化工学报 ›› 2023, Vol. 74 ›› Issue (7): 2869-2879.DOI: 10.11949/0438-1157.20230419

收稿日期:2023-04-26

修回日期:2023-06-26

出版日期:2023-07-05

发布日期:2023-08-31

通讯作者:

王军锋

作者简介:王海(1988—),男,博士,副教授,wangh@ujs.edu.cn

基金资助:

Hai WANG( ), Hong LIN, Chen WANG, Haojie XU, Lei ZUO, Junfeng WANG(

), Hong LIN, Chen WANG, Haojie XU, Lei ZUO, Junfeng WANG( )

)

Received:2023-04-26

Revised:2023-06-26

Online:2023-07-05

Published:2023-08-31

Contact:

Junfeng WANG

摘要:

采用电镀法通过调节电镀电流密度和时长制备出不同孔隙的多孔微结构表面,利用网状电极和介电流体工质AE-3000对高压静电场作用下多孔微结构表面池沸腾换热性能开展研究。通过显微可视化测量手段与沸腾传热特性实验,对比分析了高压静电场下不同多孔微结构表面沸腾换热的强化效果。实验结果表明,高压静电场在低热流区对小孔隙结构表面沸腾换热强化效果最佳,电场作用下沸腾传热系数强化因子随多孔微结构换热表面孔隙尺寸增大而减小。与无电场相比,低热流区施加场强为1600 kV/m电场后多孔微结构表面气泡脱离频率最大提升5.11倍,气泡脱离直径下降53.57%。有源电场的引入能够有效解决小孔隙结构表面沸腾气泡脱离困难、逸出阻力大等问题,提高气泡脱离效率,强化沸腾传热性能。

中图分类号:

王海, 林宏, 王晨, 许浩洁, 左磊, 王军锋. 高压静电场强化多孔介质表面沸腾传热特性研究[J]. 化工学报, 2023, 74(7): 2869-2879.

Hai WANG, Hong LIN, Chen WANG, Haojie XU, Lei ZUO, Junfeng WANG. Investigation of enhanced boiling heat transfer on porous structural surfaces by high voltage electric field[J]. CIESC Journal, 2023, 74(7): 2869-2879.

| 试样表面 | 步骤一 | 步骤二 | ||

|---|---|---|---|---|

| 电流密度/ (A/cm2) | 电镀时长/s | 电流密度/ (A/cm2) | 电镀时长/s | |

| ED-1.0-0.05 | 1.0 | 20 | 0.05 | 4500 |

| ED-1.8-0.05 | 1.8 | 20 | 0.05 | 4500 |

| ED-2.2-0.05 | 2.2 | 20 | 0.05 | 4500 |

表1 不同试样表面的电镀参数

Table 1 Electroplating parameters of different sample surfaces

| 试样表面 | 步骤一 | 步骤二 | ||

|---|---|---|---|---|

| 电流密度/ (A/cm2) | 电镀时长/s | 电流密度/ (A/cm2) | 电镀时长/s | |

| ED-1.0-0.05 | 1.0 | 20 | 0.05 | 4500 |

| ED-1.8-0.05 | 1.8 | 20 | 0.05 | 4500 |

| ED-2.2-0.05 | 2.2 | 20 | 0.05 | 4500 |

| 参数 | 数值 |

|---|---|

| 化学式 | CF3CH2OCF2CHF2 |

| 沸点/℃ | 56 |

| 表面张力(25℃)/(mN/m) | 16.4 |

| 热导率(25℃)/(mW/(m·K)) | 89 |

| 汽化潜热(25℃)/(kJ/kg) | 163 |

| 液体介电常数(25℃) | 6.6 |

| 电阻率/(Ω·m) | 1.3×109 |

| 电导率(25℃)/(μS/m) | 7.7×10-4 |

| 介质击穿电压(25℃)/kV | 39.5 |

表2 沸腾工质在标准大气压下的物理性质

Table 2 Properties of the working liquid at standard atmosphere pressure

| 参数 | 数值 |

|---|---|

| 化学式 | CF3CH2OCF2CHF2 |

| 沸点/℃ | 56 |

| 表面张力(25℃)/(mN/m) | 16.4 |

| 热导率(25℃)/(mW/(m·K)) | 89 |

| 汽化潜热(25℃)/(kJ/kg) | 163 |

| 液体介电常数(25℃) | 6.6 |

| 电阻率/(Ω·m) | 1.3×109 |

| 电导率(25℃)/(μS/m) | 7.7×10-4 |

| 介质击穿电压(25℃)/kV | 39.5 |

图5 电场作用下不同多孔微结构表面沸腾热通量与壁面过热度的关系

Fig.5 Relation between heat flux and wall superheat of different porous micro-structured surfaces under electric field

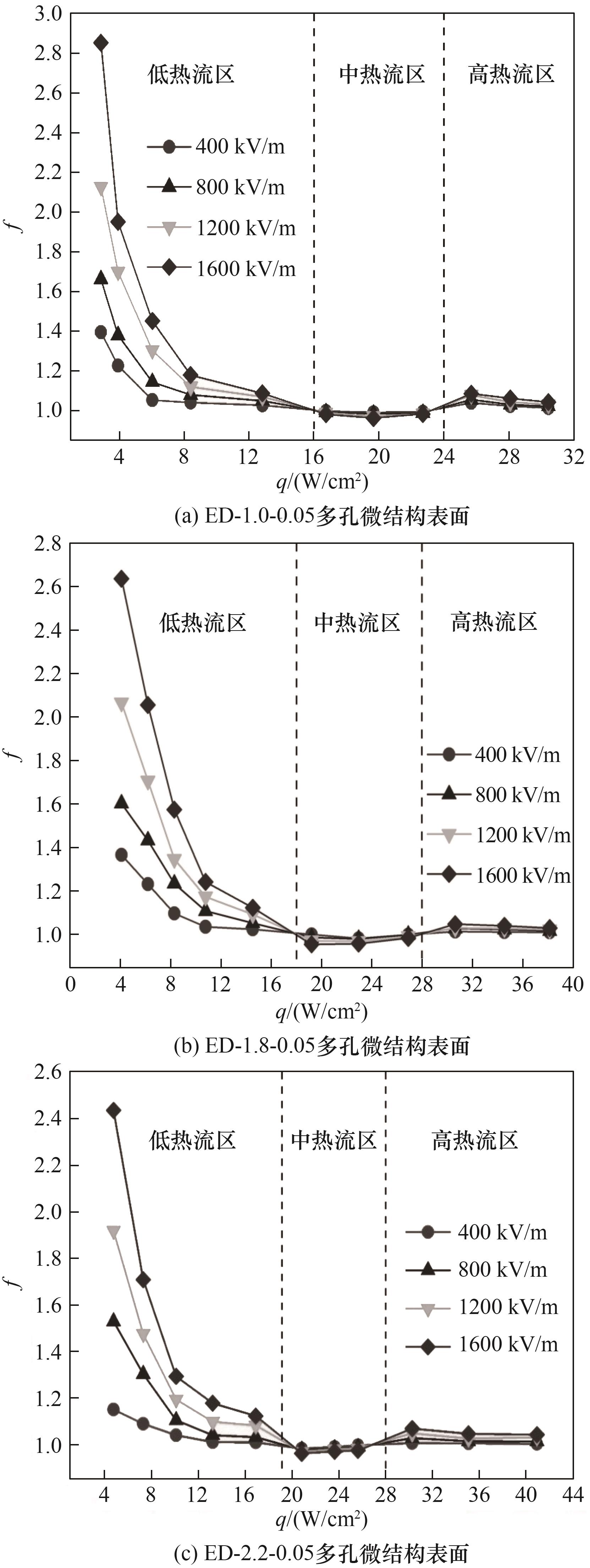

图6 多孔微结构表面在不同电场强度作用下热通量与强化因子的关系

Fig.6 Relation between heat flux and enhancement factor of porous micro-structured surfaces under different electric field

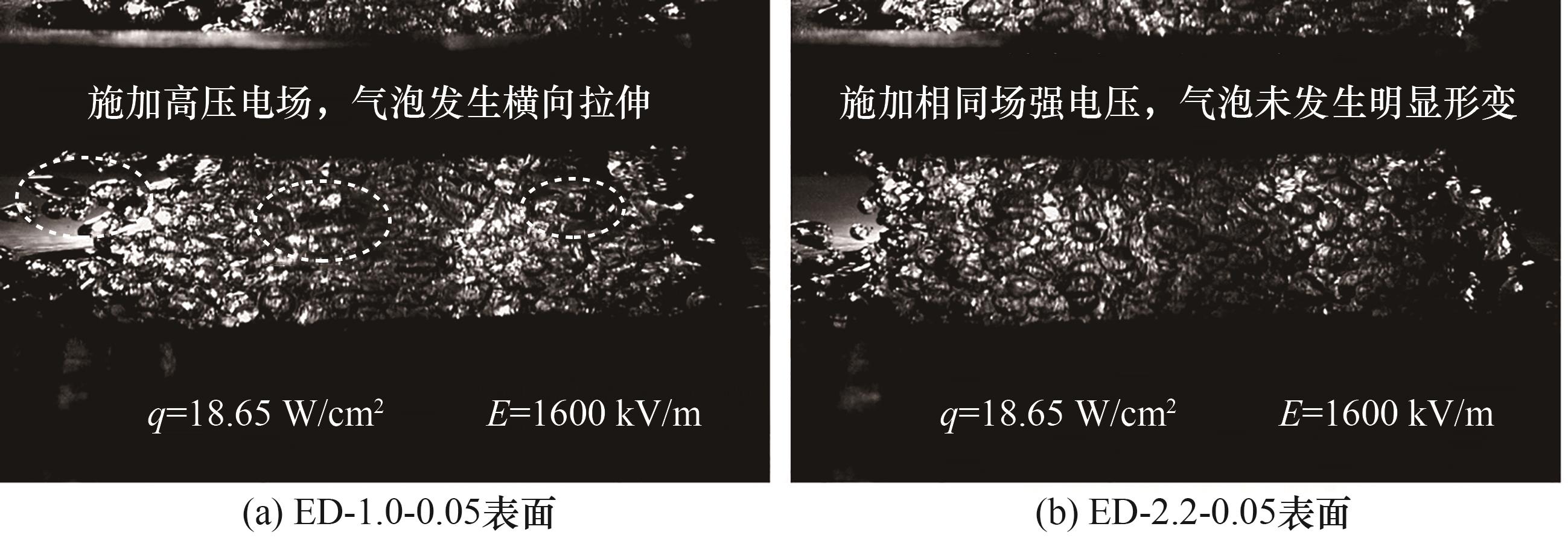

图7 相同热通量与场强下ED-1.0-0.05与ED-2.2-0.05多孔表面沸腾气泡生成状态

Fig.7 Bubble formation on ED-1.0-0.05 and ED-2.2-0.05 porous surfaces under the same heat flux and field intensity

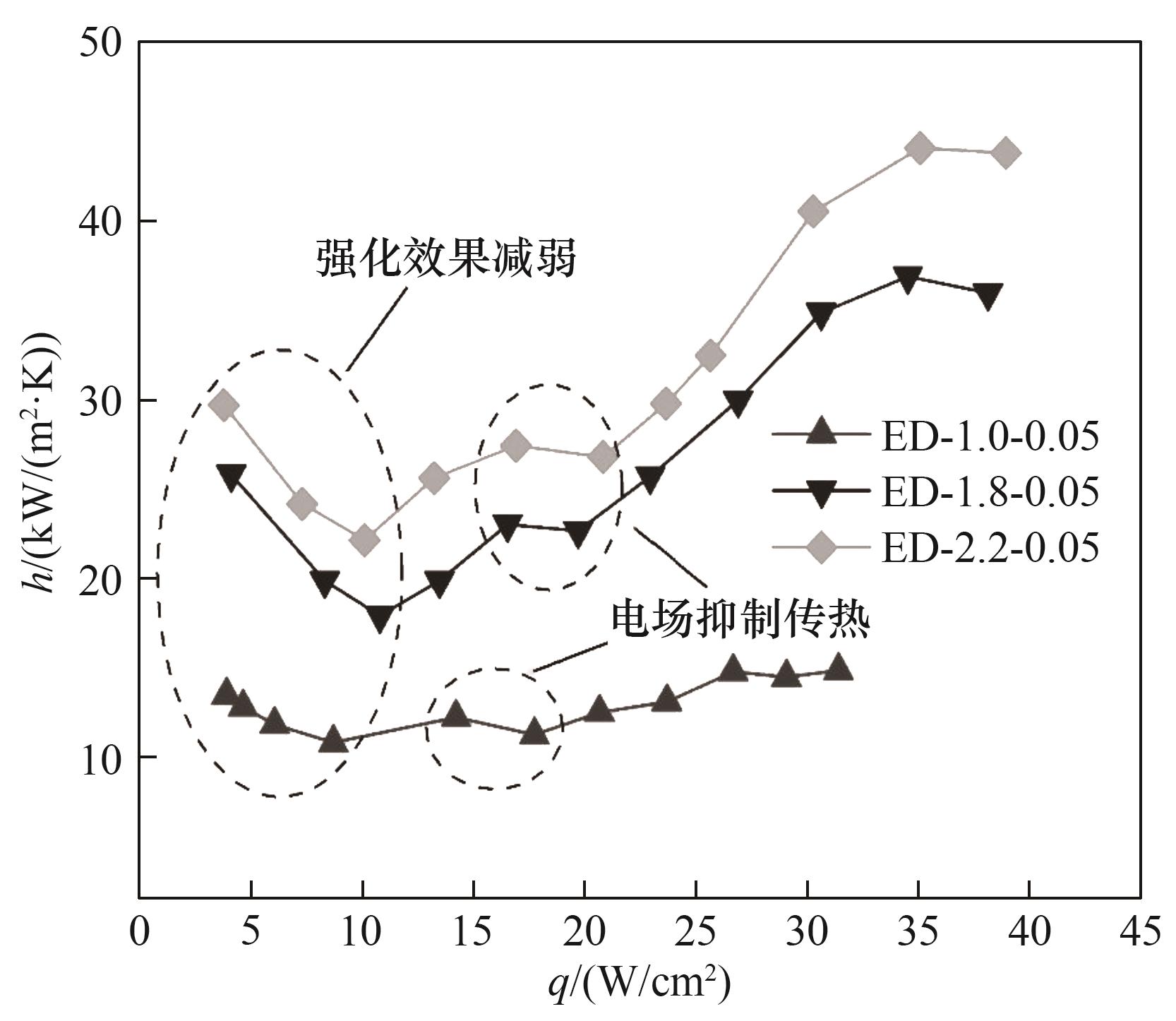

图8 不同多孔微结构换热表面在电场强度1600 kV/m下传热系数随热通量的变化

Fig.8 Heat transfer coefficients of different porous micro-structured surfaces varies with heat flux under electric field intensity of 1600 kV/m

图10 ED-1.0-0.05多孔微结构表面不同热通量与电场强度下沸腾气泡生成图像

Fig.10 Bubble formation on ED-1.0-0.05 porous micro-structured surface with different heat flux and electric field intensity

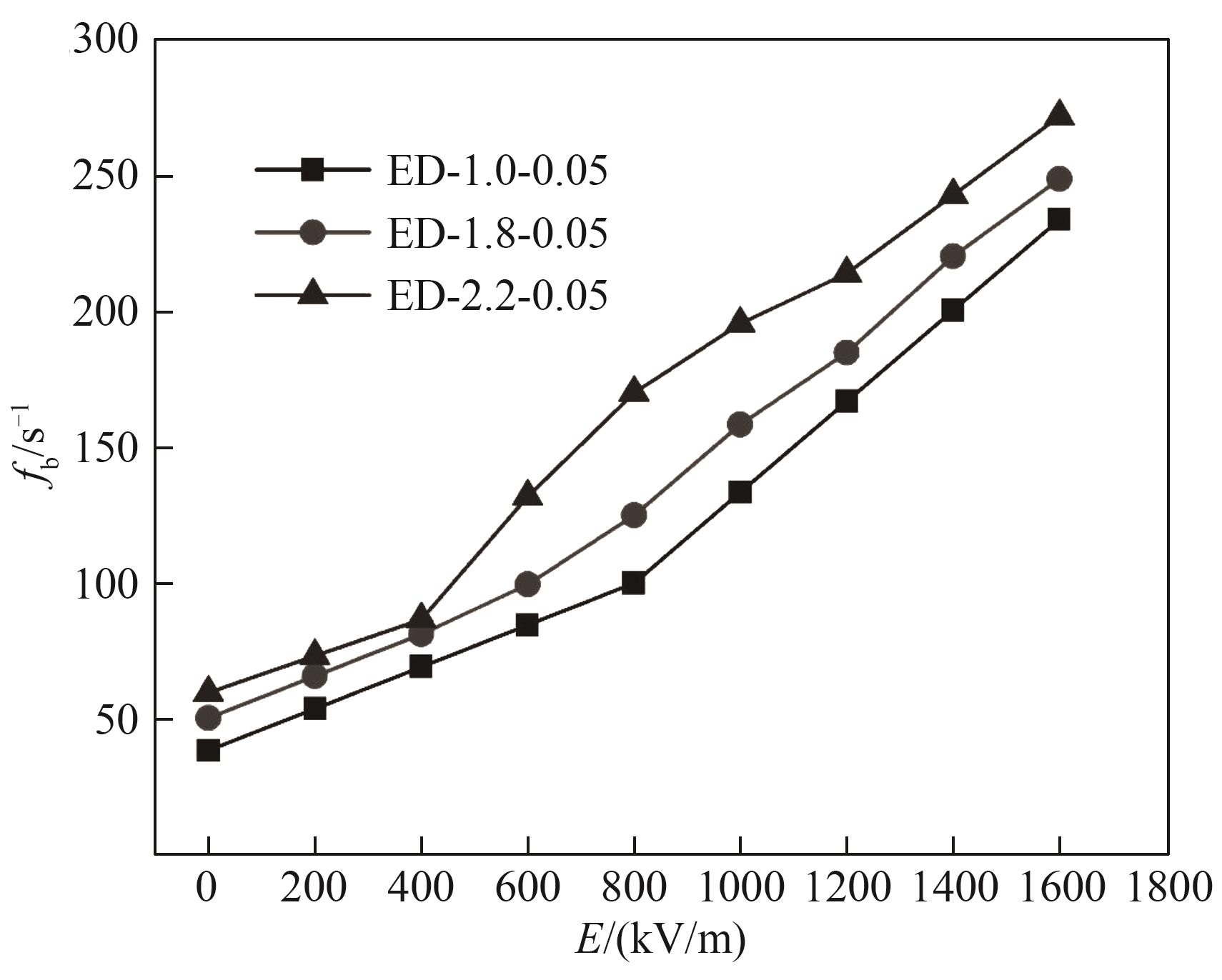

图11 热通量为2.88W/cm2不同多孔微结构表面气泡脱离频率与电场强度关系

Fig.11 Relation between bubble departure frequency and electric field intensity on different porous micro-structured surfaces with the heat flux of 2.88W/cm2

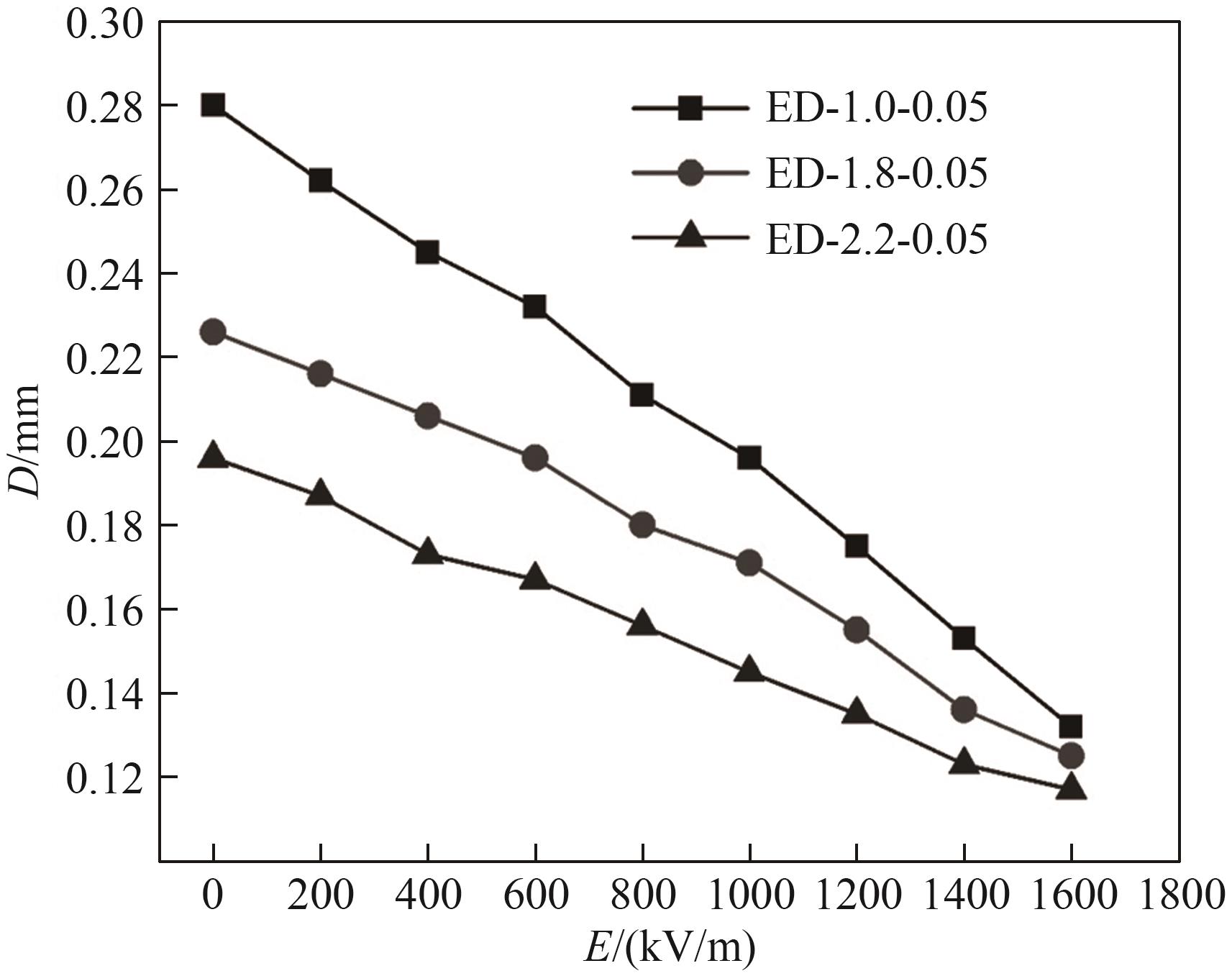

图12 热通量为2.88 W/cm2不同多孔微结构表面气泡平均脱离直径与电场强度关系

Fig.12 Relation between average bubble departure diameter and electric field intensity on different porous micro-structured surfaces with the heat flux of 2.88 W/cm2

| 1 | Li J Q, Mou L W, Zhang J Y, et al. Enhanced pool boiling heat transfer during quenching of water on superhydrophilic porous surfaces: effects of the surface wettability[J]. International Journal of Heat and Mass Transfer, 2018, 125: 494-505. |

| 2 | 纪献兵, 徐进良. 流体在超轻多孔金属泡沫中的流动和换热特性[J]. 化工学报, 2009, 60(1): 21-27. |

| Ji X B, Xu J L. Fluid flow and heat transfer characteristics in ultra-light porous metal foam[J]. CIESC Journal, 2009, 60(1): 21-27. | |

| 3 | 陈宏霞, 黄林滨, 宫逸飞. 多孔结构及表面润湿性对池沸腾传热影响的研究进展[J]. 化工进展, 2017, 36(8): 2798-2808. |

| Chen H X, Huang L B, Gong Y F. Progress on boiling heat transfer from porous structure and surface wettability[J]. Chemical Industry and Engineering Progress, 2017, 36(8): 2798-2808. | |

| 4 | Chu K H, Enright R, Wang E N. Structured surfaces for enhanced pool boiling heat transfer[J]. Applied Physics Letters, 2012, 100(24): 241603. |

| 5 | Dong L N, Quan X J, Cheng P. An experimental investigation of enhanced pool boiling heat transfer from surfaces with micro/nano structures[J]. International Journal of Heat and Mass Transfer, 2014, 71: 189-196. |

| 6 | Wang K K, Leong K C. Saturated pool boiling enhancement using porous lattice structures produced by selective laser melting[J]. International Journal of Heat and Mass Transfer, 2018, 121: 46-63. |

| 7 | Hwang G S, Kaviany M. Critical heat flux in thin, uniform particle coatings[J]. International Journal of Heat and Mass Transfer, 2006, 49: 844-849. |

| 8 | Weibel J A, Garimella S V, North M T. Characterization of evaporation and boiling from sintered powder wick fed by capillary action[J]. International Journal of Heat and Mass Transfer, 2010, 53: 4204-4215. |

| 9 | Jiang Y W, Zhou G H, Zhou J Z, et al. Saturated pool boiling heat transfer of HFE-7100 on sintered copper powder and wire mesh microporous surfaces: a comparison study[J]. Applied Thermal Engineering, 2022, 216: 119067. |

| 10 | Dang C, Min R Q, Pan L Y, et al. Saturated pool boiling heat transfer enhancement of R245fa based on the surface covered by sintered copper powder with and without nanostructure[J]. International Journal of Thermal Sciences, 2023, 187: 108183. |

| 11 | Gouda R K, Pathak M, Khan M K. Pool boiling heat transfer characteristics of a biosurfactant particle deposited heating surface[J]. International Journal of Heat and Mass Transfer, 2020, 163: 120455. |

| 12 | Filho E S, Kiyomura I S, Andrade B A, et al. Pool boiling performance of HFE-7100 on hierarchically structured surfaces[J]. Case Studies in Thermal Engineering, 2021, 28: 101536 |

| 13 | Doran B, Zhang B, Walker A, et al. Experimental determination of the role of increased surface area in pool boiling form nanostructured surfaces[J]. Experimental Thermal and Fluid Science, 2020, 111: 109956. |

| 14 | Joseph A, Mohan S, Kumar C S S, et al. An experimental investigation on pool boiling heat transfer enhancement using sol-gel derived nano CuO porous coating[J]. Experimental Thermal and Fluid Science, 2019, 103: 37-50. |

| 15 | Li C, Peterson G P. Parametric study of pool boiling on horizontal highly conductive microporous coated surfaces[J]. Journal of Heat Transfer, 2007, 129: 1465-1475. |

| 16 | EI-Genk M S, Ali A F. Enhanced nucleate boiling on copper micro-porous surfaces[J]. International Journal of Multiphase Flow, 2010, 36: 780-792. |

| 17 | Tang Y, Tang B, Li Q, et al. Pool boiling enhancement by novel metallic nanoporous surface[J]. Experimental Thermal and Fluid Science, 2013, 44: 194-198. |

| 18 | Deng D X, Feng J Y, Huang Q S, et al. Pool boiling heat transfer of porous structures with reentrant cavities[J]. International Journal of Heat and Mass Transfer, 2016, 99: 556-568. |

| 19 | Hong M, Lu H R, Luo J, et al. Model based experimental analysis of enhanced boiling heat transfer by micro-nano porous surfaces[J]. Applied Thermal Engineering, 2021, 192: 116809. |

| 20 | Sajjad U, Kumar A, Wang C C. Nucleate pool boiling of sintered coated porous surfaces with dielectric liquid, HFE-7200[J]. Journal of Enhanced Heat Transfer, 2020, 27(8): 767-784. |

| 21 | Kweon Y C, Kim M H. Experimental study on nucleate boiling enhancement and bubble dynamic behavior in saturated pool boiling using a nonuniform DC electric field[J]. International Journal of Multiphase Flow, 2000, 26: 1351-1368. |

| 22 | Gao M, Cheng P, Quan X J. An experimental investigation on effects of an electric filed on bubble growth on a smaller heater in pool boiling[J]. International Journal of Heat and Mass Transfer, 2013, 67: 984-991. |

| 23 | Kano I. Effect of electric field distribution generated in a microspace on pool boiling heat transfer[J]. Journal of Heat Transfer, 2014, 136: 101501. |

| 24 | Di Marco P, Grassi W. A review on saturated pool boiling enhancement by means of an electric field[J]. Journal of Enhanced Heat Transfer, 2017, 24: 383-398. |

| 25 | Liu B, Garivalis A L, Cao Z Z, et al. Effects of electric filed on pool boiling heat transfer over microstructured surfaces under different liquid subcoolings[J]. International Journal of Heat and Mass Transfer, 2022, 183: 122154. |

| 26 | Chang H Z, Liu B, Li Q, et al. Effects of electric field on pool boiling heat transfer over composite microstructured surfaces with microcavities on micro-pin fins[J]. International Journal of Heat and Mass Transfer, 2023, 205: 123893. |

| 27 | Chen Y J, Guo J, Liu X L, et al. Experiment and prediction model study on pool boiling heat transfer of water in the electric field with periodically changing direction[J]. International Journal of Multiphase Flow, 2022, 150: 104027. |

| 28 | 郭俊, 李双菲, 陈彦君, 等. 非匀强电场强化水的池沸腾传热特性实验研究与分析[J]. 工程热物理学报, 2022, 43(3): 788-796. |

| Guo J, Li S F, Chen Y J, et al. Experimental study and analysis of water pool boiling heat transfer enhanced by non-uniform electric field[J]. Journal of Engineering Thermophysics, 2022, 43(3): 788-796. | |

| 29 | Quan X J, Gao M, Cheng P, et al. An experimental investigation of pool boiling heat transfer on smooth/rib surfaces under an electric field[J]. International Journal of Heat and Mass Transfer, 2015, 85: 595-608. |

| 30 | Kline S J, McClintock F A. Describing uncertainties in single sample experiments[J]. Mechanical Engineering, 1953, 75: 3-8. |

| 31 | Moze M, Zupancic M, Golobic I. Investigation of the scatter in reported pool boiling CHF measurements including analysis of heat flux and measurement uncertainty evaluation methodology[J]. Applied Thermal Engineering, 2020, 169: 114938. |

| 32 | Rohsenow W M. A method of correlating heat transfer data for surface boiling of liquids[J]. Journal of Heat and Mass Transfer, 1952, 74: 969-976. |

| [1] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [2] | 张贲, 王松柏, 魏子亚, 郝婷婷, 马学虎, 温荣福. 超亲水多孔金属结构驱动的毛细液膜冷凝及传热强化[J]. 化工学报, 2023, 74(7): 2824-2835. |

| [3] | 陈建勋, 刘金平, 许雄文, 余银豪. 一种新型环路重力热管的数值模拟和性能优化[J]. 化工学报, 2023, 74(2): 721-734. |

| [4] | 苏巧玲, 王军锋, 张伟, 詹水清, 吴天一. 低电导率工质中气泡的极化运动实验研究[J]. 化工学报, 2022, 73(9): 3861-3869. |

| [5] | 董宜放, 于樱迎, 胡学功, 裴刚. 电场对竖直微槽润湿及毛细流动特性影响[J]. 化工学报, 2022, 73(7): 2952-2961. |

| [6] | 林志敏, 王崇兆, 强国智, 刘树山, 王良璧. 润滑油在内插同轴交叉翼型涡产生器管内流动与传热特性分析[J]. 化工学报, 2022, 73(11): 4957-4973. |

| [7] | 林石泉, 赵雅鑫, 吕中原, 赖展程, 胡海涛. 亲疏水性对泡沫金属池沸腾换热特性的影响[J]. 化工学报, 2021, 72(S1): 295-301. |

| [8] | 张海, 徐英, 张涛, 孙涔崴, 魏传顺, 戴志向. 丝网传感器的气液两相流可视化测量特性研究[J]. 化工学报, 2021, 72(9): 4573-4583. |

| [9] | 黄正梁, 张鹏, 杨遥, 任聪静, 王靖岱, 阳永荣. 外加电场对静电流化床中颗粒运动与床层粘壁的调控机制[J]. 化工学报, 2021, 72(9): 4544-4552. |

| [10] | 曹海亮, 张红飞, 左潜龙, 安琪, 张子阳, 刘红贝. 梯形微槽道表面池沸腾换热性能研究[J]. 化工学报, 2021, 72(8): 4111-4120. |

| [11] | 林伟翔, 苏港川, 陈强, 文键, 王斯民. 基于超声技术的沉浸式换热器强化传热研究[J]. 化工学报, 2021, 72(8): 4055-4063. |

| [12] | 高峰, 陈永昌, 赵金龙, 马重芳. 磁场对熔盐射流冲击传热的影响[J]. 化工学报, 2020, 71(S2): 92-97. |

| [13] | 郎中敏, 吴刚强, 赫文秀, 韩晓星, 苟延梦, 李双莹. 二氧化铈/水基纳米流体核沸腾传热特性[J]. 化工学报, 2020, 71(5): 2061-2068. |

| [14] | 刘占斌, 何雅玲, 王坤, 马朝, 姜涛. 泡沫填充方式对管内超临界CO2流动换热的影响研究[J]. 化工学报, 2019, 70(9): 3329-3336. |

| [15] | 高兴辉, 周帼彦, 涂善东. 缠绕管式换热器壳程强化传热性能影响因素分析[J]. 化工学报, 2019, 70(7): 2456-2471. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号