化工学报 ›› 2019, Vol. 70 ›› Issue (10): 4052-4061.DOI: 10.11949/0438-1157.20190578

收稿日期:2019-05-27

修回日期:2019-09-10

出版日期:2019-10-05

发布日期:2019-10-05

通讯作者:

辛忠

作者简介:蒋晓峰(1992—),男,博士研究生,基金资助:

Xiaofeng JIANG( ),Shicheng ZHAO,Zhong XIN(

),Shicheng ZHAO,Zhong XIN( )

)

Received:2019-05-27

Revised:2019-09-10

Online:2019-10-05

Published:2019-10-05

Contact:

Zhong XIN

摘要:

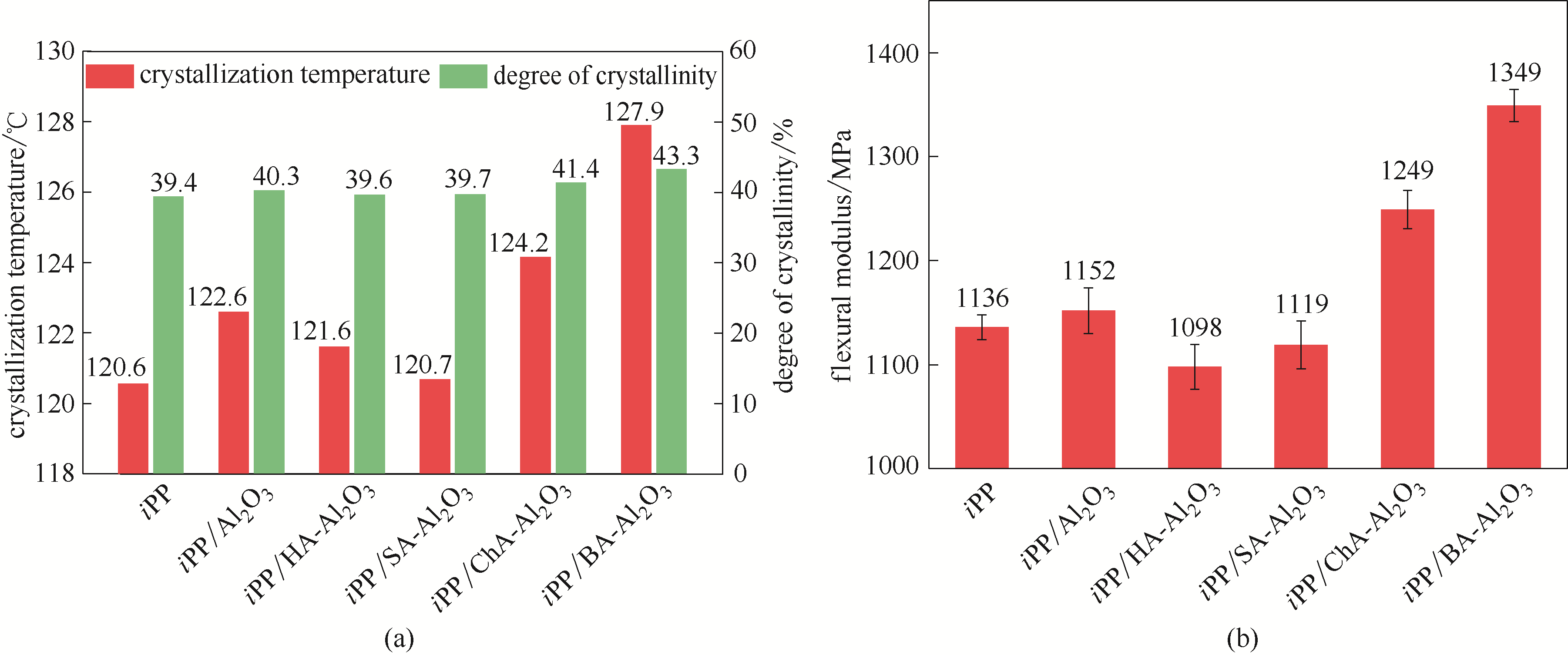

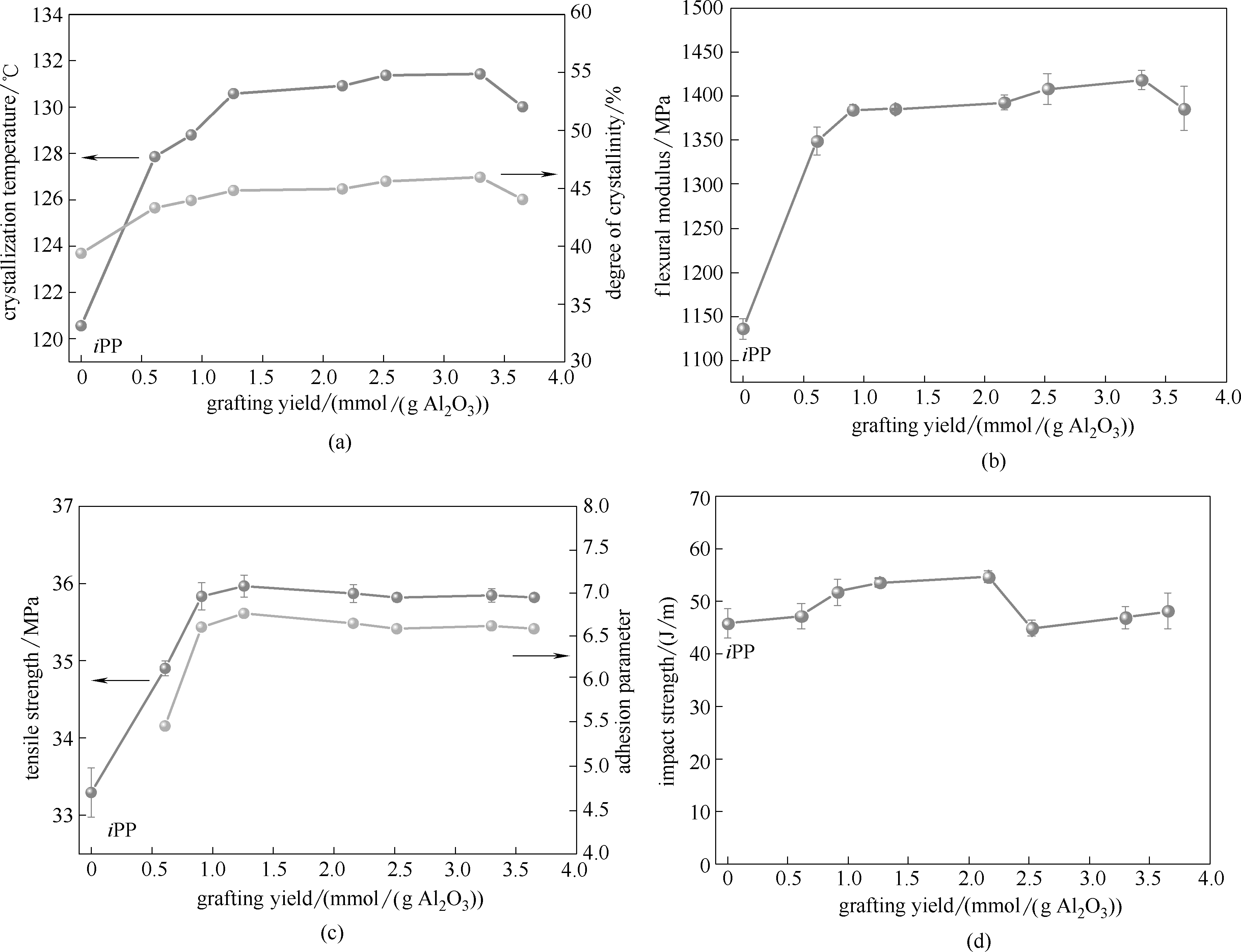

利用正庚酸、硬脂酸、环己基甲酸和苯甲酸对氧化铝纳米粒子表面进行化学改性,研究了改性粒子表面的基团结构以及接枝量对其在聚丙烯(iPP)基体中成核效果的影响。结果表明:与直链烷基和环烷基羧酸相比,苯甲酸改性颗粒(BA-Al2O3)具有优异的成核效果,当BA-Al2O3的添加量为0.1%(质量)时,成核聚丙烯的结晶温度和弯曲模量相对于纯iPP分别提高了9.4℃和21.9%。改性纳米颗粒BA-Al2O3的苯甲酸接枝量对复合材料的结晶温度和力学性能也有重要影响,接枝量小于1.3 mmol/(g Al2O3)时,BA-Al2O3的成核效果随接枝量增加而显著增加;接枝量大于1.3 mmol/(g Al2O3)时,成核效果略微增加。所以,通过调控改性颗粒的表面结构,可以有效提升iPP复合材料的结晶和力学性能。

中图分类号:

蒋晓峰, 赵世成, 辛忠. 有机羧酸改性氧化铝纳米颗粒在聚丙烯中的成核效果研究[J]. 化工学报, 2019, 70(10): 4052-4061.

Xiaofeng JIANG, Shicheng ZHAO, Zhong XIN. Nucleation effect of carboxylic acid modified alumina nanoparticles on polypropylene[J]. CIESC Journal, 2019, 70(10): 4052-4061.

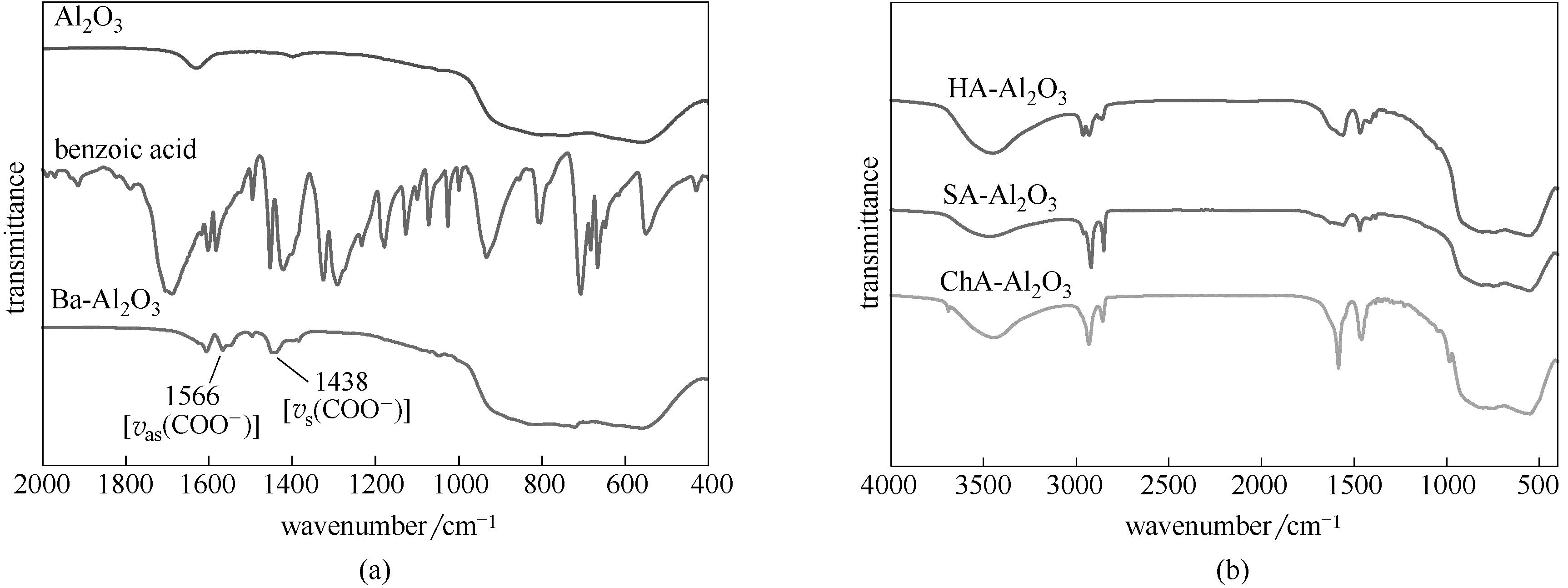

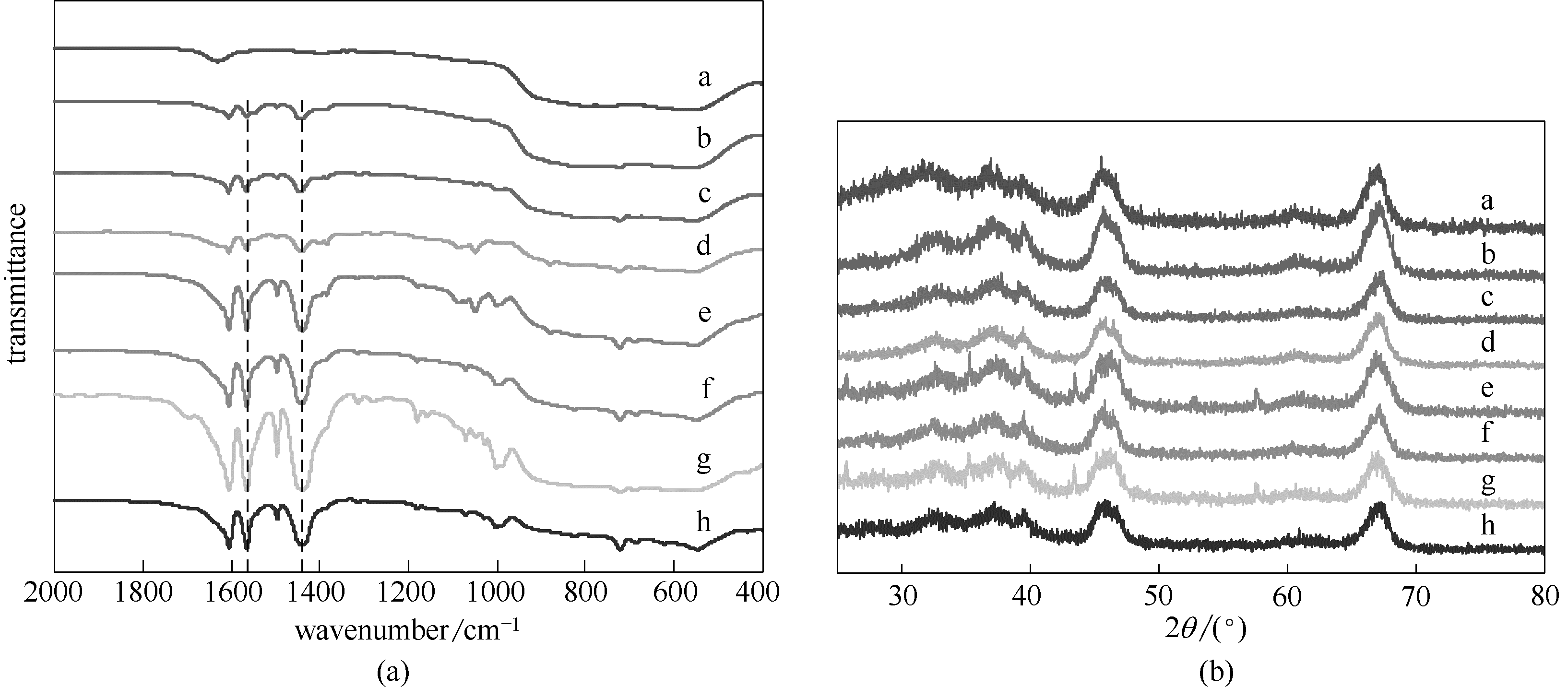

图1 未改性氧化铝颗粒,苯甲酸和改性氧化铝颗粒HA-Al2O3、SA-Al2O3、ChA-Al2O3和BA-Al2O3的红外谱图

Fig.1 FTIR spectra of pristine alumina NPs, benzoic acid, functionalized alumina NPs HA-Al2O3, SA-Al2O3, ChA-Al2O3 and BA-Al2O3

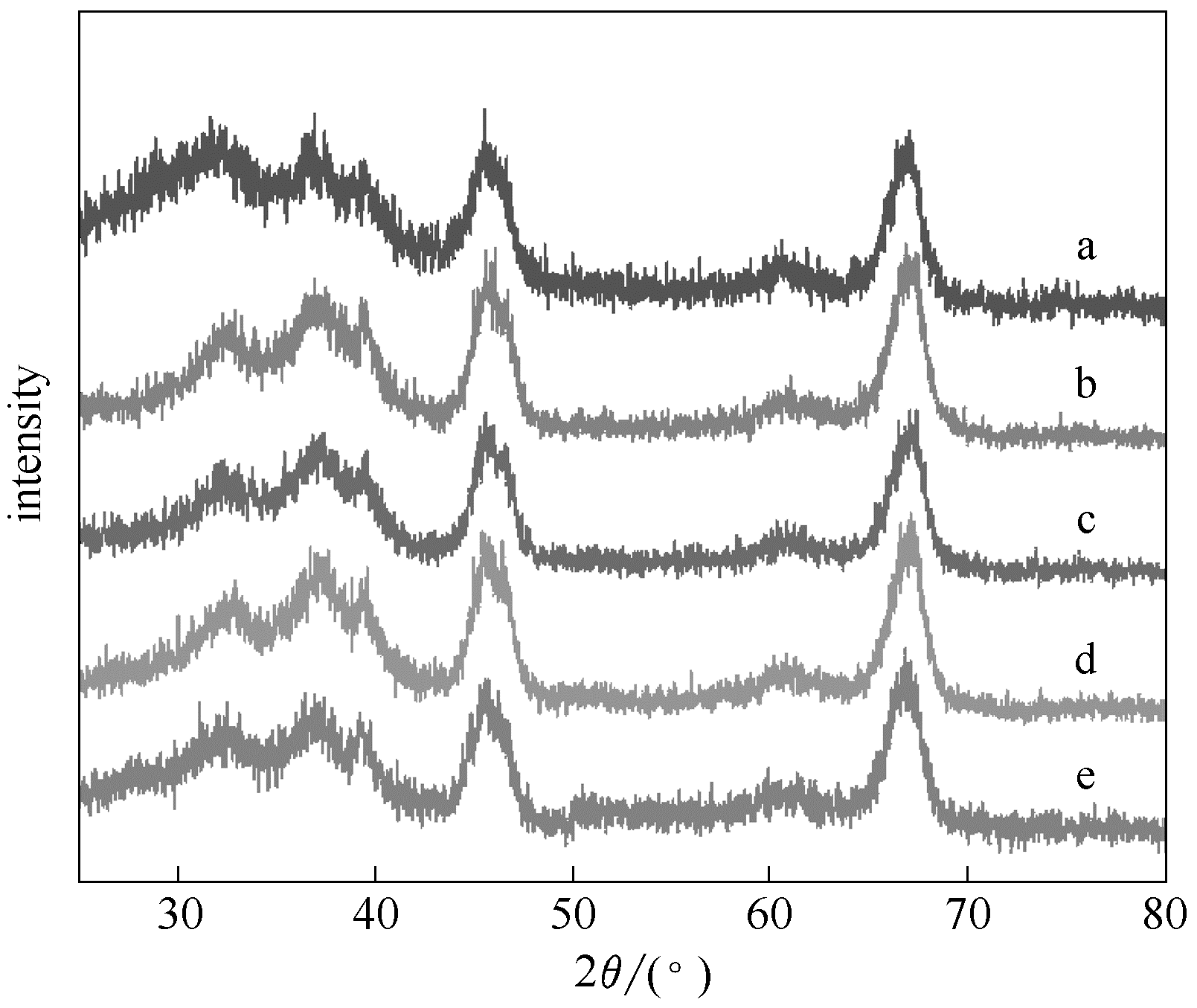

图2 未改性氧化铝颗粒、改性氧化铝颗粒的XRD谱图

Fig.2 XRD patterns of pristine alumina NPs and functionalized alumina NPsa—Al2O3;b—HA-Al2O3;c—SA-Al2O3;d—ChA-Al2O3;e—BA-Al2O3

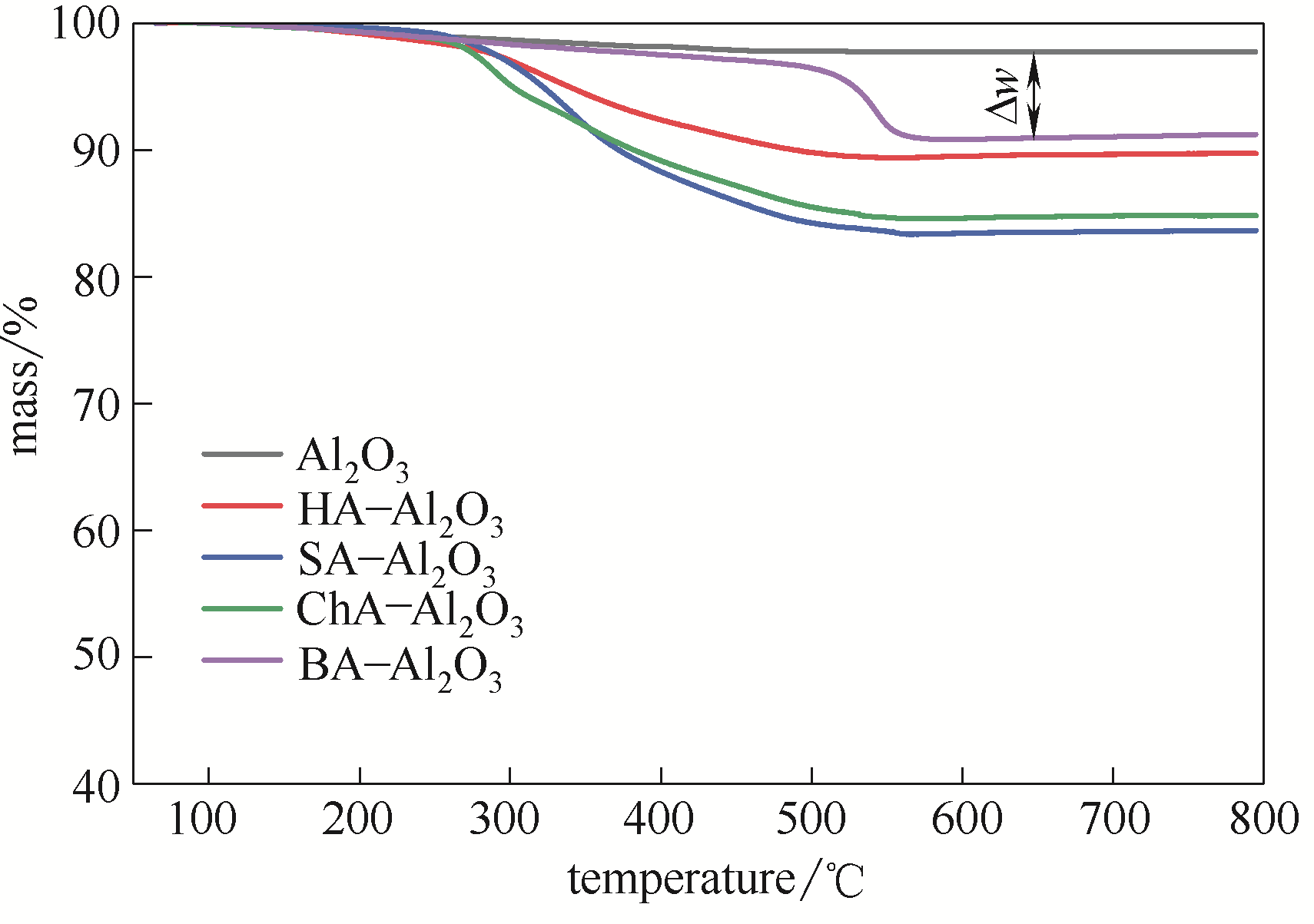

图3 未改性氧化铝颗粒,改性氧化铝颗粒HA-Al2O3、SA-Al2O3、ChA-Al2O3和BA-Al2O3的TGA曲线

Fig.3 TGA of pristine alumina NPs, functionalized alumina NPs HA-Al2O3, SA-Al2O3, ChA-Al2O3 and BA-Al2O3

| 样品 | 反应比R/ (mmol/(g Al2O3)) | ΔW/% | 接枝量Y/ (mmol/(g Al2O3)) |

|---|---|---|---|

| HA-Al2O3 | 7 | 8.4 | 0.7 |

| SA-Al2O3 | 7 | 14.4 | 0.6 |

| ChA-Al2O3 | 7 | 13.2 | 1.2 |

| BA-Al2O3 | 1 | 6.9 | 0.6 |

表1 改性氧化铝颗粒HA-Al2O3、SA-Al2O3、ChA-Al2O3和BA-Al2O3的总热失重和接枝量

Table 1 Overall mass loss and grafting yield of HA-Al2O3, SA-Al2O3, ChA-Al2O3 and BA-Al2O3

| 样品 | 反应比R/ (mmol/(g Al2O3)) | ΔW/% | 接枝量Y/ (mmol/(g Al2O3)) |

|---|---|---|---|

| HA-Al2O3 | 7 | 8.4 | 0.7 |

| SA-Al2O3 | 7 | 14.4 | 0.6 |

| ChA-Al2O3 | 7 | 13.2 | 1.2 |

| BA-Al2O3 | 1 | 6.9 | 0.6 |

图4 未改性氧化铝颗粒、改性氧化铝颗粒对PP结晶温度以及结晶度(a)和弯曲模量(b)的影响

Fig.4 Effect of pristine alumina NPs, functionalized alumina NPs on crystallization temperature and degree of crystallinity (a) and flexural modulus (b) of iPP

图6 未改性氧化铝颗粒、苯甲酸改性氧化铝颗粒BA-Al2O3-x的红外谱图(a)与XRD谱图(b)

Fig.6 FTIR spectra (a) and XRD patterns (b) of pristine alumina NPs and benzoic acid functionalized alumina NPs BA-Al2O3-xa—Al2O3;b—BA-Al2O3-1;c—BA-Al2O3-2;d—BA-Al2O3-3;e—BA-Al2O3-4;f—BA-Al2O3-5;g—BA-Al2O3-6;h—BA-Al2O3-7

| 样品 | 反应比(R)/ (mmol/(g Al2O3)) | ΔW/% | 接枝量Y/ (mmol/(g Al2O3)) |

|---|---|---|---|

| BA-Al2O3-1 | 1 | 6.9 | 0.6 |

| BA-Al2O3-2 | 2 | 10.0 | 0.9 |

| BA-Al2O3-3 | 3 | 13.3 | 1.3 |

| BA-Al2O3-4 | 4 | 20.9 | 2.2 |

| BA-Al2O3-5 | 5 | 23.5 | 2.5 |

| BA-Al2O3-6 | 6 | 28.7 | 3.3 |

| BA-Al2O3-7 | 7 | 30.8 | 3.6 |

表2 苯甲酸改性氧化铝颗粒BA-Al2O3-x的总热失重和接枝量

Table 2 Overall mass loss and grafting yield of BA-Al2O3-x

| 样品 | 反应比(R)/ (mmol/(g Al2O3)) | ΔW/% | 接枝量Y/ (mmol/(g Al2O3)) |

|---|---|---|---|

| BA-Al2O3-1 | 1 | 6.9 | 0.6 |

| BA-Al2O3-2 | 2 | 10.0 | 0.9 |

| BA-Al2O3-3 | 3 | 13.3 | 1.3 |

| BA-Al2O3-4 | 4 | 20.9 | 2.2 |

| BA-Al2O3-5 | 5 | 23.5 | 2.5 |

| BA-Al2O3-6 | 6 | 28.7 | 3.3 |

| BA-Al2O3-7 | 7 | 30.8 | 3.6 |

图7 改性氧化铝颗粒BA-Al2O3-x的苯环接枝量对PP结晶温度、结晶度、力学性能和结合系数的影响

Fig.7 Effect of aromatic group grafting yield of BA-Al2O3-x on crystallization temperature, degree of crystallinity, mechanical properties and adhesion parameter of iPP

| 1 | QinW, XinZ, PanC M, et al. In situ formation of zinc phthalate as a highly dispersed β-nucleating agent for mechanically strengthened isotactic polypropylene[J]. Chemical Engineering Journal, 2019, 358: 1243-1252. |

| 2 | ZhaoS C, QinW, XinZ, et al. In situ generation of a self-dispersed β-nucleating agent with increased nucleation efficiency in isotactic polypropylene[J]. Polymer, 2018, 151: 84-91. |

| 3 | 石尧麒, 辛忠. α/β复合成核剂对等规聚丙烯结晶形态的影响及非等温结晶动力学[J]. 化工学报, 2012, 63(4): 1274-1286. |

| ShiY Q, XinZ. Crystallization morphologies and non-isothermal crystallization kinetics of isotactic polypropylene modified by α/β compounded nucleating agents[J]. CIESC Journal, 2012, 63(4): 1274-1286. | |

| 4 | 周军, 辛忠. 亚苄基缩醛在聚丙烯中溶解性和成核作用[J]. 化工学报, 2012, 63(3): 941-947. |

| ZhouJ, XinZ. Solubility and nucleation of benzylidene acetals in polypropylene[J]. CIESC Journal, 2012, 63(3): 941-947. | |

| 5 | 张跃飞, 辛忠. 取代芳基杂环磷酸金属盐类成核剂在等规聚丙烯中的成核效应[J]. 化工学报, 2006, 57(4): 953-958. |

| ZhangY F, XinZ. Nucleation efficiency of substituted aromatic heterocyclic phosphoric acid metal salts as nucleators for isotactic polypropylene[J]. Journal of Chemical Industry and Engineering(China), 2006, 57(4): 953-958. | |

| 6 | 张恰, 赵世成, 周帅, 等. 取代芳基磷酸酯钠盐成核剂的晶体结构与聚丙烯附生结晶的过程[J]. 石油化工, 2017, 46(1): 36-43. |

| ZhangQ, ZhaoS C, ZhouS, et al. Single crystal structure of sodium phosphonate ester nucleating agents and their effects on polypropylene epitaxial crystallization[J]. Petrochemical Technology, 2017, 46(1): 36-43. | |

| 7 | 周红军, 尹国强, 林轩, 等. PP/PP-g-NH2/纳米SiO2复合材料的非等温结晶[J].化工学报, 2009, 60(4): 1046-1051. |

| ZhouH J, YinG Q, LinX, et al. Nonisothermal crystallization of PP/PP-g-NH2/nano-SiO2 composites [J]. CIESC Journal, 2009, 60(4): 1046-1051. | |

| 8 | BernlandK, TervoortT, SmithP. Phase behavior and optical- and mechanical properties of the binary system isotactic polypropylene and the nucleating/clarifying agent 1,2,3-trideoxy-4,6:5,7-bis--[(4-propylphenyl) methylene]-nonitol[J]. Polymer, 2009, 50(11): 2460-2464. |

| 9 | GuiQ, XinZ, ZhuW, et al. Effects of an organic phosphorus nucleating agent on crystallization behaviors and mechanical properties of poly (propylene)[J]. Journal of Applied Polymer Science, 2003, 88(2): 297-301. |

| 10 | MathieuC, ThierryA, WittmannJ, et al. “Multiple” nucleation of the (010) contact face of isotactic polypropylene, α phase[J]. Polymer, 2000, 41(19): 7241-7253. |

| 11 | MasirekR, PiorkowskaE. Nucleation of crystallization in isotactic polypropylene and polyoxymethylene with poly(tetrafluoroethylene) particles[J]. European Polymer Journal, 2010, 46(7): 1436-1445. |

| 12 | HanZ, FinaA. Thermal conductivity of carbon nanotubes and their polymer nanocomposites: a review[J]. Progress in Polymer Science, 2011, 36(7): 914-944. |

| 13 | GongJ, NiuR, WenX, et al. Synergistic effect of carbon fibers and carbon nanotubes on improving thermal stability and flame retardancy of polypropylene: a combination of a physical network and chemical crosslinking[J]. RSC Advances, 2014, 5(8): 5484-5493. |

| 14 | SongP, CaoZ, CaiY, et al. Fabrication of exfoliated graphene-based polypropylene nanocomposites with enhanced mechanical and thermal properties[J]. Polymer, 2011, 52(18): 4001-4010. |

| 15 | YangS, LiY, LiangY Y, et al. Graphene oxide induced isotactic polypropylene crystallization: role of structural reduction[J]. RSC Advances, 2016, 6(28): 23930-23941. |

| 16 | ZhaoH, LiR K. Crystallization, mechanical, and fracture behaviors of spherical alumina-filled polypropylene nanocomposites[J]. Journal of Polymer Science Part B: Polymer Physics, 2005, 43(24): 3652-3664. |

| 17 | NagendraB, MohanK, GowdEB. Polypropylene/layered double hydroxide (LDH) nanocomposites: influence of LDH particle size on the crystallization behavior of polypropylene[J]. ACS Applied Materials & Interfaces, 2015, 7(23): 12399-12410. |

| 18 | QiuL, GaoY, YanX, et al. Morphology-dependent performance of Mg3AlCO3 layered double hydroxide as a nanofiller for polypropylene nanocomposites[J]. RSC Advances, 2015, 5(64): 51900-51911. |

| 19 | MoniruzzamanM, WineyK I. Polymer nanocomposites containing carbon nanotubes[J]. Macromolecules, 2006, 39(16): 5194-5205. |

| 20 | LiangY Y, XuJ Z, LiuX Y, et al. Role of surface chemical groups on carbon nanotubes in nucleation forpolymer crystallization: Interfacial interaction and steric effect[J]. Polymer, 2013, 54(23): 6479-6488. |

| 21 | NingN, FuS, ZhangW, et al. Realizing the enhancement of interfacial interaction in semicrystalline polymer/filler composites via interfacial crystallization[J]. Progress in Polymer Science, 2012, 37(10): 1425-1455. |

| 22 | PedrazzoliD, KhumaloV, Karger-KocsisJ, et al. Thermal, viscoelastic and mechanical behavior of polypropylene with synthetic boehmite alumina nanoparticles[J]. Polymer Testing, 2014, 35: 92-100. |

| 23 | EbengouR H. Adsorption as a mechanism for nucleating activity: a thermodynamic explanation[J]. Journal of Polymer Science Part B Polymer Physics, 2015, 35(9): 1333-1338. |

| 24 | SmithT L, MasilamaniD, LongK B, et al. The mechanism of action of sugar acetals as nucleating agents for polypropylene[J]. Macromolecules, 1994, 27(12): 3147-3155. |

| 25 | ManiM R, ChellaswamyR, MaratheY N, et al. The role of the molecular structure of carboxylate-alumoxanes in the enhanced nucleation of polypropylene[J]. Chemical Communications, 2015, 51(49): 10026-10029. |

| 26 | YangR, DingL, ChenW, et al. Chain folding in main-chain liquid crystalline polyester with strong π-π interaction: an efficient β-nucleating agent for isotactic polypropylene[J]. Macromolecules, 2017, 50(4): 1610-1617. |

| 27 | JiangX F, ZhaoS C, MengX, et al. Effect of the metal phenylphosphonates on the nonisothermal crystallization and performance of isotactic polypropylene[J]. Journal of Polymer Science Part B: Polymer Physics, 2019, 57(3): 161-173. |

| 28 | LuK, GrossiordN, KoningC E, et al. Carbon nanotube/isotactic polypropylene composites prepared by latex technology: morphology analysis of CNT-induced nucleation[J]. Macromolecules, 2008, 41(21): 8081-8085. |

| 29 | JiangX F, ZhangW X, ZhaoS C, et al. Effect of benzoic acid surface modified alumina nanoparticles on the mechanical properties and crystallization behavior of isotactic polypropylene nanocomposites[J]. RSC Advances, 2018, 8(37): 20790-20800. |

| 30 | MohanR M, RameshC, MaratheY N, et al. The role of the molecular structure of carboxylate-alumoxanes in the enhanced nucleation of polypropylene[J]. Chemical Communications, 2015, 51(49): 10026-10029. |

| 31 | AnayaS, SerranoB, HerreroB, et al. γ-Alumina modification with long chain carboxylic acid surface nanocrystals for biocompatible polysulfone nanocomposites[J]. ACS Applied Materials & Interfaces, 2014, 6(16): 14460-14468. |

| 32 | AlexanderS, EastoeJ, LordA M, et al. Branched hydrocarbon low surface energy materials for superhydrophobic nanoparticle derived surfaces[J]. ACS Applied Materials & Interfaces, 2016, 8(1): 660-666. |

| 33 | DerakhshanA A, RajabiL, KarimnezhadH. Morphology and production mechanism of the functionalized carboxylate alumoxane micro and nanostructures[J]. Powder Technology, 2012, 225: 156-166. |

| 34 | FuS Y, FengX Q, LaukeB, et al. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate-polymer composites[J]. Composites Part B: Engineering, 2008, 39(6): 933-961. |

| 35 | 张以河, 付绍云, 李国耀, 等. 聚合物基纳米复合材料的增强增韧机理[J]. 高技术通讯, 2004, 14(5): 99-105. |

| ZhangY H, FuS Y, LiG Y, et al. Strengthening and toughening mechanisms of polymer based nanocomposites[J]. Chinese High Technology Letters, 2004, 14(5): 99-105. | |

| 36 | ZhangQ X, YuZ Z, XieX L, et al. Crystallization and impact energy of polypropylene/CaCO3 nanocomposites with nonionic modifier[J]. Polymer, 2004, 45(17): 5985-5994. |

| [1] | 王琪, 张斌, 张晓昕, 武虎建, 战海涛, 王涛. 氯铝酸-三乙胺离子液体/P2O5催化合成伊索克酸和2-乙基蒽醌[J]. 化工学报, 2023, 74(S1): 245-249. |

| [2] | 仪显亨, 周骛, 蔡小舒, 蔡天意. 光纤后向动态光散射测量纳米颗粒的浓度适用范围研究[J]. 化工学报, 2023, 74(8): 3320-3328. |

| [3] | 胡兴枝, 张皓焱, 庄境坤, 范雨晴, 张开银, 向军. 嵌有超小CeO2纳米粒子的碳纳米纤维的制备及其吸波性能[J]. 化工学报, 2023, 74(8): 3584-3596. |

| [4] | 杨菲菲, 赵世熙, 周维, 倪中海. Sn掺杂的In2O3催化CO2选择性加氢制甲醇[J]. 化工学报, 2023, 74(8): 3366-3374. |

| [5] | 葛加丽, 管图祥, 邱新民, 吴健, 沈丽明, 暴宁钟. 垂直多孔碳包覆的FeF3正极的构筑及储锂性能研究[J]. 化工学报, 2023, 74(7): 3058-3067. |

| [6] | 张澳, 罗英武. 低模量、高弹性、高剥离强度丙烯酸酯压敏胶[J]. 化工学报, 2023, 74(7): 3079-3092. |

| [7] | 王杰, 丘晓琳, 赵烨, 刘鑫洋, 韩忠强, 许雍, 蒋文瀚. 聚电解质静电沉积改性PHBV抗氧化膜的制备与性能研究[J]. 化工学报, 2023, 74(7): 3068-3078. |

| [8] | 涂玉明, 邵高燕, 陈健杰, 刘凤, 田世超, 周智勇, 任钟旗. 钙基催化剂的设计合成及应用研究进展[J]. 化工学报, 2023, 74(7): 2717-2734. |

| [9] | 李彬, 徐正虎, 姜爽, 张天永. 双氧水催化氧化法清洁高效合成促进剂CBS[J]. 化工学报, 2023, 74(7): 2919-2925. |

| [10] | 张谭, 刘光, 李晋平, 孙予罕. Ru基氮还原电催化剂性能调控策略[J]. 化工学报, 2023, 74(6): 2264-2280. |

| [11] | 蔡斌, 张效林, 罗倩, 党江涛, 左栗源, 刘欣梅. 导电薄膜材料的研究进展[J]. 化工学报, 2023, 74(6): 2308-2321. |

| [12] | 李勇, 高佳琦, 杜超, 赵亚丽, 李伯琼, 申倩倩, 贾虎生, 薛晋波. Ni@C@TiO2核壳双重异质结的构筑及光热催化分解水产氢[J]. 化工学报, 2023, 74(6): 2458-2467. |

| [13] | 崔张宁, 胡紫璇, 吴雷, 周军, 叶干, 刘田田, 张秋利, 宋永辉. 可降解纤维素基材料的耐水性能研究进展[J]. 化工学报, 2023, 74(6): 2296-2307. |

| [14] | 李振, 张博, 王丽伟. PEG-EG固-固相变材料的制备和性能研究[J]. 化工学报, 2023, 74(6): 2680-2688. |

| [15] | 代佳琳, 毕唯东, 雍玉梅, 陈文强, 莫晗旸, 孙兵, 杨超. 热物性对混合型CPCMs固液相变特性影响模拟研究[J]. 化工学报, 2023, 74(5): 1914-1927. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号