化工学报 ›› 2023, Vol. 74 ›› Issue (8): 3292-3308.DOI: 10.11949/0438-1157.20230465

岳林静1( ), 廖艺涵2, 薛源1, 李雪洁1, 李玉星1, 刘翠伟1(

), 廖艺涵2, 薛源1, 李雪洁1, 李玉星1, 刘翠伟1( )

)

收稿日期:2023-05-12

修回日期:2023-08-12

出版日期:2023-08-25

发布日期:2023-10-18

通讯作者:

刘翠伟

作者简介:岳林静(1999—),女,硕士研究生,yuelinj@163.com

基金资助:

Linjing YUE1( ), Yihan LIAO2, Yuan XUE1, Xuejie LI1, Yuxing LI1, Cuiwei LIU1(

), Yihan LIAO2, Yuan XUE1, Xuejie LI1, Yuxing LI1, Cuiwei LIU1( )

)

Received:2023-05-12

Revised:2023-08-12

Online:2023-08-25

Published:2023-10-18

Contact:

Cuiwei LIU

摘要:

管道系统中的各类阀门、孔板等节流件,随系统工作前后压差的增大会出现水力空化现象,对系统的工作性能和安全造成严重影响。通过数值模拟探究了厚孔板空化的临界压比以及凹坑对孔板空化临界压比的影响,并进一步研究了凹坑与空化耦合作用下的空化流动特性,阐明了凹坑作用下的空泡溃灭机理。结果表明,只有当孔板出口压力与入口压力之比小于0.5时,才会发生空化。凹坑有促进空化气泡初生-发展-溃灭演变行为的作用,但压比在空化临界压比附近时,孔板各点压力峰值出现在无凹坑孔板以及存在凹坑缺陷孔板的无凹坑一侧。在液体管道和阀门的安全设计中,应考虑空化临界压比下气蚀的风险以及凹坑缺陷受空化剥蚀导致管壁减薄的危害。

中图分类号:

岳林静, 廖艺涵, 薛源, 李雪洁, 李玉星, 刘翠伟. 凹坑缺陷对厚孔板喉部空化流动特性影响研究[J]. 化工学报, 2023, 74(8): 3292-3308.

Linjing YUE, Yihan LIAO, Yuan XUE, Xuejie LI, Yuxing LI, Cuiwei LIU. Study on influence of pit defects on cavitation flow characteristics of throat of thick orifice plates[J]. CIESC Journal, 2023, 74(8): 3292-3308.

| 序号 | P1/psi | P2/psi | ΔP/psi | P2/P1 |

|---|---|---|---|---|

| 1 | 2000 | 1000 | 1000 | 0.50 |

| 2 | 5000 | 2500 | 2500 | 0.50 |

| 3 | 5000 | 2050 | 2950 | 0.41 |

| 4 | 5000 | 1100 | 3900 | 0.22 |

| 5 | 5000 | 500 | 4500 | 0.10 |

| 6 | 5000 | 3750 | 1250 | 0.75 |

| 7 | 5000 | 2800 | 2200 | 0.56 |

| 8 | 5000 | 2500 | 2500 | 0.50 |

| 9 | 5000 | 2050 | 2950 | 0.41 |

| 10 | 5000 | 1100 | 3900 | 0.22 |

| 11 | 5000 | 500 | 4500 | 0.10 |

表1 无凹坑孔板及含凹坑缺陷孔板模拟工况

Table 1 Simulation conditions of an orifice plate with or without pits

| 序号 | P1/psi | P2/psi | ΔP/psi | P2/P1 |

|---|---|---|---|---|

| 1 | 2000 | 1000 | 1000 | 0.50 |

| 2 | 5000 | 2500 | 2500 | 0.50 |

| 3 | 5000 | 2050 | 2950 | 0.41 |

| 4 | 5000 | 1100 | 3900 | 0.22 |

| 5 | 5000 | 500 | 4500 | 0.10 |

| 6 | 5000 | 3750 | 1250 | 0.75 |

| 7 | 5000 | 2800 | 2200 | 0.56 |

| 8 | 5000 | 2500 | 2500 | 0.50 |

| 9 | 5000 | 2050 | 2950 | 0.41 |

| 10 | 5000 | 1100 | 3900 | 0.22 |

| 11 | 5000 | 500 | 4500 | 0.10 |

| P1/psi | P2/psi | ΔP/psi | P2/P1 | Q/gpm | Qs/gpm | Error/% |

|---|---|---|---|---|---|---|

| 4993 | 345 | 4648 | 0.07 | 77 | 82.7 | 7.40 |

| 5003 | 506 | 4497 | 0.10 | 77.1 | 82.8 | 7.39 |

| 5000 | 1101 | 3899 | 0.22 | 77.1 | 82.7 | 7.26 |

| 5004 | 2052 | 2952 | 0.41 | 77 | 80.0 | 3.90 |

| 5006 | 2502 | 2504 | 0.50 | 75.2 | 73.8 | 1.86 |

| 5005 | 2813 | 2192 | 0.56 | 70.7 | 70.0 | 0.99 |

| 5006 | 3738 | 1268 | 0.75 | 54.2 | 52.5 | 3.14 |

表2 文献[24]中关于高压水流通过孔板的实验数据和本文所建模型模拟的数据

Table 2 Experimental data of high-pressure water flow through orifice in Ref. [24] and data simulated by the model built in this paper

| P1/psi | P2/psi | ΔP/psi | P2/P1 | Q/gpm | Qs/gpm | Error/% |

|---|---|---|---|---|---|---|

| 4993 | 345 | 4648 | 0.07 | 77 | 82.7 | 7.40 |

| 5003 | 506 | 4497 | 0.10 | 77.1 | 82.8 | 7.39 |

| 5000 | 1101 | 3899 | 0.22 | 77.1 | 82.7 | 7.26 |

| 5004 | 2052 | 2952 | 0.41 | 77 | 80.0 | 3.90 |

| 5006 | 2502 | 2504 | 0.50 | 75.2 | 73.8 | 1.86 |

| 5005 | 2813 | 2192 | 0.56 | 70.7 | 70.0 | 0.99 |

| 5006 | 3738 | 1268 | 0.75 | 54.2 | 52.5 | 3.14 |

图5 上游压力为5000 psi时孔板内静压和液相体积分数的分布

Fig.5 Distribution of hydrostatic pressure and liquid volume fraction in an orifice plate at upstream pressure of 5000 psi

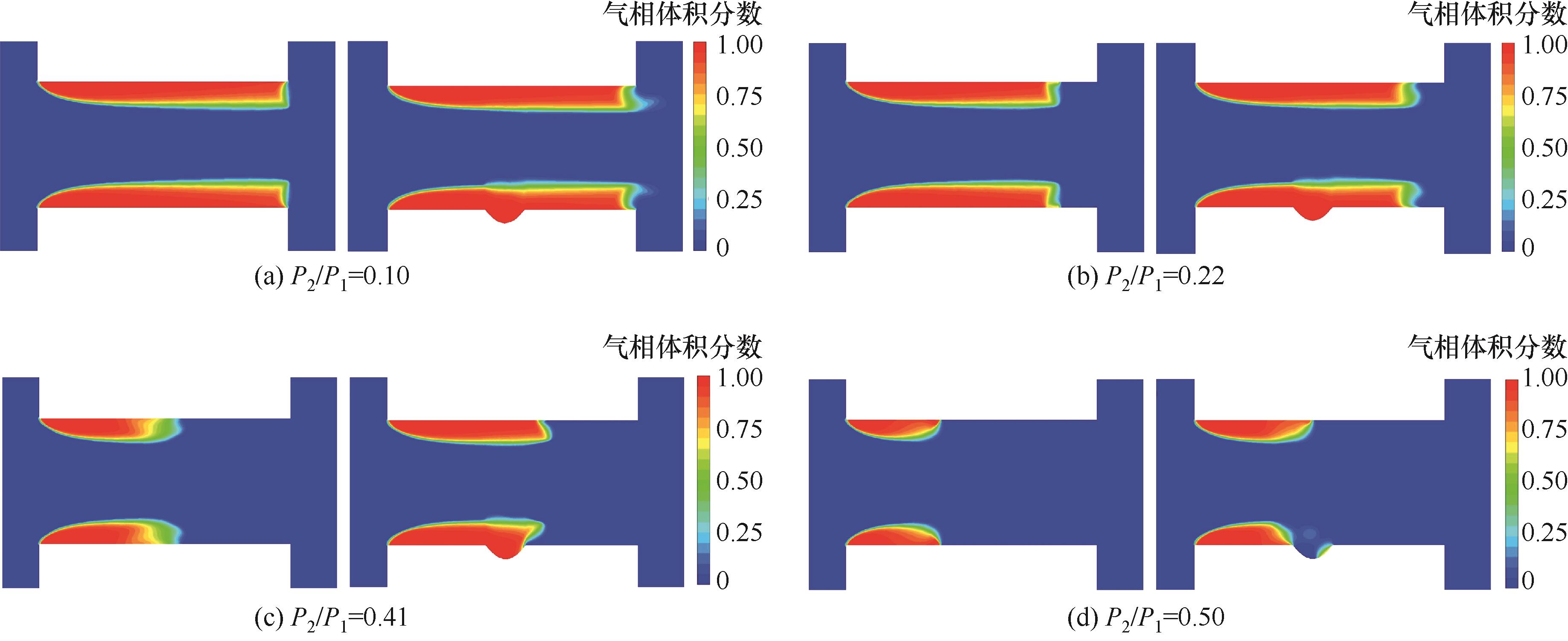

图7 入口压力5000 psi时不同压比工况下有无凹坑孔板的稳态模拟相图

Fig.7 Steady-state simulation phase diagram of an orifice plate with or without pits under different pressure ratios at 5000 psi inlet pressure

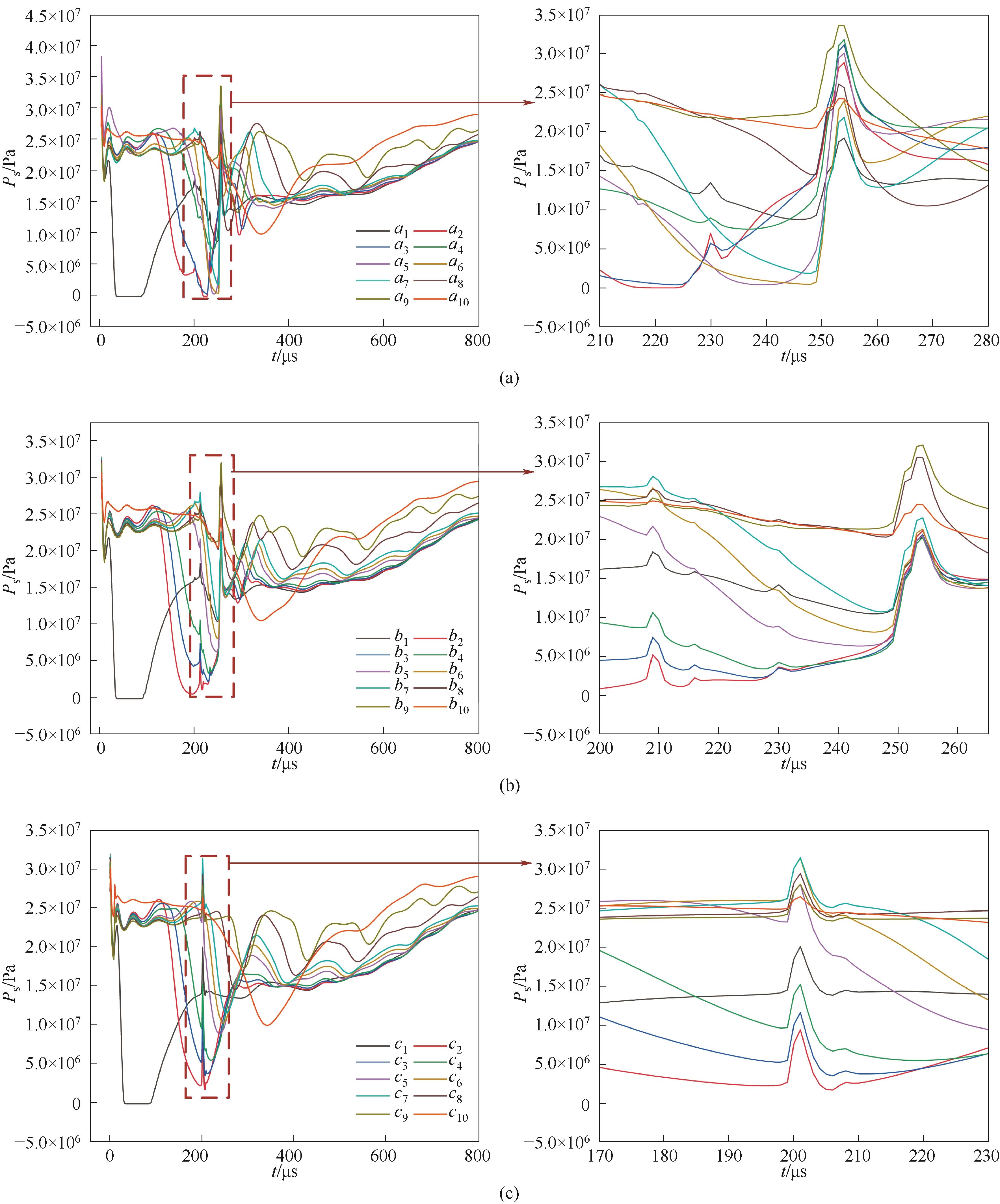

图13 压比为0.75时瞬态模拟下有凹坑孔板和无凹坑孔板各监测点的压力曲线

Fig.13 Pressure curves of monitoring points of an orifice plate with or without pits under transient simulation at a pressure ratio of 0.75

图14 压比为0.50时瞬态模拟下有凹坑孔板和无凹坑孔板各监测点的压力曲线

Fig.14 Pressure curves of monitoring points of an orifice plate with or without pits under transient simulation at a pressure ratio of 0.50

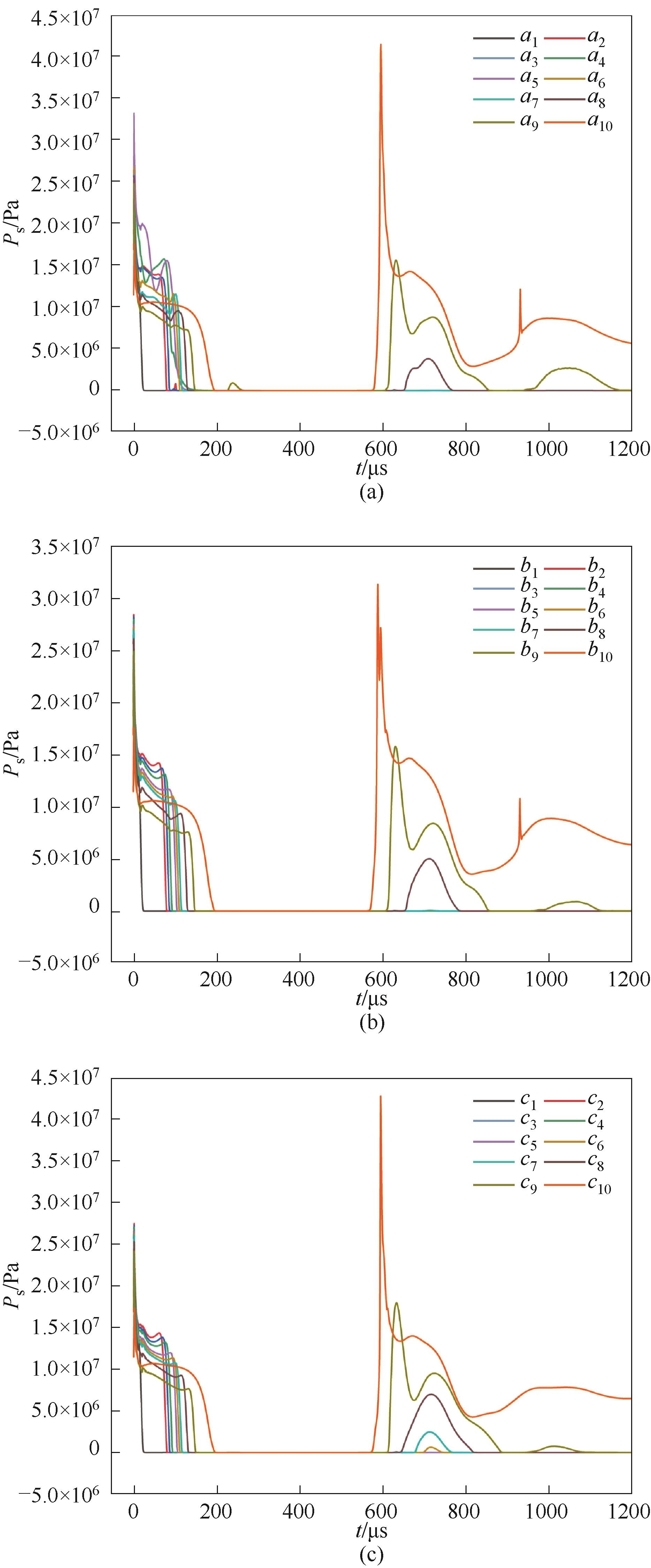

图16 压比为0.22时瞬态模拟下有凹坑孔板和无凹坑孔板各监测点的压力曲线

Fig.16 Pressure curves of monitoring points of an orifice plate with or without pits under transient simulation at a pressure ratio of 0.22

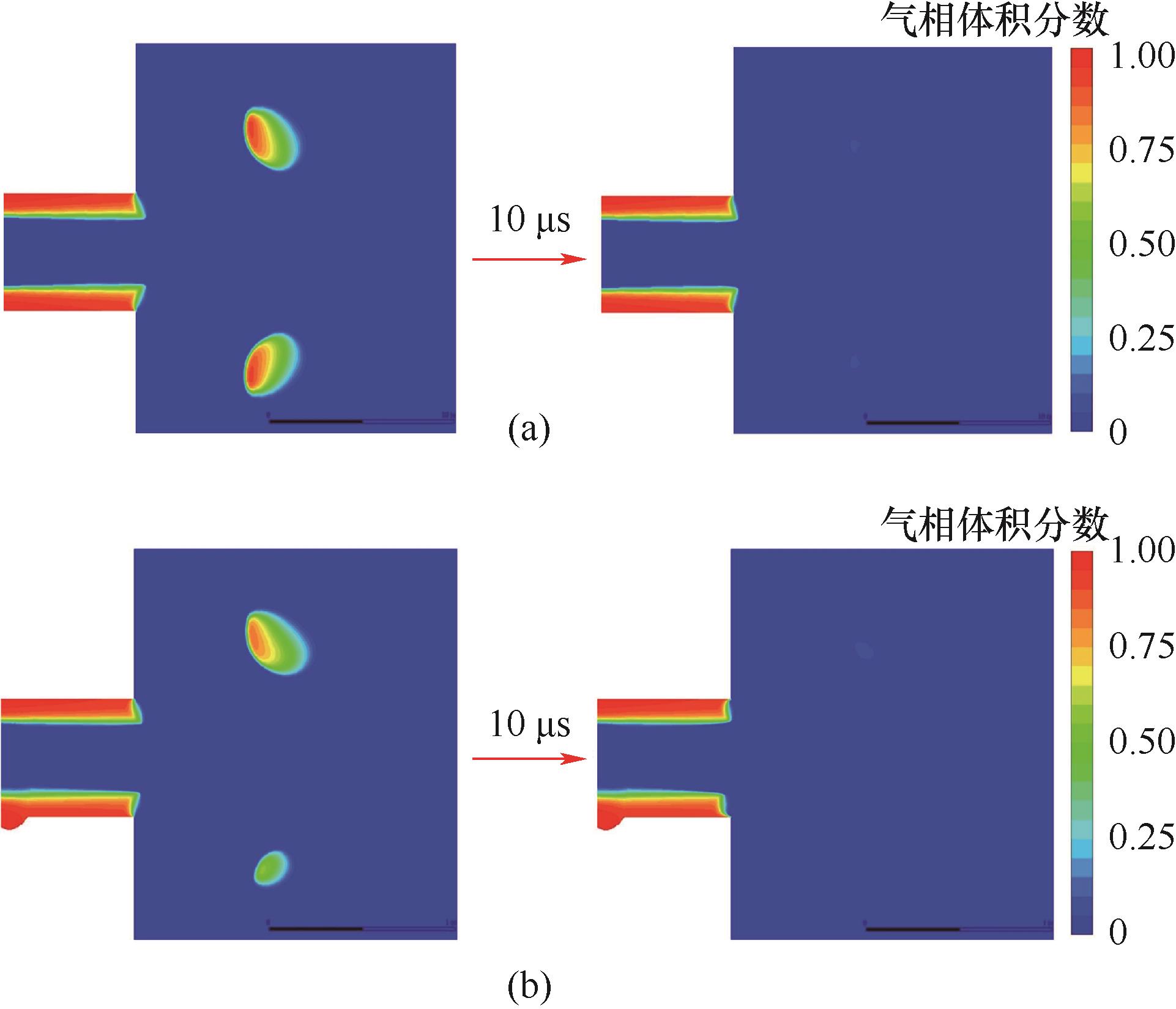

图17 压比为0.22时监测点压力波动幅值时刻前后相图

Fig.17 Phase diagram before and after the pressure fluctuation amplitude of the monitoring point at a pressure ratio of 0.22

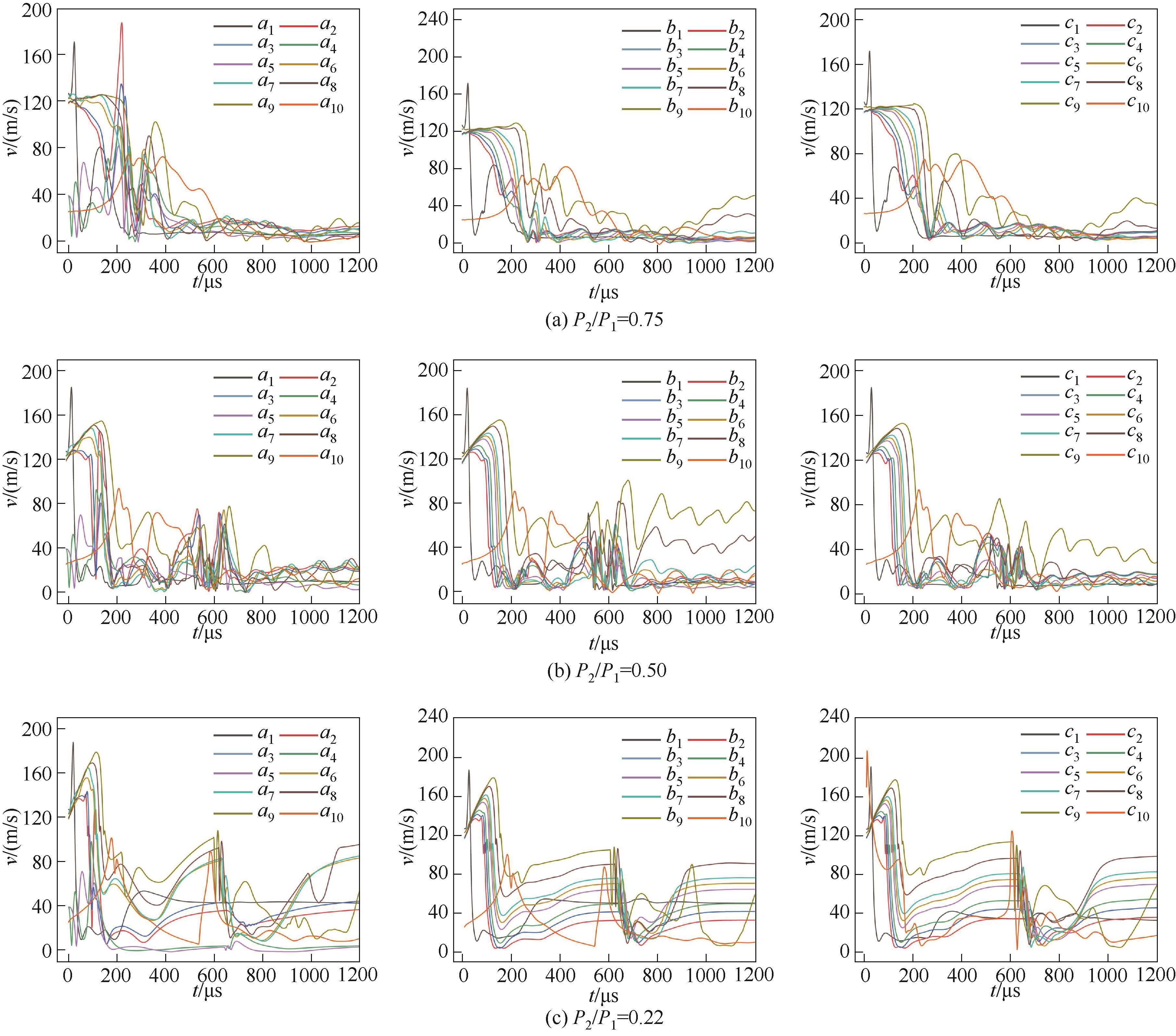

图18 压比为0.75、0.50、0.22时瞬态模拟下有凹坑孔板和无凹坑孔板各监测点的速度曲线

Fig.18 Velocity curves of monitoring points of an orifice plate with or without pits under transient simulation at pressure ratios of 0.75, 0.50 and 0.22

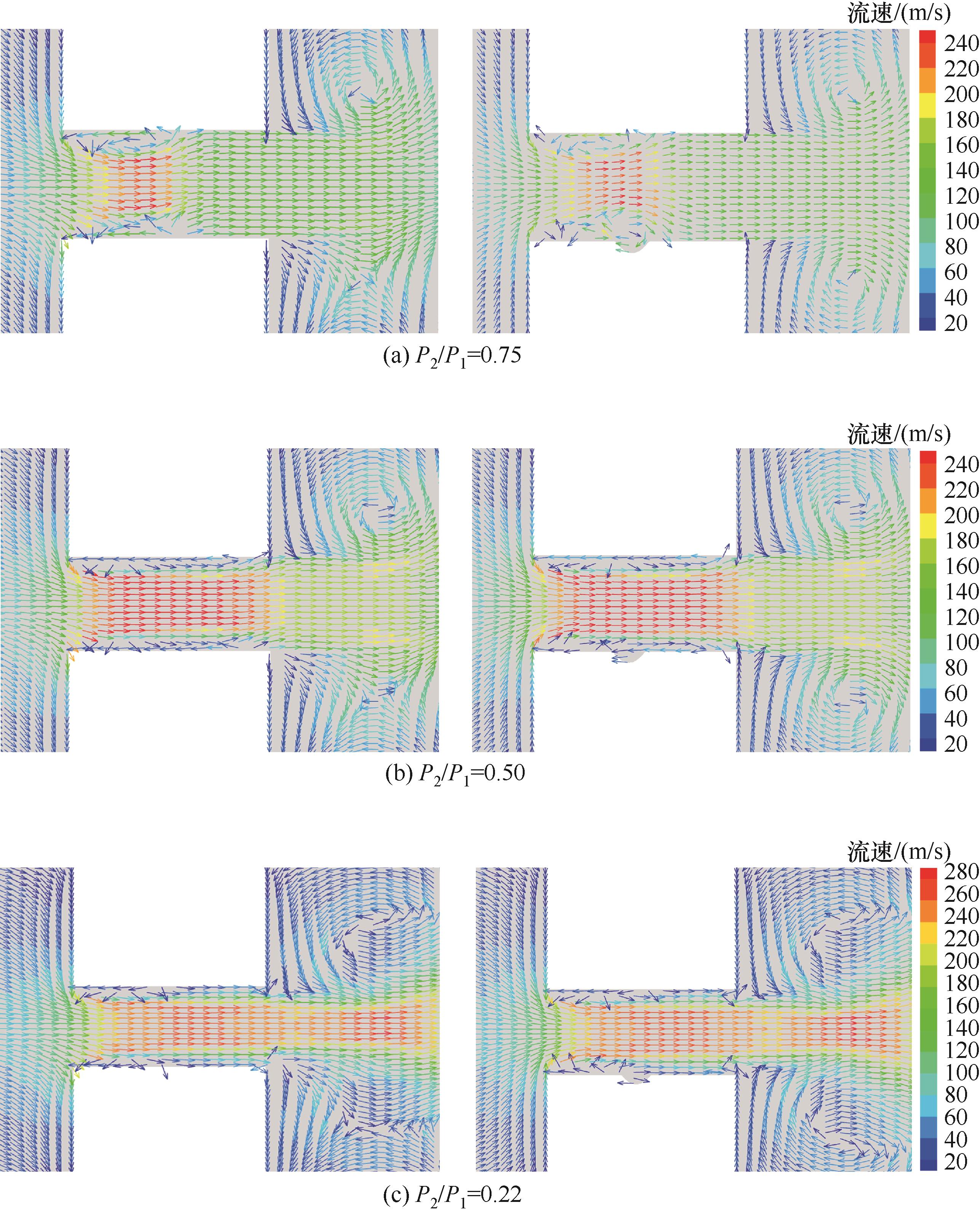

图19 压比为0.75、0.50、0.22工况下t=230 μs时有凹坑孔板和无凹坑孔板速度矢量图

Fig.19 Velocity vectors of an orifice plate with or without pits at t=230 μs for pressure ratios of 0.75, 0.50 and 0.22

| 1 | Dular M, Griessler-Bulc T, Gutierrez-Aguirre I, et al. Use of hydrodynamic cavitation in (waste) water treatment[J]. Ultrasonics Sonochemistry, 2016, 29: 577-588. |

| 2 | Bethi B, Sonawane S H, Potoroko I, et al. Novel hybrid system based on hydrodynamic cavitation for treatment of dye waste water: a first report on bench scale study[J]. Journal of Environmental Chemical Engineering, 2017, 5(2): 1874-1884. |

| 3 | Divekar P, Bondre A, Bhoir N, et al. Experimental investigation of hydrodynamic cavitation of single and multiple hole orifice for wastewater treatment[J]. Materials Today: Proceedings, 2023, 72: 1841-1846. |

| 4 | Lanfranchi A, Tassinato G, Valentino F, et al. Hydrodynamic cavitation pre-treatment of urban waste: integration with acidogenic fermentation, PHAs synthesis and anaerobic digestion processes[J]. Chemosphere, 2022, 301: 134624. |

| 5 | Mazzocchi E, Pachoud A J, Farhat M, et al. Signal analysis of an actively generated cavitation bubble in pressurized pipes for detection of wall stiffness drops[J]. Journal of Fluids and Structures, 2016, 65: 60-75. |

| 6 | 许健. 多相流阀门及相连管道空化/空蚀特性及预测方法研究[D]. 杭州: 浙江理工大学, 2017. |

| Xu J. Study on cavitation/cavitation characteristics and prediction method of multiphase flow valves and connected pipelines[D]. Hangzhou: Zhejiang Sci-Tech University, 2017. | |

| 7 | Zhang Q L, Hu Y G, Liu M S, et al. Role of negative pressure in structural responses of gravity dams to underwater explosion loadings: the need to consider local cavitation[J]. Engineering Failure Analysis, 2021, 122: 105270. |

| 8 | Yin J Y, Zhang Y X, Zhu J J, et al. An experimental and numerical study on the dynamical behaviors of the rebound cavitation bubble near the solid wall[J]. International Journal of Heat and Mass Transfer, 2021, 177: 121525. |

| 9 | Yang Y, Shan M L, Su N N, et al. Role of wall temperature on cavitation bubble collapse near a wall investigated using thermal lattice Boltzmann method[J]. International Communications in Heat and Mass Transfer, 2022, 134: 105988. |

| 10 | Li S, Zuo Z G, Li S C. Stochastic study of cavitation bubbles near boundary wall[J]. Journal of Hydrodynamics, Ser. B, 2006, 18(3): 487-491. |

| 11 | Rayleigh L. Ⅷ. On the pressure developed in a liquid during the collapse of a spherical cavity[J]. The London, Edinburgh, and Dublin Philosophical Magazine and Journal of Science, 1917, 34(200): 94-98. |

| 12 | Plesset M S. The dynamics of cavitation bubbles[J]. Journal of Applied Mechanics, 1949, 16(3): 277-282. |

| 13 | Noltingk B E, Neppiras E A. Cavitation produced by ultrasonics[J]. Proceedings of the Physical Society Section B, 1950, 63(9): 674-685. |

| 14 | Washio S, Kikui S, Takahashi S. Nucleation and subsequent cavitation in a hydraulic oil poppet valve[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2010, 224(4): 947-958. |

| 15 | Washio S, Takahashi S, Yoshimori S. Study on cavitation starting at the point of separation on a smooth wall in hydraulic oil flow[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2003, 217(6): 619-630. |

| 16 | Washio S, Takahashi S, Uemura K, et al. Singular properties of flow separation as a real cause of cavitation inception[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2008, 222(4): 667-678. |

| 17 | Liang J, Luo X H, Liu Y S, et al. A numerical investigation in effects of inlet pressure fluctuations on the flow and cavitation characteristics inside water hydraulic poppet valves[J]. International Journal of Heat and Mass Transfer, 2016, 103: 684-700. |

| 18 | Le Q, Franc J P, Michel J M. Partial cavities: pressure pulse distribution around cavity closure[J]. Journal of Fluids Engineering, 1993, 115(2): 249-254. |

| 19 | McKenney E A, Brennen C E. On the dynamics and acoustics of cloud cavitation on an oscillating hydrofoil[C]//Proceedings of 19th Symposium on Naval Hydrodynamics.Washington D C: National Academy Press, 1994: 195-202. |

| 20 | Reisman G E, Wang Y C, Brennen C E. Observations of shock waves in cloud cavitation[J]. Journal of Fluid Mechanics, 1998, 355: 255-283. |

| 21 | Leroux J B, Coutier-Delgosha O, Astolfi J A. A joint experimental and numerical study of mechanisms associated to instability of partial cavitation on two-dimensional hydrofoil[J]. Physics of Fluids, 2005, 17(5): 052101-052120. |

| 22 | 陈广豪. 附着型非定常空化流体动力特性与机理研究[D]. 北京: 北京理工大学, 2016. |

| Chen G H. Study on hydrodynamic characteristics and mechanism of attached unsteady cavitation[D]. Beijing: Beijing Institute of Technology, 2016. | |

| 23 | 陈广豪, 王国玉, 黄彪. 云状空化的非定常流体动力特性[J]. 船舶力学, 2016, 20(1/2): 1-9. |

| Chen G H, Wang G Y, Huang B. Unsteady hydrodynamics of cloud cavitating flows in a convergent-divergent channel[J]. Journal of Ship Mechanics, 2016, 20(1/2): 1-9. | |

| 24 | Ebrahimi B, He G L, Tang Y J, et al. Characterization of high-pressure cavitating flow through a thick orifice plate in a pipe of constant cross section[J]. International Journal of Thermal Sciences, 2017, 114: 229-240. |

| 25 | 俞轲鑫, 尚群立, 吴欣. 节流孔板空化特性分析[J]. 中国机械工程, 2021, 32(3): 290-296. |

| Yu K X, Shang Q L, Wu X. Analysis of cavitation characteristics for orifice plates[J]. China Mechanical Engineering, 2021, 32(3): 290-296. | |

| 26 | 陈艳宇, 尚群立, 吴欣, 等. 节流孔板非线性空化特征实验研究[J]. 高技术通讯, 2022, 32(6): 632-639. |

| Chen Y Y, Shang Q L, Wu X, et al. Research on nonlinear cavitation of orifice plate blocked flow[J]. Chinese High Technology Letters, 2022, 32(6): 632-639. | |

| 27 | Jin Z J, Gao Z X, Li X J, et al. Cavitating flow through a micro-orifice[J]. Micromachines, 2019, 10(3): 191. |

| 28 | 赵志伟. 基于纯水介质的孔板空化数值模拟及实验研究[D]. 哈尔滨: 哈尔滨理工大学, 2022. |

| Zhao Z W. Numerical simulation and experimental study on cavitation of orifice plate based on pure water medium[D]. Harbin: Harbin University of Science and Technology, 2022. | |

| 29 | 侯进军. 孔板空化器内空化特性及效应研究[D]. 哈尔滨: 哈尔滨理工大学, 2021. |

| Hou J J. Study on cavitation characteristics and effect in orifice cavitation device[D]. Harbin: Harbin University of Science and Technology, 2021. | |

| 30 | 韩桂华, 洪健, 侯进军, 等. 孔板通道结构参数对空化效应的影响[J]. 哈尔滨理工大学学报, 2022, 27(1): 108-114. |

| Han G H, Hong J, Hou J J, et al. Influence of orifice channel structure parameters on cavitation effect[J]. Journal of Harbin University of Science and Technology, 2022, 27(1): 108-114. | |

| 31 | 韩桂华, 葛宁, 侯进军, 等. 孔板空化器内流体空化特性研究[J]. 哈尔滨理工大学学报, 2022, 27(3): 22-29. |

| Han G H, Ge N, Hou J J, et al. Cavitation characteristics of fluid in orifice cavitator[J]. Journal of Harbin University of Science and Technology, 2022, 27(3): 22-29. | |

| 32 | Zwart P J, Gerber A G, Belamri T. A two-phase flow model for predicting cavitation dynamics[C]//Fifth International Conference on Multiphase Flow. Yokohama, 2004. |

| 33 | Schnerr G H, Sauer J. Physical and numerical modeling of unsteady cavitation dynamics[C]//Fourth International Conference on Multiphase Flow. New Orleans, 2001. |

| 34 | Gogate P R. Cavitation: an auxiliary technique in wastewater treatment schemes[J]. Advances in Environmental Research, 2002, 6(3): 335-358. |

| 35 | Jyoti K K, Pandit A B. Water disinfection by acoustic and hydrodynamic cavitation[J]. Biochemical Engineering Journal, 2001, 7(3): 201-212. |

| [1] | 张思雨, 殷勇高, 贾鹏琦, 叶威. 双U型地埋管群跨季节蓄热特性研究[J]. 化工学报, 2023, 74(S1): 295-301. |

| [2] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [3] | 邵苛苛, 宋孟杰, 江正勇, 张旋, 张龙, 高润淼, 甄泽康. 水平方向上冰中受陷气泡形成和分布实验研究[J]. 化工学报, 2023, 74(S1): 161-164. |

| [4] | 温凯杰, 郭力, 夏诏杰, 陈建华. 一种耦合CFD与深度学习的气固快速模拟方法[J]. 化工学报, 2023, 74(9): 3775-3785. |

| [5] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [6] | 汪林正, 陆俞冰, 张睿智, 罗永浩. 基于分子动力学模拟的VOCs热氧化特性分析[J]. 化工学报, 2023, 74(8): 3242-3255. |

| [7] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [8] | 王海, 林宏, 王晨, 许浩洁, 左磊, 王军锋. 高压静电场强化多孔介质表面沸腾传热特性研究[J]. 化工学报, 2023, 74(7): 2869-2879. |

| [9] | 牛超, 沈胜强, 杨艳, 潘泊年, 李熠桥. 甲烷BOG喷射器流动过程计算与性能分析[J]. 化工学报, 2023, 74(7): 2858-2868. |

| [10] | 何晓崐, 刘锐, 薛园, 左然. MOCVD生长AlN单晶薄膜的气相和表面化学反应综述[J]. 化工学报, 2023, 74(7): 2800-2813. |

| [11] | 刘道银, 陈柄岐, 张祖扬, 吴琰. 颗粒聚团结构对曳力特性影响的数值模拟[J]. 化工学报, 2023, 74(6): 2351-2362. |

| [12] | 李晨曦, 刘永峰, 张璐, 刘海峰, 宋金瓯, 何旭. O2/CO2氛围下正庚烷的燃烧机理研究[J]. 化工学报, 2023, 74(5): 2157-2169. |

| [13] | 董鑫, 单永瑞, 刘易诺, 冯颖, 张建伟. 非牛顿流体气泡羽流涡特性数值模拟研究[J]. 化工学报, 2023, 74(5): 1950-1964. |

| [14] | 丁俊华, 俞树荣, 王世鹏, 洪先志, 包鑫, 丁雪兴. 多重效应下超高速干气密封流场模拟及密封性能试验[J]. 化工学报, 2023, 74(5): 2088-2099. |

| [15] | 李正涛, 袁志杰, 贺高红, 姜晓滨. 疏水界面上的NaCl液滴蒸发过程内环流调控机制研究[J]. 化工学报, 2023, 74(5): 1904-1913. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号