化工学报 ›› 2023, Vol. 74 ›› Issue (5): 1939-1949.DOI: 10.11949/0438-1157.20230140

周必茂1( ), 许世森2, 王肖肖1, 刘刚2, 李小宇2, 任永强2, 谭厚章1(

), 许世森2, 王肖肖1, 刘刚2, 李小宇2, 任永强2, 谭厚章1( )

)

收稿日期:2023-02-21

修回日期:2023-05-04

出版日期:2023-05-05

发布日期:2023-06-29

通讯作者:

谭厚章

作者简介:周必茂(1997—),男,硕士研究生,2960474331@qq.com

基金资助:

Bimao ZHOU1( ), Shisen XU2, Xiaoxiao WANG1, Gang LIU2, Xiaoyu LI2, Yongqiang REN2, Houzhang TAN1(

), Shisen XU2, Xiaoxiao WANG1, Gang LIU2, Xiaoyu LI2, Yongqiang REN2, Houzhang TAN1( )

)

Received:2023-02-21

Revised:2023-05-04

Online:2023-05-05

Published:2023-06-29

Contact:

Houzhang TAN

摘要:

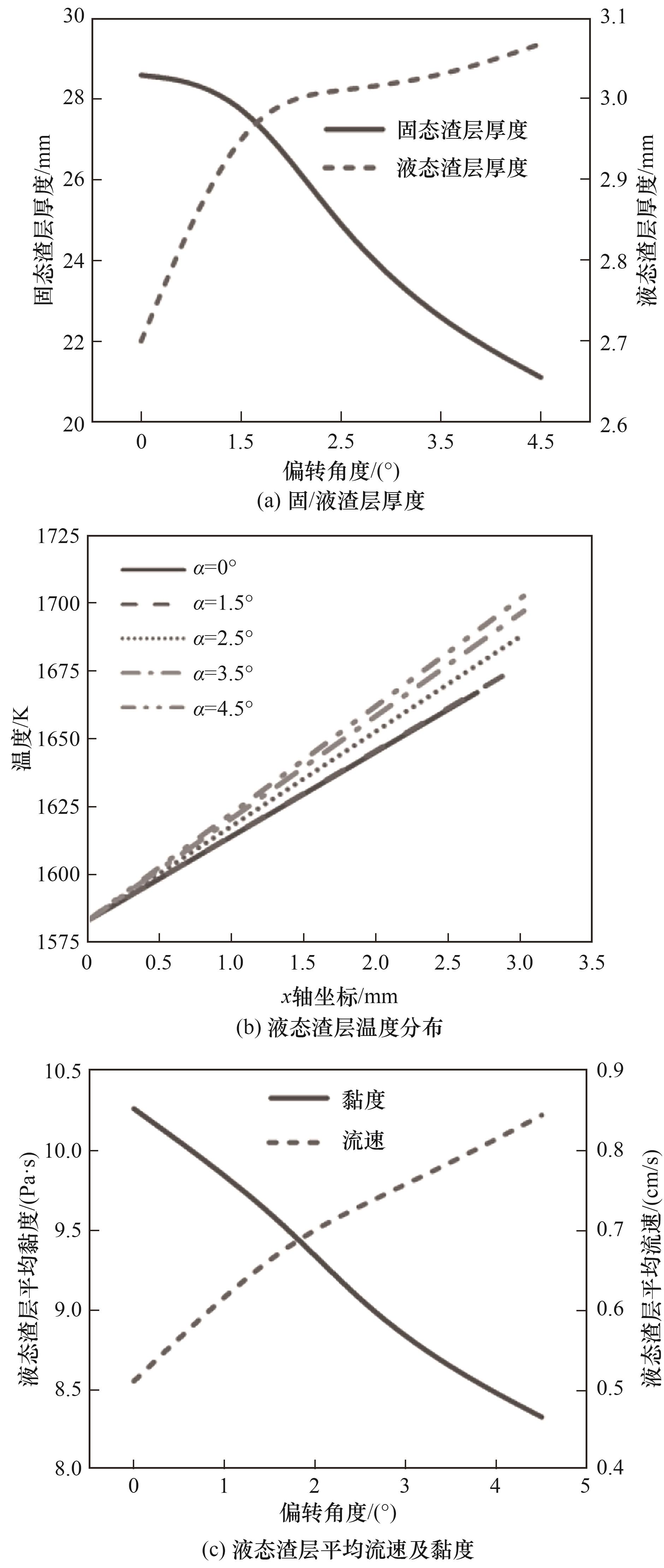

气化炉灰渣比(合成气携带走的飞灰与沉积至壁面的熔渣的质量比)是影响后续合成气净化设备寿命的关键因素,优化烧嘴偏转角度是控制气化炉灰渣比的有效方法。采用数值模拟方法,研究了HNCERI (Huaneng Clean Energy Research Institute)气化炉一段四烧嘴偏转角度对气化炉灰渣比、壁面渣层及耐火材料的影响。数值模拟结果表明,烧嘴偏转角度由0°增加至4.5°,灰渣比由2.0降低至0.8,液态渣层平均停留时间减少31.5%。偏转角度增加,渣口位置液/固态渣层厚度均增加;H=4.45~5.07 m位置固态渣层厚度下降,液态渣层厚度则增加。液态渣层流速与黏度呈负相关,与厚度呈正相关,液态渣层厚度主要受流速和颗粒沉积率影响。偏转角度增加,烧嘴平面上方耐火材料表面平均温度升高,烧嘴平面下方耐火材料表面平均温度降低,偏转角度为3.5°时耐火材料需要承受的最高温度取得最低值。在有效降低灰渣比前提下,为减少气化炉堵渣、渣层脱落和耐火材料烧蚀概率,HNCERI气化炉烧嘴偏转角度建议取3.5°。

中图分类号:

周必茂, 许世森, 王肖肖, 刘刚, 李小宇, 任永强, 谭厚章. 烧嘴偏转角度对气化炉渣层分布特性的影响[J]. 化工学报, 2023, 74(5): 1939-1949.

Bimao ZHOU, Shisen XU, Xiaoxiao WANG, Gang LIU, Xiaoyu LI, Yongqiang REN, Houzhang TAN. Effect of burner bias angle on distribution characteristics of gasifier slag layer[J]. CIESC Journal, 2023, 74(5): 1939-1949.

| 序号 | 均相反应 | 指前因子Ai /(kg/(m2·s·Pa)) | 活化能Ei /(J/kmol) |

|---|---|---|---|

| 1 | Vol | 4.26×105 | 1.08×108 |

| 2 | Vol + 1.21355 O2 | 9.2×106 | 8.02×107 |

| 3 | H2 + 0.5 O2 | 6.8×1015(β=-1) | 1.68×108 |

| 4 | CO + H2O | 2.75×1010 | 8.37×107 |

| 5 | CO + 0.5 O2 | 2.239×1012 | 1.674×108 |

| 6 | CO2 + H2 | 2.2×107 | 1.98×108 |

| 7 | C6H6 + 3 O2 | 1.58×1015 | 2.206×108 |

| 8 | CH4 + 0.5 O2 | 4.4×1011 | 1.25×108 |

| 9 | C6H6 + 6 H2O | 3.0×108 | 1.26×108 |

| 10 | C7H8 + 9 O2 | 1.6×108 | 1.255×108 |

| 11 | C6H6 + 7.5 O2 | 1.125×109 | 1.256×108 |

| 12 | C7H8 + H2 | 1.04×1012 | 2.47×108 |

| 13 | CH4 + H2O | 3×108 | 1.25×108 |

表1 气相化学反应动力学参数[21]

Table 1 Kinetic parameters of gas phase chemical reaction[21]

| 序号 | 均相反应 | 指前因子Ai /(kg/(m2·s·Pa)) | 活化能Ei /(J/kmol) |

|---|---|---|---|

| 1 | Vol | 4.26×105 | 1.08×108 |

| 2 | Vol + 1.21355 O2 | 9.2×106 | 8.02×107 |

| 3 | H2 + 0.5 O2 | 6.8×1015(β=-1) | 1.68×108 |

| 4 | CO + H2O | 2.75×1010 | 8.37×107 |

| 5 | CO + 0.5 O2 | 2.239×1012 | 1.674×108 |

| 6 | CO2 + H2 | 2.2×107 | 1.98×108 |

| 7 | C6H6 + 3 O2 | 1.58×1015 | 2.206×108 |

| 8 | CH4 + 0.5 O2 | 4.4×1011 | 1.25×108 |

| 9 | C6H6 + 6 H2O | 3.0×108 | 1.26×108 |

| 10 | C7H8 + 9 O2 | 1.6×108 | 1.255×108 |

| 11 | C6H6 + 7.5 O2 | 1.125×109 | 1.256×108 |

| 12 | C7H8 + H2 | 1.04×1012 | 2.47×108 |

| 13 | CH4 + H2O | 3×108 | 1.25×108 |

| 序号 | 异相反应 | ni | ψi | Ai | Ep,i /(J/kmol) |

|---|---|---|---|---|---|

| 1 | C+H2O | 0.64 | 3 | 4.18×104 Pa-0.64·s-1 | 2.52×108 |

| 2 | C+CO2 | 0.54 | 3 | 6.27×105 Pa-0.54·s-1 | 2.83×108 |

| 3 | C+0.5 O2 | 0.68 | 14 | 1.13×102 Pa-0.68·s-1 | 1.30×108 |

表2 焦炭异相反应动力学参数[23]

Table 2 Kinetic parameters of heterogeneous reaction of char[23]

| 序号 | 异相反应 | ni | ψi | Ai | Ep,i /(J/kmol) |

|---|---|---|---|---|---|

| 1 | C+H2O | 0.64 | 3 | 4.18×104 Pa-0.64·s-1 | 2.52×108 |

| 2 | C+CO2 | 0.54 | 3 | 6.27×105 Pa-0.54·s-1 | 2.83×108 |

| 3 | C+0.5 O2 | 0.68 | 14 | 1.13×102 Pa-0.68·s-1 | 1.30×108 |

| 项目 | 质量流率/(kg/h) | ||

|---|---|---|---|

| O2 | H2O | coal | |

| 一段 | 63198.83 | 2000 | 69626.8 |

| 二段 | 0 | 0 | 2603.62 |

表3 入口边界条件

Table 3 Inlet boundary conditions

| 项目 | 质量流率/(kg/h) | ||

|---|---|---|---|

| O2 | H2O | coal | |

| 一段 | 63198.83 | 2000 | 69626.8 |

| 二段 | 0 | 0 | 2603.62 |

| 工业分析/%(mass, ar) | 元素分析/%(mass, d) | Qnet/(MJ/kg) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| M | A | V | FC | C | H | N | S | O | |

| 3.88 | 11.09 | 32.15 | 52.88 | 69.78 | 4.27 | 1.25 | 0.25 | 9.22 | 28.3 |

表4 煤质分析

Table 4 Properties of the coal

| 工业分析/%(mass, ar) | 元素分析/%(mass, d) | Qnet/(MJ/kg) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| M | A | V | FC | C | H | N | S | O | |

| 3.88 | 11.09 | 32.15 | 52.88 | 69.78 | 4.27 | 1.25 | 0.25 | 9.22 | 28.3 |

| 项目 | CO/% | H2/% | CO2/% | 一段散热量/MW | 一段碳 转化率/% |

|---|---|---|---|---|---|

| 工业数据 | 57.52 | 23.93 | 3.32 | 9~10.3 | 99.42 |

| 模拟数据 | 57.11 | 23.90 | 3.97 | 9.31 | 99.54 |

表5 模型验证数据对比

Table 5 Comparison of model verification data

| 项目 | CO/% | H2/% | CO2/% | 一段散热量/MW | 一段碳 转化率/% |

|---|---|---|---|---|---|

| 工业数据 | 57.52 | 23.93 | 3.32 | 9~10.3 | 99.42 |

| 模拟数据 | 57.11 | 23.90 | 3.97 | 9.31 | 99.54 |

图10 H=4.45~5.07 m位置偏转角度对渣层厚度、温度分布及流动特性的影响

Fig.10 Effect of bias angle on slag layer thickness, temperature distribution and flow characteristics at 4.45—5.07 m

| 1 | Pin L R, Georg S L, Huang Q L, et al. An analysis of waste gasification and its contribution to China’s transition towards carbon neutrality and zero waste cities[J]. Journal of Fuel Chemistry and Technology, 2021, 49(8): 1057-1076. |

| 2 | 汪寿建. 现代煤气化技术发展趋势及应用综述[J]. 化工进展, 2016, 35(3): 653-664. |

| Wang S J. Development and applicatin of modern coal gasification technology[J]. Chemical Industry and Engineering Progress, 2016, 35(3): 653-664. | |

| 3 | 桂霞, 王陈魏, 云志, 等. 燃烧前CO2捕集技术研究进展[J]. 化工进展, 2014, 33(7): 1895-1901. |

| Gui X, Wang C W, Yun Z, et al. Research progress of pre-combustion CO2 capture[J]. Chemical Industry and Engineering Progress, 2014, 33(7): 1895-1901. | |

| 4 | 吴海茜, 许利华. 碳捕集利用与封存研究进展[J]. 余热锅炉, 2021(2): 1-7. |

| Wu H X, Xu L H. Research progress in carbon capture, utilization, and storage[J]. Waste Heat Boiler, 2021(2): 1-7. | |

| 5 | 柳康, 许世森, 李广宇, 等. 基于整体煤气化联合循环的燃烧前CO2捕集工艺及系统分析[J]. 化工进展, 2018, 37(12): 4897-4907. |

| Liu K, Xu S S, Li G Y, et al. Technological process and system analysis of pre-combustion CO2 capture based on IGCC[J]. Chemical Industry and Engineering Progress, 2018, 37(12): 4897-4907. | |

| 6 | Xu S S, Ren Y Q, Wang B M, et al. Development of a novel 2-stage entrained flow coal dry powder gasifier[J]. Applied Energy, 2014, 113: 318-323. |

| 7 | 李小宇, 李广宇, 许世森, 等. 液态排渣煤气化炉炉内灰渣的流动和换热研究[J]. 中国电机工程学报, 2009, 29(14): 12-17. |

| Li X Y, Li G Y, Xu S S, et al. Research on flow and heat transfer of slag film in gasifier with liquid slag-removal process[J]. Proceedings of the CSEE, 2009, 29(14): 12-17. | |

| 8 | Watanabe H, Kurose R. Modeling and simulation of coal gasification on an entrained flow coal gasifier[J]. Advanced Powder Technology, 2020, 31(7): 2733-2741. |

| 9 | Wang X X, Xu S S, Wang Y B, et al. Numerical simulation on the effect of burner bias angles on the performance of a two-stage entrained-flow gasifier[J]. ACS Omega, 2022, 7(8): 6640-6654. |

| 10 | 付彬, 徐庆洋. 两段式气化炉二段充分反应的条件及气化炉冷煤气效率变化的分析[J]. 煤化工, 2018, 46(6): 5-7. |

| Fu B, Xu Q Y. Analysis on the second stage full reaction condition and cold gas efficiency change of two-stage gasifier[J]. Coal Chemical Industry, 2018, 46(6): 5-7. | |

| 11 | Zhang B B, Shen Z J, Liang Q F, et al. Numerical study of dynamic response analysis of slag behaviors in an entrained flow gasifier[J]. Fuel, 2018, 234: 1071-1080. |

| 12 | Zhang B B, Shen Z J, Liang Q F, et al. Modeling study of residence time of molten slag on the wall in an entrained flow gasifier[J]. Fuel, 2018, 212: 437-447. |

| 13 | Chen C X, Horio M, Kojima T. Use of numerical modeling in the design and scale-up of entrained flow coal gasifiers[J]. Fuel, 2001, 80(10): 1513-1523. |

| 14 | Gong Y, Guo Q H, Zhu H W, et al. Refractory failure in entrained-flow gasifier: investigation of partitioned erosion characteristics in an industrial opposed multi-burner gasifier[J]. Chemical Engineering Science, 2019, 210: 115227. |

| 15 | 张宾宾. 气流床气化炉内壁面熔渣流动与传热过程研究[D]. 上海: 华东理工大学, 2018. |

| Zhang B B. Modeling study of slag flow and heat transfer process on the wall for an entrained-flow gasifier[D]. Shanghai: East China University of Science and Technology, 2018. | |

| 16 | Xuan W W, Zhang J S, Xia D H. Crystallization characteristics of a coal slag and influence of crystals on the sharp increase of viscosity[J]. Fuel, 2016, 176: 102-109. |

| 17 | Kim Y, Oh M S. Effect of cooling rate and alumina dissolution on the determination of temperature of critical viscosity of molten slag[J]. Fuel Processing Technology, 2010, 91(8): 853-858. |

| 18 | Kalmanovitch D P, Williamson J. Crystallization of Coal Ash Melts[M]. Washington, DC: American Chemical Society, 1986: 234-255. |

| 19 | Nowok J W. Viscosity and phase transformation in coal ash slags near and below the temperature of critical viscosity[J]. Energy & Fuels, 1994, 8(6): 1324-1336. |

| 20 | Ye I, Ryu C, Koo J H. Influence of critical viscosity and its temperature on the slag behavior on the wall of an entrained coal gasifier[J]. Applied Thermal Engineering, 2015, 87: 175-184. |

| 21 | Jeong H J, Seo D K, Hwang J. CFD modeling for coal size effect on coal gasification in a two-stage commercial entrained-bed gasifier with an improved char gasification model[J]. Applied Energy, 2014, 123: 29-36. |

| 22 | Halama S, Spliethoff H. Numerical simulation of entrained flow gasification: reaction kinetics and char structure evolution[J]. Fuel Processing Technology, 2015, 138: 314-324. |

| 23 | Kajitani S, Hara S, Matsuda H. Gasification rate analysis of coal char with a pressurized drop tube furnace[J]. Fuel, 2002, 81(5): 539-546. |

| 24 | 杨帆, 范晓雷, 周志杰, 等. 随机孔模型应用于煤焦与CO2气化的动力学研究[J]. 燃料化学学报, 2005, 33(6): 671-676. |

| Yang F, Fan X L, Zhou Z J, et al. Kinetics of coal char gasification with CO2 random pore model[J]. Journal of Fuel Chemistry and Technology, 2005, 33(6): 671-676. | |

| 25 | 许世森, 周必茂, 王肖肖, 等. 高温下煤焦孔结构系数变化规律及其对气化速率影响的研究[J]. 燃料化学学报, 2022, 50(9): 1116-1125. |

| Xu S S, Zhou B M, Wang X X, et al. Study on the variation of pore structure parameter of coal char at high temperature and its effect on gasification rate[J]. Journal of Fuel Chemistry and Technology, 2022, 50(9): 1116-1125. | |

| 26 | Laurendeau N M. Heterogeneous kinetics of coal char gasification and combustion[J]. Progress in Energy and Combustion Science, 1978, 4(4): 221-270. |

| 27 | Abu El-Rub Z. Biomass char as an in-situ catalyst for tar removal in gasification systems[D]. Enschede, Netherlands: University of Twente, 2008. |

| 28 | Seggiani M. Modelling and simulation of time varying slag flow in a Prenflo entrained-flow gasifier[J]. Fuel, 1998, 77(14): 1611-1621. |

| 29 | Ren Y Q, Xu S S, Li G Y. Experimental study on the operational performance of an advanced two-stage entrained-flow coal gasifier[J]. Energy & Fuels, 2014, 28(8): 4911-4917. |

| 30 | 许世森, 王肖肖, 刘刚, 等. 煤粉粒径对HNCERI气化炉碳转化率与固/液渣层分布的影响[J]. 化工进展, 2022, 41(3): 1517-1527. |

| Xu S S, Wang X X, Liu G, et al. Numerical simulation on the effect of coal size on slag distribution and carbon conversion efficiency of HNCERI gasifier[J]. Chemical Industry and Engineering Progress, 2022, 41(3): 1517-1527. | |

| 31 | Lin K, Shen Z J, Liang Q F, et al. The study of slag discharge behavior of entrained-flow gasifier based on the viscosity-temperature characteristics of different types of coals[J]. Fuel, 2021, 292: 120314. |

| 32 | Ge J, Wang Z H, Wan K D, et al. Slagging behavior modeling in coal gasifiers using two-way coupled slag model with CFD[J]. Fuel, 2020, 281: 118736. |

| 33 | Xu J L, Dai Z H, Liu H F, et al. Modeling of multiphase reaction and slag flow in single-burner coal water slurry gasifier[J]. Chemical Engineering Science, 2017, 162: 41-52. |

| [1] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [2] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [3] | 刘爽, 张霖宙, 许志明, 赵锁奇. 渣油及其组分黏度的分子层次组成关联研究[J]. 化工学报, 2023, 74(8): 3226-3241. |

| [4] | 韩晨, 司徒友珉, 朱斌, 许建良, 郭晓镭, 刘海峰. 协同处理废液的多喷嘴粉煤气化炉内反应流动研究[J]. 化工学报, 2023, 74(8): 3266-3278. |

| [5] | 文兆伦, 李沛睿, 张忠林, 杜晓, 侯起旺, 刘叶刚, 郝晓刚, 官国清. 基于自热再生的隔壁塔深冷空分工艺设计及优化[J]. 化工学报, 2023, 74(7): 2988-2998. |

| [6] | 江锦波, 彭新, 许文烜, 门日秀, 刘畅, 彭旭东. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| [7] | 雷博雯, 吴建华, 吴启航. R290低压比热泵高补气过热度循环研究[J]. 化工学报, 2023, 74(5): 1875-1883. |

| [8] | 孙永尧, 高秋英, 曾文广, 王佳铭, 陈艺飞, 周永哲, 贺高红, 阮雪华. 面向含氮油田伴生气提质利用的膜耦合分离工艺设计优化[J]. 化工学报, 2023, 74(5): 2034-2045. |

| [9] | 刘尚豪, 贾胜坤, 罗祎青, 袁希钢. 基于梯度提升决策树的三组元精馏流程结构最优化[J]. 化工学报, 2023, 74(5): 2075-2087. |

| [10] | 王泽栋, 石至平, 刘丽艳. 考虑气泡非均匀耗散的矩形反应器声流场数值模拟及结构优化[J]. 化工学报, 2023, 74(5): 1965-1973. |

| [11] | 葛泽峰, 吴雨青, 曾名迅, 查振婷, 马宇娜, 侯增辉, 张会岩. 灰化学成分对生物质气化特性的影响规律[J]. 化工学报, 2023, 74(5): 2136-2146. |

| [12] | 许文烜, 江锦波, 彭新, 门日秀, 刘畅, 彭旭东. 宽速域三种典型型槽油气密封泄漏与成膜特性对比研究[J]. 化工学报, 2023, 74(4): 1660-1679. |

| [13] | 李纪元, 李金旺, 周刘伟. 不同扰流结构冷板传热性能研究[J]. 化工学报, 2023, 74(4): 1474-1488. |

| [14] | 张永泉, 玄伟伟. 碱金属/(FeO+CaO+MgO)对硅酸盐灰熔渣结构和黏度的影响机理[J]. 化工学报, 2023, 74(4): 1764-1771. |

| [15] | 陈俊先, 姬忠礼, 赵瑜, 张倩, 周岩, 刘猛, 刘震. 基于微波技术的天然气管道内颗粒物在线检测方法研究[J]. 化工学报, 2023, 74(3): 1042-1053. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号