化工学报 ›› 2023, Vol. 74 ›› Issue (4): 1660-1679.DOI: 10.11949/0438-1157.20221545

许文烜1( ), 江锦波1(

), 江锦波1( ), 彭新1, 门日秀2, 刘畅2, 彭旭东1

), 彭新1, 门日秀2, 刘畅2, 彭旭东1

收稿日期:2022-11-28

修回日期:2023-01-04

出版日期:2023-04-05

发布日期:2023-06-02

通讯作者:

江锦波

作者简介:许文烜(1997—),男,硕士研究生,xul9857195246@163.com

基金资助:

Wenxuan XU1( ), Jinbo JIANG1(

), Jinbo JIANG1( ), Xin PENG1, Rixiu MEN2, Chang LIU2, Xudong PENG1

), Xin PENG1, Rixiu MEN2, Chang LIU2, Xudong PENG1

Received:2022-11-28

Revised:2023-01-04

Online:2023-04-05

Published:2023-06-02

Contact:

Jinbo JIANG

摘要:

如何实现涡轮增压器气膜密封在低速状态的低漏油和高速状态的低窜气、高刚度是其设计的关键问题。以泵出型螺旋槽、八字复合型槽和雷列台阶复合型槽油气密封作为研究对象,基于双相雷诺模型数值求解了三种型槽油气密封的流场分布,测试了不同工况下气膜密封的气膜厚度和介质泄漏,对比研究了宽速域范围内三种型槽油气密封的泄漏和成膜特性,重点分析了槽深、螺旋角和泵出槽长比等关键结构参数对八字复合型槽油气密封泄漏和成膜特性的影响规律。结果表明:泵出型螺旋槽密封因具有最小的漏油量可作为低速状态的优选方案,八字复合型槽密封因具有显著更低的窜气量和更大的气膜刚度可作为高速状态的优选方案,不过这依赖其槽深、螺旋角和泵出槽长比的合理设计;在一定的工况和结构参数时,复合型槽密封有望在端面形成明显的油气径向分界面,从而实现油气近零泄漏。

中图分类号:

许文烜, 江锦波, 彭新, 门日秀, 刘畅, 彭旭东. 宽速域三种典型型槽油气密封泄漏与成膜特性对比研究[J]. 化工学报, 2023, 74(4): 1660-1679.

Wenxuan XU, Jinbo JIANG, Xin PENG, Rixiu MEN, Chang LIU, Xudong PENG. Comparative study on leakage and film-forming characteristics of oil-gas seal with three-typical groove in a wide speed range[J]. CIESC Journal, 2023, 74(4): 1660-1679.

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| 密封面内径ri/mm | 29.5 | 密封间隙h0/μm | 3 |

| 密封面外径ro/mm | 37.5 | 外径侧压力pout/kPa | 150 |

| 槽深hg/μm | 5 | 内径侧压力pin/kPa | 100 |

| 泵出槽螺旋角β/(°) | 20 | 入口油气比Fl | 0.1 |

| 泵入槽螺旋角β2/(°) | 20 | 介质温度T/K | 300 |

| 泵出槽宽比δ1 | 0.5 | 转速n/(r·min-1) | 1000~50000 |

| 泵入槽宽比δ2 | 0.5 | 空气黏度μg/(μPa·s) | 17.9 |

| 泵出槽长比α1 | 0.6 | 润滑油黏度μl /(mPa·s) | 42.5 |

| 泵入槽长比α2 | 0.2 | 润滑油密度ρl /(kg·m-3) | 886 |

| 槽数Ng | 12 |

表1 油气密封性能分析计算初始参数

Table 1 Initial parameters adopted in the sealing performance analysis of oil-gas seal

| 参数 | 数值 | 参数 | 数值 |

|---|---|---|---|

| 密封面内径ri/mm | 29.5 | 密封间隙h0/μm | 3 |

| 密封面外径ro/mm | 37.5 | 外径侧压力pout/kPa | 150 |

| 槽深hg/μm | 5 | 内径侧压力pin/kPa | 100 |

| 泵出槽螺旋角β/(°) | 20 | 入口油气比Fl | 0.1 |

| 泵入槽螺旋角β2/(°) | 20 | 介质温度T/K | 300 |

| 泵出槽宽比δ1 | 0.5 | 转速n/(r·min-1) | 1000~50000 |

| 泵入槽宽比δ2 | 0.5 | 空气黏度μg/(μPa·s) | 17.9 |

| 泵出槽长比α1 | 0.6 | 润滑油黏度μl /(mPa·s) | 42.5 |

| 泵入槽长比α2 | 0.2 | 润滑油密度ρl /(kg·m-3) | 886 |

| 槽数Ng | 12 |

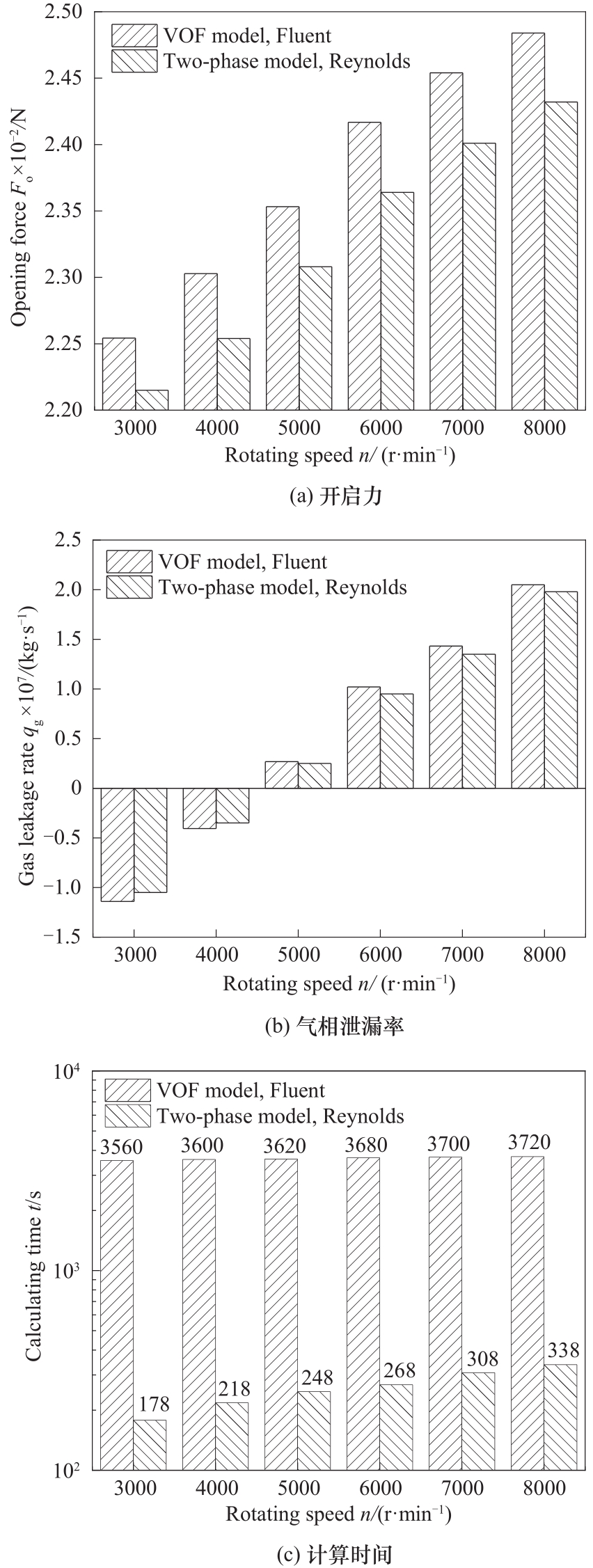

图6 不同转速下基于双相雷诺模型和VOF模型的密封性能计算精度和时间对比

Fig.6 Comparison of calculating time and accuracy of sealing performance between two-phase Reynolds model and VOF model under different rotating speed

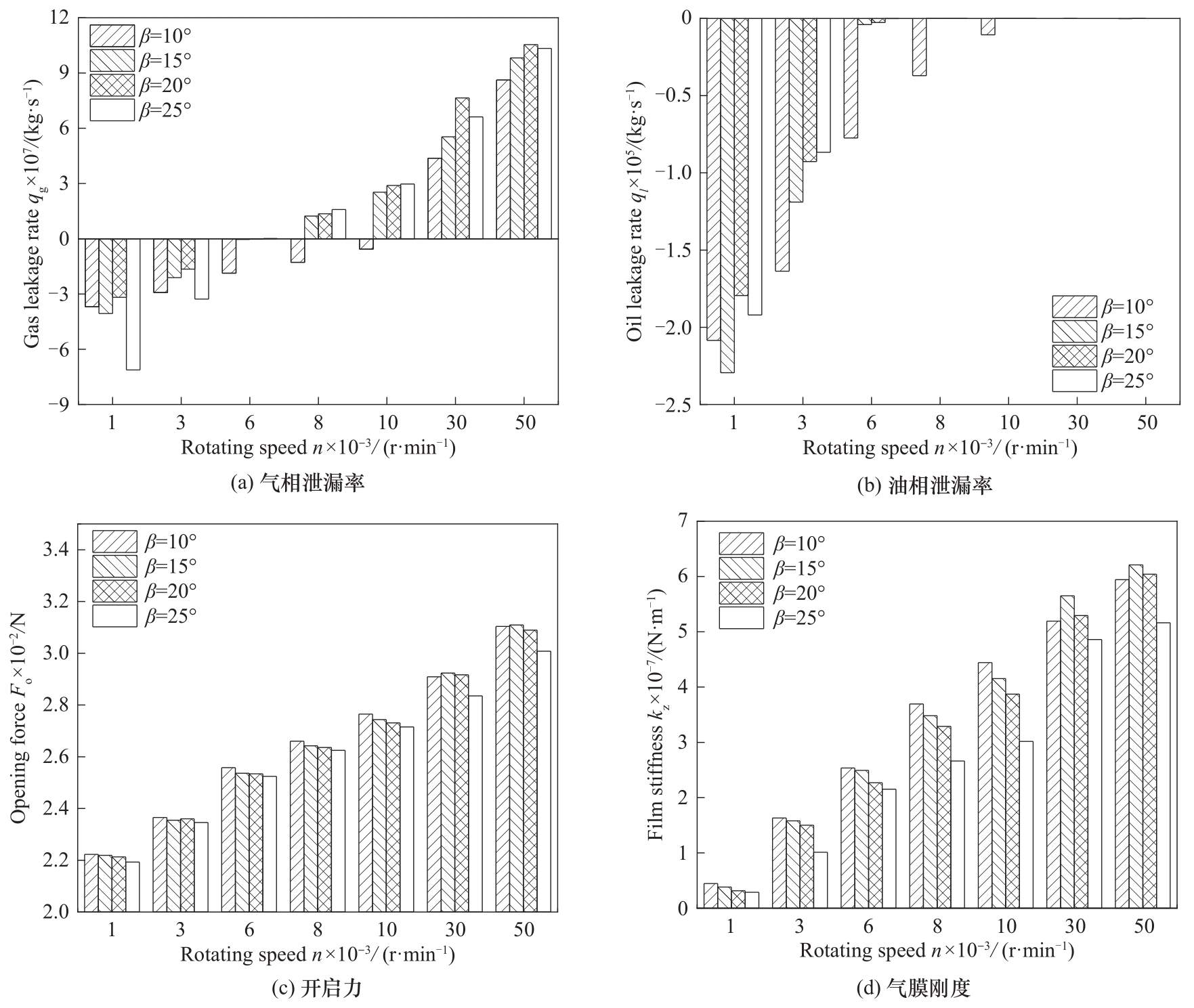

图10 不同泵出槽长比时转速对八字复合型槽密封稳态性能影响

Fig.10 Effect of rotating speed on the steady-state performance of splayed compound groove seal at different pump outlet groove length ratio

图14 不同转速下螺旋角对八字复合型槽密封稳态性能影响

Fig.14 Effect of spiral angle on the steady state performance of the splayed compound groove seal under different rotating speed

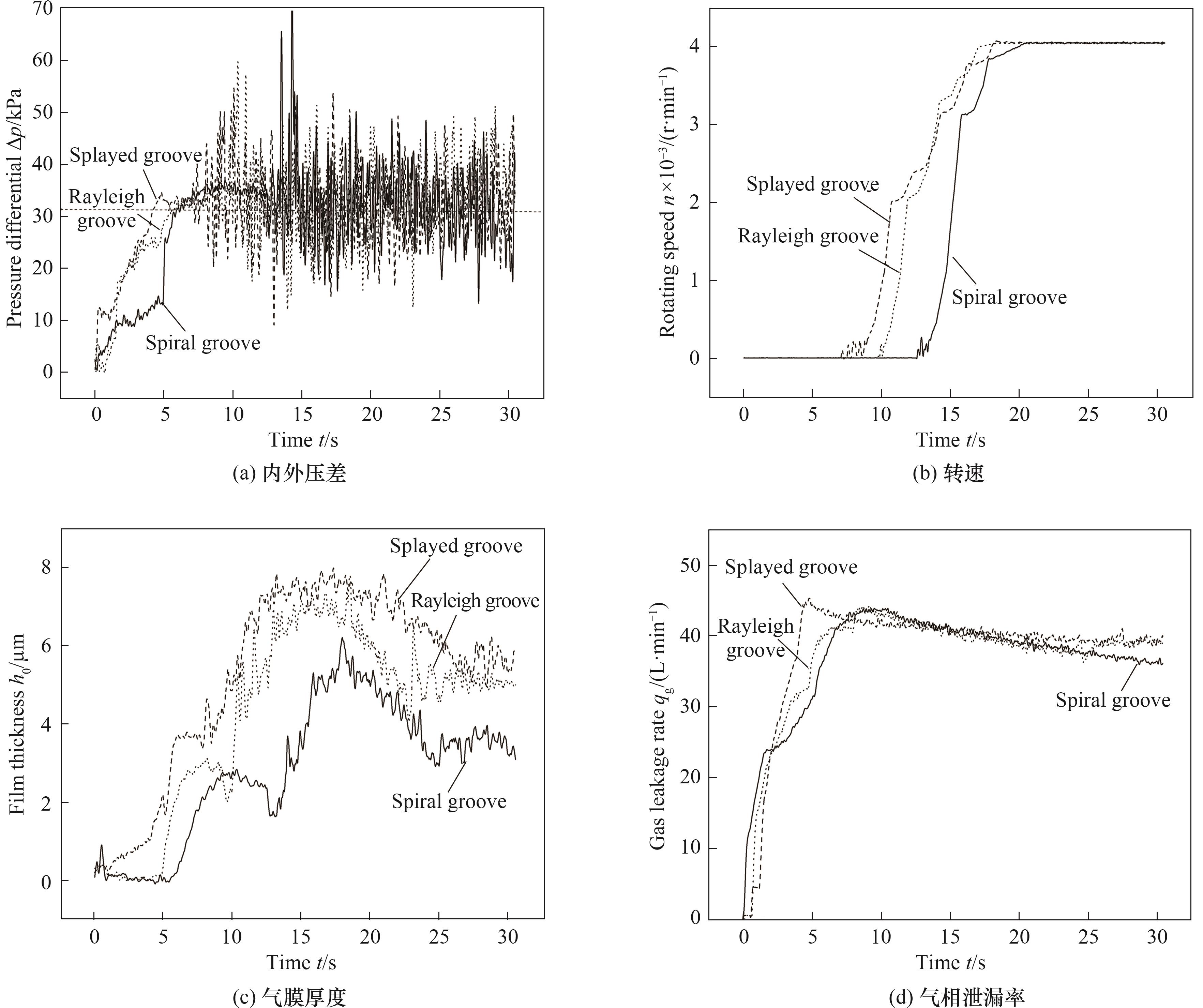

图23 变速变压过程中三种型槽端面油气密封参数时变曲线

Fig.23 Time varying curve of oil-gas seal parameters of three types of groove end faces during variable speed and pressure transformation

| 1 | Plaksin A, Gritsenko A, Glemba K. Modernization of the turbocharger lubrication system of an internal combustion engine[J]. Procedia Engineering, 2015, 129: 857-862. |

| 2 | Hunziker R, Jacoby P, Meier A. A new series of small turbochargers for high flow rates and high pressure ratios[J]. MTZ Worldwide, 2002, 63(6): 10-13. |

| 3 | Schmitt F. Powerful turbocharging system for passenger car diesel engines[J]. MTZ Worldwide, 2014, 75(3): 12-19. |

| 4 | 王胜光, 张炳闻, 陈长征. 涡轮增压器密封环的温度场及热变形研究[J]. 润滑与密封, 2005, 30(1): 44-46. |

| Wang S G, Zhang B W, Chen C Z. Study on temperature field and thermal deformation for sealing ring of turbocharger[J]. Lubrication Engineering, 2005, 30(1): 44-46. | |

| 5 | 宫燃, 程志高, 徐宜, 等. 旋转密封两种热失稳现象的表征建模与特性研究[J]. 机械工程学报, 2019, 55(9): 55-62. |

| Gong R, Cheng Z G, Xu Y, et al. Modeling research on characteristics of two types of thermal instability for rotary seal[J]. Journal of Mechanical Engineering, 2019, 55(9): 55-62. | |

| 6 | 郭志强, 门日秀, 闫柯, 等. 涡轮增压器甩油环密封性能研究[J]. 西安交通大学学报, 2019, 53(10): 143-150. |

| Guo Z Q, Men R X, Yan K, et al. Sealing performance of turbocharger oil slinger[J]. Journal of Xi'an Jiaotong University, 2019, 53(10):143-150. | |

| 7 | Neuberger S, Bock E, Haas W, et al. Gas-lubricated mechanical face seals reduce CO2 emissions[J]. Sealing Technology, 2014, 2014(9): 8-12. |

| 8 | Jiang J B, Peng X D, Li J Y, et al. A comparative study on the performance of typical types of bionic groove dry gas seal based on bird wing[J]. Journal of Bionic Engineering, 2016, 13(2): 324-334. |

| 9 | Jiang J B, Zhao W J, Peng X D, et al. A novel design for discrete surface texture on gas face seals based on a superposed groove model[J]. Tribology International, 2020, 147: 106269. |

| 10 | 彭旭东,宗聪,江锦波. 干气密封单向螺旋槽及其衍生结构功能演变进展[J]. 化工学报, 2017, 68(4): 1271-1281. |

| Peng X D, Zong C, Jiang J B. Progress in dry gas seal performance evolution of unidirectional spiral groove and its derivative structures[J]. CIESC Journal, 2017, 68(4): 1271-1281. | |

| 11 | Etsion I. A new concept of zero-leakage noncontacting mechanical face seal[J]. Journal of Tribology, 1984, 106(3): 338-343. |

| 12 | 宋鹏云, 丁志浩. 螺旋槽泵出型干气密封端面气膜压力近似解析计算[J]. 润滑与密封, 2011, 36(4): 1-3. |

| Song P Y, Ding Z H. An approximate analytical method of the gas film pressure of the outward pumping spiral groove dry gas seals[J]. Lubrication Engineering, 2011, 36(4): 1-3. | |

| 13 | 郝木明, 蔡厚振, 刘维滨, 等. 泵出型螺旋槽机械密封端面间隙气液两相流动数值分析[J]. 中国石油大学学报(自然科学版), 2015, 39(6): 129-137. |

| Hao M M, Cai H Z, Liu W B, et al. Numerical analysis on gas-liquid two-phase flow of outward pumping spiral-grooved mechanical seal clearance[J]. Journal of China University of Petroleum (Edition of Natural Science), 2015, 39(6): 129-137. | |

| 14 | Li S C, Qian C F, Li S X, et al. Study of sealing mechanism of gas-liquid miscible backflow pumping seal[J]. Tribology International, 2020, 142: 105974. |

| 15 | 李世聪, 钱才富, 李双喜, 等. 油气两相动压密封动态特性的热流固耦合研究[J]. 化工学报, 2020, 71(5): 2190-2201. |

| Li S C, Qian C F, Li S X, et al. Study of thermal-fluid-solid coupling on dynamic characteristics of oil-gas miscible backflow pumping seal[J]. CIESC Journal, 2020, 71(5): 2190-2201. | |

| 16 | 陈汇龙, 桂铠, 韩婷, 等. 上游泵送机械密封润滑膜固体颗粒沉积特性研究[J]. 化工学报, 2020, 71(4): 1712-1722. |

| Chen H L, Gui K, Han T, et al. Study on deposition characteristics of solid particles in lubricating film of upstream pumping mechanical seal[J]. CIESC Journal, 2020, 71(4): 1712-1722. | |

| 17 | 陈汇龙, 左木子, 吴强波, 等. 上游泵送机械密封润滑膜固液两相流动特性[J]. 排灌机械工程学报, 2015, 33(8): 685-690. |

| Chen H L, Zuo M Z, Wu Q B, et al. Solid-liquid two-phase flow characteristics of lubricating film in upstream pumping mechanical seal[J]. Journal of Drainage and Irrigation Machinery Engineering, 2015, 33(8): 685-690. | |

| 18 | Simon C, Lang K, Feigl P, et al. Turbocharger seal for zero oil consumption and minimised blow-by[J]. MTZ Worldwide, 2010, 71(4): 36-41. |

| 19 | Simon C, Lang K, Feigl P, et al. Turbocharger seal as a decisive enabler for downsizing concepts[J]. Sealing Technology, 2011, 2011(1): 10-11. |

| 20 | Nelson D A. Development of a noncontacting mechanical seal for high performance turbocharger applications[J]. Journal of Engineering for Gas Turbines and Power, 2019, 141(3): 031008. |

| 21 | 刘雨川, 徐万孚, 陈国林, 等. 端面气膜密封的高性能端面结构[J]. 航空学报, 2000, 21(2): 187-190. |

| Liu Y C, Xu W F, Chen G L, et al. Face configuration with high performance for gas film face seal[J]. Acta Aeronautica et Astronautica Sinica, 2000, 21(2): 187-190. | |

| 22 | 庄永福. 循环气压缩机浮环密封失效分析及改造[J]. 流体机械, 2006, 34(3): 48-51. |

| Zhuang Y F. Failure analysis and technical improvement of float ring seals for cycle compressor[J]. Fluid Machinery, 2006, 34(3): 48-51. | |

| 23 | 汤臣杭, 杨惠霞, 王玉明. 单向双列螺旋槽干气密封流场数值模拟[J]. 润滑与密封, 2007, 32(1): 145-148. |

| Tang C H, Yang H X, Wang Y M. Flow numerical simulation of dry gas seal with double-row spiral grooves[J]. Lubrication Engineering, 2007, 32(1): 145-148. | |

| 24 | Inoue H, Takigahira Y, Dircks R. Low-friction sealing system for e-drives[J]. MTZ worldwide, 2020, 81(11): 28-35. |

| 25 | 雷晨辉. 低温易汽化介质雷列槽非接触式密封性能的研究[D]. 北京: 北京化工大学, 2018. |

| Lei C H. Study on sealing performance of ryrus groove seal in low temperature and easy vaporizing medium[D]. Beijing: Beijing University of Chemical Technology, 2018. | |

| 26 | 马学忠, 孟祥铠, 张伟政, 等. 反向瑞利台阶构型液膜空化性能与机械密封空化抽吸效应评价[J]. 化工学报, 2020, 71(12): 5715-5724. |

| Ma X Z, Meng X K, Zhang W Z, et al. Evaluation on liquid film cavitation capacity in reverse Rayleigh step and cavitation suction effect in its mechanical seals[J]. CIESC Journal, 2020, 71(12): 5715-5724. | |

| 27 | 马学忠, 孟祥铠, 王玉明, 等. 机械端面密封反向螺旋槽空化效应与泄漏控制机理[J]. 化工学报, 2018, 69(4): 1558-1568. |

| Ma X Z, Meng X K, Wang Y M, et al. Cavitation effect and leakage control mechanism of reverse spiral grooves mechanical end face seals[J]. CIESC Journal, 2018, 69(4): 1558-1568. | |

| 28 | Wallis G B. One-Dimensional Two-Phase Flow[M]. New York: McGraw-Hill, 1969. |

| 29 | Li D Y, Christian H. Simulation of bubbly flows with special numerical treatments of the semi-conservative and fully conservative two-fluid model[J]. Chemical Engineering Science, 2017, 174: 25-39. |

| [1] | 江河, 袁俊飞, 王林, 邢谷雨. 均流腔结构对微细通道内相变流动特性影响的实验研究[J]. 化工学报, 2023, 74(S1): 235-244. |

| [2] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [3] | 袁佳琦, 刘政, 黄锐, 张乐福, 贺登辉. 泡状入流条件下旋流泵能量转换特性研究[J]. 化工学报, 2023, 74(9): 3807-3820. |

| [4] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [5] | 邢雷, 苗春雨, 蒋明虎, 赵立新, 李新亚. 井下微型气液旋流分离器优化设计与性能分析[J]. 化工学报, 2023, 74(8): 3394-3406. |

| [6] | 高燕, 伍鹏, 尚超, 胡泽君, 陈晓东. 基于双流体喷嘴的磁性琼脂糖微球的制备及其蛋白吸附性能探究[J]. 化工学报, 2023, 74(8): 3457-3471. |

| [7] | 闫琳琦, 王振雷. 基于STA-BiLSTM-LightGBM组合模型的多步预测软测量建模[J]. 化工学报, 2023, 74(8): 3407-3418. |

| [8] | 高金明, 郭玉娇, 鄂承林, 卢春喜. 一种封闭罩内顺流多旋臂气液分离器的分离特性研究[J]. 化工学报, 2023, 74(7): 2957-2966. |

| [9] | 文兆伦, 李沛睿, 张忠林, 杜晓, 侯起旺, 刘叶刚, 郝晓刚, 官国清. 基于自热再生的隔壁塔深冷空分工艺设计及优化[J]. 化工学报, 2023, 74(7): 2988-2998. |

| [10] | 刘起超, 周云龙, 陈聪. 起伏振动垂直上升管气液两相流截面含气率分析与计算[J]. 化工学报, 2023, 74(6): 2391-2403. |

| [11] | 江锦波, 彭新, 许文烜, 门日秀, 刘畅, 彭旭东. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| [12] | 董鑫, 单永瑞, 刘易诺, 冯颖, 张建伟. 非牛顿流体气泡羽流涡特性数值模拟研究[J]. 化工学报, 2023, 74(5): 1950-1964. |

| [13] | 孙永尧, 高秋英, 曾文广, 王佳铭, 陈艺飞, 周永哲, 贺高红, 阮雪华. 面向含氮油田伴生气提质利用的膜耦合分离工艺设计优化[J]. 化工学报, 2023, 74(5): 2034-2045. |

| [14] | 刘尚豪, 贾胜坤, 罗祎青, 袁希钢. 基于梯度提升决策树的三组元精馏流程结构最优化[J]. 化工学报, 2023, 74(5): 2075-2087. |

| [15] | 周必茂, 许世森, 王肖肖, 刘刚, 李小宇, 任永强, 谭厚章. 烧嘴偏转角度对气化炉渣层分布特性的影响[J]. 化工学报, 2023, 74(5): 1939-1949. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号