化工学报 ›› 2021, Vol. 72 ›› Issue (5): 2887-2895.DOI: 10.11949/0438-1157.20201386

侯玉洁1( ),梁琳2(

),梁琳2( ),江子旭1,闫兴清1,于小哲1,吕先舒1,喻健良1

),江子旭1,闫兴清1,于小哲1,吕先舒1,喻健良1

收稿日期:2020-09-29

修回日期:2020-12-23

出版日期:2021-05-05

发布日期:2021-05-05

通讯作者:

梁琳

作者简介:侯玉洁(1995—),女,博士研究生,基金资助:

HOU Yujie1( ),LIANG Lin2(

),LIANG Lin2( ),JIANG Zixu1,YAN Xingqing1,YU Xiaozhe1,LYU Xianshu1,YU Jianliang1

),JIANG Zixu1,YAN Xingqing1,YU Xiaozhe1,LYU Xianshu1,YU Jianliang1

Received:2020-09-29

Revised:2020-12-23

Online:2021-05-05

Published:2021-05-05

Contact:

LIANG Lin

摘要:

爆炸泄放和爆炸抑制是工业上降低粉尘爆炸危害性的两个重要手段,同时实现粉尘爆炸抑制和泄放共同作用的效果值得关注。基于标准20 L球形粉尘爆炸装置侧向开泄放口,实验研究不同泄放口径和静态动作压力时CO2/N2对石松子粉泄放过程压力的影响,采用热重分析法分析了石松子粉尘分别在CO2、N2氛围的热重变化。结果表明,在20 mm泄放口径时,随着CO2/N2浓度的增加,泄放压力的降低幅值逐渐增大,且CO2对粉尘爆炸泄放最大超压的减小效果要优于N2。泄放压力值随着CO2浓度的增加基本呈线性降低,当体系中的CO2和N2浓度增加到10%时对体系泄放压力值的降低效果开始趋于一致。对于40 mm泄放口径,添加相同浓度的CO2体系泄放压力值要略低于N2,降低幅值为6%~8%。对于60 mm泄放口径,CO2/N2两者抑制效果差别不大,且在添加浓度不超过8%时对体系泄放压力值的降低幅值影响较小。通过TGA曲线可以发现,在N2气氛和CO2气氛的热流条件中,石松子粉的热解过程在370℃左右开始出现明显的差异,CO2气氛中石松子粉的热解速率要快于其在N2气氛中的,因此在这个过程中CO2的存在一定程度上会促进石松子粉的热解,随着热解温度进一步提升,CO2对石松子粉热解的抑制效果开始逐渐体现。

中图分类号:

侯玉洁, 梁琳, 江子旭, 闫兴清, 于小哲, 吕先舒, 喻健良. 惰性气体对粉尘爆炸泄放特性影响的实验研究[J]. 化工学报, 2021, 72(5): 2887-2895.

HOU Yujie, LIANG Lin, JIANG Zixu, YAN Xingqing, YU Xiaozhe, LYU Xianshu, YU Jianliang. Experimental study on the dust explosion venting behavior by the addition of inert gas[J]. CIESC Journal, 2021, 72(5): 2887-2895.

| 元素 | 质量分数/% |

|---|---|

| C | 69.2 |

| H | 9.2 |

| O | 19.6 |

| N | 1.1 |

| S | 0.1 |

| 杂质 | 0.8 |

表1 石松子粉元素组成

Table 1 Lycopodium element composition

| 元素 | 质量分数/% |

|---|---|

| C | 69.2 |

| H | 9.2 |

| O | 19.6 |

| N | 1.1 |

| S | 0.1 |

| 杂质 | 0.8 |

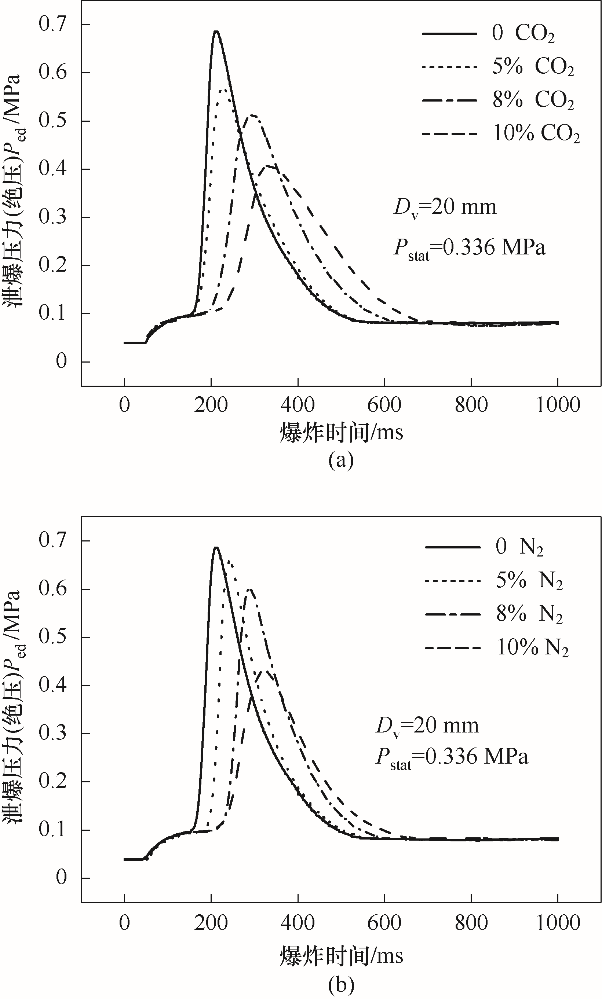

图5 泄放口径20 mm、静态动作压力0.336 MPa下添加不同浓度CO2(a)/N2(b)体系泄爆压力随时间变化规律

Fig.5 The reduced pressures change with CO2(a)/N2(b) concentration under a vent diameter of 20 mm and static activation pressure of 0.336 MPa

| 气体 | 体积分数/% | 爆炸超压/MPa | 达到超压峰值时间/ms |

|---|---|---|---|

| CO2 | 0 | 0.687 | 90 |

| 5 | 0.546 | 110 | |

| 8 | 0.496 | 180 | |

| 10 | 0.383 | 210 | |

| N2 | 0 | 0.687 | 90 |

| 5 | 0.639 | 120 | |

| 8 | 0.583 | 175 | |

| 10 | 0.425 | 205 |

表2 泄放口径20 mm、Pstat=0.336 MPa泄爆超压值及峰值时间

Table 2 The reduced pressure and peak time under vent diameter of 20 mm, Pstat=0.336 MPa

| 气体 | 体积分数/% | 爆炸超压/MPa | 达到超压峰值时间/ms |

|---|---|---|---|

| CO2 | 0 | 0.687 | 90 |

| 5 | 0.546 | 110 | |

| 8 | 0.496 | 180 | |

| 10 | 0.383 | 210 | |

| N2 | 0 | 0.687 | 90 |

| 5 | 0.639 | 120 | |

| 8 | 0.583 | 175 | |

| 10 | 0.425 | 205 |

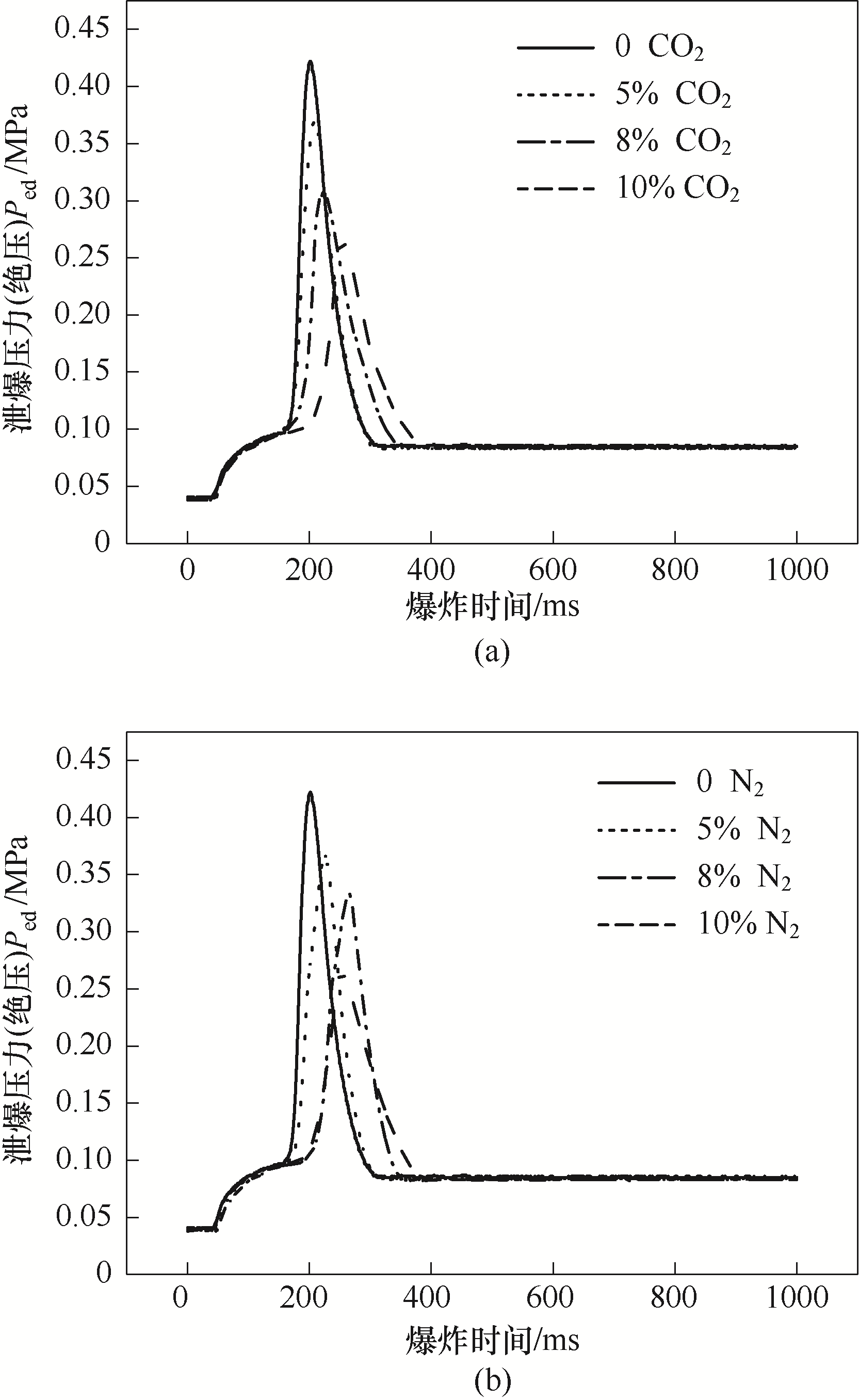

图6 泄放口径40 mm、静态动作压力0.138 MPa时添加不同浓度CO2(a)/N2(b)体系泄爆压力随时间变化规律

Fig.6 The reduced pressures Pedchange with CO2(a)/N2(b) concentration with a vent diameter of 40 mm and static activation pressure of 0.138 MPa

图7 不同泄放口径和静态动作压力条件下最大泄爆压力随CO2/N2浓度变化规律

Fig.7 The reduced pressures Pred change with CO2/N2 concentration with different vent diameters and static activation pressures

图8 20、60 mm泄放口径不同静态动作压力时泄爆压力减小比例?随CO2/N2浓度变化规律

Fig.8 20 mm and 60 mm vent diameter with different static activation pressures on reduced pressures reduction ratio ? various with CO2/N2 concentrations

| 1 | Joseph G. Combustible dusts: a serious industrial hazard[J]. Journal of Hazardous Materials, 2007, 142(3): 589-591. |

| 2 | Copelli S, Raboni M, Ragazzi M, et al. Variation of the explosion risk in a hybrid collector during revamping operations[J]. International Journal of Safety and Security Engineering, 2017, 7(2): 113-125. |

| 3 | 喻健良, 闫兴清. 高静态动作压力下粉尘爆炸泄放标准的可靠性[J]. 东北大学学报(自然科学版), 2015, 36(9): 1316-1320. |

| Yu J L, Yan X Q. Reliability of dust explosion venting standards under elevated static activation overpressures[J]. Journal of Northeastern University (Natural Science), 2015, 36(9): 1316-1320. | |

| 4 | 胡东涛, 陈曦. 工业粉尘惰化抑爆技术研究现状分析[J]. 工业安全与环保, 2016, 42(12): 10-14. |

| Hu D T, Chen X. Review of inerting explosion suppression research of industrial dust[J]. Industrial Safety and Environmental Protection, 2016, 42(12): 10-14. | |

| 5 | Du B, Huang W X, Kuai N S, et al. Experimental investigation on inerting mechanism of dust explosion[J]. Procedia Engineering, 2012, 43: 338-342. |

| 6 | Jiang H P, Bi M S, Li B, et al. Inhibition evaluation of ABC powder in aluminum dust explosion[J]. Journal of Hazardous Materials, 2019, 361: 273-282. |

| 7 | Amyotte P R. Solid inertants and their use in dust explosion prevention and mitigation[J]. Journal of Loss Prevention in the Process Industries, 2006, 19(2/3): 161-173. |

| 8 | Dounia O, Vermorel O, Poinsot T. Theoretical analysis and simulation of methane/air flame inhibition by sodium bicarbonate particles[J]. Combustion and Flame, 2018, 193: 313-326. |

| 9 | Lei B W, He B B, Xiao B W, et al. Comparative study of single inert gas in confined space inhibiting open flame coal combustion[J]. Fuel, 2020, 265: 116976. |

| 10 | Shen G D, Wang Z Q, Wu J L, et al. Combustion characteristics of low-rank coal chars in O2/CO2, O2/N2 and O2/Ar by TGA[J]. Journal of Fuel Chemistry and Technology, 2016, 44(9): 1066-1073. |

| 11 | 贾宝山, 温海燕, 梁运涛, 等. 煤矿巷道内N2及CO2抑制瓦斯爆炸的机理特性[J]. 煤炭学报, 2013, 38(3): 361-366. |

| Jia B S, Wen H Y, Liang Y T, et al. Mechanism characteristics of CO2 and N2 inhibiting methane explosions in coal mine roadways[J]. Journal of China Coal Society, 2013, 38(3): 361-366. | |

| 12 | 邵昊, 蒋曙光, 吴征艳, 等. 二氧化碳和氮气对煤自燃性能影响的对比试验研究[J]. 煤炭学报, 2014, 39(11): 2244-2249. |

| Shao H, Jiang S G, Wu Z Y, et al. Comparative research on the influence of dioxide carbon and nitrogen on performance of coal spontaneous combustion[J]. Journal of China Coal Society, 2014, 39(11): 2244-2249. | |

| 13 | Razus D, Movileanu C, Brinzea V, et al. Closed vessel combustion of propylene-air mixtures in the presence of exhaust gas[J]. Fuel, 2007, 86(12/13): 1865-1872. |

| 14 | Mitu M, Prodan M, Giurcan V, et al. Influence of inert gas addition on propagation indices of methane-air deflagrations[J]. Process Safety and Environmental Protection, 2016, 102: 513-522. |

| 15 | Chen Z, Qin X, Xu B, et al. Studies of radiation absorption on flame speed and flammability limit of CO2 diluted methane flames at elevated pressures[J]. Proceedings of the Combustion Institute, 2007, 31(2): 2693-2700. |

| 16 | Razus D, Movileanua C, Oancea D. The rate of pressure rise of gaseous propylene-air explosions in spherical and cylindrical enclosures[J]. Journal of Hazardous Materials, 2007, 139(1): 1-8. |

| 17 | Zhang Q W, Yu Y, Li Y H, et al. Coupling effects of venting and inerting on explosions in interconnected vessels[J]. Journal of Loss Prevention in the Process Industries, 2020, 65: 104132. |

| 18 | European Committee for Standardization. Dust explosion venting protective systems: EN14491[S]. London: British Standards Institution,2012. |

| 19 | National Fire Protection Association. Standard on Explosion Protection by Deflagration Venting: [S]. 2016. |

| 20 | 王远丽, 王勤辉, 李开坤, 等. 焦载体下CH4及CO2气氛对低阶煤流化床热解特性的影响[J]. 热力发电, 2020, 49(6): 7-14. |

| Wang Y L, Wang Q H, Li K K, et al. Effect of CH4 and CO2 atmosphere under coke carrier on pyrolysis characteristics of low-order coal fluidized bed[J]. Thermal Power Generation, 2020, 49(6): 7-14. | |

| 21 | Zeng W, Ma H, Liang Y T, et al. Experimental and modeling study on effects of N2 and CO2 on ignition characteristics of methane/air mixture[J]. Journal of Advanced Research, 2015, 6(2): 189-201. |

| 22 | Di Benedetto A, Di Sarli V, Salzano E, et al. Explosion behavior of CH4/O2/N2/CO2 and H2/O2/N2/CO2 mixtures[J]. International Journal of Hydrogen Energy, 2009, 34(16): 6970-6978. |

| 23 | Li H Y, Yue Y H, Miao C X, et al. Dehydrogenation of ethylbenzene and propane over Ga2O3-ZrO2 catalysts in the presence of CO2[J]. Catalysis Communications, 2007, 8(9): 1317-1322. |

| 24 | Li G, Yuan C M, Fu Y, et al. Inerting of magnesium dust cloud with Ar, N2 and CO2[J]. Journal of Hazardous Materials, 2009, 170(1): 180-183. |

| 25 | Zheng K, Yang X F, Yu M G, et al. Effect of N2 and CO2 on explosion behavior of syngas/air mixtures in a closed duct[J]. International Journal of Hydrogen Energy, 2019, 44(51): 28044-28055. |

| 26 | Xiang L K, Chu H Q, Ren F, et al. Numerical analysis of the effect of CO2 on combustion characteristics of laminar premixed methane/air flames[J]. Journal of the Energy Institute, 2019, 92(5): 1487-1501. |

| 27 | Chen Z Y, Tang C L, Fu J, et al. Experimental and numerical investigation on diluted DME flames: thermal and chemical kinetic effects on laminar flame speeds[J]. Fuel, 2012, 102: 567-573. |

| 28 | Xie M K, Fu J Q, Zhang Y X, et al. Numerical analysis on the effects of CO2 dilution on the laminar burning velocity of premixed methane/air flame with elevated initial temperature and pressure[J]. Fuel, 2020, 264: 116858. |

| 29 | Ji W T, Yan X Q, Sun H L, et al. Comparative analysis of the explosibility of several different hybrid mixtures[J]. Powder Technology, 2018, 325: 42-48. |

| 30 | Yan X Q, Yu J L. Dust explosion venting of small vessels at the elevated static activation overpressure[J]. Powder Technology, 2014, 261: 250-256. |

| 31 | Yang J, Li Y H, Yu Y, et al. Experimental investigation of the inerting effect of CO2 on explosion characteristics of micron-size Acrylate Copolymer dust[J]. Journal of Loss Prevention in the Process Industries, 2019, 62: 103979. |

| [1] | 宋瑞涛, 王派, 王云鹏, 李敏霞, 党超镔, 陈振国, 童欢, 周佳琦. 二氧化碳直接蒸发冰场排管内流动沸腾换热数值模拟分析[J]. 化工学报, 2023, 74(S1): 96-103. |

| [2] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [3] | 程业品, 胡达清, 徐奕莎, 刘华彦, 卢晗锋, 崔国凯. 离子液体基低共熔溶剂在转化CO2中的应用[J]. 化工学报, 2023, 74(9): 3640-3653. |

| [4] | 李珍宝, 李超, 王虎, 王绍瑞, 黎泉. MPP抑制铝镁合金粉尘爆炸微观机理研究[J]. 化工学报, 2023, 74(8): 3608-3614. |

| [5] | 杨菲菲, 赵世熙, 周维, 倪中海. Sn掺杂的In2O3催化CO2选择性加氢制甲醇[J]. 化工学报, 2023, 74(8): 3366-3374. |

| [6] | 洪瑞, 袁宝强, 杜文静. 垂直上升管内超临界二氧化碳传热恶化机理分析[J]. 化工学报, 2023, 74(8): 3309-3319. |

| [7] | 杨克, 贾岳, 纪虹, 邢志祥, 蒋军成. 垃圾焚烧飞灰对瓦斯爆炸压力及火焰传播的抑制作用及机理研究[J]. 化工学报, 2023, 74(8): 3597-3607. |

| [8] | 张琦钰, 高利军, 苏宇航, 马晓博, 王翊丞, 张亚婷, 胡超. 碳基催化材料在电化学还原二氧化碳中的研究进展[J]. 化工学报, 2023, 74(7): 2753-2772. |

| [9] | 毛磊, 刘冠章, 袁航, 张光亚. 可捕集CO2的纳米碳酸酐酶粒子的高效制备及性能研究[J]. 化工学报, 2023, 74(6): 2589-2598. |

| [10] | 蔺彩虹, 王丽, 吴瑜, 刘鹏, 杨江峰, 李晋平. 沸石中碱金属阳离子对CO2/N2O吸附分离性能的影响[J]. 化工学报, 2023, 74(5): 2013-2021. |

| [11] | 何汉兵, 刘真, 陈勇, 王小锋, 曾婧. 直写成型电极锰氧化物粉末的合成与浆料调控[J]. 化工学报, 2023, 74(5): 2239-2247. |

| [12] | 李晨曦, 刘永峰, 张璐, 刘海峰, 宋金瓯, 何旭. O2/CO2氛围下正庚烷的燃烧机理研究[J]. 化工学报, 2023, 74(5): 2157-2169. |

| [13] | 王皓, 唐思扬, 钟山, 梁斌. MEA吸收CO2富液解吸过程中固体颗粒表面的强化作用分析[J]. 化工学报, 2023, 74(4): 1539-1548. |

| [14] | 衣思敏, 马亚丽, 刘伟强, 张金帅, 岳岩, 郑强, 贾松岩, 李雪. 微晶菱镁矿蒸氨及水化动力学研究[J]. 化工学报, 2023, 74(4): 1578-1586. |

| [15] | 朱兵国, 何吉祥, 徐进良, 彭斌. 冷却条件下渐扩/渐缩管内超临界压力二氧化碳的传热特性[J]. 化工学报, 2023, 74(3): 1062-1072. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号