有良好的相容性,PLA作为支撑基底有效防止了PEG液体的泄漏,所制备的柔性相变薄膜具有良好的形状稳定性。PEG/PLA的熔融和凝固过程中的潜热分别为120.2和128.5 J/g,潜热留存率分别为62.2%和67.6%,添加20%的氧化铝,潜热值仅降低12.5%,而热导率提高了75.0%,热传递效率得到明显提升。PEG/PLA的降解速率明显高于PLA,PEG/PLA薄膜在NaOH溶液(pH=13)中4 h左右可完全降解,具有良好的环境友好性。

中图分类号:

吴学红, 栾林林, 陈亚南, 赵敏, 吕财, 刘勇. 可降解柔性相变薄膜的制备及其热性能[J]. 化工学报, 2023, 74(4): 1818-1826.

Xuehong WU, Linlin LUAN, Yanan CHEN, Min ZHAO, Cai LYU, Yong LIU. Preparation and thermal properties of degradable flexible phase change films[J]. CIESC Journal, 2023, 74(4): 1818-1826.

图7 PEG、PEG/PLA、PEG/PLA/Al2O3的DSC曲线[(a)~(b)],PEG/PLA/Al2O3冷热循环DSC曲线(c)及循环测试对应的柱状图(d)

Fig.7 DSC curves of PEG,PEG/PLA,PEG/PLA/Al2O3 [(a)—(b)], DSC curves of PEG/PLA/Al2O3 (c) and corresponding column chart during cycle test (d)

| 样品 | ΔH/(J/g) | Tpeak/℃ | Ton/℃ | Tend/℃ | ||||

|---|---|---|---|---|---|---|---|---|

| M | S | M | S | M | S | M | S | |

| PEG | 193.3 | 190.1 | 54.15 | 24.26 | 49.04 | 16.67 | 60.85 | 28.82 |

| PEG/PLA | 120.2 | 128.5 | 55.85 | 24.4 | 47.30 | 18.1 | 65.74 | 32.32 |

| PEG/PLA/Al2O35% | 115.0 | 121.0 | 54.52 | 29.84 | 46.18 | 20.76 | 65.94 | 35.30 |

| PEG/PLA/Al2O310% | 107.6 | 109.7 | 53.87 | 23.66 | 45.46 | 15.57 | 62.22 | 30.69 |

| PEG/PLA/Al2O315% | 106.5 | 108.6 | 53.34 | 14.25 | 34.11 | 6.25 | 54.39 | 22.62 |

| PEG/PLA/Al2O320% | 105.2 | 99.6 | 52.97 | 26.34 | 43.25 | 18.83 | 59.68 | 30.77 |

表1 柔性相变薄膜的DSC数据

Table 1 DSC data of flexible phase change films

| 样品 | ΔH/(J/g) | Tpeak/℃ | Ton/℃ | Tend/℃ | ||||

|---|---|---|---|---|---|---|---|---|

| M | S | M | S | M | S | M | S | |

| PEG | 193.3 | 190.1 | 54.15 | 24.26 | 49.04 | 16.67 | 60.85 | 28.82 |

| PEG/PLA | 120.2 | 128.5 | 55.85 | 24.4 | 47.30 | 18.1 | 65.74 | 32.32 |

| PEG/PLA/Al2O35% | 115.0 | 121.0 | 54.52 | 29.84 | 46.18 | 20.76 | 65.94 | 35.30 |

| PEG/PLA/Al2O310% | 107.6 | 109.7 | 53.87 | 23.66 | 45.46 | 15.57 | 62.22 | 30.69 |

| PEG/PLA/Al2O315% | 106.5 | 108.6 | 53.34 | 14.25 | 34.11 | 6.25 | 54.39 | 22.62 |

| PEG/PLA/Al2O320% | 105.2 | 99.6 | 52.97 | 26.34 | 43.25 | 18.83 | 59.68 | 30.77 |

| 循环次数 | ΔH/(J/g) | Tpeak/℃ | ||

|---|---|---|---|---|

| M | S | M | S | |

| 0 | 107.6 | 109.7 | 53.34 | 24.65 |

| 100 | 107.5 | 109.7 | 53.51 | 24.30 |

| 200 | 106.6 | 109.1 | 53.41 | 23.90 |

| 300 | 105.8 | 108.7 | 53.51 | 24.65 |

| 400 | 105.2 | 108 | 53.36 | 23.09 |

| 500 | 104.7 | 107.7 | 53.51 | 25.24 |

表2 样品循环前后的DSC数据

Table 2 DSC data before and after the cycle

| 循环次数 | ΔH/(J/g) | Tpeak/℃ | ||

|---|---|---|---|---|

| M | S | M | S | |

| 0 | 107.6 | 109.7 | 53.34 | 24.65 |

| 100 | 107.5 | 109.7 | 53.51 | 24.30 |

| 200 | 106.6 | 109.1 | 53.41 | 23.90 |

| 300 | 105.8 | 108.7 | 53.51 | 24.65 |

| 400 | 105.2 | 108 | 53.36 | 23.09 |

| 500 | 104.7 | 107.7 | 53.51 | 25.24 |

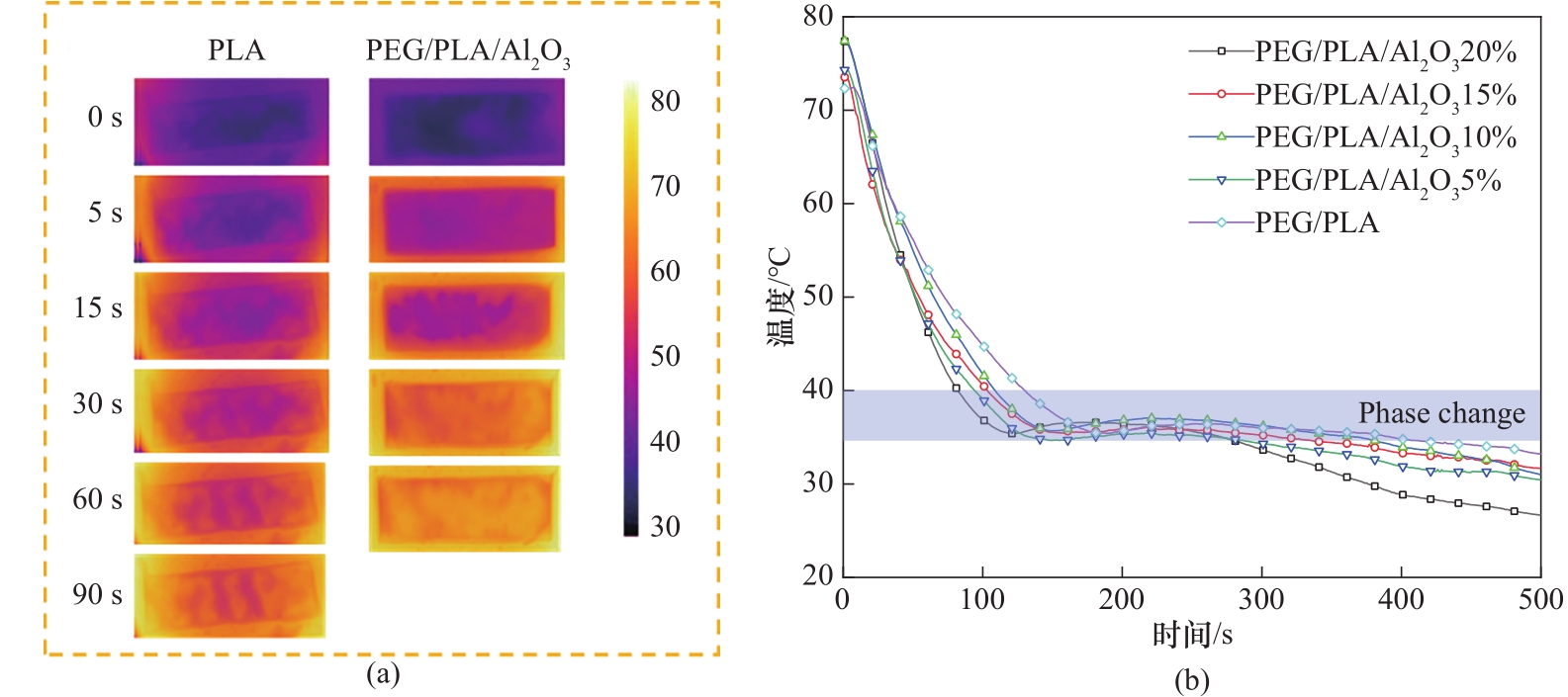

图8 PLA薄膜和PEG/PLA/Al2O3复合薄膜在加热过程中的热成像图及柔性相变薄膜的降温曲线

Fig.8 Thermal image during heating process and cooling curves of flexible phase change films of PLA film and PEG/PLA/ Al2O3 composite film

| 1 | Ravotti R, Fellmann O, Lardon N, et al. Investigation of lactones as innovative bio-sourced phase change materials for latent heat storage[J]. Molecules, 2019, 24(7): 1300. |

| 2 | Umair M M, Zhang Y A, Iqbal K, et al. Novel strategies and supporting materials applied to shape-stabilize organic phase change materials for thermal energy storage—a review[J]. Applied Energy, 2019, 235: 846-873. |

| 3 | Yang L, Yang J, Tang L S, et al. Hierarchically porous PVA aerogel for leakage-proof phase change materials with superior energy storage capacity[J]. Energy & Fuels, 2020, 34(2): 2471-2479. |

| 4 | 何起帆, 吴闽强, 李廷贤, 等. 正十八烷/OBC/EG复合定型相变材料制备及热物性[J]. 化工学报, 2021, 72(S1): 539-545. |

| He Q F, Wu M Q, Li T X, et al. Preparation and thermophysical properties of octadecane/OBC/EG composite shaped phase change material[J]. CIESC Journal, 2021, 72(S1): 539-545. | |

| 5 | Wang C Y, Feng L L, Li W, et al. Shape-stabilized phase change materials based on polyethylene glycol/porous carbon composite: the influence of the pore structure of the carbon materials[J]. Solar Energy Materials and Solar Cells, 2012, 105: 21-26. |

| 6 | Huang Q Q, Deng J, Li X X, et al. Experimental investigation on thermally induced aluminum nitride based flexible composite phase change material for battery thermal management[J]. Journal of Energy Storage, 2020, 32: 101755. |

| 7 | Huang Q Q, Li X X, Zhang G Q, et al. Thermal management of lithium-ion battery pack through the application of flexible form-stable composite phase change materials[J]. Applied Thermal Engineering, 2021, 183: 116151. |

| 8 | 方玉堂, 康慧英, 张正国, 等. 聚乙二醇相变储能材料研究进展[J]. 化工进展, 2007, 26(8): 1063-1067. |

| Fang Y T, Kang H Y, Zhang Z G, et al. Review of polyethylene glycol for energy storage[J]. Chemical Industry and Engineering Progress, 2007, 26(8): 1063-1067. | |

| 9 | Huang Q Q, Li X X, Zhang G Q, et al. Flexible composite phase change material with anti-leakage and anti-vibration properties for battery thermal management[J]. Applied Energy, 2022, 309: 118434. |

| 10 | Chai S Y, Sun K Y, Zhao D H, et al. Form-stable erythritol/HDPE composite phase change material with flexibility, tailorability, and high transition enthalpy[J]. ACS Applied Polymer Materials, 2020, 2(11): 4464-4471. |

| 11 | Cai Z D, Liu J, Zhou Y X, et al. Flexible phase change materials with enhanced tensile strength, thermal conductivity and photo-thermal performance[J]. Solar Energy Materials and Solar Cells, 2021, 219: 110728. |

| 12 | Kenisarin M M, Kenisarina K M. Form-stable phase change materials for thermal energy storage[J]. Renewable and Sustainable Energy Reviews, 2012, 16(4): 1999-2040. |

| 13 | 郭制安, 隋智慧, 李亚萍, 等. 相变双向调温纺织材料制备技术研究进展[J]. 化工进展, 2022, 41(7): 3648-3659. |

| Guo Z A, Sui Z H, Li Y P, et al. Research progress on preparation technology of phase-change bidirectional temperature-regulating textile materials[J]. Chemical Industry and Engineering Progress, 2022, 41(7): 3648-3659. | |

| 14 | Kou Y, Sun K Y, Luo J P, et al. An intrinsically flexible phase change film for wearable thermal managements[J]. Energy Storage Materials, 2021, 34: 508-514. |

| 15 | 周晓明, 刘亚楠. 可生物降解PEG/PBS高分子相变储能材料的制备[J]. 合成树脂及塑料, 2012, 29(6): 54-57. |

| Zhou X M, Liu Y N. Preparation of biodegradable polymeric phase change materials of PEG/PBS for energy storage[J]. China Synthetic Resin and Plastics, 2012, 29(6): 54-57. | |

| 16 | 单梦瑶, 杨操, 张世科, 等. 聚乳酸增强增韧的研究进展[J]. 高分子材料科学与工程, 2022, 38(3): 183-190. |

| Shan M Y, Yang C, Zhang S K, et al. Progress in reinforcing and toughening of polylactic acid[J]. Polymer Materials Science & Engineering, 2022, 38(3): 183-190. | |

| 17 | Lu X, Huang J T, Kang B H, et al. Bio-based poly (lactic acid)/high-density polyethylene blends as shape-stabilized phase change material for thermal energy storage applications[J]. Solar Energy Materials and Solar Cells, 2019, 192: 170-178. |

| 18 | 姚鹏成, 夏鑫. 聚乳酸包覆相变材料复合织物的制备及其性能[J]. 纺织学报, 2017, 38(1): 67-72. |

| Yao P C, Xia X. Preparation and properties of polylactic acid coated phase change material composite fabric[J]. Journal of Textile Research, 2017, 38(1): 67-72. | |

| 19 | Ostafinska A, Fortelny I, Nevoralova M, et al. Synergistic effects in mechanical properties of PLA/PCL blends with optimized composition, processing, and morphology[J]. RSC Advances, 2015, 5(120): 98971-98982. |

| 20 | Wang B, Hina K, Zou H T, et al. Thermal, crystallization, mechanical and decomposition properties of poly(lactic acid) plasticized with poly(ethylene glycol)[J]. Journal of Vinyl and Additive Technology, 2018, 24: E154-E163. |

| 21 | Li Y L, Wu H Y, Wang Y, et al. Synergistic effects of PEG and MWCNTs on crystallization behavior of PLLA[J]. Journal of Polymer Science Part B: Polymer Physics, 2010, 48(5): 520-528. |

| 22 | Baiardo M, Frisoni G, Scandola M, et al. Thermal and mechanical properties of plasticized poly(L-lactic acid)[J]. Journal of Applied Polymer Science, 2003, 90(7): 1731-1738. |

| 23 | Sundararajan S, Samui A B, Kulkarni P S. Versatility of polyethylene glycol (PEG) in designing solid-solid phase change materials (PCMs) for thermal management and their application to innovative technologies[J]. Journal of Materials Chemistry A, 2017, 5(35): 18379-18396. |

| 24 | Al-Ahmed A, Mazumder M A J, Salhi B, et al. Effects of carbon-based fillers on thermal properties of fatty acids and their eutectics as phase change materials used for thermal energy storage: a review[J]. Journal of Energy Storage, 2021, 35: 102329. |

| 25 | Liu Z M, Wu B, Fu X W, et al. Two components based polyethylene glycol/thermosetting solid-solid phase change material composites as novel form stable phase change materials for flexible thermal energy storage application[J]. Solar Energy Materials and Solar Cells, 2017, 170: 197-204. |

| 26 | Darzi M E, Golestaneh S I, Kamali M, et al. Thermal and electrical performance analysis of co-electrospun-electrosprayed PCM nanofiber composites in the presence of graphene and carbon fiber powder[J]. Renewable Energy, 2019, 135: 719-728. |

| 27 | Jebasingh E B, Arasu V A. A comprehensive review on latent heat and thermal conductivity of nanoparticle dispersed phase change material for low-temperature applications[J]. Energy Storage Materials, 2020, 24: 52-74. |

| 28 | Wang J F, Xie H Q, Xin Z, et al. Enhancing thermal conductivity of palmitic acid based phase change materials with carbon nanotubes as fillers[J]. Solar Energy, 2010, 84(2): 339-344. |

| 29 | 刘庆祎, 肖桐, 孙文杰, 等. 纳米二氧化钛强化的相变储能研究进展[J]. 化工学报,2022,73(5):1863-1882. |

| Liu Q Y, Xiao T, Sun W J, et al. Progress in the research of phase change energy storage enhanced by titanium dioxide nanoparticles[J]. CIESC Journal, 2022, 73(5): 1863-1882. | |

| 30 | Zhang X G, Wu B G, Chen G, et al. Preparation and characterization of flexible smart glycol/polyvinylpyrrolidone/nano-Al2O3 phase change fibers[J]. Energy & Fuels, 2021, 35(1): 877-882. |

| 31 | 周雪. 聚乳酸/生物降解聚酯弹性体粒子复合材料的制备与性能研究[D]. 青岛: 青岛科技大学, 2016. |

| Zhou X. Preparation and properties of poly (lactic acid)(PLA)/biodegradable polyester elastomer particles composites[D]. Qingdao: Qingdao University of Science & Technology, 2016. | |

| 32 | Chen C Z, Liu K C, Wang H W, et al. Morphology and performances of electrospun polyethylene glycol/poly (DL-lactide) phase change ultrafine fibers for thermal energy storage[J]. Solar Energy Materials and Solar Cells, 2013, 117: 372-381. |

| [1] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [2] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [3] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [4] | 刘明栖, 吴延鹏. 导光管直径和长度对传热影响的模拟分析[J]. 化工学报, 2023, 74(S1): 206-212. |

| [5] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [6] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [7] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [8] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [9] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [10] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| [11] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [12] | 杨越, 张丹, 郑巨淦, 涂茂萍, 杨庆忠. NaCl水溶液喷射闪蒸-掺混蒸发的实验研究[J]. 化工学报, 2023, 74(8): 3279-3291. |

| [13] | 陈天华, 刘兆轩, 韩群, 张程宾, 李文明. 喷雾冷却换热强化研究进展及影响因素[J]. 化工学报, 2023, 74(8): 3149-3170. |

| [14] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [15] | 王海, 林宏, 王晨, 许浩洁, 左磊, 王军锋. 高压静电场强化多孔介质表面沸腾传热特性研究[J]. 化工学报, 2023, 74(7): 2869-2879. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号