化工学报 ›› 2022, Vol. 73 ›› Issue (5): 2073-2082.DOI: 10.11949/0438-1157.20211568

侯起旺1( ),文兆伦1,张忠林1(

),文兆伦1,张忠林1( ),刘叶刚1,2,杨景轩1,陈东良1,2,郝晓刚1(

),刘叶刚1,2,杨景轩1,陈东良1,2,郝晓刚1( ),官国清3

),官国清3

收稿日期:2021-11-03

修回日期:2022-02-09

出版日期:2022-05-05

发布日期:2022-05-24

通讯作者:

张忠林,郝晓刚

作者简介:侯起旺(1995—),男,硕士研究生,基金资助:

Qiwang HOU1( ),Zhaolun WEN1,Zhonglin ZHANG1(

),Zhaolun WEN1,Zhonglin ZHANG1( ),Yegang LIU1,2,Jingxuan YANG1,Dongliang CHEN1,2,Xiaogang HAO1(

),Yegang LIU1,2,Jingxuan YANG1,Dongliang CHEN1,2,Xiaogang HAO1( ),Guoqing GUAN3

),Guoqing GUAN3

Received:2021-11-03

Revised:2022-02-09

Online:2022-05-05

Published:2022-05-24

Contact:

Zhonglin ZHANG,Xiaogang HAO

摘要:

将高密度三塔式循环流化床(TBCFB)应用于串并联综合型多联产系统,提出一种基于碳循环的流程与参数共优化的煤基多联产系统,促进低阶煤资源的高质高效转化。碳循环体现在两方面,一是系统以热解煤气循环作为热解气氛,提高了焦油产率,实现低阶煤高质化转化;二是在TBCFB使用富氧燃烧,提高了烟气中二氧化碳浓度,将烟气替代氮气直接用于燃气轮机发电工质,减少了氮气消耗。利用Aspen Plus对全系统进行模拟,对多联产系统进行物料、能量和?衡算,研究未反应合成气循环比和烟气注入量对过程的影响;以能量利用效率为优化目标,对煤基多联产碳循环系统的操作条件寻优。结果表明,动力单元注入气体使用烟气时,煤基多联产碳循环系统的能量利用效率达49.7%,高于用氮气作为热解气氛的传统煤基多联产系统,相比传统的单产系统,煤基多联产系统的能量可节约13%,对于年处理30万吨煤的系统,折合减少二氧化碳排放量为14.9万吨/年。

中图分类号:

侯起旺, 文兆伦, 张忠林, 刘叶刚, 杨景轩, 陈东良, 郝晓刚, 官国清. 一种煤基多联产碳循环系统的设计及评价[J]. 化工学报, 2022, 73(5): 2073-2082.

Qiwang HOU, Zhaolun WEN, Zhonglin ZHANG, Yegang LIU, Jingxuan YANG, Dongliang CHEN, Xiaogang HAO, Guoqing GUAN. Design and evaluation of a coal-based polygeneration system with carbon cycle[J]. CIESC Journal, 2022, 73(5): 2073-2082.

| Proximate analysis/ %(mass,d) | Ultimate analysis/ %(mass,daf) | LHV/(MJ/kg) | ||||||

|---|---|---|---|---|---|---|---|---|

| FC | A | V | C | H | N | S | O① | |

| 47.21 | 5.8 | 46.99 | 74.35 | 5.13 | 0.72 | 0.31 | 19.49 | 23.45 |

表1 NMH工业分析和元素分析[16]

Table 1 Proximate and ultimate analyses of coal NMH[16]

| Proximate analysis/ %(mass,d) | Ultimate analysis/ %(mass,daf) | LHV/(MJ/kg) | ||||||

|---|---|---|---|---|---|---|---|---|

| FC | A | V | C | H | N | S | O① | |

| 47.21 | 5.8 | 46.99 | 74.35 | 5.13 | 0.72 | 0.31 | 19.49 | 23.45 |

| 参数 | 值 |

|---|---|

| 压气机绝热压缩效率/% | 91 |

| 透平绝热膨胀效率/% | 86 |

| 氧气温度/℃ | 15 |

| 氧气压缩比/% | 29.6 |

| 汽轮机高压缸效率/% | 87 |

| 汽轮机中压缸效率/% | 90 |

| 汽轮机低压缸效率/% | 88 |

| 机械电机效率/% | 98 |

表2 燃气轮机、蒸汽轮机参数

Table 2 Parameters of the gas turbine and steam turbine

| 参数 | 值 |

|---|---|

| 压气机绝热压缩效率/% | 91 |

| 透平绝热膨胀效率/% | 86 |

| 氧气温度/℃ | 15 |

| 氧气压缩比/% | 29.6 |

| 汽轮机高压缸效率/% | 87 |

| 汽轮机中压缸效率/% | 90 |

| 汽轮机低压缸效率/% | 88 |

| 机械电机效率/% | 98 |

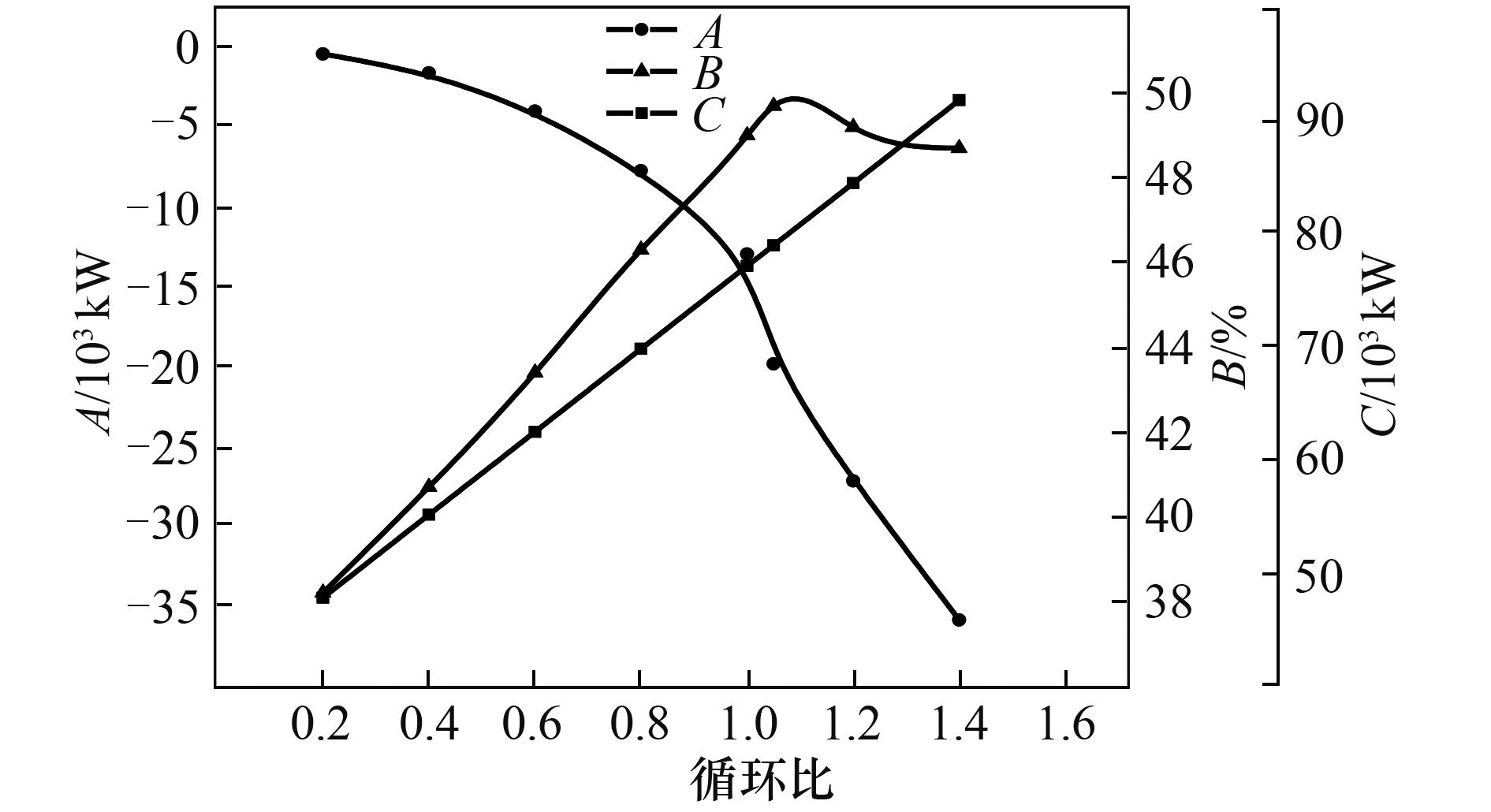

图3 碳循环多联产循环比对系统能量利用率的影响A—发电量与循环压缩机功耗、精馏能耗之差;B—系统能量利用率;C—甲醇能量

Fig.3 Effects of carbon cycle ratio on system energy utilization in the carbon-cycled polygeneration systemA—the difference between power generation and power consumption of the circulating compressor and energy consumption of distillation; B—system energy utilization efficiency; C—methanol energy

图4 碳循环多联产烟气回注量对动力单元的影响A—NO x 排放量;B—动力单元输出电量;C—燃烧室出口温度

Fig.4 Effects of flue gas reinjection on power unit in the carbon-cycled polygeneration systemA—NO x emission; B—power unit output power; C—combustion chamber outlet temperature

| 物流 | 摩尔分数/% | 摩尔流量/ (kmol/h) | 质量流量/(t/h) | 温度/℃ | 压力/MPa | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| H2+CH4 | CO | CO2 | N2 | O2 | H2O | CH3OH | |||||

| 1 | — | — | — | — | — | — | — | — | 37.5 | 200 | 0.1 |

| 2 | 59.1 | 27.7 | 5.4 | — | — | 7.7 | — | 1398.1 | 18.3 | 40 | 6.5 |

| 3 | 67.9 | 30.0 | 2.1 | — | — | — | — | 1204.6 | 13.2 | 35.9 | 5.57 |

| 4 | — | — | — | — | — | 10.8 | 86.6 | 462.0 | 14.3 | 65.3 | 3.5 |

| 5 | — | — | 93.6 | 1.2 | 5.1 | — | — | 885.8 | 38.3 | 843.8 | 0.1 |

| 6 | 3.6 | 3.4 | 6.8 | — | — | 85.3 | — | 599.9 | 12.0 | 593.7 | 5.0 |

| 7 | — | — | 54.6 | 0.6 | 3.0 | 41.8 | — | 1347.2 | 44.1 | 227.8 | 0.1 |

表3 多联产碳循环系统主要物流模拟数据

Table 3 Simulation results of main streams of polygeneration carbon cycle system

| 物流 | 摩尔分数/% | 摩尔流量/ (kmol/h) | 质量流量/(t/h) | 温度/℃ | 压力/MPa | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| H2+CH4 | CO | CO2 | N2 | O2 | H2O | CH3OH | |||||

| 1 | — | — | — | — | — | — | — | — | 37.5 | 200 | 0.1 |

| 2 | 59.1 | 27.7 | 5.4 | — | — | 7.7 | — | 1398.1 | 18.3 | 40 | 6.5 |

| 3 | 67.9 | 30.0 | 2.1 | — | — | — | — | 1204.6 | 13.2 | 35.9 | 5.57 |

| 4 | — | — | — | — | — | 10.8 | 86.6 | 462.0 | 14.3 | 65.3 | 3.5 |

| 5 | — | — | 93.6 | 1.2 | 5.1 | — | — | 885.8 | 38.3 | 843.8 | 0.1 |

| 6 | 3.6 | 3.4 | 6.8 | — | — | 85.3 | — | 599.9 | 12.0 | 593.7 | 5.0 |

| 7 | — | — | 54.6 | 0.6 | 3.0 | 41.8 | — | 1347.2 | 44.1 | 227.8 | 0.1 |

| 系统 | 系统输入 总能量/MW | 系统输出 总功率/ MW | 系统输出 净功率/MW | 产生甲醇 能量/MW | 产生焦油 能量/MW | 系统能量 利用率/% | ?效率/% |

|---|---|---|---|---|---|---|---|

| 传统煤基多联产 | 244.27 | 24.32 | 18.44 | 66.53 | 32.15 | 47.9 | 39 |

| 煤基多联产碳循环 | 244.27 | 26.33 | 20.45 | 63.32 | 37.57 | 49.7 | 40 |

表4 两种多联产系统性能对比分析

Table 4 Comparative analysis of two kinds of polygeneration systems

| 系统 | 系统输入 总能量/MW | 系统输出 总功率/ MW | 系统输出 净功率/MW | 产生甲醇 能量/MW | 产生焦油 能量/MW | 系统能量 利用率/% | ?效率/% |

|---|---|---|---|---|---|---|---|

| 传统煤基多联产 | 244.27 | 24.32 | 18.44 | 66.53 | 32.15 | 47.9 | 39 |

| 煤基多联产碳循环 | 244.27 | 26.33 | 20.45 | 63.32 | 37.57 | 49.7 | 40 |

| 项目 | 输入 | 输出 | 系统输出能量/MW | 相对能量节约率/% | |

|---|---|---|---|---|---|

| 煤/(t/h) | 甲醇/(t/h) | 焦油/(t/h) | |||

| 煤基多联产碳循环系统 | 37.5 | 11.46 | 4.1 | 26.33 | 13 |

| 煤气化联合循环发电系统 | 11.89 | — | — | 26.33 | — |

| 煤制甲醇系统 | 24.37 | 11.46 | — | — | — |

| 费托合成油系统 | 6.83 | — | 4.1 | — | — |

表5 联产系统与单产系统性能

Table 5 Performance of polygeneration system and reference systems

| 项目 | 输入 | 输出 | 系统输出能量/MW | 相对能量节约率/% | |

|---|---|---|---|---|---|

| 煤/(t/h) | 甲醇/(t/h) | 焦油/(t/h) | |||

| 煤基多联产碳循环系统 | 37.5 | 11.46 | 4.1 | 26.33 | 13 |

| 煤气化联合循环发电系统 | 11.89 | — | — | 26.33 | — |

| 煤制甲醇系统 | 24.37 | 11.46 | — | — | — |

| 费托合成油系统 | 6.83 | — | 4.1 | — | — |

| 1 | An energy sector roadmap to carbon neutrality in China[EB/OL]. [2021-09]. . |

| 2 | Fushimi C, Wada T, Tsutsumi A. Inhibition of steam gasification of biomass char by hydrogen and tar[J]. Biomass and Bioenergy, 2011, 35(1): 179-185. |

| 3 | Bayarsaikhan B, Sonoyam N, Hosokai S, et al. Inhibition of steam gasification of char by volatiles in a fluidized bed under continuous feeding of a brown coal[J]. Fuel, 2006, 85(3): 340-349. |

| 4 | Zhang Y M, Wang Y, Cai L G, et al. Dual bed pyrolysis gasification of coal: process analysis and pilot test[J]. Fuel, 2013, 112: 624-634. |

| 5 | Tsutsumi A, Guan G Q, Fushimi C, et al. Flow behaviors in a high solid flux circulating fluidized bed composed of a riser, a downer and a bubbling fluidized bed[C]//Fluidization : New Paradigm in Fluidization Engineering. Gyeong‐ju, Korea, 2010: 407-414. |

| 6 | Fushimi C, Guan G Q, Ishizuka M, et al. High-flux triple bed circulating fluidized bed (TBCFB) gasifier for exergy recuperative IGCC/IGFC[C]// International Conference on Circulating Fluidized Beds & Fluidization Technology-cfb. Sunriver, Oregon, USA, 2014. |

| 7 | 郝晓刚, 王俊丽, 连文豪, 等. 一种热解气化装置和工艺: 104789245B[P]. 2017-12-05. |

| Hao X G, Wang J L, Lian W H, et al. Pyrolysis and gasification device and technology: 104789245B[P]. 2017-12-05. | |

| 8 | 王亚雄, 杨景轩, 张忠林, 等. 低阶煤热解-气化-燃烧TBCFB系统模拟及优化[J]. 化工学报, 2018, 69(8): 3596-3604. |

| Wang Y X, Yang J X, Zhang Z L, et al. TBCFB system simulation and optimization for pyrolysis-gasificationcombustion of low rank coal[J]. CIESC Journal, 2018, 69(8): 3596-3604. | |

| 9 | 陈东良, 张忠林, 杨景轩, 等. 基于自热再生的化学吸收法CO2捕集工艺模拟及节能分析[J]. 化工学报, 2019, 70(8): 2938-2945. |

| Chen D L, Zhang Z L, Yang J X, et al. Process simulation and energy saving analysis of CO2 capture by chemical absorption method based on self-heat recuperation[J]. CIESC Journal, 2019, 70(8): 2938-2945. | |

| 10 | Li H Q, Hong H, Jin H G, et al. Analysis of a feasible polygeneration system for power and methanol production taking natural gas and biomass as materials[J]. Applied Energy, 2010, 87(9): 2846-2853. |

| 11 | 林汝谋, 金红光, 高林. 化工动力多联产系统及其集成优化机理[J]. 热能动力工程, 2006, 21(4): 331-337, 433. |

| Lin R M, Jin H G, Gao L. Chemical engineering power polygeneration system and its integrated optimization mechanism[J]. Journal of Engineering for Thermal Energy and Power, 2006, 21(4): 331-337, 433. | |

| 12 | 岑建孟, 方梦祥, 王勤辉, 等. 煤分级利用多联产技术及其发展前景[J]. 化工进展, 2010, 29(S1): 705. |

| Cen J M, Fang M X, Wang Q H, et al. Development and prospect of coal staged conversion poly-generation technology[J]. Chemical Industry and Engineering Progress, 2010, 29(S1): 705. | |

| 13 | 刘敬尧, 何畅, 李璟, 等. 以合成气为核心的多联供多联产集成能源化工系统[J]. 煤炭学报, 2010, 35(2): 293-298. |

| Liu J Y, He C, Li J, et al. Syngas-based multi-fuel multi-product integrated energy and chemical system[J]. Journal of China Coal Society, 2010, 35(2): 293-298. | |

| 14 | Gong M H, Yi Q, Huang Y, et al. Coke oven gas to methanol process integrated with CO2 recycle for high energy efficiency,economic benefits and low emissions[J]. Energy Conversion and Management, 2017, 133: 318-331. |

| 15 | Moore M J. NO x emission control in gas turbines for combined cycle gas turbine plant[J]. Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, 1997, 211(1): 43-52. |

| 16 | Wang Q, Wang M J, Wang H, et al. Effect of temperature and gasification gas from char on the reactions of volatiles generated from rapid pyrolysis of a low rank coal[J]. Fuel Processing Technology, 2021, 212: 106601. |

| 17 | Li X R, Jin X, Wang M J, et al. Effect of volatiles’ reaction on coking of tar during pyrolysis of Naomaohu coal in a downer-bed reactor[J]. Fuel Processing Technology, 2021, 212: 106623. |

| 18 | Jin X, Li X R, Kong J, et al. Insights into coke formation during thermal reaction of six different distillates from the same coal tar[J]. Fuel Processing Technology, 2021, 211: 106592. |

| 19 | Kuo P C, Wu W. Thermodynamic analysis of a combined heat and power system with CO2 utilization based on co-gasification of biomass and coal[J]. Chemical Engineering Science, 2016, 142: 201-214. |

| 20 | 焦树建. 燃气-蒸汽联合循环的理论基础[M]. 北京: 清华大学出版社, 2003. |

| Jiao S J. Theoretical Basis of Combined Gas-steam Cycle[M]. Beijing: Tsinghua University Press, 2003. | |

| 21 | Sun L, Smith R. Rectisol wash process simulation and analysis[J]. Journal of Cleaner Production, 2013, 39: 321-328. |

| 22 | Shi B, Wen F, Wu W. Performance evaluation of air-blown IGCC polygeneration plants using chemical looping hydrogen generation and methanol synthesis loop[J]. Energy, 2020, 200: 117564. |

| 23 | 刘叶刚, 张忠林, 侯起旺, 等. TBCFB合成气制甲醇工艺过程的概念设计和计算机模拟[J]. 化工学报, 2021, 72(9): 4838-4846. |

| Liu Y G, Zhang Z L, Hou Q W, et al. Process design and simulation of synthesis gas to methanol in TBCFB system[J]. CIESC Journal, 2021, 72(9): 4838-4846. | |

| 24 | Fu Q, Kansha Y, Song C F, et al. A cryogenic air separation process based on self-heat recuperation for oxy-combustion plants[J]. Applied Energy, 2016, 162: 1114-1121. |

| 25 | 游卓. 富氧燃烧过程中的NO x 控制及其系统效率研究[D]. 杭州: 浙江大学, 2013. |

| You Z. NO x control and efficiency optimization of oxy-fuel combustion system[D]. Hangzhou: Zhejiang University, 2013. | |

| 26 | Cengel Y A, Boles M A. Thermodynamics: An Engineering Approach[M]. New York: McGraw-Hill, 2009. |

| 27 | Zhang Y N, Zhao Y J, Gao X Y, et al. Energy and exergy analyses of syngas produced from rice husk gasification in an entrained flow reactor[J]. Journal of Cleaner Production, 2015, 95: 273-280. |

| 28 | Bilgen S, Kaygusuz K, Sari A. Second law analysis of various types of coal and woody biomass in Turkey[J]. Energy Sources, 2004, 26(11): 1083-1094. |

| 29 | 王东亮, 冯宵, 李广播, 等. 基于流程模拟的㶲计算方法及其应用[J]. 计算机与应用化学, 2012, 29(9): 1069-1074. |

| Wang D L, Feng X, Li G B, et al. Exergy calculation method based on flowsheeting simulation and its application[J]. Computers and Applied Chemistry, 2012, 29(9): 1069-1074. | |

| 30 | Al-Weshahi M A, Anderson A, Tian G H. Exergy efficiency enhancement of MSF desalination by heat recovery from hot distillate water stages[J]. Applied Thermal Engineering, 2013, 53(2): 226-233. |

| 31 | Duan W J, Yu Q B, Wang K, et al. ASPEN Plus simulation of coal integrated gasification combined blast furnace slag waste heat recovery system[J]. Energy Conversion and Management, 2015, 100: 30-36. |

| 32 | Chen S Y, Lior N, Xiang W G. Coal gasification integration with solid oxide fuel cell and chemical looping combustion for high-efficiency power generation with inherent CO2 capture[J]. Applied Energy, 2015, 146: 298-312. |

| 33 | Zhang Y N, Li B X, Li H T, et al. Exergy analysis of biomass utilization via steam gasification and partial oxidation[J]. Thermochimica Acta, 2012, 538: 21-28. |

| 34 | 张亚宁, 李炳熙, 张波, 等. 生物质氧气气化和水蒸汽气化的能量分析及㶲分析[J]. 华北电力大学学报(自然科学版), 2012, 39(1): 64-69. |

| Zhang Y N, Li B X, Zhang B. Energy and exergy analysis of biomass gasification with oxygen or steam[J]. Journal of North China Electric Power University(Natural Science Edition), 2012, 39(1): 64-69. | |

| 35 | 于戈文, 王延铭, 杨小丽, 等. 基于CO2捕集的煤基费托合成油-动力多联产系统㶲分析[J]. 化工进展, 2017, 36(10): 3682-3689. |

| Yu G W, Wang Y M, Yang X L, et al. Exergy analysis for the coal-based polygeneration system of FT syncrudes-power with CO2 capture[J]. Chemical Industry and Engineering Progress, 2017, 36(10): 3682-3689. | |

| 36 | Reddy B R, Shravani B, Das B, et al. Microwave-assisted and analytical pyrolysis of coking and non-coking coals: comparison of tar and char compositions[J]. Journal of Analytical and Applied Pyrolysis, 2019, 142: 104614. |

| 37 | He S, Li S, Gao L. Proposal and energy saving analysis of novel methanol-electricity polygeneration system based on staged coal gasification method[J]. Energy Conversion and Management, 2021, 233(2): 113931. |

| 38 | 黄宏, 杨思宇. 一种低能耗捕集CO2煤基甲醇和电力联产过程设计[J]. 化工学报, 2017, 68(10): 3860-3869. |

| Huang H, Yang S Y. Design of a coal based methanol and power polygeneration process with low energy consumption for CO2 capture[J]. CIESC Journal, 2017, 68(10): 3860-3869. | |

| 39 | 范江, 王巧荣, 王进, 等. 循环比对甲醇-电的多联产系统能耗影响的分析[J]. 化学工程, 2009, 37(4): 68-71, 78. |

| Fan J, Wang Q R, Wang J, et al. Analysis for effect of recycle ratio on energy consumption of methanol-electric polygeneration system[J]. Chemical Engineering(China), 2009, 37(4): 68-71, 78. | |

| 40 | 黄雪丽. IGCC电厂脱硝方式一体化研究[D]. 北京: 华北电力大学, 2014. |

| Huang X L. Integrated study on denitraton methods of IGCC plant[D]. Beijing: North China Electric Power University, 2014. | |

| 41 | 林汝谋, 金红光, 高林. 化工动力多联产系统评价准则问题研究综述[J]. 燃气轮机技术, 2012, 25(4): 1-14. |

| Lin R M, Jin H G, Gao L. Review on the evaluation criteria of polygeneration system for power and chemical production[J]. Gas Turbine Technology, 2012, 25(4): 1-14. | |

| 42 | Fan Y F, Ye Q, Cen H, et al. Design and optimization of reactive distillation processes for synthesis of isopropanol based on self-heat recuperation technology[J]. Chemical Engineering Research and Design, 2019, 147: 171-186. |

| [1] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [2] | 曹跃, 余冲, 李智, 杨明磊. 工业数据驱动的加氢裂化装置多工况切换过渡状态检测[J]. 化工学报, 2023, 74(9): 3841-3854. |

| [3] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [4] | 刘远超, 关斌, 钟建斌, 徐一帆, 蒋旭浩, 李耑. 单层XSe2(X=Zr/Hf)的热电输运特性研究[J]. 化工学报, 2023, 74(9): 3968-3978. |

| [5] | 余娅洁, 李静茹, 周树锋, 李清彪, 詹国武. 基于天然生物模板构建纳米材料及集成催化剂研究进展[J]. 化工学报, 2023, 74(7): 2735-2752. |

| [6] | 李贵贤, 曹阿波, 孟文亮, 王东亮, 杨勇, 周怀荣. 耦合固体氧化物电解槽的CO2制甲醇过程设计与评价研究[J]. 化工学报, 2023, 74(7): 2999-3009. |

| [7] | 文兆伦, 李沛睿, 张忠林, 杜晓, 侯起旺, 刘叶刚, 郝晓刚, 官国清. 基于自热再生的隔壁塔深冷空分工艺设计及优化[J]. 化工学报, 2023, 74(7): 2988-2998. |

| [8] | 王光, 单发顺, 钱禹丞, 焦建芳. 基于集成学习传递熵的化工过程微小故障检测方法[J]. 化工学报, 2023, 74(7): 2967-2978. |

| [9] | 邵远哲, 赵忠盖, 刘飞. 基于共同趋势模型的非平稳过程质量相关故障检测方法[J]. 化工学报, 2023, 74(6): 2522-2537. |

| [10] | 江锦波, 彭新, 许文烜, 门日秀, 刘畅, 彭旭东. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| [11] | 孙永尧, 高秋英, 曾文广, 王佳铭, 陈艺飞, 周永哲, 贺高红, 阮雪华. 面向含氮油田伴生气提质利用的膜耦合分离工艺设计优化[J]. 化工学报, 2023, 74(5): 2034-2045. |

| [12] | 刘尚豪, 贾胜坤, 罗祎青, 袁希钢. 基于梯度提升决策树的三组元精馏流程结构最优化[J]. 化工学报, 2023, 74(5): 2075-2087. |

| [13] | 周必茂, 许世森, 王肖肖, 刘刚, 李小宇, 任永强, 谭厚章. 烧嘴偏转角度对气化炉渣层分布特性的影响[J]. 化工学报, 2023, 74(5): 1939-1949. |

| [14] | 王泽栋, 石至平, 刘丽艳. 考虑气泡非均匀耗散的矩形反应器声流场数值模拟及结构优化[J]. 化工学报, 2023, 74(5): 1965-1973. |

| [15] | 许文烜, 江锦波, 彭新, 门日秀, 刘畅, 彭旭东. 宽速域三种典型型槽油气密封泄漏与成膜特性对比研究[J]. 化工学报, 2023, 74(4): 1660-1679. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号