化工学报 ›› 2023, Vol. 74 ›› Issue (7): 2957-2966.DOI: 10.11949/0438-1157.20230363

收稿日期:2023-04-12

修回日期:2023-07-12

出版日期:2023-07-05

发布日期:2023-08-31

通讯作者:

卢春喜

作者简介:高金明(1995—),男,博士研究生,gjm114@126.com

基金资助:

Jinming GAO( ), Yujiao GUO, Chenglin E, Chunxi LU(

), Yujiao GUO, Chenglin E, Chunxi LU( )

)

Received:2023-04-12

Revised:2023-07-12

Online:2023-07-05

Published:2023-08-31

Contact:

Chunxi LU

摘要:

为了解决多旋臂气液旋流分离器(GLVS)中旋臂上方存在的小液滴夹带逃逸现象,设计了一种封闭罩内顺流多旋臂气液分离器(D-GLVS)。通过大型冷模实验,从压降和分离效率角度考察了其分离性能,实验结果表明,D-GLVS通过增加封闭罩,分隔了分离空间和排气空间,使排气压降占比较大,约为总压降的60%,但其阻力系数仍在常规旋风分离器的范围内;且其分离效率随气速增大,表现为先升高后降低的变化趋势,并在14.69 m/s附近达到最大值,同时发现偶数个喷嘴数对应进液质量的分离效率明显比奇数个喷嘴更高,这一结果在逆流式多旋臂气液分离器(B-GLVS)中同样得以证实。进一步对比了D-GLVS和B-GLVS间分离性能差异,结果表明封闭罩的引入可以极大地改善B-GLVS中小液滴被气流夹带逃逸的现象,使气液分离效率有明显提升,同时使D-GLVS分离效率随气速的变化规律与常规旋风分离器更为相似。在低气速下,二者的总压降几乎相同,当旋臂喷出口气速较大时,D-GLVS的总压降略大于B-GLVS,增幅均值约为5.04%。

中图分类号:

高金明, 郭玉娇, 鄂承林, 卢春喜. 一种封闭罩内顺流多旋臂气液分离器的分离特性研究[J]. 化工学报, 2023, 74(7): 2957-2966.

Jinming GAO, Yujiao GUO, Chenglin E, Chunxi LU. Study on the separation characteristics of a downstream gas-liquid vortex separator in a closed hood[J]. CIESC Journal, 2023, 74(7): 2957-2966.

| 参数 | B-GLVS | D-GLVS |

|---|---|---|

| 入口进料管内径Di /mm | 283 | 283 |

| 气相出口管内径Do1 /mm | 207 | 207 |

| 液相出口管内径Do2 /mm | 100 | 100 |

| 分离罐体内径D1 /mm | 800 | 800 |

| 分离罐体高度H1 /mm | 3000 | 3000 |

| 封闭罩内径D2 /mm | — | 500 |

| 封闭罩插入深度H2 /mm | — | 1800 |

| 沉降高度H3 /mm | 1000 | 1000 |

| 旋臂中心距气相出口管高度H4 /mm | 940 | 940 |

| 旋臂半径r/mm | 141.5 | 141.5 |

| 旋臂圆心与罐体中心间距B/mm | 95.5 | 95.5 |

| 旋臂喷出口高度L/mm | 192 | 192 |

表1 实验样机的主要结构参数

Table 1 Structural parameters of experimental prototypes

| 参数 | B-GLVS | D-GLVS |

|---|---|---|

| 入口进料管内径Di /mm | 283 | 283 |

| 气相出口管内径Do1 /mm | 207 | 207 |

| 液相出口管内径Do2 /mm | 100 | 100 |

| 分离罐体内径D1 /mm | 800 | 800 |

| 分离罐体高度H1 /mm | 3000 | 3000 |

| 封闭罩内径D2 /mm | — | 500 |

| 封闭罩插入深度H2 /mm | — | 1800 |

| 沉降高度H3 /mm | 1000 | 1000 |

| 旋臂中心距气相出口管高度H4 /mm | 940 | 940 |

| 旋臂半径r/mm | 141.5 | 141.5 |

| 旋臂圆心与罐体中心间距B/mm | 95.5 | 95.5 |

| 旋臂喷出口高度L/mm | 192 | 192 |

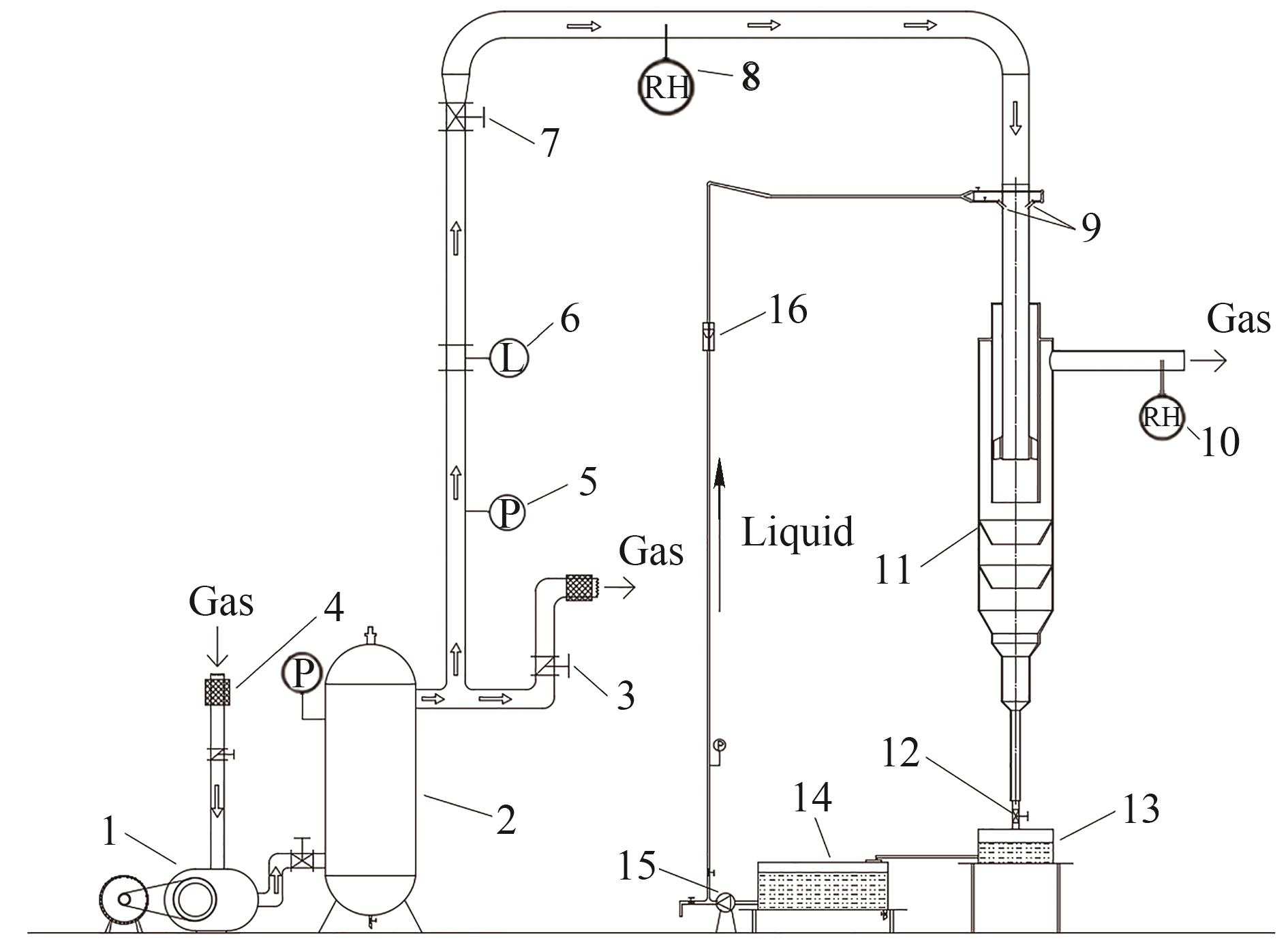

图3 实验流程1—鼓风机; 2—储气罐; 3—放空阀; 4—过滤网; 5—压力表; 6—涡街流量计; 7—调节阀; 8—入口温湿度计; 9—超声波喷嘴; 10—出口温湿度计; 11—D-GLVS/B-GLVS; 12—排液阀; 13—收集罐; 14—水箱; 15—水泵; 16—液体流量计

Fig.3 Schematic diagram of the experimental apparatus

| 实验物料 | 动力黏度(20℃)/ (mPa·s) | 密度(20℃)/ (kg/m3) | 粒径/μm |

|---|---|---|---|

| 空气 | 1 | 1.2 | — |

| 水 | 0.018 | 998 | 5.75~36.65 |

表2 实验物料参数

Table 2 Experimental material parameters

| 实验物料 | 动力黏度(20℃)/ (mPa·s) | 密度(20℃)/ (kg/m3) | 粒径/μm |

|---|---|---|---|

| 空气 | 1 | 1.2 | — |

| 水 | 0.018 | 998 | 5.75~36.65 |

| Qi/(m3/h) | Vi/(m/s) | Va/(m/s) |

|---|---|---|

| 1100 | 4.86 | 6.22 |

| 1400 | 6.18 | 7.91 |

| 1800 | 7.95 | 10.17 |

| 2200 | 9.72 | 12.43 |

| 2600 | 11.48 | 14.69 |

| 3000 | 13.25 | 16.95 |

| 3600 | 15.90 | 20.35 |

| 4000 | 17.66 | 22.61 |

表3 实验入口气量参数

Table 3 Experimental parameters of inlet gas volume

| Qi/(m3/h) | Vi/(m/s) | Va/(m/s) |

|---|---|---|

| 1100 | 4.86 | 6.22 |

| 1400 | 6.18 | 7.91 |

| 1800 | 7.95 | 10.17 |

| 2200 | 9.72 | 12.43 |

| 2600 | 11.48 | 14.69 |

| 3000 | 13.25 | 16.95 |

| 3600 | 15.90 | 20.35 |

| 4000 | 17.66 | 22.61 |

| 喷嘴数 | mi/(kg/h) |

|---|---|

| 3 | 55.56 |

| 4 | 74.62 |

| 5 | 92.50 |

| 6 | 111.38 |

| 7 | 127.34 |

| 8 | 146.69 |

表4 实验进液质量参数

Table 4 Experimental parameters of inlet liquid quality

| 喷嘴数 | mi/(kg/h) |

|---|---|

| 3 | 55.56 |

| 4 | 74.62 |

| 5 | 92.50 |

| 6 | 111.38 |

| 7 | 127.34 |

| 8 | 146.69 |

| Va/(m/s) | ΔP1/Pa | ΔP2/Pa | ΔP΄/Pa | ΔP/Pa | ε/% |

|---|---|---|---|---|---|

| 6.22 | 61.62 | 138.86 | 200.48 | 204.90 | 2.16 |

| 7.91 | 184.13 | 221.78 | 405.91 | 395.09 | 2.74 |

| 10.17 | 267.44 | 381.39 | 648.83 | 663.93 | 2.27 |

| 12.43 | 387.78 | 548.88 | 936.65 | 950.88 | 1.50 |

| 14.69 | 543.07 | 776.24 | 1319.31 | 1336.58 | 1.29 |

| 16.95 | 760.18 | 1038.44 | 1798.62 | 1812.12 | 0.74 |

| 20.35 | 1116.69 | 1493.18 | 2609.87 | 2611.84 | 0.08 |

| 22.61 | 1341.09 | 1794.74 | 3135.83 | 3146.80 | 0.35 |

表5 分段压降测量值

Table 5 Measured values of segmental pressure drop

| Va/(m/s) | ΔP1/Pa | ΔP2/Pa | ΔP΄/Pa | ΔP/Pa | ε/% |

|---|---|---|---|---|---|

| 6.22 | 61.62 | 138.86 | 200.48 | 204.90 | 2.16 |

| 7.91 | 184.13 | 221.78 | 405.91 | 395.09 | 2.74 |

| 10.17 | 267.44 | 381.39 | 648.83 | 663.93 | 2.27 |

| 12.43 | 387.78 | 548.88 | 936.65 | 950.88 | 1.50 |

| 14.69 | 543.07 | 776.24 | 1319.31 | 1336.58 | 1.29 |

| 16.95 | 760.18 | 1038.44 | 1798.62 | 1812.12 | 0.74 |

| 20.35 | 1116.69 | 1493.18 | 2609.87 | 2611.84 | 0.08 |

| 22.61 | 1341.09 | 1794.74 | 3135.83 | 3146.80 | 0.35 |

| 分段压降 | ξ | R2 |

|---|---|---|

| ΔP1 | 4.161 | 0.9976 |

| ΔP2 | 5.487 | 0.9994 |

| ΔP | 9.666 | 0.9993 |

表6 分段压降结果分析

Table 6 Analysis of the results of segmental pressure

| 分段压降 | ξ | R2 |

|---|---|---|

| ΔP1 | 4.161 | 0.9976 |

| ΔP2 | 5.487 | 0.9994 |

| ΔP | 9.666 | 0.9993 |

| 1 | 崔勍焱, 颜超, 张浩彬, 等. 不同天然矿物载体钼基催化剂悬浮床加氢裂化反应性能[J]. 石油学报(石油加工), 2022, 38(1): 29-36. |

| Cui Q Y, Yan C, Zhang H B, et al. Catalytic performance of molybdenum based catalysts supported on different natural minerals in slurry-phase hydrocracking[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2022, 38(1): 29-36. | |

| 2 | Ma L A, Shen Q S, Li J P, et al. Efficient gas-liquid cyclone device for recycled hydrogen in a hydrogenation unit[J]. Chemical Engineering & Technology, 2014, 37(6): 1072-1078. |

| 3 | 崔敏, 韩亚鹏, 杨腾飞, 等. 反应时间对重油悬浮床加氢裂化反应的影响[J]. 石油学报(石油加工), 2020, 36(4): 823-831. |

| Cui M, Han Y P, Yang T F, et al. Effect of reaction time on slurry-bed hydrocracking for heavy oils[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2020, 36(4): 823-831. | |

| 4 | Castañeda L C, Muñoz J A D, Ancheyta J. Current situation of emerging technologies for upgrading of heavy oils[J]. Catalysis Today, 2014, 220/221/222: 248-273. |

| 5 | 张庆军, 刘文洁, 王鑫, 等. 国外渣油加氢技术研究进展[J]. 化工进展, 2015, 34(8): 2988-3002. |

| Zhang Q J, Liu W J, Wang X, et al. Research progress in hydroprocessing technology for imported residuum[J]. Chemical Industry and Engineering Progress, 2015, 34(8): 2988-3002. | |

| 6 | 王祖纲, 李颖. 加氢裂化技术发展现状及展望[J]. 世界石油工业, 2020, 27(4): 12-21. |

| Wang Z G, Li Y. Development and prospect of hydrocracking technology[J]. World Petroleum Industry, 2020, 27(4): 12-21. | |

| 7 | 王紫玉. 重质油悬浮床加氢工艺研究[J]. 石化技术, 2020, 27(6): 62-63. |

| Wang Z Y. Study on the hydrogenation process of heavy oil in suspension bed[J]. Petrochemical Industry Technology, 2020, 27(6): 62-63. | |

| 8 | 薄守石, 王剑, 白飞, 等. 2种重油悬浮床加氢反应器流体力学特性的比较[J]. 石油学报(石油加工), 2015, 31(6): 1408-1415. |

| Bo S S, Wang J, Bai F, et al. Comparison of hydrodynamic characteristics in two heavy oil slurry bed hydrocracking reactors[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2015, 31(6): 1408-1415. | |

| 9 | Lim S H, Kwon E H, Go K S, et al. Estimation of the gas hold up and flow regime of a bubble column reactor for the slurry phase hydrocracking of heavy oil[J]. Fuel, 2023, 338: 127190. |

| 10 | 黄锟腾, 陈健勇, 陈颖, 等. 气液分离技术的研究现状[J]. 化工学报, 2021, 72(S1): 30-41. |

| Huang K T, Chen J Y, Chen Y, et al. Research status of vapor-liquid separation technology[J]. CIESC Journal, 2021, 72(S1): 30-41. | |

| 11 | 蔡禄, 孙治谦, 朱丽云, 等. 气液旋流分离技术应用研究进展[J]. 石油机械, 2021, 49(1): 102-109. |

| Cai L, Sun Z Q, Zhu L Y, et al. Application and research progress of gas-liquid cyclone separation technology[J]. China Petroleum Machinery, 2021, 49(1): 102-109. | |

| 12 | Wang G, Yan C Q, Fan G M, et al. Experimental study on a swirl-vane separator for gas-liquid separation[J]. Chemical Engineering Research and Design, 2019, 151: 108-119. |

| 13 | Liu L, Ying B B, Gu H Y, et al. Experimental study on the separation performance of a full-scale SG steam-water separator[J]. Annals of Nuclear Energy, 2020, 141: 107330. |

| 14 | Babaoğlu N U, Parvaz F, Hosseini S H, et al. Influence of the inlet cross-sectional shape on the performance of a multi-inlet gas cyclone[J]. Powder Technology, 2021, 384: 82-99. |

| 15 | Kolla S S, Mohan R S, Shoham O. Swirling flow regimes and gas carry-under in gas-liquid cylindrical cyclone separator in a separated outlet configuration[J]. Journal of Energy Resources Technology, 2021, 143(4): 042304. |

| 16 | Yang Z M, Wang J, Zhang J J, et al. A statistical method for flow pattern and efficiency prediction using pressure drop in a two-stage gas liquid cylindrical cyclone[J]. Journal of Natural Gas Science and Engineering, 2022, 99: 104414. |

| 17 | Wang J R, Ji Z L, Liu Z. Experimental and numerical investigation on the gas-liquid separation performance of a novel vane separator with grooves[J]. Chemical Engineering Research and Design, 2022, 180: 306-317. |

| 18 | Sun Y, Zhu X Q, Huang W Q, et al. Simulation and experimental investigation on gas-liquid two-phase flow separation behaviors in multitube T-junction separator[J]. Flow Measurement and Instrumentation, 2022, 85: 102166. |

| 19 | Anderson K, Zhang X A, Abbasi B. A method to design and optimize axial flow cyclones for gas-liquid separation[J]. Journal of Fluids Engineering, 2021, 143(9): 091402. |

| 20 | Wang Y A, Chen J Y, Yang Y, et al. Experimental and numerical performance study of a downward dual-inlet gas-liquid cylindrical cyclone (GLCC)[J]. Chemical Engineering Science, 2021, 238: 116595. |

| 21 | 卢春喜, 魏耀东, 时铭显. 提升管气固旋流组合快分设备: 1511627A[P]. 2005-11-23. |

| Lu C X, Wei Y D, Shi M X. Gas-solid cyclone combination fast separation device for lifting pipe: 1511627A[P]. 2005-11-23. | |

| 22 | 孙凤侠, 卢春喜, 时铭显. 旋流快分器内气相流场的实验与数值模拟研究[J]. 石油大学学报(自然科学版), 2005, 29(3): 106-111. |

| Sun F X, Lu C X, Shi M X. Experiment and numerical simulation of gas flow field in new vortex quick separation system[J]. Journal of the University of Petroleum, China, 2005, 29(3): 106-111. | |

| 23 | Liu F, Chen J Y, Zhang A Q, et al. Performance and flow behavior of four identical parallel cyclones[J]. Separation and Purification Technology, 2014, 134: 147-157. |

| 24 | Yang S L, Wang S, Luo K, et al. Numerical investigation of the back-mixing and non-uniform characteristics in the three-dimensional full-loop circulating fluidized bed combustor with six parallel cyclones[J]. Applied Thermal Engineering, 2019, 153: 524-535. |

| 25 | 周闻, 王康松, 鄂承林, 等. 多旋臂气液旋流分离器压降特性试验[J]. 化工学报, 2019, 70(7): 2564-2573. |

| Zhou W, Wang K S, E C L, et al. Multi-spiral gas-liquid vortex separator pressure drop characteristics test[J]. CIESC Journal, 2019, 70(7): 2564-2573. | |

| 26 | 周闻, 鄂承林, 李永祺, 等. 新型多旋臂气液分离器入口旋流头的预分离特性研究[J]. 化工学报, 2021, 72(9): 4775-4785. |

| Zhou W, E C L, Li Y Q, et al. Study on pre-separation characteristics of inlet vortex head in novel gas-liquid vortex separator[J]. CIESC Journal, 2021, 72(9): 4775-4785. | |

| 27 | Wei P K, Wang D, Niu P M, et al. A novel centrifugal gas liquid pipe separator for high velocity wet gas separation[J]. International Journal of Multiphase Flow, 2020, 124: 103190. |

| 28 | 卢春喜, 徐文清, 魏耀东, 等. 新型紧凑式催化裂化沉降系统的实验研究[J]. 石油学报(石油加工), 2007, 23(6): 6-12. |

| Lu C X, Xu W Q, Wei Y D, et al. Experimental studies of a novel compact FCC disengager[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2007, 23(6): 6-12. | |

| 29 | 胡艳华, 卢春喜, 时铭显. 催化裂化提升管出口紧凑式旋流快分系统[J]. 石油学报(石油加工), 2009, 25(1): 20-25. |

| Hu Y H, Lu C X, Shi M X. Optimal structure of compact vortex quick separator at FCC riser outlet[J]. Acta Petrolei Sinica (Petroleum Processing Section), 2009, 25(1): 20-25. | |

| 30 | Mikheev N, Saushin I, Goltsman A, et al. Data of numerical simulation and experimental research on the design of a cyclone separator with a high flux density[J]. Data in Brief, 2018, 20: 1836-1843. |

| 31 | Mikheev N, Saushin I, Paereliy A, et al. Cyclone separator for gas-liquid mixture with high flux density[J]. Powder Technology, 2018, 339: 326-333. |

| 32 | Wang L Z, Hu T, Xue G, et al. Experimental study on the entrainment of the liquid film in the annular channel of the vortex separator[J]. Annals of Nuclear Energy, 2022, 179: 109428. |

| 33 | 白翔宇, 王建军, 杜明生, 等. 气液逆流接触过程及液滴夹带特性[J]. 高校化学工程学报, 2019, 33(6): 1344-1353. |

| Bai X Y, Wang J J, Du M S, et al. Characteristics of gas-liquid countercurrent contact processes and droplet entrainment[J]. Journal of Chemical Engineering of Chinese Universities, 2019, 33(6): 1344-1353. | |

| 34 | 戚贵强, 王立新. 多效旋风分离器压降的实验研究[J]. 中国粉体技术, 2010, 16(5): 69-71. |

| Qi G Q, Wang L X. Experimental study of pressure drop for multi-effect cyclone separator[J]. China Powder Science and Technology, 2010, 16(5): 69-71. | |

| 35 | Zhou W, E C L, Li Z X, et al. Separation characteristics in a novel gas-liquid vortex separator[J]. Industrial & Engineering Chemistry Research, 2020, 59(40): 18115-18125. |

| 36 | Yang J X, Sun G G, Zhan M S. Prediction of the maximum-efficiency inlet velocity in cyclones[J]. Powder Technology, 2015, 286: 124-131. |

| [1] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [2] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [3] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [4] | 高燕, 伍鹏, 尚超, 胡泽君, 陈晓东. 基于双流体喷嘴的磁性琼脂糖微球的制备及其蛋白吸附性能探究[J]. 化工学报, 2023, 74(8): 3457-3471. |

| [5] | 江锦波, 彭新, 许文烜, 门日秀, 刘畅, 彭旭东. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| [6] | 刘起超, 周云龙, 陈聪. 起伏振动垂直上升管气液两相流截面含气率分析与计算[J]. 化工学报, 2023, 74(6): 2391-2403. |

| [7] | 董鑫, 单永瑞, 刘易诺, 冯颖, 张建伟. 非牛顿流体气泡羽流涡特性数值模拟研究[J]. 化工学报, 2023, 74(5): 1950-1964. |

| [8] | 许文烜, 江锦波, 彭新, 门日秀, 刘畅, 彭旭东. 宽速域三种典型型槽油气密封泄漏与成膜特性对比研究[J]. 化工学报, 2023, 74(4): 1660-1679. |

| [9] | 白剑钊, 郭子轩, 王德武, 刘燕, 王若瑾, 唐猛, 张少峰. 摇摆对气液并流模式立体旋流筛板压降的影响研究[J]. 化工学报, 2023, 74(2): 707-720. |

| [10] | 何万媛, 陈一宇, 朱春英, 付涛涛, 高习群, 马友光. 阵列凸起微通道内气液两相传质特性研究[J]. 化工学报, 2023, 74(2): 690-697. |

| [11] | 盛林, 昌宇, 邓建, 骆广生. 阶梯式T型微通道内有序气泡群的形成和流动特性研究[J]. 化工学报, 2023, 74(1): 416-427. |

| [12] | 张童, 杨扬, 叶丁丁, 陈蓉, 朱恂, 廖强. 催化剂分布对可渗透阳极微流体燃料电池性能特性影响的研究[J]. 化工学报, 2022, 73(9): 4156-4162. |

| [13] | 苏巧玲, 王军锋, 张伟, 詹水清, 吴天一. 低电导率工质中气泡的极化运动实验研究[J]. 化工学报, 2022, 73(9): 3861-3869. |

| [14] | 禹言芳, 刘桓辰, 孟辉波, 刘励图, 李毓, 吴剑华. Lightnin静态混合器内气泡分散流体动力学特性实验研究[J]. 化工学报, 2022, 73(8): 3565-3575. |

| [15] | 李亚飞, 邓建强, 何阳. 跨临界CO2快速膨胀过程中非平衡冷凝和闪蒸机理的数值研究[J]. 化工学报, 2022, 73(7): 2912-2923. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号