化工学报 ›› 2023, Vol. 74 ›› Issue (9): 3807-3820.DOI: 10.11949/0438-1157.20230696

袁佳琦1,2( ), 刘政2, 黄锐2, 张乐福2, 贺登辉1,2(

), 刘政2, 黄锐2, 张乐福2, 贺登辉1,2( )

)

收稿日期:2023-07-05

修回日期:2023-09-02

出版日期:2023-09-25

发布日期:2023-11-20

通讯作者:

贺登辉

作者简介:袁佳琦(2000—),男,硕士研究生,3186933771@qq.com

基金资助:

Jiaqi YUAN1,2( ), Zheng LIU2, Rui HUANG2, Lefu ZHANG2, Denghui HE1,2(

), Zheng LIU2, Rui HUANG2, Lefu ZHANG2, Denghui HE1,2( )

)

Received:2023-07-05

Revised:2023-09-02

Online:2023-09-25

Published:2023-11-20

Contact:

Denghui HE

摘要:

探究泡状入流条件下旋流泵流场演化机理和能量转换特性,对优化旋流泵结构和提升其气液混输性能具有重要意义。采用混合多相流模型与种群平衡模型进行耦合计算了旋流泵气液两相流场,结合能量梯度理论、熵产分析与流场演化规律,获得了泡状入流条件下旋流泵的能量转换特性。结果表明,循环流在无叶腔内呈涡带分布,其中涡室附近的循环流强度较高,涡带分布范围广且结构稳定,而无叶腔小半径处的循环流涡带强度较弱,仅存在于部分流道。随着入口体积含气率的增加,无叶腔内涡团面积逐渐增大,涡核数量有所增加。但当入口体积含气率增加到10%后,继续提高含气率,则循环流数量没有明显变化。在高入口体积含气率下,气相在后缩腔叶轮内聚集,使得后缩腔与无叶腔外缘能量梯度函数值增大,脉动熵产损失提高,流场更加紊乱,旋流泵效率与压差下降。

中图分类号:

袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820.

Jiaqi YUAN, Zheng LIU, Rui HUANG, Lefu ZHANG, Denghui HE. Investigation on energy conversion characteristics of vortex pump under bubble inflow[J]. CIESC Journal, 2023, 74(9): 3807-3820.

| 参数 | 数值 |

|---|---|

| 叶轮水力参数 | |

| 叶轮直径D2/mm | 220 |

| 叶轮出口宽度b2/mm | 50 |

| 叶片数Z/片 | 8 |

| 叶片厚度δ/mm | 2.5~16 |

| 后缩腔壁面与叶轮外径间隙e/mm | 10 |

| 无叶腔水力参数 | |

| 无叶腔宽度L/mm | 50 |

| 无叶腔基圆D3/mm | 240 |

| 出口直径d1/mm | 50 |

| 进口直径d2/mm | 65 |

| 扩散管高度h/mm | 250 |

表1 旋流泵主要结构参数

Table 1 Main structural parameters of vortex pump

| 参数 | 数值 |

|---|---|

| 叶轮水力参数 | |

| 叶轮直径D2/mm | 220 |

| 叶轮出口宽度b2/mm | 50 |

| 叶片数Z/片 | 8 |

| 叶片厚度δ/mm | 2.5~16 |

| 后缩腔壁面与叶轮外径间隙e/mm | 10 |

| 无叶腔水力参数 | |

| 无叶腔宽度L/mm | 50 |

| 无叶腔基圆D3/mm | 240 |

| 出口直径d1/mm | 50 |

| 进口直径d2/mm | 65 |

| 扩散管高度h/mm | 250 |

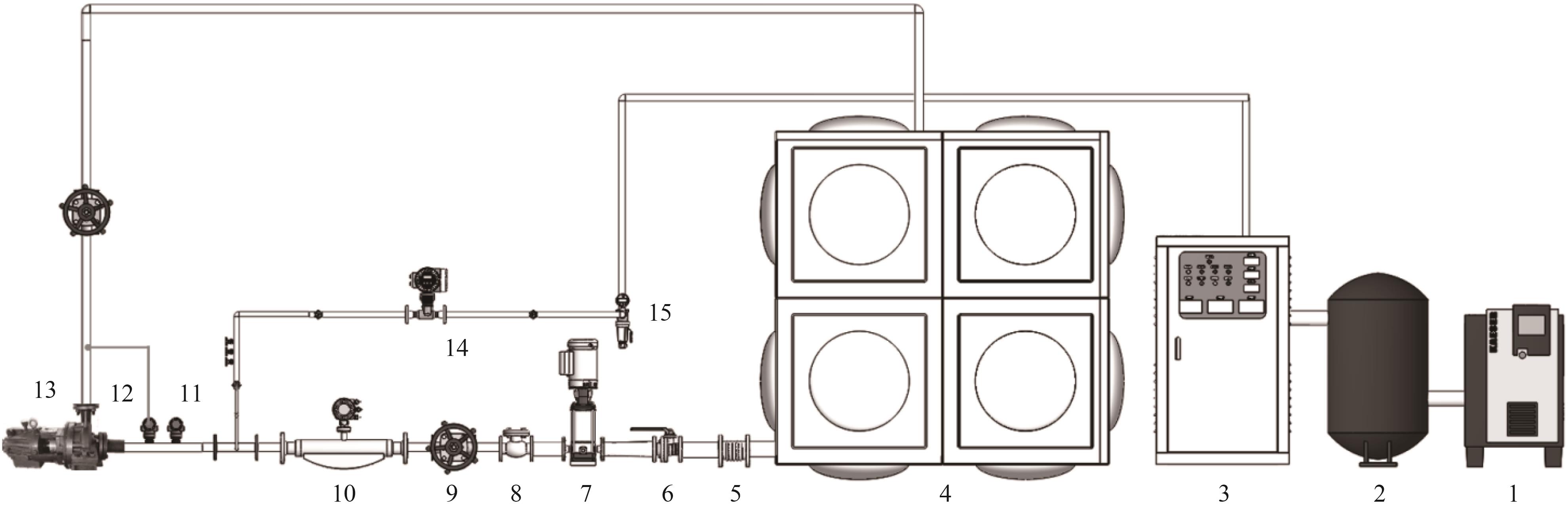

图4 实验系统1—空压机; 2—储气罐; 3—空冷机; 4—储水箱; 5—补偿器; 6—球阀; 7—增压泵; 8—止回阀; 9—闸阀; 10—液体质量流量计; 11—压力变送器; 12—压差变送器; 13—实验旋流泵; 14—气体质量流量计; 15—压力表

Fig.4 Experimental system

| 1 | 袁寿其, 施卫东, 刘厚林. 泵理论与技术[M]. 北京: 机械工业出版社, 2014: 242-246. |

| Yuan S Q, Shi W D, Liu H L. Pump Theory and Technology[M]. Beijing: China Machine Press, 2014: 242-246. | |

| 2 | 谈明高, 赵凯尧, 吴贤芳, 等. 隔舌安放角对旋流泵内非稳态流动特性的影响[J]. 农业工程学报, 2022, 38(10): 47-53. |

| Tan M G, Zhao K Y, Wu X F, et al. Effects of volute tongue angels on unsteady flow characteristics in a vortex pump[J]. Transactions of the Chinese Society of Agricultural Engineering, 2022, 38(10): 47-53. | |

| 3 | 张德胜, 潘大志, 施卫东, 等. 轴流泵叶顶区的空化流场与叶片载荷分布特性[J]. 化工学报, 2014, 65(2): 501-507. |

| Zhang D S, Pan D Z, Shi W D, et al. Cavitation flow and blade loading characteristic in impeller tip region of axial flow pump[J]. CIESC Journal, 2014, 65(2): 501-507. | |

| 4 | 朱荣生, 陈景俊, 王秀礼, 等. 高低折边叶片对旋流泵影响的数值模拟与实验研究[J]. 流体机械, 2012, 40(1): 1-5. |

| Zhu R S, Chen J J, Wang X L, et al. Numerical simulation and experimental of influence of hem and high-low blade on performance of vortex pump[J]. Fluid Machinery, 2012, 40(1): 1-5. | |

| 5 | 唐靖轩, 刘轶伦, 何巍, 等. 双进双出气泡泵输送性能[J]. 化工学报, 2021, 72(S1): 140-145. |

| Tang J X, Liu Y L, He W, et al. Pumping performance of bubble pump with dual entrances and dual exits[J]. CIESC Journal, 2021, 72(S1): 140-145. | |

| 6 | 权辉, 傅百恒, 李仁年, 等. 旋流泵的研究现状及发展趋势[J]. 流体机械, 2016, 44(9): 36-40. |

| Quan H, Fu B H, Li R N, et al. Research stage and development tendency of vortex pump[J]. Fluid Machinery, 2016, 44(9): 36-40. | |

| 7 | 汪永志, 施卫东, 董颖, 等. 旋流泵的研究现状与展望[J]. 排灌机械, 2004, 22(2): 8-11. |

| Wang Y Z, Shi W D, Dong Y, et al. Present status and development prospect of vortex pump[J]. Journal of Drainage and Irrigation Machinery Engineering, 2004, 22(2): 8-11. | |

| 8 | Schivley G P, Dussourd J L. An analytical and experimental study of a vortex pump[J]. Journal of Basic Engineering, 1970, 92(4): 889-900. |

| 9 | Ohba H, Nakashima Y, Shiramoto K. A study on internal flow and performance of a vortex pump (1): Theoretical analysis[J]. Bulletin of JSME, 1983, 26(216): 999-1006. |

| 10 | Gu Y Q, Zhang W Q, Mou J G, et al. Effect of bionic mantis shrimp groove volute on vortex pump pressure pulsation[J]. Journal of Central South University, 2018, 25(10): 2399-2409. |

| 11 | Gao X F, Zhao T, Shi W D, et al. Numerical investigation of an open-design vortex pump with different blade wrap angles of impeller[J]. Processes, 2020, 8(12): 1601. |

| 12 | Ye D X, Li H, Ma Q Y, et al. Numerical investigation of performance improvement and erosion characteristics of vortex pump using particle model[J]. Shock and Vibration, 2020, 2020: 1-10. |

| 13 | Quan H, Chai Y, Li R N, et al. Influence of circulating-flow's geometric characters on energy transition of a vortex pump[J]. Engineering Computations, 2019, 36(9): 3122-3137. |

| 14 | Gerlach A, Preuss E, Thamsen P U, et al. Numerical simulations of the internal flow pattern of a vortex pump compared to the Hamel-Oseen vortex[J]. Journal of Mechanical Science and Technology, 2017, 31(4): 1711-1719. |

| 15 | Tan P, Sha Y, Bai X B, et al. A performance test and internal flow field simulation of a vortex pump[J]. Applied Sciences, 2017, 7(12): 1273. |

| 16 | Mao W Y, Song P Y, Deng Q G, et al. Numerical simulation on the performance of the vortex pump for transporting solid-liquid two-phase with light particles[J]. IOP Conference Series: Materials Science and Engineering, 2016, 129: 012018. |

| 17 | Steinmann A, Wurm H, Otto A. Numerical and experimental investigations of the unsteady cavitating flow in a vortex pump[J]. Journal of Hydrodynamics, Ser. B, 2010, 22(51): 319-324. |

| 18 | 赖天伟, 杨山举, 张兴群, 等. 直叶片离心泵内R134a流动与空化特性的CFD分析[J]. 化工学报, 2014, 65(S2): 45-51. |

| Lai T W, Yang S J, Zhang X Q, et al. Computational fluid dynamic analysis on flow and cavitation characteristics of R134a in centrifugal pump with straight blades[J]. CIESC Journal, 2014, 65(S2): 45-51. | |

| 19 | Chen Y M, Patil A, Chen Y, et al. Numerical study on the first stage head degradation in an electrical submersible pump with population balance model[J]. Journal of Energy Resources Technology, 2019, 141(2): 022003. |

| 20 | Lehr F, Mewes D. A transport equation for the interfacial area density applied to bubble columns[J].Chemical Engineering Science, 2001, 56(3): 1159-1166. |

| 21 | Verde W M, Biazussi J L, Sassim N A, et al. Experimental study of gas-liquid two-phase flow patterns within centrifugal pumps impellers[J]. Experimental Thermal and Fluid Science, 2017, 85: 37-51. |

| 22 | Ge Z G, He D H, Huang R, et al. Application of CFD-PBM coupling model for analysis of gas-liquid distribution characteristics in centrifugal pump[J]. Journal of Petroleum Science and Engineering, 2020, 194: 107518. |

| 23 | He D H, Ge Z G, Bai B F, et al. Gas-liquid two-phase performance of centrifugal pump under bubble inflow based on computational fluid dynamics-population balance model coupling model[J]. Journal of Fluids Engineering, 2020, 142(8): 081402. |

| 24 | He D H, Zhao L, Chang Z, et al. On the performance of a centrifugal pump under bubble inflow: effect of gas-liquid distribution in the impeller[J]. Journal of Petroleum Science and Engineering, 2021, 203: 108587. |

| 25 | Gamboa J, Prado M. Experimental study of two-phase performance of an electric-submersible-pump stage[J]. SPE Production & Operations, 2012, 27(4): 414-421. |

| 26 | Barrios L, Prado M G. Experimental visualization of two-phase flow inside an electrical submersible pump stage[J]. Journal of Energy Resources Technology, 2011, 133(4): 042901. |

| 27 | Parikh T, Mansour M, Thévenin D. Investigations on the effect of tip clearance gap and inducer on the transport of air-water two-phase flow by centrifugal pumps[J]. Chemical Engineering Science, 2020, 218: 115554. |

| 28 | Lee C H, Erickson L E, Glasgow L A. Bubble breakup and coalescence in turbulent gas-liquid dispersions[J]. Chemical Engineering Communications, 1987, 59(1/2/3/4/5/6): 65-84. |

| 29 | 高颂, 徐燕燕, 李继香, 等. 基于TFM-PBM耦合模型的离心泵内微气泡破碎合并的模拟研究[J]. 化工学报, 2021, 72(10): 5082-5093. |

| Gao S, Xu Y Y, Li J X, et al. Simulation study of microbubbles break-up and coalescence in centrifugal pump based on TFM-PBM coupling model[J]. CIESC Journal, 2021, 72(10): 5082-5093. | |

| 30 | Luo H A. Coalescence,breakup and liquid circulation in bubble column reactors[D]. Trondheim: The University of Trondheim, 1993. |

| 31 | Luo H A, Svendsen H F. Theoretical model for drop and bubble breakup in turbulent dispersions[J]. AIChE Journal, 1996, 42(5): 1225-1233. |

| 32 | 冯建军, 张钰, 朱国俊, 等. 采用熵产理论的离心泵断电过渡过程特性[J]. 农业工程学报, 2020, 36(4): 10-17. |

| Feng J J, Zhang Y, Zhu G J, et al. Transition process characteristics of centrifugal pump with power-off based on entropy production theory[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(4): 10-17. | |

| 33 | Kock F, Herwig H. Local entropy production in turbulent shear flows: a high-Reynolds number model with wall functions[J]. International Journal of Heat and Mass Transfer, 2004, 47(10/11): 2205-2215. |

| 34 | Dou H S. Physics of flow instability and turbulent transition in shear flows[EB/OL]. OALib Journal, 2006, arXiv: physics/0607004. |

| 35 | 窦华书, 蒋威, 张玉良, 等. 基于能量梯度理论的离心泵内流动不稳定研究[J]. 农业机械学报, 2014, 45(12): 88-92, 103. |

| Dou H S, Jiang W, Zhang Y L, et al. Flow instability in centrifugal pump based on energy gradient theory[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(12): 88-92, 103. |

| [1] | 肖明堃, 杨光, 黄永华, 吴静怡. 浸没孔液氧气泡动力学数值研究[J]. 化工学报, 2023, 74(S1): 87-95. |

| [2] | 邵苛苛, 宋孟杰, 江正勇, 张旋, 张龙, 高润淼, 甄泽康. 水平方向上冰中受陷气泡形成和分布实验研究[J]. 化工学报, 2023, 74(S1): 161-164. |

| [3] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [4] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [5] | 高燕, 伍鹏, 尚超, 胡泽君, 陈晓东. 基于双流体喷嘴的磁性琼脂糖微球的制备及其蛋白吸附性能探究[J]. 化工学报, 2023, 74(8): 3457-3471. |

| [6] | 岳林静, 廖艺涵, 薛源, 李雪洁, 李玉星, 刘翠伟. 凹坑缺陷对厚孔板喉部空化流动特性影响研究[J]. 化工学报, 2023, 74(8): 3292-3308. |

| [7] | 王海, 林宏, 王晨, 许浩洁, 左磊, 王军锋. 高压静电场强化多孔介质表面沸腾传热特性研究[J]. 化工学报, 2023, 74(7): 2869-2879. |

| [8] | 高金明, 郭玉娇, 鄂承林, 卢春喜. 一种封闭罩内顺流多旋臂气液分离器的分离特性研究[J]. 化工学报, 2023, 74(7): 2957-2966. |

| [9] | 江锦波, 彭新, 许文烜, 门日秀, 刘畅, 彭旭东. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| [10] | 刘起超, 周云龙, 陈聪. 起伏振动垂直上升管气液两相流截面含气率分析与计算[J]. 化工学报, 2023, 74(6): 2391-2403. |

| [11] | 董鑫, 单永瑞, 刘易诺, 冯颖, 张建伟. 非牛顿流体气泡羽流涡特性数值模拟研究[J]. 化工学报, 2023, 74(5): 1950-1964. |

| [12] | 王泽栋, 石至平, 刘丽艳. 考虑气泡非均匀耗散的矩形反应器声流场数值模拟及结构优化[J]. 化工学报, 2023, 74(5): 1965-1973. |

| [13] | 许文烜, 江锦波, 彭新, 门日秀, 刘畅, 彭旭东. 宽速域三种典型型槽油气密封泄漏与成膜特性对比研究[J]. 化工学报, 2023, 74(4): 1660-1679. |

| [14] | 张银宁, 王进卿, 冯致, 詹明秀, 徐旭, 张光学, 池作和. 升温条件下多孔介质内气泡的生长和聚并行为[J]. 化工学报, 2023, 74(4): 1509-1518. |

| [15] | 项星宇, 王忠东, 董艳鹏, 李守川, 朱春英, 马友光, 付涛涛. 微通道内屈服应力型流体的流变特性及多相流研究进展[J]. 化工学报, 2023, 74(2): 546-558. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号