化工学报 ›› 2021, Vol. 72 ›› Issue (7): 3856-3868.DOI: 10.11949/0438-1157.20201832

纪荣彬( ),陈婷,彭超华,夏龙,陈国荣,罗伟昂,曾碧榕,许一婷,袁丛辉,戴李宗(

),陈婷,彭超华,夏龙,陈国荣,罗伟昂,曾碧榕,许一婷,袁丛辉,戴李宗( )

)

收稿日期:2020-12-16

修回日期:2021-04-02

出版日期:2021-07-05

发布日期:2021-07-05

通讯作者:

戴李宗

作者简介:纪荣彬(1995—),男,硕士研究生,基金资助:

JI Rongbin( ),CHEN Ting,PENG Chaohua,XIA Long,CHEN Guorong,LUO Wei'ang,ZENG Birong,XU Yiting,YUAN Conghui,DAI Lizong(

),CHEN Ting,PENG Chaohua,XIA Long,CHEN Guorong,LUO Wei'ang,ZENG Birong,XU Yiting,YUAN Conghui,DAI Lizong( )

)

Received:2020-12-16

Revised:2021-04-02

Online:2021-07-05

Published:2021-07-05

Contact:

DAI Lizong

摘要:

从二苯基次膦酰氯和苯基磷酰二氯出发,分别合成了含单个苯硼酸基团和含两个苯硼酸基团的两种有机磷/硼杂化小分子(缩写为:DPC-1B和PDS-2B)。两种杂化小分子与环氧树脂有着良好的相容性并可参与环氧固化,在比较低的添加量下便有较高的机械强度和优异的阻燃性能,且保持环氧的透明度。DPC-1B和PDS-2B添加量为2%(质量)时,复合材料氧指数从25.7%分别提高到了31.8%和31.5%,热释放速率峰值分别降低了26.5%与21.8%,UL-94阻燃等级均达到了V-0级。改性环氧树脂燃烧后的残炭分析表明,炭层外部连续紧密,内部多蓬松,硼磷共同作用形成致密炭层,隔绝热质传递,从而达到阻燃效果。

中图分类号:

纪荣彬, 陈婷, 彭超华, 夏龙, 陈国荣, 罗伟昂, 曾碧榕, 许一婷, 袁丛辉, 戴李宗. 有机磷/硼杂化小分子阻燃改性环氧树脂[J]. 化工学报, 2021, 72(7): 3856-3868.

JI Rongbin, CHEN Ting, PENG Chaohua, XIA Long, CHEN Guorong, LUO Wei'ang, ZENG Birong, XU Yiting, YUAN Conghui, DAI Lizong. Flame retardant epoxy resin composites modified with organophosphorus and boron hybrid molecules[J]. CIESC Journal, 2021, 72(7): 3856-3868.

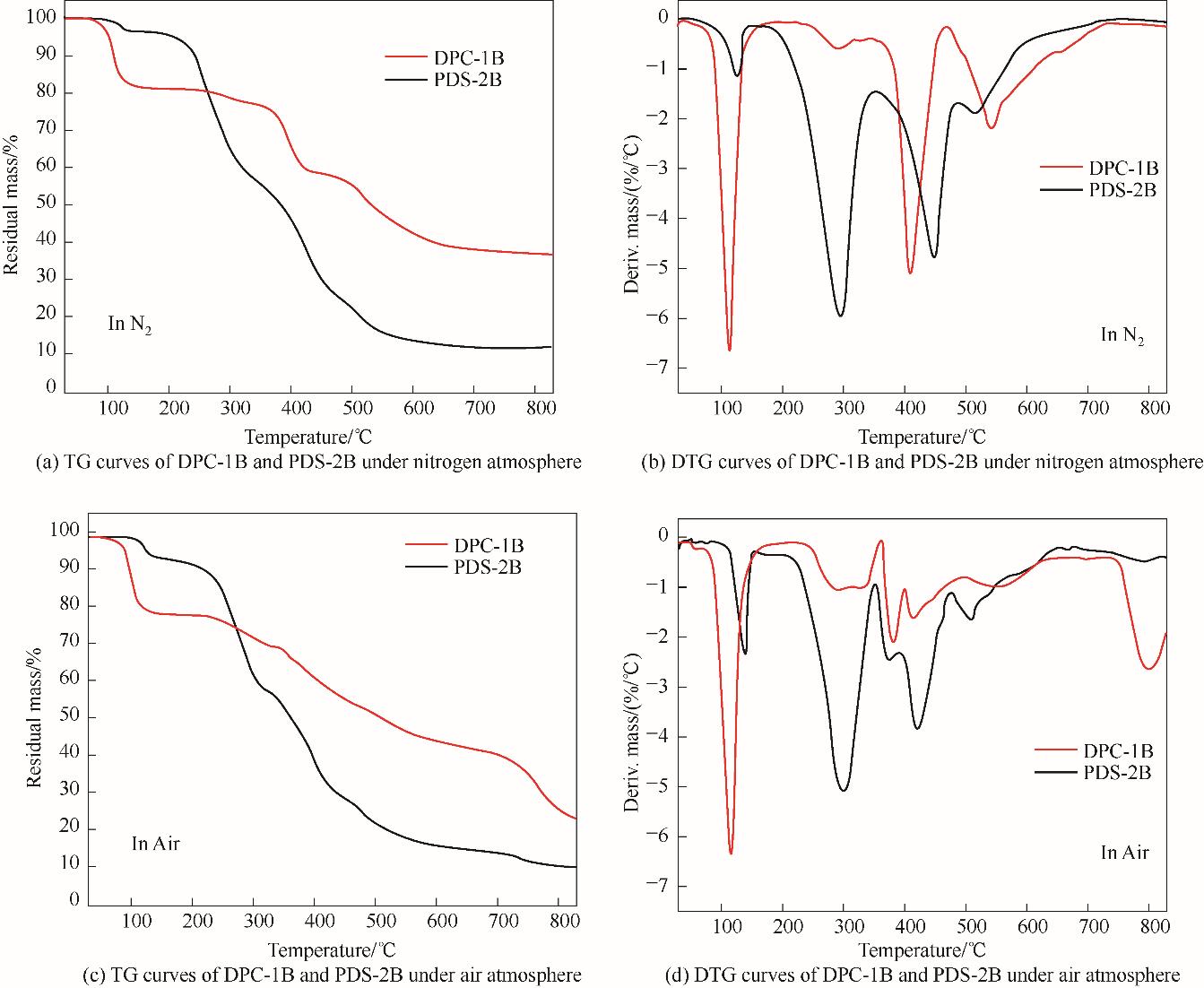

| Samples | Nitrogen | Air | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| To/℃ | Tmax1/℃ | Tmax2/℃ | Tmax3/℃ | Wre/% | To/℃ | Tmax1/℃ | Tmax2/℃ | Tmax3/℃ | Wre/% | |

| DPC-1B | 120.80 | 134.40 | 288.31 | 432.73 | 11.53 | 116.75 | 143.36 | 290.43 | 400.11 | 19.62 |

| PDS-2B | 100.12 | 113.21 | 392.53 | 515.16 | 36.55 | 93.29 | 122.25 | 398.43 | 518.77 | 31.13 |

表1 DPC-1B、PDS-2B的热分解数据

Table 1 Thermal decomposition data of DPC-1B and PDS-2B

| Samples | Nitrogen | Air | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| To/℃ | Tmax1/℃ | Tmax2/℃ | Tmax3/℃ | Wre/% | To/℃ | Tmax1/℃ | Tmax2/℃ | Tmax3/℃ | Wre/% | |

| DPC-1B | 120.80 | 134.40 | 288.31 | 432.73 | 11.53 | 116.75 | 143.36 | 290.43 | 400.11 | 19.62 |

| PDS-2B | 100.12 | 113.21 | 392.53 | 515.16 | 36.55 | 93.29 | 122.25 | 398.43 | 518.77 | 31.13 |

图6 DPC-1B、PDS-2B在氮气氛围和空气氛围下的TG曲线(a),(c)和DTG曲线(b), (d)

Fig.6 TG (a), (c) and DTG (b), (d) curves of DPC-1B and PDS-2B under nitrogen atmosphere and air atmosphere

| Samples | Nitrogen | ||

|---|---|---|---|

| To/℃ | Tmax/℃ | Wre/% | |

| EP | 355.3 | 392.65 | 12.66 |

| EP/1% DPC-1B | 352.4 | 387.89 | 15.28 |

| EP/2% DPC-1B | 347.0 | 390.84 | 16.12 |

| EP/1% PDS-2B | 343.6 | 388.95 | 16.66 |

| EP/2% PDS-2B | 340.9 | 389.88 | 19.27 |

表2 环氧树脂固化物的热失重数据

Table 2 TGA data of cured epoxy resin

| Samples | Nitrogen | ||

|---|---|---|---|

| To/℃ | Tmax/℃ | Wre/% | |

| EP | 355.3 | 392.65 | 12.66 |

| EP/1% DPC-1B | 352.4 | 387.89 | 15.28 |

| EP/2% DPC-1B | 347.0 | 390.84 | 16.12 |

| EP/1% PDS-2B | 343.6 | 388.95 | 16.66 |

| EP/2% PDS-2B | 340.9 | 389.88 | 19.27 |

| Samples | LOI/% | UL-94 | |||

|---|---|---|---|---|---|

| T1/s | T2/s | Dripping | Rating | ||

| EP | 25.7 | >30 | — | Yes | NR |

| EP/2% DDP | 28.9 | 17 | 11 | No | V-1 |

| EP/2% HPB | 26.6 | 25 | 14 | No | V-1 |

| EP/2% PB | 30.1 | 12 | 6 | No | V-1 |

| EP/1% DPC-1B | 31.1 | 6 | 1 | No | V-0 |

| EP/2% DPC-1B | 31.8 | 3 | 1 | No | V-0 |

| EP/1% PDS-2B | 31.0 | 11 | 3 | No | V-1 |

| EP/2% PDS-2B | 31.5 | 3 | 3 | No | V-0 |

表3 阻燃剂/环氧树脂固化物的氧指数测试及UL-94垂直燃烧试验

Table 3 LOI and UL-94 vertical burning data of cured epoxy resin

| Samples | LOI/% | UL-94 | |||

|---|---|---|---|---|---|

| T1/s | T2/s | Dripping | Rating | ||

| EP | 25.7 | >30 | — | Yes | NR |

| EP/2% DDP | 28.9 | 17 | 11 | No | V-1 |

| EP/2% HPB | 26.6 | 25 | 14 | No | V-1 |

| EP/2% PB | 30.1 | 12 | 6 | No | V-1 |

| EP/1% DPC-1B | 31.1 | 6 | 1 | No | V-0 |

| EP/2% DPC-1B | 31.8 | 3 | 1 | No | V-0 |

| EP/1% PDS-2B | 31.0 | 11 | 3 | No | V-1 |

| EP/2% PDS-2B | 31.5 | 3 | 3 | No | V-0 |

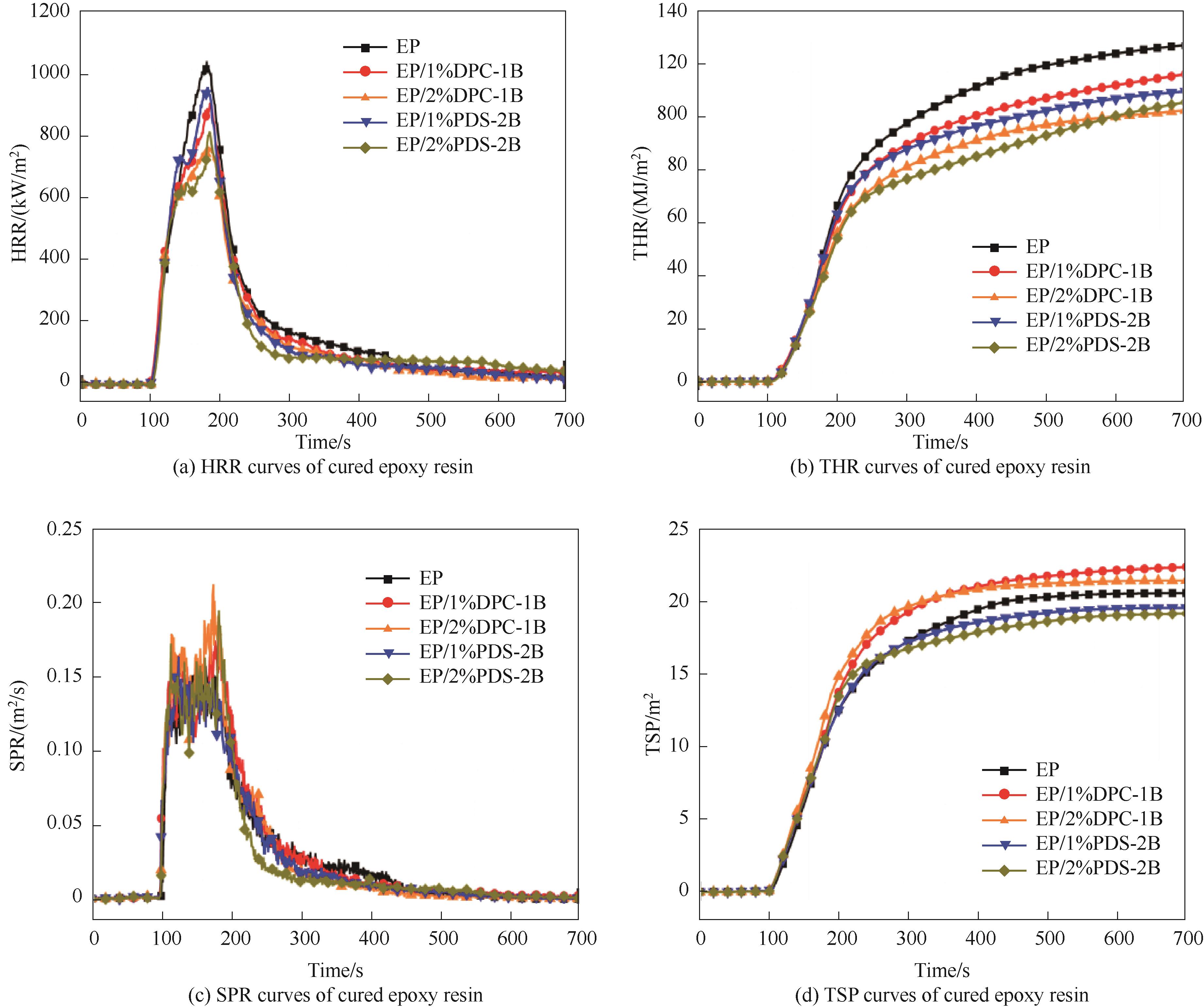

图8 EP、EP/1% DPC-1B、EP/2% DPC-1B、EP/1% PDS-2B和EP/2% PDS-2B的HRR(a)、THR(b)、SPR(c)和TSP(d)曲线

Fig.8 HRR (a), THR (b), SPR (c) and TSP (d) curves of EP, EP/1% DPC-1B, EP/2% DPC-1B, EP/1% PDS-2B and EP/2% PDS-2B

| Samples | TTI /s | PHRR/(kW/m2) | THR/(MJ/m2) | FIGRA/(kW/(m2·s)) | SPR/(m2/s) | TSP/m2 | Residue/%(mass) |

|---|---|---|---|---|---|---|---|

| EP | 101 | 1042.5 | 128.5 | 5.75 | 0.16 | 20.7 | 10.3 |

| EP/1% DPC-1B | 99 | 908.3 | 117.4 | 4.88 | 0.17 | 22.4 | 17.0 |

| EP/2% DPC-1B | 101 | 766.5 | 103.7 | 4.16 | 0.20 | 21.5 | 24.2 |

| EP/1% PDS-2B | 100 | 958.7 | 110.8 | 5.26 | 0.16 | 19.6 | 20.0 |

| EP/2% PDS-2B | 99 | 815.1 | 106.7 | 4.40 | 0.16 | 19.2 | 23.6 |

表4 环氧固化物的锥形量热试验的相关数据

Table 4 Cone calorimeter tests data of cured epoxy resin

| Samples | TTI /s | PHRR/(kW/m2) | THR/(MJ/m2) | FIGRA/(kW/(m2·s)) | SPR/(m2/s) | TSP/m2 | Residue/%(mass) |

|---|---|---|---|---|---|---|---|

| EP | 101 | 1042.5 | 128.5 | 5.75 | 0.16 | 20.7 | 10.3 |

| EP/1% DPC-1B | 99 | 908.3 | 117.4 | 4.88 | 0.17 | 22.4 | 17.0 |

| EP/2% DPC-1B | 101 | 766.5 | 103.7 | 4.16 | 0.20 | 21.5 | 24.2 |

| EP/1% PDS-2B | 100 | 958.7 | 110.8 | 5.26 | 0.16 | 19.6 | 20.0 |

| EP/2% PDS-2B | 99 | 815.1 | 106.7 | 4.40 | 0.16 | 19.2 | 23.6 |

图10 EP、EP/1% DPC-1B、EP/2% DPC-1B、EP/1% PDS-2B和EP/2% PDS-2B由锥形量热测试所得内外炭层SEM图

Fig.10 SEM images of char residue internal and exterior obtained from cone calorimeter tests for EP, EP/1% DPC-1B, EP/2% DPC-1B, EP/1% PDS-2B and EP/2% PDS-2B

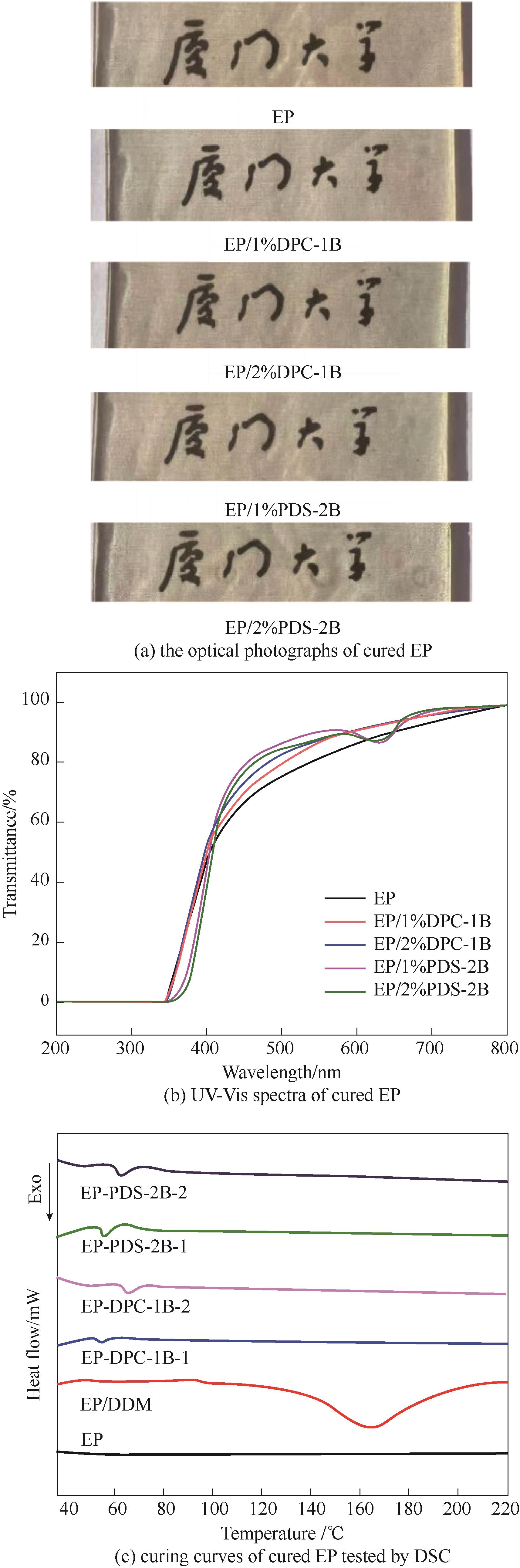

图13 环氧树脂固化物的光学照片(a)、紫外-可见光谱(b);环氧树脂预聚体的DSC固化曲线(c)

Fig.13 The optical photographs (a) and UV-Vis spectra(b) of cured epoxy resin; Curing curves of EP cured tested by DSC (c)

| Samples | Flexural strength/MPa | Elasticity modulus/(N/mm2) |

|---|---|---|

| EP | 87.39 | 2045.9 |

| EP/1% DPC-1B | 98.13 | 2230.1 |

| EP/2% DPC-1B | 103.45 | 2328.4 |

| EP/1% PDS-2B | 114.80 | 2357.5 |

| EP/2% PDS-2B | 126.34 | 2391.3 |

表5 环氧树脂固化物的弯曲强度和弯曲模量

Table 5 Three-point bending test data of cured epoxy resin

| Samples | Flexural strength/MPa | Elasticity modulus/(N/mm2) |

|---|---|---|

| EP | 87.39 | 2045.9 |

| EP/1% DPC-1B | 98.13 | 2230.1 |

| EP/2% DPC-1B | 103.45 | 2328.4 |

| EP/1% PDS-2B | 114.80 | 2357.5 |

| EP/2% PDS-2B | 126.34 | 2391.3 |

| 1 | 蔡坤鹏, 黄淼铭, 刘文涛, 等. 无卤阻燃剂合成及应用研究进展[J]. 工程塑料应用, 2021, 49(1): 152-156. |

| Cai K P, Huang M M, Liu W T, et al. Research progress on synthesis and application of halogen-free flame retardants[J]. Engineering Plastics Application, 2021, 49(1): 152-156. | |

| 2 | Liu Q Y, Wang D H, Li Z K, et al. Recent developments in the flame-retardant system of epoxy resin[J]. Materials, 2020, 13(9): 2145. |

| 3 | Singh H, Jain A K. Ignition, combustion, toxicity, and fire retardancy of polyurethane foams: a comprehensive review[J]. Journal of Applied Polymer Science, 2009, 111(2): 1115-1143. |

| 4 | Irvine D J, McCluskey J A, Robinson I M. Fire hazards and some common polymers[J]. Polymer Degradation and Stability, 2000, 67(3): 383-396. |

| 5 | Hamciuc C, Vlad-Bubulac T, Serbezeanu D, et al. Environmentally friendly fire-resistant epoxy resins based on a new oligophosphonate with high flame retardant efficiency[J]. RSC Advances, 2016, 6(27): 22764-22776. |

| 6 | Wang N, Gao H Y, Zhang J, et al. Phytic acid intercalated graphene oxide for anticorrosive reinforcement of waterborne epoxy resin coating[J]. Polymers, 2019, 11(12): E1950. |

| 7 | Jang J B, Kim T H, Kim T, et al. Modified epoxy resin synthesis from phosphorus-containing polyol and physical changes studies in the synthesized products[J]. Polymers, 2019, 11(12): E2116. |

| 8 | 李绒绒, 陈伟. 阻燃剂在环氧树脂体系中的应用[J]. 热固性树脂, 2021, 36(1): 66-70. |

| Li R R, Chen W. Application of flame retardants in epoxy resin system[J]. Thermosetting Resin, 2021, 36(1): 66-70. | |

| 9 | 南巡, 蒋文革, 周宇, 等. 一种潜伏性无卤阻燃中温固化环氧树脂体系[J]. 宇航材料工艺, 2020, 50(1): 44-48. |

| Nan X, Jiang W G, Zhou Y, et al. A non-halogen flame-retardant latent epoxy resin system curing at medium temperature[J]. Aerospace Materials & Technology, 2020, 50(1): 44-48. | |

| 10 | Naderi M, Hoseinabadi M, Najafi M, et al. Investigation of the mechanical, thermal, and anticorrosion properties of epoxy nanocomposite coatings: effect of synthetic hardener and nanoporous graphene[J]. Journal of Applied Polymer Science, 2018, 135(17): 46201. |

| 11 | Kireev V V, Bilichenko Y V, Borisov R S, et al. Synthesis of bisphenol A based phosphazene-containing epoxy resin with reduced viscosity[J]. Polymers, 2019, 11(12): 1914. |

| 12 | Movahedifar E, Vahabi H, Saeb M R, et al. Flame retardant epoxy composites on the road of innovation: an analysis with flame retardancy index for future development[J]. Molecules, 2019, 24(21): 3964. |

| 13 | Vahabi H, Laoutid F, Movahedifar E, et al. Description of complementary actions of mineral and organic additives in thermoplastic polymer composites by flame retardancy index[J]. Polymers for Advanced Technologies, 2019, 30(8): 2056-2066. |

| 14 | Wang X, Kalali E N, Wang D Y. Renewable cardanol-based surfactant modified layered double hydroxide as a flame retardant for epoxy resin[J]. ACS Sustainable Chemistry & Engineering, 2015, 3(12): 3281-3290. |

| 15 | Zotti A, Borriello A, Ricciardi M, et al. Effects of sepiolite clay on degradation and fire behaviour of a bisphenol A-based epoxy[J]. Composites Part B: Engineering, 2015, 73: 139-148. |

| 16 | Shree Meenakshi K, Pradeep Jaya Sudhan E, Ananda Kumar S, et al. Development and characterization of novel DOPO based phosphorus tetraglycidyl epoxy nanocomposites for aerospace applications[J]. Progress in Organic Coatings, 2011, 72(3): 402-409. |

| 17 | Qian L J, Ye L J, Qiu Y, et al. Thermal degradation behavior of the compound containing phosphaphenanthrene and phosphazene groups and its flame retardant mechanism on epoxy resin[J]. Polymer, 2011, 52(24): 5486-5493. |

| 18 | Wagner J, Deglmann P, Fuchs S, et al. A flame retardant synergism of organic disulfides and phosphorous compounds[J]. Polymer Degradation and Stability, 2016, 129: 63-76. |

| 19 | Zhao W, Liu J P, Peng H, et al. Synthesis of a novel PEPA-substituted polyphosphoramide with high char residues and its performance as an intumescent flame retardant for epoxy resins[J]. Polymer Degradation and Stability, 2015, 118: 120-129. |

| 20 | Liu Y L, Chou C I. The effect of silicon sources on the mechanism of phosphorus-silicon synergism of flame retardation of epoxy resins[J]. Polymer Degradation and Stability, 2005, 90(3): 515-522. |

| 21 | Shi Y C, Wang G J. The novel silicon-containing epoxy/PEPA phosphate flame retardant for transparent intumescent fire resistant coating[J]. Applied Surface Science, 2016, 385: 453-463. |

| 22 | Kalali E N, Wang X, Wang D Y. Functionalized layered double hydroxide-based epoxy nanocomposites with improved flame retardancy and mechanical properties[J]. Journal of Materials Chemistry A, 2015, 3(13): 6819-6826. |

| 23 | 田时开. 纳米SiO2/石墨烯-阻燃环氧树脂复合材料的制备及性能研究[J]. 功能材料, 2020, 51(6): 6052-6056. |

| Tian S K. Preparation and properties of nano-SiO2/grapheme flame retardant epoxy resin composites[J]. Journal of Functional Materials, 2020, 51(6): 6052-6056. | |

| 24 | Zhang T, Liu W S, Wang M X, et al. Synergistic effect of an aromatic boronic acid derivative and magnesium hydroxide on the flame retardancy of epoxy resin[J]. Polymer Degradation and Stability, 2016, 130: 257-263. |

| 25 | 贾园, 张鹏, 刘振, 等. 阻燃高分子材料的开发及其应用研究进展[J]. 中国塑料, 2019, 33(10): 120-127. |

| Jia Y, Zhang P, Liu Z, et al. Development, application and research progress in flame-retardant polymeric materials[J]. China Plastics, 2019, 33(10): 120-127. | |

| 26 | 宋昆朋, 王银杰, 刘吉平, 等. 磷腈化合物在阻燃聚合物领域的研究进展[J]. 中国塑料, 2021, 35(2): 107-118. |

| Song K P, Wang Y J, Liu J P, et al. Research progress in applications of phosphazene compounds in flame-retardant polymers field[J]. China Plastics, 2021, 35(2): 107-118. | |

| 27 | Jang B N, Wilkie C A. The effects of triphenylphosphate and recorcinolbis(diphenylphosphate) on the thermal degradation of polycarbonate in air[J]. Thermochimica Acta, 2005, 433(1/2): 1-12. |

| 28 | Pawlowski K H, Schartel B. Flame retardancy mechanisms of triphenyl phosphate, resorcinol bis(diphenyl phosphate) and bisphenol A bis(diphenyl phosphate) in polycarbonate/acrylonitrile-butadiene-styrene blends[J]. Polymer International, 2007, 56(11): 1404-1414. |

| 29 | Cote A P. Porous, crystalline, covalent organic frameworks[J]. Science, 2005, 310(5751): 1166-1170. |

| 30 | Jian R K, Ai Y F, Xia L, et al. Single component phosphamide-based intumescent flame retardant with potential reactivity towards low flammability and smoke epoxy resins[J]. Journal of Hazardous Materials, 2019, 371: 529-539. |

| 31 | Kandola B K, Krishnan L, Ebdon J R, et al. Structure-property relationships in structural glass fibre reinforced composites from unsaturated polyester and inherently fire retardant phenolic resin matrix blends[J]. Composites Part B: Engineering, 2020, 182: 107607. |

| 32 | Morgan A B, Jurs J L, Tour J M. Synthesis, flame-retardancy testing, and preliminary mechanism studies of nonhalogenated aromatic boronic acids: a new class of condensed-phase polymer flame-retardant additives for acrylonitrile-butadiene-styrene and polycarbonate[J]. Journal of Applied Polymer Science, 2000, 76(8): 1257-1268. |

| 33 | Liu X, Zhou Y, Peng H, et al. Catalyzing charring effect of solid acid boron phosphate on dipentaerythritol during the thermal degradation and combustion[J]. Polymer Degradation and Stability, 2015, 119: 242-250. |

| [1] | 徐文杰, 贾献峰, 王际童, 乔文明, 凌立成, 王任平, 余子舰, 张寅旭. 有机硅/酚醛杂化气凝胶的制备和性能研究[J]. 化工学报, 2023, 74(8): 3572-3583. |

| [2] | 王杰, 丘晓琳, 赵烨, 刘鑫洋, 韩忠强, 许雍, 蒋文瀚. 聚电解质静电沉积改性PHBV抗氧化膜的制备与性能研究[J]. 化工学报, 2023, 74(7): 3068-3078. |

| [3] | 刘杰, 吴立盛, 李锦锦, 罗正鸿, 周寅宁. 含乙烯基胺酯键聚醚类可逆交联聚合物的制备及性能研究[J]. 化工学报, 2023, 74(7): 3051-3057. |

| [4] | 龙臻, 王谨航, 任俊杰, 何勇, 周雪冰, 梁德青. 离子液体协同PVCap抑制天然气水合物生成实验研究[J]. 化工学报, 2023, 74(6): 2639-2646. |

| [5] | 朱理想, 罗默也, 张晓东, 龙涛, 余冉. 醌指纹法指示三氯乙烯污染土功能微生物活性应用研究[J]. 化工学报, 2023, 74(6): 2647-2654. |

| [6] | 杨琴, 秦传鉴, 李明梓, 杨文晶, 赵卫杰, 刘虎. 用于柔性传感的双形状记忆MXene基水凝胶的制备及性能研究[J]. 化工学报, 2023, 74(6): 2699-2707. |

| [7] | 张建华, 陈萌萌, 孙雅雯, 彭永臻. 部分短程硝化同步除磷耦合Anammox实现生活污水高效脱氮除磷[J]. 化工学报, 2023, 74(5): 2147-2156. |

| [8] | 陈韶云, 徐东, 陈龙, 张禹, 张远方, 尤庆亮, 胡成龙, 陈建. 单层聚苯胺微球阵列结构的制备及其吸附性能[J]. 化工学报, 2023, 74(5): 2228-2238. |

| [9] | 龙臻, 王谨航, 何勇, 梁德青. 离子液体与动力学抑制剂作用下混合气体水合物生成特性研究[J]. 化工学报, 2023, 74(4): 1703-1711. |

| [10] | 吴学红, 栾林林, 陈亚南, 赵敏, 吕财, 刘勇. 可降解柔性相变薄膜的制备及其热性能[J]. 化工学报, 2023, 74(4): 1818-1826. |

| [11] | 吕阳光, 左培培, 杨正金, 徐铜文. 三嗪框架聚合物膜用于有机纳滤甲醇/正己烷分离[J]. 化工学报, 2023, 74(4): 1598-1606. |

| [12] | 罗来明, 张劲, 郭志斌, 王海宁, 卢善富, 相艳. 1~5 kW高温聚合物电解质膜燃料电池堆的理论模拟与组装测试[J]. 化工学报, 2023, 74(4): 1724-1734. |

| [13] | 刘海芹, 李博文, 凌喆, 刘亮, 俞娟, 范一民, 勇强. 羟基-炔点击化学改性半乳甘露聚糖薄膜的制备及性能研究[J]. 化工学报, 2023, 74(3): 1370-1378. |

| [14] | 王帅, 杨富凯, 徐新宇. 阻燃型全生物基多元醇聚氨酯泡沫的制备及性能研究[J]. 化工学报, 2023, 74(3): 1399-1408. |

| [15] | 黄玉龙, 吕凡, 仇俊杰, 章骅, 何品晶. 易腐垃圾厌氧消化沼液理化性质及VOCs分子特征[J]. 化工学报, 2023, 74(3): 1275-1285. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号