化工学报 ›› 2020, Vol. 71 ›› Issue (9): 3905-3918.DOI: 10.11949/0438-1157.20200542

收稿日期:2020-05-09

修回日期:2020-07-14

出版日期:2020-09-05

发布日期:2020-09-05

通讯作者:

贺高红

作者简介:姜晓滨(1984—),男,博士,教授,基金资助:

Xiaobin JIANG( ),Guoxin SUN,Gaohong HE(

),Guoxin SUN,Gaohong HE( )

)

Received:2020-05-09

Revised:2020-07-14

Online:2020-09-05

Published:2020-09-05

Contact:

Gaohong HE

摘要:

全球性的水资源短缺及环境污染问题,使得工业废水处理、海水淡化、高价值溶质综合利用的需求日益迫切。膜蒸馏结晶过程可以充分利用低品质热源,实现高纯度水溶剂分离、盐分结晶制备,对于实现分离过程零排放和协同增效有重要意义。同时,膜蒸馏结晶也可以与多级闪蒸,多效精馏、纳滤、正向渗透、反渗透等过程进行耦合,进一步提高整体分离效率。此外,该过程对于调控晶体外部形貌,制备晶体尺寸分布集中、流动性好的晶体产品也有积极作用。基于此,针对膜蒸馏结晶原理、过程调控机制以及创新过程应用几个方面开展论述,总结了膜蒸馏结晶技术在高效分离、结晶过程精准控制等领域的关键问题和发展趋势。

中图分类号:

姜晓滨, 孙国鑫, 贺高红. 高效膜蒸馏结晶过程的研究进展[J]. 化工学报, 2020, 71(9): 3905-3918.

Xiaobin JIANG, Guoxin SUN, Gaohong HE. Research progress of high-efficiency membrane distillation crystallization process[J]. CIESC Journal, 2020, 71(9): 3905-3918.

图2 空心钇稳定氧化锆(YSZ)管表面上制备的C-D35-2膜的SEM图(a),YSZ和碳层之间界面的FIB-SEM图,即图(a)中方框区域放大图(碳和YSZ之间的界面清晰可见。碳纤维-陶瓷界面附近的孔径被认为是最小的,通过气体渗透确定约为31 nm)(b),C-D35-2膜中典型的单碳纳米纤维的HRTEM图(箭头指向碳纤维内部的“竹节状”结构,该结构将内部空间划分为多个隔室,1 ? =0.1 nm)(c)[31]

Fig.2 SEM image of C-D35-2 film prepared on the surface of hollow yttrium-stabilized zirconia (YSZ) tube (a); FIB-SEM image of the square in Fig.2(a)(The clear interface between carbon and YSZ is clearly visible. You can also see the nanopores on the carbon side. The pore size near the carbon fiber-ceramic interface is considered to be the smallest, which is determined to be about 31 nm by gas penetration) (b); HRTEM image of typical single carbon nanofibers in C-D35-2 film (The arrow points to the “slubby” structure inside the carbon fiber, which divides the internal space into multiple compartments) (c)[31]

图3 在T = 70°C(343.15 K)和S = 1.01时KNO3在不同膜材料和孔隙率的膜蒸馏结晶中成核功W对比[32]

Fig.3 Comparison of nucleation work W of KNO3 in membrane distillation crystallization of different membrane materials and porosities at T = 70℃ (343.15 K) and S = 1.01[32]

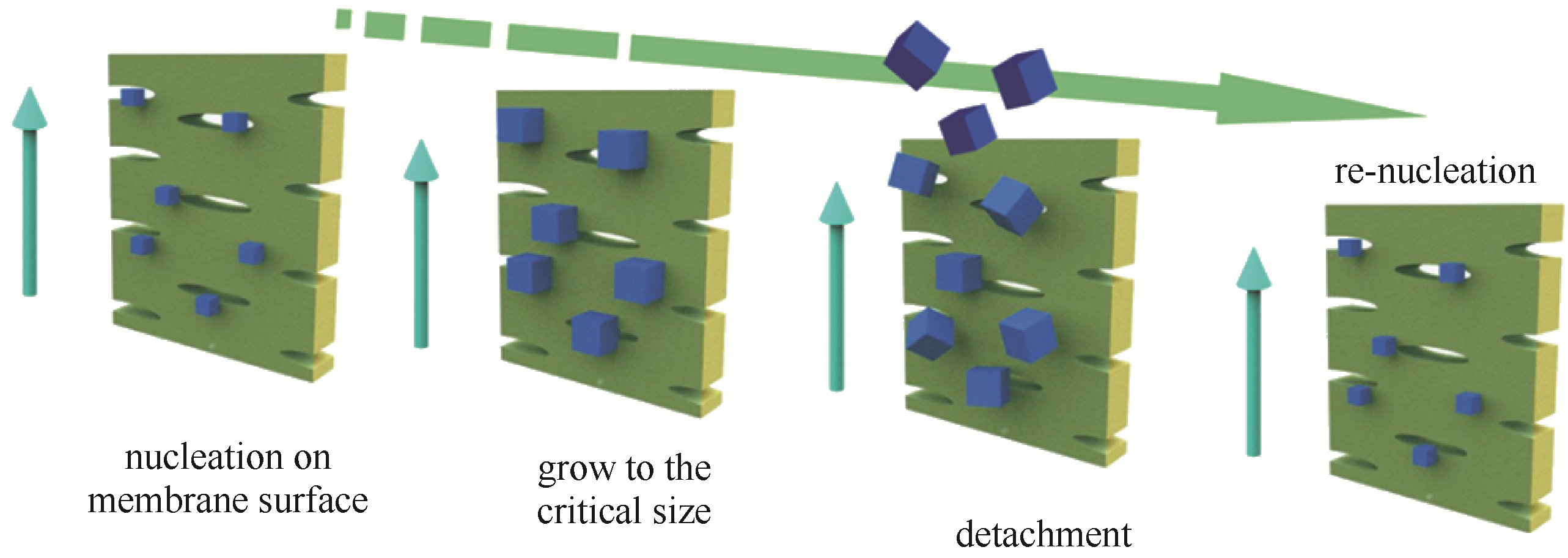

图4 MDC过程中溶液在膜表面非均相成核、生长及脱附的示意图[33]

Fig.4 Schematic diagram of solution heterogeneous nucleation, growth and detachment on the membrane surface during MDC[33]

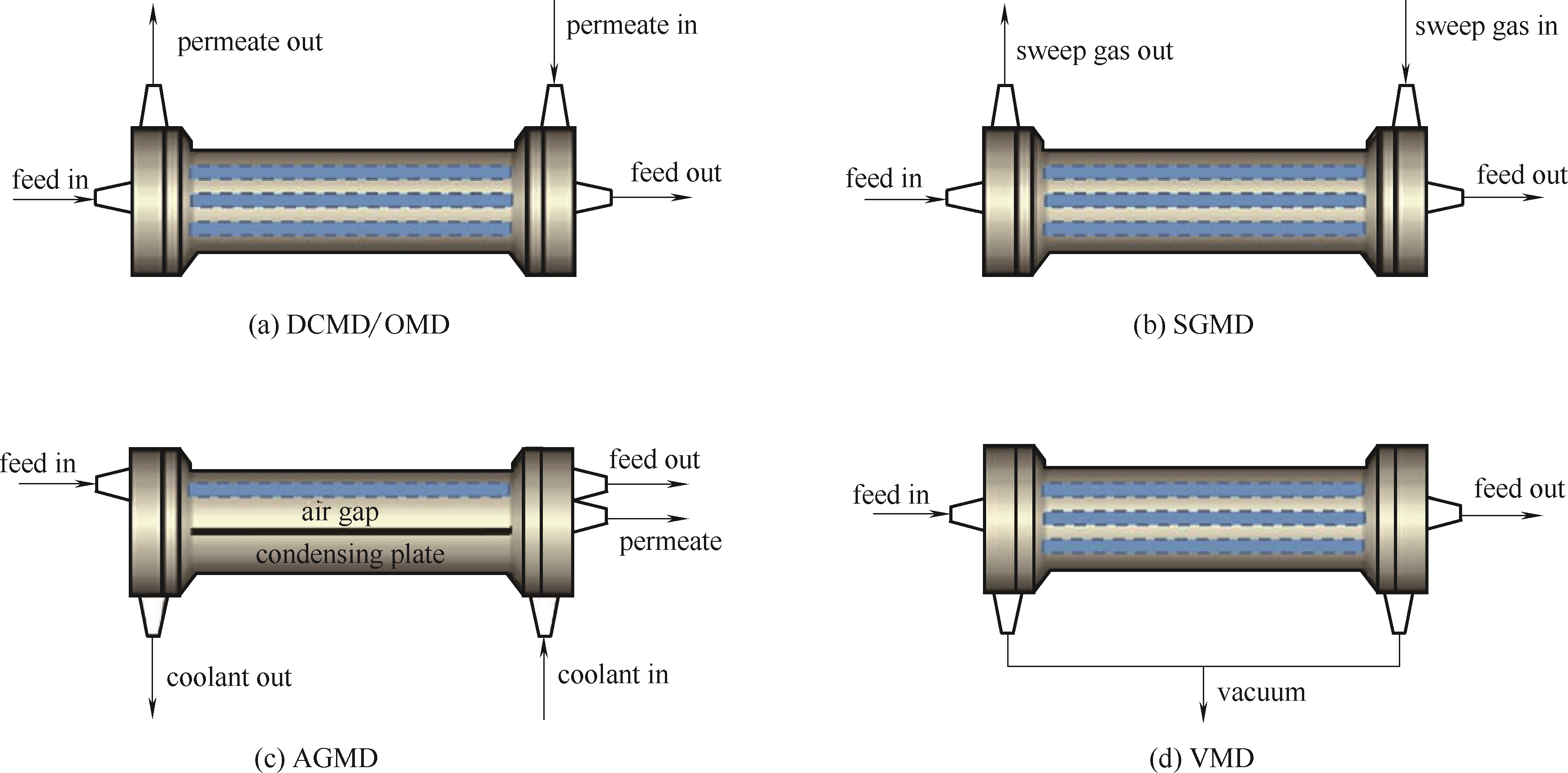

图5 膜蒸馏装置:直接接触膜蒸馏(DCMD)、渗透膜蒸馏(OMD)、吹扫气膜蒸馏(SGMD)、气隙膜蒸馏(AGMD)和真空膜蒸馏(VMD)[34]

Fig.5 Membrane distillation unit: direct contact membrane distillation (DCMD), osmotic membrane distillation (OMD), sweep gas membrane distillation (SGMD), air gap membrane distillation (AGMD) and vacuum membrane distillation (VMD)[34]

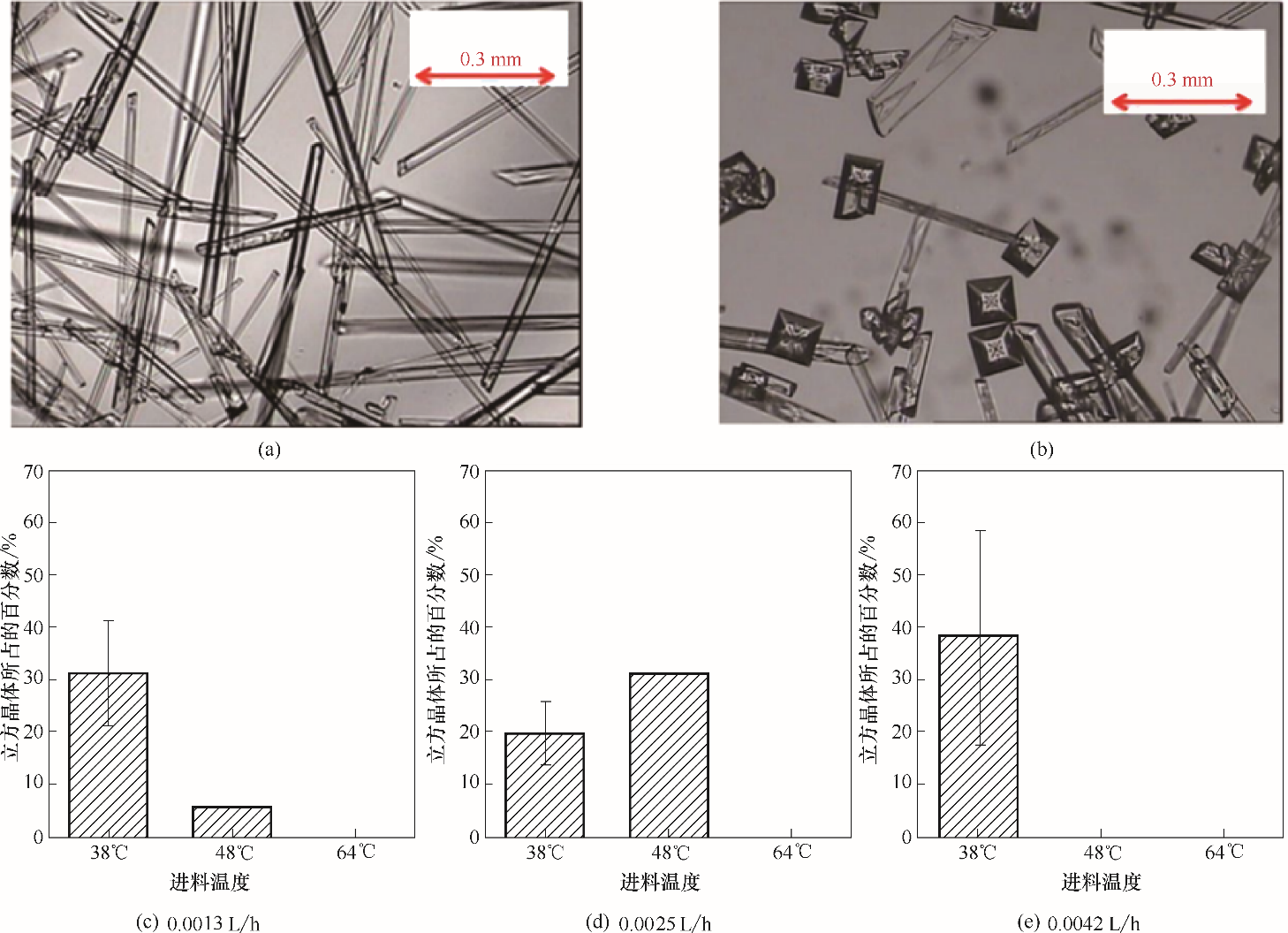

图7 通过膜结晶得到的LiCl晶体的形态:斜方多晶型(a),立方多晶型(b); 各种进料温度和流速下立方和斜方晶型的分布[(c)~(e)][47]

Fig.7 Morphology of LiCl crystals obtained by film crystallization: orthogonal polymorph (a), cubic polymorph (b); distribution of cubic and orthogonal structures at various feed temperatures and flow rates[(c)—(e)][47]

图8 自然冷却结晶,冷却速率为0.1 K/min下的膜蒸馏耦合冷却结晶(KNO3)不同结晶时间的CSD(柱形图)(a),晶体的光学显微镜图[放大100倍(b),放大40倍(c)];膜辅助结晶,冷却速率为0.2 K/min下的膜蒸馏耦合冷却结晶(KNO3)的温度曲线及不同结晶时间的CSD(d),晶体的光学显微镜图[放大100倍(e),放大40倍(f)];快速冷却结晶,冷却速率为0.33 K/min下的膜蒸馏耦合冷却结晶(KNO3)的温度曲线及不同结晶时间的CSD(g),晶体的光学显微镜图[放大100倍(h),放大40倍(i)] (图中虚线表示由MATLAB编程建立粒数衡算方程得出的动力学模拟结果,Ni/Ntotal表示不同尺寸晶体数占晶体总数百分比,峰值数字为变异系数,lˉ表示晶体平均尺寸)[32]

Fig.8 Under natural cooling and cooling rate of 0.1 K/min, CSD (bar graph) of different crystallization time of membrane distillation coupled cooling crystallization (KNO3) (a), optical microscope image of the crystal [magnification 100 times (b), magnification 40 times (c)]; under membrane assisted crystallization and cooling rate of 0.2 K/min, CSD of different crystallization time of membrane distillation coupled cooling crystallization (KNO3) (d), optical microscope image of the crystal [magnification 100 (e), magnification 40 times (f)]; under rapid cooling crystallization and cooling rate of 0.33 K/min, CSD of different crystallization time of membrane distillation coupled cooling crystallization (KNO3) (g),the optical microscope image of the crystal [magnification 100 times (h), magnified 40 times (i)] (The dot line in the figure: the kinetic simulation results obtained by the MATLAB programming to establish the particle number balance equation; Ni/Ntotal: the percentage of the number of crystals of different sizes; the number marked at the peak: C.V.; lˉ: the average crystal size)[32]

图11 在MDC中同时进行EG、有机含盐废水的回收和结晶控制:实验装置(a);重复实验下渗透通量、EG和NaCl截留率(b);通过MDC和真空蒸发结晶(VEC)获得的晶体颗粒性质的比较(c)[58]

Fig.11 Simultaneous recovery and crystallization control of EG and organic saline wastewater in MDC: experimental device (a); permeation flux, EG and NaCl rejection rate under repeated experiments (b); comparison of the properties of crystal particles obtained by MDC and vacuum evaporation crystallization (VEC) (c)[58]

图13 HCMs膜结晶流程示意图(a);膜组件单元分解示意图(b);多通道连续实验平台(c);PEGDA-NIPAM HCMs的晶体成核调控及高选择性生长机理与实验结果(d) [69]G*nucleation—临界成核能; Tfeed—进料结晶溶液的温度; vflow—进料流动的速度; Cs—晶体组分的浓度

Fig.13 Schematic diagram of HCMs membrane crystallization process(a); schematic diagram of membrane module unit decomposition(b); multi-channel continuous experiment platform(c); crystal nucleation regulation and highly selective growth mechanism and experimental results of PEGDA-NIPAM HCMs(d) [69]

| 1 | Lyu S D, Chen W P, Zhang W L, et al. Wastewater reclamation and reuse in China: opportunities and challenges[J]. Journal of Environmental Sciences, 2016, 39: 86-96. |

| 2 | Ahmad N A, Leo C P, Ahmad A L, et al. Membranes with great hydrophobicity: a review on preparation and characterization[J]. Separation & Purification Methods, 2015, 44(2): 109-134. |

| 3 | Chen L, Shi G S, Shen J, et al. Ion sieving in graphene oxide membranes via cationic control of interlayer spacing[J]. Nature, 2017, 550(7676): 415-418. |

| 4 | 张芷铭, 邢瑞思, 吴洪, 等. 埃洛石纳米管掺杂海藻酸复合膜制备及其渗透蒸发脱水研究[J]. 膜科学与技术, 2020, 40(1): 45-52. |

| Zhang Z M, Xing R S, Wu H, et al. Preparation and performance of alginate composite membrane doped with halloysite nanotube for pervaporation dehydration[J]. Membrane Science and Technology, 2020, 40(1): 45-52. | |

| 5 | 白炳林, 杨晓宏, 田瑞, 等. 太阳能光热-光电中空纤维真空膜蒸馏系统理论与实验研究[J]. 化工学报, 2019, 70(9): 3517-3526 |

| Bai B L, Yang X H, Tian R, et al. Theoretical and experimental research on solar thermal-photovoltaic hollow fiber vacuum membrane distillation system[J]. CIESC Journal, 2019, 70(9): 3517-3526 | |

| 6 | Tong T Z, Elimelech M. The global rise of zero liquid discharge for wastewater management: drivers, technologies, and future directions[J]. Environmental Science & Technology, 2016, 50(13): 6846-6855. |

| 7 | Bodell B R. Silicone rubber vapor diffusion in saline water distillation: US3361645[P]. 1963. |

| 8 | Weyl P K. Recovery of demineralized water from saline waters: US3340186[P]. 1967. |

| 9 | 袁子怡, 樊华, 侯得印, 等. 十二烷基硫酸钠对膜蒸馏过程影响[J]. 化工学报, 2019, 70(4): 1455-1463. |

| Yuan Z Y, Fan H, Hou D Y, et al. Effects of sodium dodecyl sulfate in DCMD process[J]. CIESC Journal, 2019, 70(4): 1455-1463. | |

| 10 | Quist-Jensen C A, Macedonio F, Horbez D, et al. Reclamation of sodium sulfate from industrial wastewater by using membrane distillation and membrane crystallization[J]. Desalination, 2017, 401: 112-119. |

| 11 | Di Profio G, Salehi S M, Caliandro R, et al. Bioinspired synthesis of CaCO3 superstructures through a novel hydrogel composite membranes mineralization platform: a comprehensive view[J]. Advanced Materials, 2016, 28(4): 610-616. |

| 12 | Curcio E, Curcio V, Di Profio G, et al. Energetics of protein nucleation on rough polymeric surfaces[J]. Journal of Physical Chemistry B, 2010, 114(43): 13650-13655. |

| 13 | Drioli E, Curcio E, Criscuoli A, et al. Integrated system for recovery of CaCO3, NaCl and MgSO4·7H2O from nanofiltration retentate[J]. Journal of Membrane Science, 2004, 239(1): 27-38. |

| 14 | Di Profio G, Polino M, Nicoletta F P, et al. Tailored hydrogel membranes for efficient protein crystallization[J]. Advanced Functional Materials, 2014, 24(11): 1582-1590. |

| 15 | Lakerveld R, Verzijden N G, Kramer H, et al. Application of ultrasound for start-up of evaporative batch crystallization of ammonium sulfate in a 75-L crystallizer[J]. AIChE Journal, 2011, 57(12): 3367-3377. |

| 16 | Jiang X B, Tuo L H, Lu D P, et al. Progress in membrane distillation crystallization: process models, crystallization control and innovative applications[J]. Frontiers of Chemical Science and Engineering, 2017, 11(4): 647-662. |

| 17 | Meng S W, Hsu Y, Ye Y, et al. Submerged membrane distillation for inland desalination applications[J]. Desalination, 2015, 361: 72-80 |

| 18 | Drioli E, Di Profio G, Curcio E. Progress in membrane crystallization[J]. Current Opinion in Chemical Engineering, 2012, 1(2): 178-182. |

| 19 | Ji Z G, Wang J, Yin Z F, et al. Effect of microwave irradiation on typical inorganic salts crystallization in membrane distillation process[J]. Journal of Membrane Science, 2014, 455: 24-30. |

| 20 | Kim J H, Park S H, Lee M J, et al. Thermally rearranged polymer membranes for desalination[J]. Energy & Environmental Science, 2016, 9(3): 878-884. |

| 21 | Di Profio G, Curcio E, Ferraro S, et al. Effect of supersaturation control and heterogeneous nucleation on porous membrane surfaces in the crystallization of L-glutamic acid polymorphs[J]. Crystal Growth and Design, 2009, 9(5): 2179-2186. |

| 22 | Nakoa K, Date A, Akbarzadeh A. A research on water desalination using membrane distillation[J]. Desalination and Water Treatment, 2015, 56(10): 2618-2630. |

| 23 | Kim Y, Jung J, Lee S, et al. Modeling fouling of hollow fiber membrane using response surface methodology[J]. Desalination and Water Treatment, 2015, 54(4/5): 966-972. |

| 24 | Francis L, Ghaffour N, Al-Saadi A S, et al. Performance of different hollow fiber membranes for seawater desalination using membrane distillation[J]. Desalination and Water Treatment, 2015, 55(10): 2786-2791. |

| 25 | Perrotta M L, Macedonio F, Tocci E, et al. Graphene stimulates the nucleation and growth rate of NaCl crystals from hypersaline solution via membrane crystallization[J]. Environmental Science: Water Research & Technology, 2020, 6(6): 1723-1736. |

| 26 | Duong H C, Cooper P, Nelemans B, et al. Optimising thermal efficiency of direct contact membrane distillation by brine recycling for small-scale seawater desalination[J]. Desalination, 2015, 374: 1-9. |

| 27 | Alkhudhiri A, Darwish N, Hilal N. Membrane distillation: a comprehensive review[J]. Desalination, 2012, 287: 2-18. |

| 28 | Warsinger D M, Swaminathan J, Guillen-Burrieza E, et al. Scaling and fouling in membrane distillation for desalination applications: a review[J]. Desalination, 2015, 356: 294-313. |

| 29 | Boubakri A, Hafiane A, Al Tahar Bouguecha S. Nitrate removal from aqueous solution by direct contact membrane distillation using two different commercial membranes[J]. Desalination and Water Treatment, 2015, 56(10): 2723-2730. |

| 30 | Feng X, Jiang L Y, Song Y. Titanium white sulfuric acid concentration by direct contact membrane distillation[J]. Chemical Engineering Journal, 2016, 285: 101-111. |

| 31 | Chen W, Chen S Y, Liang T F, et al. High-flux water desalination with interfacial salt sieving effect in nanoporous carbon composite membranes[J]. Nature Nanotechnology, 2018, 13(4): 345. |

| 32 | Jiang X B, Lu D P, Xiao W, et al. Membrane assisted cooling crystallization: process model, nucleation, metastable zone, and crystal size distribution[J]. AIChE Journal, 2016, 62(3): 829-841. |

| 33 | Jiang X B, Lu D P, Xiao W, et al. Interface-based crystal particle autoselection via membrane crystallization: from scaling to process control[J]. AIChE Journal, 2019, 65(2): 723-733. |

| 34 | Salmón I R, Luis P. Membrane crystallization via membrane distillation[J]. Chemical Engineering and Processing-Process Intensification, 2018, 123: 258-271. |

| 35 | Eykens L, Reyns T, De Sitter K, et al. How to select a membrane distillation configuration? Process conditions and membrane influence unraveled[J]. Desalination, 2016, 399: 105-115. |

| 36 | Shahu V T, Thombre S B. Air gap membrane distillation: a review[J]. Journal of Renewable and Sustainable Energy, 2019, 11(4):045901. |

| 37 | Feng C, Khulbe K C, Matsuura I, et al. Production of drinking water from saline water by air-gap membrane distillation using polyvinylidene fluoride nanofiber membrane[J]. Journal of Membrane Science, 2008, 311(1/2): 1-6. |

| 38 | Khayet M. Membranes and theoretical modeling of membrane distillation: a review[J]. Advances in Colloid and Interface Science, 2011, 164(1/2): 56-88. |

| 39 | Boucif N, Roizard D, Corriou J, et al. To what extent does temperature affect absorption in gas-liquid hollow fiber membrane contactors?[J]. Separation Science and Technology, 2015, 50(9): 1331-1343. |

| 40 | Zhang Y G, Peng Y L, Ji S L, et al. Review of thermal efficiency and heat recycling in membrane distillation processes[J]. Desalination, 2015, 367: 223-239. |

| 41 | Al Obaidani S, Curcio E, Di Profio G, et al. The role of membrane distillation/crystallization technologies in the integrated membrane system for seawater desalination[J]. Desalination and Water Treatment, 2009, 10(1/2/3): 210-219. |

| 42 | Edwie F, Chung T. Development of simultaneous membrane distillation-crystallization (SMDC) technology for treatment of saturated brine[J]. Chemical Engineering Science, 2013, 98: 160-172. |

| 43 | Shirazi M M A, Kargari A, Ismail A F, et al. Computational fluid dynamic (CFD) opportunities applied to the membrane distillation process: state-of-the-art and perspectives[J]. Desalination, 2016, 377: 73-90. |

| 44 | Li W Q, van der Bruggen B, Luis P. Integration of reverse osmosis and membrane crystallization for sodium sulphate recovery[J]. Chemical Engineering and Processing: Process Intensification, 2014, 85: 57-68. |

| 45 | Pantoja C E, Nariyoshi Y N, Seckler M M. Membrane distillation crystallization applied to brine desalination: a hierarchical design procedure[J]. Industrial & Engineering Chemistry Research, 2015, 54(10): 2776-2793. |

| 46 | Hasanoğlu A, Rebolledo F, Plaza A, et al. Effect of the operating variables on the extraction and recovery of aroma compounds in an osmotic distillation process coupled to a vacuum membrane distillation system[J]. Journal of Food Engineering, 2012, 111(4): 632-641. |

| 47 | Quist-Jensen C A, Ali A, Mondal S, et al. A study of membrane distillation and crystallization for lithium recovery from high-concentrated aqueous solutions[J]. Journal of Membrane Science, 2016, 505: 167-173. |

| 48 | Chen G Z, Lu Y H, Krantz W B, et al. Optimization of operating conditions for a continuous membrane distillation crystallization process with zero salty water discharge[J]. Journal of Membrane Science, 2014, 450: 1-11. |

| 49 | 关云山, 武警, 程文婷, 等. 膜蒸馏-结晶耦合从高浓度KCl-MgCl2-H2O溶液中回收KCl[J]. 化工学报, 2015, 66(5): 1767-1776. |

| Guan Y S, Wu J, Cheng W T, et al. Recovery of KCl crystalline product from highly concentrated KCl-MgCl2-H2O solution with membrane distillation crystallization[J]. CIESC Journal, 2015, 66(5): 1767-1776. | |

| 50 | Bolzonella D, Fatone F, Di Fabio S, et al. Application of membrane bioreactor technology for wastewater treatment and reuse in the Mediterranean region: focusing on removal efficiency of non-conventional pollutants[J]. Journal of Environmental Management, 2010, 91(12): 2424-2431. |

| 51 | Khayet M. Treatment of radioactive wastewater solutions by direct contact membrane distillation using surface modified membranes[J]. Desalination, 2013, 321: 60-66. |

| 52 | Liu H Y, Wang J L. Treatment of radioactive wastewater using direct contact membrane distillation[J]. Journal of Hazardous Materials, 2013, 261: 307-315. |

| 53 | Quist-Jensen C A, Macedonio F, Drioli E. Membrane crystallization for salts recovery from brine-an experimental and theoretical analysis[J]. Desalination and Water Treatment, 2016, 57(16): 7593-7603. |

| 54 | Zhang H, Lu X L, Liu Z Y, et al. The unidirectional regulatory role of coagulation bath temperature on cross-section radius of the PVDF hollow-fiber membrane[J]. Journal of Membrane Science, 2018, 550: 9-17. |

| 55 | Yan H Q, Lu X L, Wu C R, et al. Fabrication of a super-hydrophobic polyvinylidene fluoride hollow fiber membrane using a particle coating process[J]. Journal of Membrane Science, 2017, 533: 130-140. |

| 56 | 李冠男, 贺高红, 姜晓滨. 膜结晶处理高浓度Na+、Mg2+//Cl--H2O溶液的结晶调控[J]. 化工学报, 2019, 70(9): 3412-3420. |

| Li G N, He G H, Jiang X B. Treatment of high concentration Na+, Mg2+//Cl--H2O solution andcrystallization control via membrane distillation crystallization[J]. CIESC Journal, 2019, 70(9): 3412-3420. | |

| 57 | Edwie F, Chung T. Development of hollow fiber membranes for water and salt recovery from highly concentrated brine via direct contact membrane distillation and crystallization[J]. Journal of Membrane Science, 2012, 421: 111-123. |

| 58 | Lu D P, Li P, Xiao W, et al. Simultaneous recovery and crystallization control of saline organic wastewater by membrane distillation crystallization[J]. AIChE Journal, 2017, 63(6): 2187-2197. |

| 59 | 李卜义, 王建友. 浓海水处理及综合利用技术的新进展[J]. 化工进展, 2014, 33(11): 3067-3074. |

| Li B Y, Wang J Y. Progress on treatment and comprehensive utilization of concentrated seawater[J]. Chemical Industry and Engineering Progress, 2014, 33(11): 3067-3074. | |

| 60 | Macedonio F, Politano A, Drioli E, et al. Bi2Se3-assisted membrane crystallization[J]. Materials Horizons, 2018, 5(5): 912-919. |

| 61 | Turek M, Mitko K, Piotrowski K, et al. Prospects for high water recovery membrane desalination[J]. Desalination, 2017, 401: 180-189. |

| 62 | Yu X X, Ulrich J, Wang J K. Crystallization and stability of different protein crystal modifications: a case study of lysozyme[J]. Crystal Research and Technology, 2015, 50(2): 179-187. |

| 63 | Studart A R. Towards high-performance bioinspired composites[J]. Advanced Materials, 2012, 24(37): 5024-5044. |

| 64 | Bayerlein B, Zaslansky P, Dauphin Y, et al. Self-similar mesostructure evolution of the growing mollusc shell reminiscent of thermodynamically driven grain growth[J]. Nature Materials, 2014, 13(12): 1102. |

| 65 | Hu Y F, Chen Z H, Fu Y J, et al. The amino-terminal structure of human fragile X mental retardation protein obtained using precipitant-immobilized imprinted polymers[J]. Nature Communications, 2015, 6: 6634. |

| 66 | Vekilov P G. Nucleation of protein condensed phases[J]. Reviews in Chemical Engineering, 2011, 27(1/2): 1-13. |

| 67 | 庞鸿宇, 刘丽英, 宋恒凯, 等. 木瓜蛋白酶动态膜结晶的实验研究[J]. 膜科学与技术, 2010, 30(1): 30-33. |

| Pang H Y, Liu L Y, Song H K, et al. Experimental study on papain dynamic membrane crystallization[J]. Membrane Science and Technology, 2010, 30(1): 30-33. | |

| 68 | 刘丽英, 宋恒凯, 庞鸿宇, 等. 溶菌酶动态膜结晶传质过程研究[J]. 膜科学与技术, 2010, 30(2): 25-28. |

| Liu L Y, Song H K, Pang H Y, et al. Study on mass transfer process of lysozyme dynamic membrane crystallization[J]. Membrane Science and Technology, 2010, 30(2): 25-28. | |

| 69 | Wang L, He G H, Ruan X H, et al. Tailored robust hydrogel composite membranes for continuous protein crystallization with ultrahigh morphology selectivity[J]. ACS Applied Materials & Interfaces, 2018, 10(31): 26653-26661. |

| 70 | Myerson A S, Trout B L. Nucleation from solution[J]. Science, 2013, 341(6148): 855-856. |

| 71 | Giegé R. A historical perspective on protein crystallization from 1840 to the present day[J]. FEBS Journal, 2013, 280(24): 6456-6497. |

| [1] | 于宏鑫, 邵双全. 水结晶过程的分子动力学模拟分析[J]. 化工学报, 2023, 74(S1): 250-258. |

| [2] | 傅予, 刘兴翀, 王瀚雨, 李海敏, 倪亚飞, 邹文静, 雷月, 彭永姗. F3EACl修饰层对钙钛矿太阳能电池性能提升的研究[J]. 化工学报, 2023, 74(8): 3554-3563. |

| [3] | 郭旭, 张永政, 夏厚兵, 杨娜, 朱真珍, 齐晶瑶. 碳基材料电氧化去除水体污染物的研究进展[J]. 化工学报, 2023, 74(5): 1862-1874. |

| [4] | 苏晓丹, 朱干宇, 李会泉, 郑光明, 孟子衡, 李防, 杨云瑞, 习本军, 崔玉. 湿法磷酸半水工艺考察与石膏结晶过程研究[J]. 化工学报, 2023, 74(4): 1805-1817. |

| [5] | 周璇, 李孟亚, 孙杰, 岑振凯, 吕强三, 周立山, 王海涛, 韩丹丹, 龚俊波. 添加剂对氨基酸晶体生长的影响[J]. 化工学报, 2023, 74(2): 500-510. |

| [6] | 陈毓明, 历伟, 严翔, 王靖岱, 阳永荣. 初生态聚乙烯聚集态结构调控研究进展[J]. 化工学报, 2023, 74(2): 487-499. |

| [7] | 苏伟怡, 丁佳慧, 李春利, 王洪海, 姜艳军. 酶促反应结晶研究进展[J]. 化工学报, 2023, 74(2): 617-629. |

| [8] | 乃学瑛, 吴鹏, 程远, 肖剑飞, 刘鑫, 董亚萍. 水热生长碱式硫酸镁纳米线结晶动力学研究[J]. 化工学报, 2022, 73(7): 3038-3044. |

| [9] | 孙国鑫, 苟萌萱, 周诚, 常佩, 贺高红, 姜晓滨. 高浓度Na+//NO |

| [10] | 李智超, 郑瑜, 张润楠, 姜忠义. 高通量抗污染氧化石墨烯膜研究进展[J]. 化工学报, 2022, 73(6): 2370-2380. |

| [11] | 殷海青, 马祎明, 万旭兴, 董伟兵, 张玉龙, 吴送姑. 碳酸锂气液固三相反应结晶过程研究[J]. 化工学报, 2022, 73(3): 1207-1220. |

| [12] | 王洁冰, 高金彤, 徐震原. 基于不同类型溶液蒸气压特性的太阳能界面蒸发实验研究[J]. 化工学报, 2022, 73(2): 663-671. |

| [13] | 陈雪梅, 王彤, 高玉箔, 彭鼎程, 罗雨婷. 利用激光诱导石墨烯实现高效太阳能界面蒸发[J]. 化工学报, 2022, 73(12): 5648-5659. |

| [14] | 敬鹏程, 陈立涛, 闫传梁, 姜传祥, 夏煜翔, 于常宏, 王昊天. 超声波悬浮TBAB溶液液滴表面半笼型水合物生长过程研究[J]. 化工学报, 2022, 73(11): 4893-4902. |

| [15] | 贺冲, 白进, 郭晶, 孔令学, 鲁浩, 李怀柱, 秦育红, 李文. 气氛和化学组成对高铁煤灰熔融特性的影响机理[J]. 化工学报, 2022, 73(10): 4648-4658. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号