化工学报 ›› 2021, Vol. 72 ›› Issue (10): 5102-5113.DOI: 10.11949/0438-1157.20210383

田朋1( ),王德武1,2(

),王德武1,2( ),王若瑾1,唐猛3,郝晓磊1,张少峰1,2

),王若瑾1,唐猛3,郝晓磊1,张少峰1,2

收稿日期:2021-03-15

修回日期:2021-06-10

出版日期:2021-10-05

发布日期:2021-10-05

通讯作者:

王德武

作者简介:田朋(1996—),男,硕士研究生,基金资助:

Peng TIAN1( ),Dewu WANG1,2(

),Dewu WANG1,2( ),Ruojin WANG1,Meng TANG3,Xiaolei HAO1,Shaofeng ZHANG1,2

),Ruojin WANG1,Meng TANG3,Xiaolei HAO1,Shaofeng ZHANG1,2

Received:2021-03-15

Revised:2021-06-10

Online:2021-10-05

Published:2021-10-05

Contact:

Dewu WANG

摘要:

采用二维床及D类玻璃珠颗粒,在表观气速Ug=0.267~0.978 m/s、摇摆幅值Θ=5°~15°、摇摆周期T=8~20 s的实验条件下,对摇摆流化床内气固流动过程及气体通过流化床的时均总压降进行了研究,并通过与常规直立床和倾斜床进行对比,分析了床体摇摆对气固流动的影响。结果表明,在平均角速度ωave>2(°)/s的条件下,当初始装料量和表观气速相同时,气体通过摇摆流化床的时均总压降低于直立床,高于相同最大倾角时的倾斜床;惯性力所产生的压降在0.15 kPa以下,其对床层压降的影响较小,床体倾斜导致气体向边壁区域聚集是影响摇摆流化床内气固流动特性的主要因素,由此导致床内存在固定床和下行移动床状态的非流化区域,使得处于流化区域的颗粒量减少,同时还降低了流化床层在竖直方向的静压。非流化区域的存在还会造成流化区域的气速高于直立床表观气速,两者表观气速之比为1.04~1.49。

中图分类号:

田朋,王德武,王若瑾,唐猛,郝晓磊,张少峰. 摇摆流化床的气固流动特性[J]. 化工学报, 2021, 72(10): 5102-5113.

Peng TIAN,Dewu WANG,Ruojin WANG,Meng TANG,Xiaolei HAO,Shaofeng ZHANG. Gas-solid flow characteristics in the rolling fluidized-bed[J]. CIESC Journal, 2021, 72(10): 5102-5113.

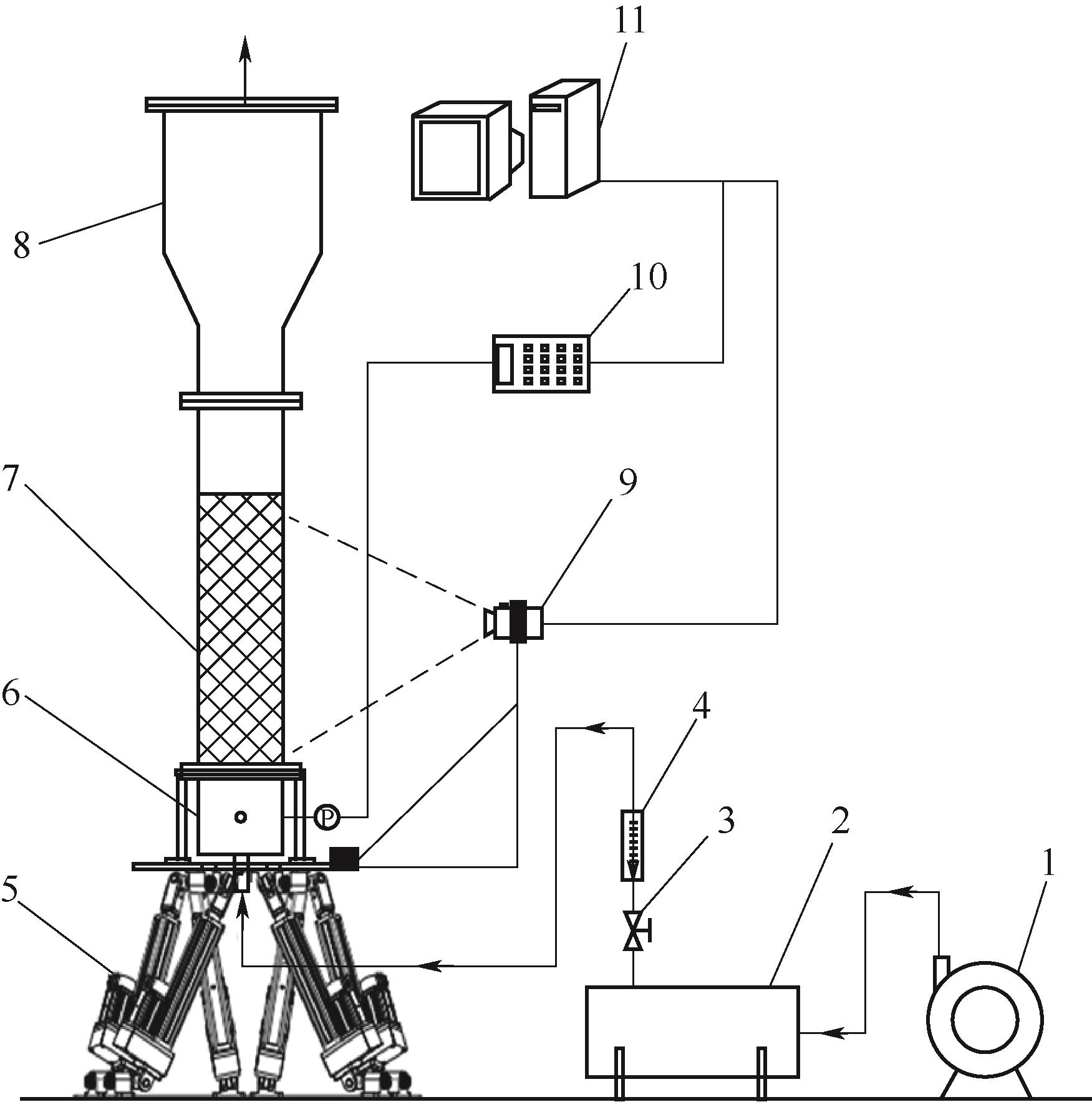

图1 气固摇摆流化床实验装置及流程示意图1—罗茨鼓风机;2—气体缓冲罐;3—截止阀;4—转子流量计;5—摇摆平台;6—气室;7—床层段;8—扩大段;9—摄录机;10—压力信号采集系统;11—计算机

Fig.1 Schematic diagram of experimental apparatus and flow process of gas-solid rolling fluidized-bed

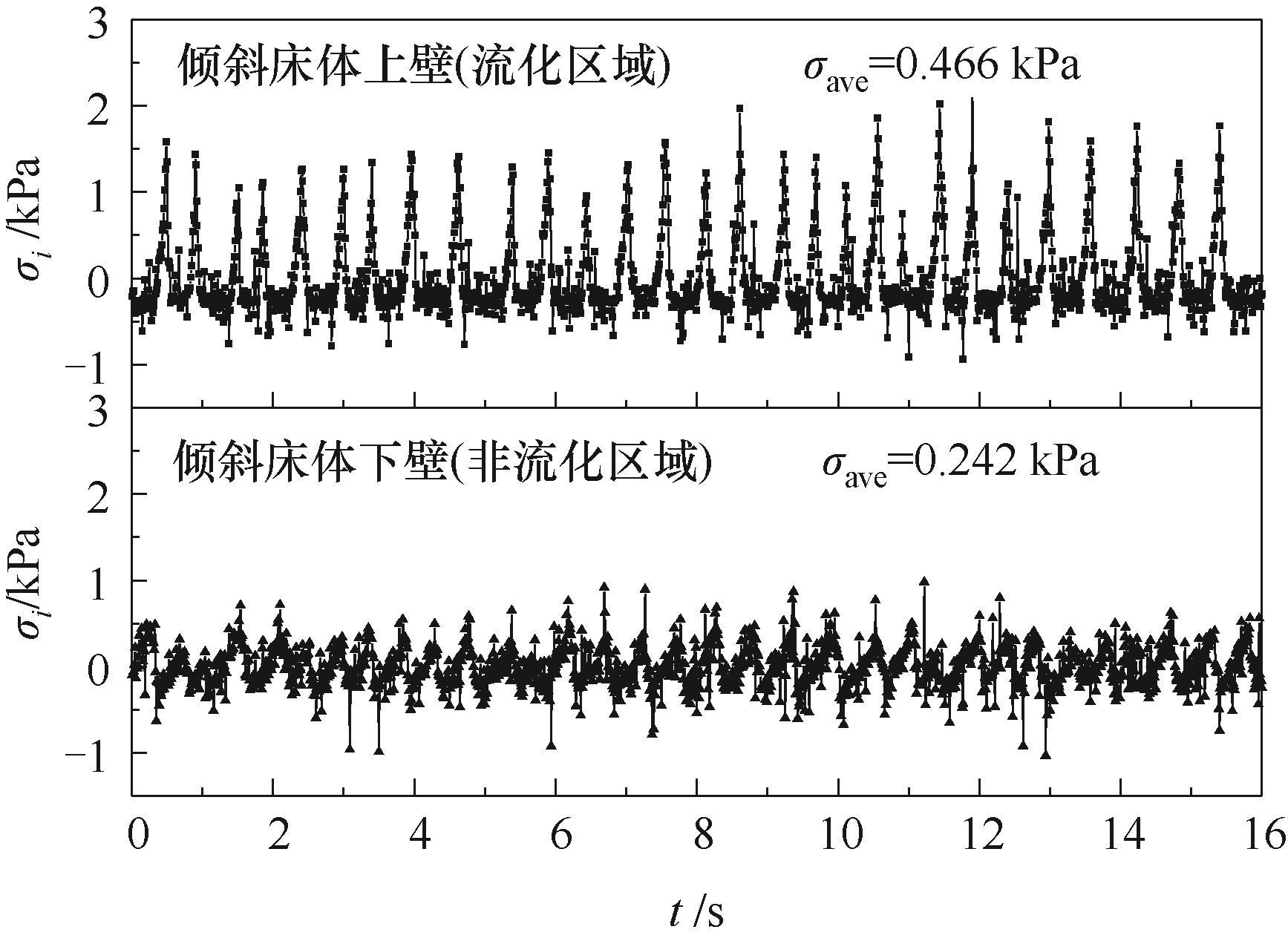

图5 床体倾斜时流化区域和非流化区域的瞬时压力波动时间序列对比(Ug=0.444 m/s,Θ=15°)

Fig.5 Comparison of time series pressure fluctuations between fluidization regions and defluidization regions in the inclined fluidized bed (Ug=0.444 m/s,Θ=15°)

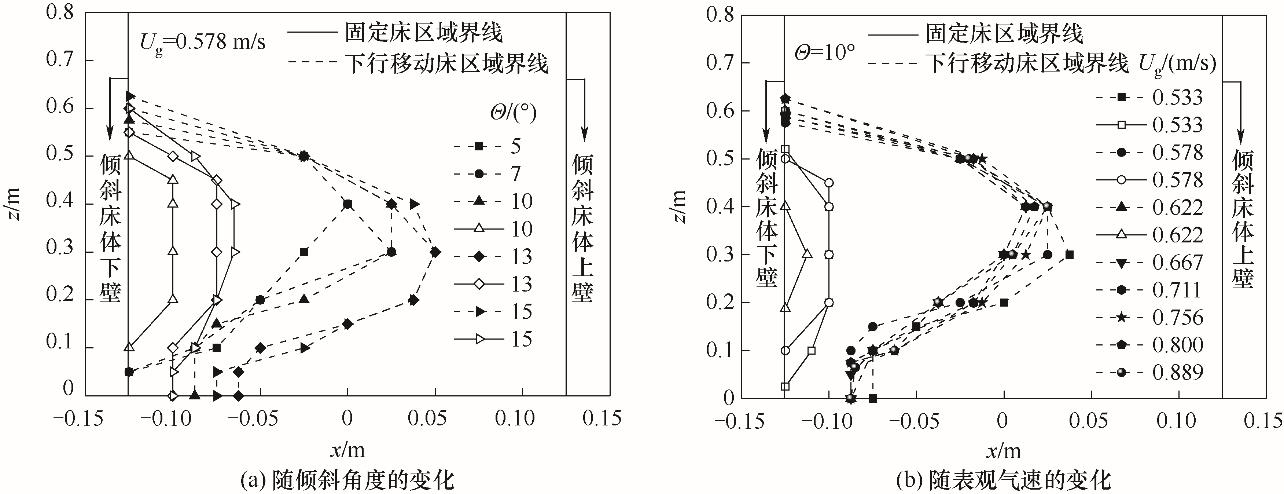

图6 倾斜床内部固定床与下行移动床区域范围随操作条件的变化

Fig.6 Variation of the areas of both the fixed bed and the downward moving bed under different operating conditionsin the inclined bed

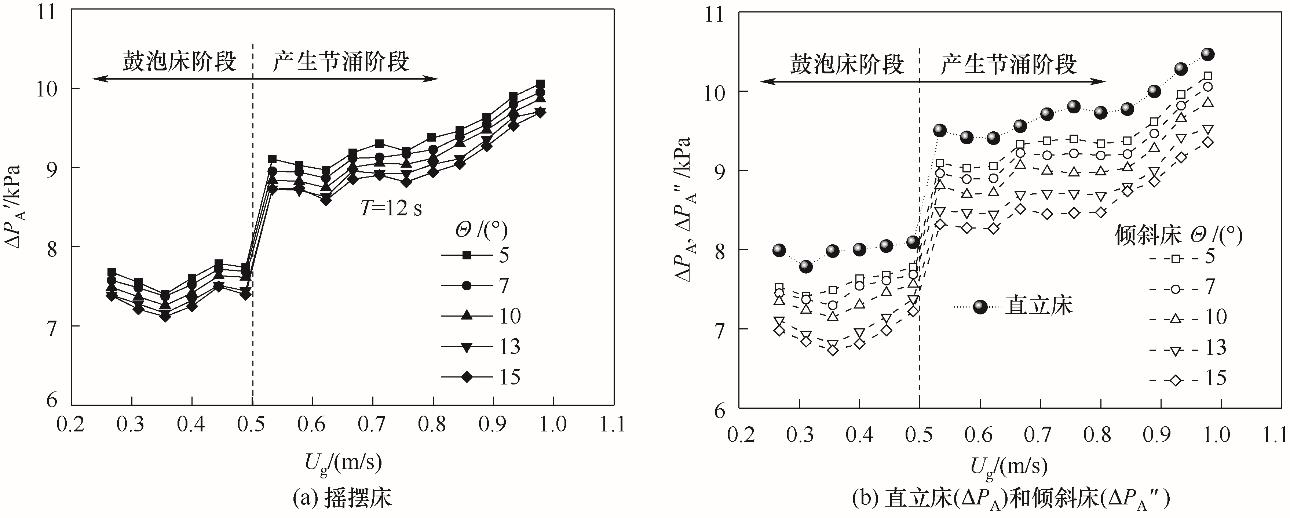

图8 气体通过流化床时均总压降随表观气速的变化

Fig.8 Variation of the time-averaged total pressure drop with gas superficial velocity when the gas passing through the fluidized bed

图9 气体通过流化床时均总压降随摇摆幅值和摇摆周期的变化

Fig.9 Variation of the time-averaged total pressure drop with both the rolling amplitude and period when the gas passing through the fluidized bed

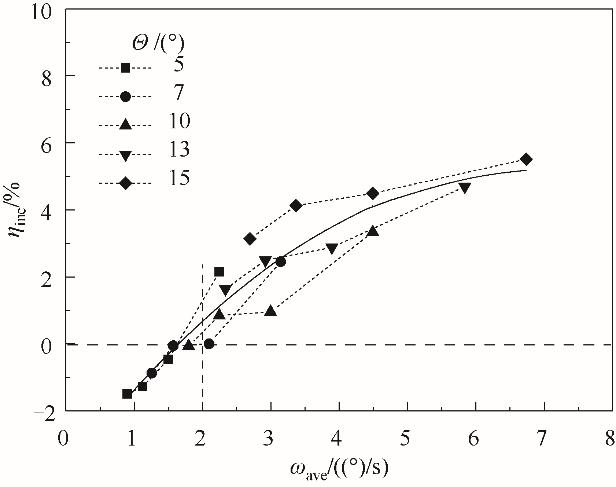

图10 摇摆床时均总压降较倾斜床的相对增加幅度随平均摇摆角速度的变化(Ug>0.500 m/s)

Fig.10 Variation of the relative increase amplitude of the time-averaged total pressure drop in the rolling bed compared to that in the inclined bed with the average rolling angular velocity (Ug>0.500 m/s)

图11 摇摆床与倾斜/直立床时均总压降差值中的床层静压差值和惯性力压降

Fig.11 Bed static pressure difference and inertial pressure drop in the difference of time-averaged total pressure drop between rolling bed and inclined/vertical bed

| 1 | 张亮亮, 付纪文, 罗勇, 等. 面向海洋工程的超重力过程强化技术及应用[J]. 化工学报, 2020, 71(1): 1-15. |

| Zhang L L, Fu J W, Luo Y, et al. Higee process intensification technology and application for oceaneering[J]. CIESC Journal, 2020, 71(1): 1-15. | |

| 2 | Dashliborun A M, Zhang J, Taghavi S M, et al. Marinization of multiphase reactors through the prism of chemical engineers[J]. Industrial & Engineering Chemistry Research, 2019, 58(8): 2607-2630. |

| 3 | 朱建鲁, 常学煜, 韩辉, 等. FLNG绕管式换热器晃动实验分析[J]. 化工学报, 2017, 68(9): 3358-3367. |

| Zhu J L, Chang X Y, Han H, et al. Experimental study on effect of sloshing on performance of heat exchanger[J]. CIESC Journal, 2017, 68(9): 3358-3367. | |

| 4 | 唐建峰, 崔健, 修云飞, 等. 海上天然气脱酸塔内排管式液体分布器各喷淋密度下的孔径研究[J]. 化工进展, 2017, 36(4): 1192-1201. |

| Tang J F, Cui J, Xiu Y F, et al. Research on orifices diameter of calandria liquid distributor used in offshore deacidification tower with different spray densities[J]. Chemical Industry and Engineering Progress, 2017, 36(4): 1192-1201. | |

| 5 | Namie S, Osanai T, Yamanouchi H, et al. Investigation on fluidized bed combustion for marine application[J]. Journal of the Marine Engineering Society in Japan, 1984, 19(12): 943-950. |

| 6 | 赵申. 船用流化床废气锅炉研究[J]. 舰船科学技术, 1992, 14(4): 13-18. |

| Zhao S. Research of fluidized bed exhaust boiler for marine application [J]. Ship Science and Technology, 1992, 14(4): 13-18. | |

| 7 | Zhu Z Q, Ren T T, Liu Y W, et al. Natural circulation two-phase flow characteristics in a rod bundle channel under stable and rolling motion conditions[J]. International Journal of Heat and Mass Transfer, 2019, 141: 517-529. |

| 8 | 鲍伟, 陈炳德, 徐建军, 等. 摇摆条件下圆管内过冷沸腾局部空泡时空分布特性[J]. 化工学报, 2016, 67(6): 2277-2283. |

| Bao W, Chen B D, Xu J J, et al. Distribution of local void fraction for subcooled boiling flow in rolling circular tube[J]. CIESC Journal, 2016, 67(6): 2277-2283. | |

| 9 | 陈冲, 高璞珍, 余志庭, 等. 摇摆工况下窄矩形通道内两相沸腾摩擦压降特性[J]. 化工学报, 2015, 66(10): 3874-3880. |

| Chen C, Gao P Z, Yu Z T, et al. Two-phase frictional pressure drop characteristics of boiling flow in rectangular narrow channel under rolling motion[J]. CIESC Journal, 2015, 66(10): 3874-3880. | |

| 10 | Iliuta I, Larachi F. Hydrocarbon hydrodesulfurization in vertical, inclined and oscillating trickle beds — hydrodynamics & reactor performance for offshore petroleum marine applications[J]. Fuel, 2016, 186: 35-49. |

| 11 | Iliuta I, Larachi F. Fischer-Tropsch synthesis in vertical, inclined and oscillating trickle-bed reactors for offshore floating applications[J]. Chemical Engineering Science, 2018, 177: 509-522. |

| 12 | Dashliborun A M, Füssel A, Larachi F. Prospect of open-cell solid foams for floating-platform multiphase reactor applications —maldistribution susceptibility and hydrodynamic behavior[J]. Chemical Engineering Journal, 2018, 332: 596-607. |

| 13 | Xiang L Y, Wu L K, Gao L D, et al. Pilot scale applied research on CO2 removal of natural gas using a rotating packed bed with propylene carbonate[J]. Chemical Engineering Research and Design, 2019, 150: 33-39. |

| 14 | Assima G P, Larachi F, Schleicher E, et al. Capacitance wire mesh imaging of bubbly flows for offshore treatment applications[J]. Flow Measurement and Instrumentation, 2015, 45: 298-307. |

| 15 | Motamed Dashliborun A, Larachi F. Hydrodynamics of gas-liquid cocurrent downflow in floating packed beds[J]. Chemical Engineering Science, 2015, 137: 665-676. |

| 16 | Assima G P, Motamed-Dashliborun A, Larachi F. Emulation of gas-liquid flow in packed beds for offshore floating applications using a swell simulation hexapod[J]. AIChE Journal, 2015, 61(7): 2354-2367. |

| 17 | 唐建峰, 杨帆, 崔健, 等. 晃动对FLNG排管式液体分布器性能的影响[J]. 天然气工业, 2016, 36(1): 123-128. |

| Tang J F, Yang F, Cui J, et al. Effects of sloshing on the performance of FLNG calandria liquid distributors[J]. Natural Gas Industry, 2016, 36(1): 123-128. | |

| 18 | Yasui T, Nakayama T, Yoshida K. Heat-transfer characteristics in a rocking fluidized bed[J]. International Communications in Heat and Mass Transfer, 1984, 11(5): 477-488. |

| 19 | Nishi Y. Characteristics of fluidized bed under oscillation[J]. Kagaku Kogaku Ronbunshu, 1986, 12(4): 414-419. |

| 20 | Murata H, Oka H, Adachi M, et al. Effects of the ship motion on gas-solid flow and heat transfer in a circulating fluidized bed[J]. Powder Technology, 2012, 231: 7-17. |

| 21 | Zhao T, Liu K, Murata H, et al. Experimental and numerical investigation of particle distribution behaviors in a rolling circulating fluidized bed[J]. Powder Technology, 2014, 258: 38-48. |

| 22 | Zhao T, Liu K, Murata H, et al. Investigation of bed-to-wall heat transfer characteristics in a rolling circulating fluidized bed[J]. Powder Technology, 2015, 269: 46-54. |

| 23 | Zhao T, Nakamura Y, Liu K, et al. The effect of rolling amplitude and period on particle distribution behavior in a rolling circulating fluidized bed[J]. Powder Technology, 2016, 294: 484-492. |

| 24 | Wang Z L, Zhao T, Liu K, et al. Clarification of an improved cluster renewal model (ICRM) for heat transfer characteristics in a rolling circulating fluidized bed (RCFB)[J]. Advanced Powder Technology, 2020, 31(7): 2866-2879. |

| 25 | Baeyens J, Geldart D. An investigation into slugging fluidized beds[J]. Chemical Engineering Science, 1974, 29(1): 255-265. |

| 26 | Journée J M J, Massie W W. Offshore Hydromechanics[M]. Delft: Delft University of Technology, 2001. |

| 27 | Murata H, Sawada K I, Kobayashi M. Natural circulation characteristics of a marine reactor in rolling motion and heat transfer in the core[J]. Nuclear Engineering and Design, 2002, 215(1/2): 69-85. |

| 28 | 金涌, 祝京旭, 汪展文, 等. 流态化工程原理[M]. 北京: 清华大学出版社, 2001: 85. |

| Jin Y, Zhu J X, Wang Z W, et al. Fluidization Engineering Principles[M]. Beijing: Tsinghua University Press, 2001: 85. | |

| 29 | Yamazaki R, Sugioka R, Ando O, et al. Minimum fluidization velocity of inclined fluidized bed[J]. Kagaku Kogaku Ronbunshu, 1989, 15(2): 219-225. |

| 30 | 李珺. 振动流化床的动态特性及稳定性研究[D]. 徐州: 中国矿业大学, 2014. |

| Li J. Dynamic characteristics and stability of vibrating fluidized bed[D]. Xuzhou: China University of Mining and Technology, 2014. |

| [1] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [2] | 邵苛苛, 宋孟杰, 江正勇, 张旋, 张龙, 高润淼, 甄泽康. 水平方向上冰中受陷气泡形成和分布实验研究[J]. 化工学报, 2023, 74(S1): 161-164. |

| [3] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [4] | 赵亚欣, 张雪芹, 王荣柱, 孙国, 姚善泾, 林东强. 流穿模式离子交换层析去除单抗聚集体[J]. 化工学报, 2023, 74(9): 3879-3887. |

| [5] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [6] | 岳林静, 廖艺涵, 薛源, 李雪洁, 李玉星, 刘翠伟. 凹坑缺陷对厚孔板喉部空化流动特性影响研究[J]. 化工学报, 2023, 74(8): 3292-3308. |

| [7] | 王海, 林宏, 王晨, 许浩洁, 左磊, 王军锋. 高压静电场强化多孔介质表面沸腾传热特性研究[J]. 化工学报, 2023, 74(7): 2869-2879. |

| [8] | 高金明, 郭玉娇, 鄂承林, 卢春喜. 一种封闭罩内顺流多旋臂气液分离器的分离特性研究[J]. 化工学报, 2023, 74(7): 2957-2966. |

| [9] | 杨峥豪, 何臻, 常玉龙, 靳紫恒, 江霞. 生物质快速热解下行式流化床反应器研究进展[J]. 化工学报, 2023, 74(6): 2249-2263. |

| [10] | 陈巨辉, 张谦, 舒崚峰, 李丹, 徐鑫, 刘晓刚, 赵晨希, 曹希峰. 基于DEM方法的旋转流化床纳米颗粒流动特性研究[J]. 化工学报, 2023, 74(6): 2374-2381. |

| [11] | 张媛媛, 曲江源, 苏欣欣, 杨静, 张锴. 循环流化床燃煤机组SNCR脱硝过程气液传质和反应特性[J]. 化工学报, 2023, 74(6): 2404-2415. |

| [12] | 王新悦, 王俊杰, 曹思贤, 王翠, 李灵坤, 吴宏宇, 韩静, 吴昊. 玻璃内包材界面修饰对机械应力诱导的单克隆抗体聚集体形成的影响[J]. 化工学报, 2023, 74(6): 2580-2588. |

| [13] | 侯文起, 孙彦, 董晓燕. 碱化修饰甲状腺素运载蛋白显著增强对淀粉样β蛋白聚集的抑制作用[J]. 化工学报, 2023, 74(5): 2100-2110. |

| [14] | 袁子涵, 王淑彦, 邵宝力, 谢磊, 陈曦, 马一玫. 基于幂律液固曳力模型流化床内湿颗粒流动特性的研究[J]. 化工学报, 2023, 74(5): 2000-2012. |

| [15] | 王泽栋, 石至平, 刘丽艳. 考虑气泡非均匀耗散的矩形反应器声流场数值模拟及结构优化[J]. 化工学报, 2023, 74(5): 1965-1973. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号