化工学报 ›› 2023, Vol. 74 ›› Issue (5): 2034-2045.DOI: 10.11949/0438-1157.20221611

孙永尧1,2( ), 高秋英1,2, 曾文广1,2, 王佳铭3, 陈艺飞3, 周永哲3, 贺高红3, 阮雪华3(

), 高秋英1,2, 曾文广1,2, 王佳铭3, 陈艺飞3, 周永哲3, 贺高红3, 阮雪华3( )

)

收稿日期:2022-12-13

修回日期:2023-05-03

出版日期:2023-05-05

发布日期:2023-06-29

通讯作者:

阮雪华

作者简介:孙永尧(1996—),男,硕士,工程师,2253893150@qq.com

基金资助:

Yongyao SUN1,2( ), Qiuying GAO1,2, Wenguang ZENG1,2, Jiaming WANG3, Yifei CHEN3, Yongzhe ZHOU3, Gaohong HE3, Xuehua RUAN3(

), Qiuying GAO1,2, Wenguang ZENG1,2, Jiaming WANG3, Yifei CHEN3, Yongzhe ZHOU3, Gaohong HE3, Xuehua RUAN3( )

)

Received:2022-12-13

Revised:2023-05-03

Online:2023-05-05

Published:2023-06-29

Contact:

Xuehua RUAN

摘要:

近年来,随着氮气强化采油的不断推广,含氮油田伴生气产量不断增加,生产合格的管道天然气成为提高资源利用率、增加经济效益的重要命题。本研究从组成特征出发,成功研制并批量生产功能层减薄至700 nm的硅橡胶复合膜,大幅提高分离能力,未溶胀状态下甲烷渗透速率达到358 GPU [1 GPU=1.24 mol/(m2·h·MPa)],同时提出浅冷液化与多级膜渗透集成的耦合分离工艺,在充分回收乙烷和丙烷等化工原料的同时,生产热值满足国家标准GB 17820—2018的管道天然气,实现伴生气高效提质和综合利用。以西北油田某集输站为实施案例,针对7000 m3/h(标准工况)伴生气进行耦合工艺设计,模拟结果显示轻烃收率大于77.6%,甲烷提质利用率大于54.4%,乙烯裂解原料产量23604 t/a,管道天然气产量18.03×106 m3/a(标准工况),创造经济效益预计可达79.0×106 CNY/a,为含氮油田伴生气的高效利用提供了极具前景的加工途径。

中图分类号:

孙永尧, 高秋英, 曾文广, 王佳铭, 陈艺飞, 周永哲, 贺高红, 阮雪华. 面向含氮油田伴生气提质利用的膜耦合分离工艺设计优化[J]. 化工学报, 2023, 74(5): 2034-2045.

Yongyao SUN, Qiuying GAO, Wenguang ZENG, Jiaming WANG, Yifei CHEN, Yongzhe ZHOU, Gaohong HE, Xuehua RUAN. Design and optimization of membrane-based integration process for advanced utilization of associated gases in N2-EOR oilfields[J]. CIESC Journal, 2023, 74(5): 2034-2045.

| Component | Generation cases in oilfield/ %(mol) | Critical properties | |||

|---|---|---|---|---|---|

| Early stage | Middle stage | Later stage | Tc/K | Vc/ (cm3/mol) | |

| N2 | 11.43 | 23.87 | 33.26 | 126.2 | 90.0 |

| CH4 | 58.53 | 47.67 | 39.71 | 190.7 | 99.0 |

| C2H6 | 11.30 | 10.35 | 9.48 | 305.5 | 98.6 |

| C3H8 | 6.30 | 6.12 | 5.94 | 369.9 | 200.0 |

| i-C4H10 | 2.02 | 1.99 | 1.97 | 408.1 | 263.0 |

| n-C4H10 | 2.75 | 2.73 | 2.71 | 425.2 | 255.0 |

| i-C5H12 | 1.71 | 1.71 | 1.71 | 460.4 | 308.0 |

| n-C5H12 | 1.44 | 1.44 | 1.44 | 469.7 | 311.0 |

| C6H14 | 0.50 | 0.50 | 0.50 | 507.9 | 368.0 |

| C7H16 | 0.21 | 0.21 | 0.21 | 540.2 | 426.0 |

| CO2 | 2.56 | 2.21 | 1.92 | 304.2 | 93.9 |

| H2S | 0.85 | 0.78 | 0.72 | 373.7 | 98.0 |

| H2O | 0.41 | 0.42 | 0.42 | 647.3 | 57.1 |

表1 西北油田某集输站油田伴生气的组成

Table 1 Composition of associated gas in a gathering and transportation station of Northwest Oilfield

| Component | Generation cases in oilfield/ %(mol) | Critical properties | |||

|---|---|---|---|---|---|

| Early stage | Middle stage | Later stage | Tc/K | Vc/ (cm3/mol) | |

| N2 | 11.43 | 23.87 | 33.26 | 126.2 | 90.0 |

| CH4 | 58.53 | 47.67 | 39.71 | 190.7 | 99.0 |

| C2H6 | 11.30 | 10.35 | 9.48 | 305.5 | 98.6 |

| C3H8 | 6.30 | 6.12 | 5.94 | 369.9 | 200.0 |

| i-C4H10 | 2.02 | 1.99 | 1.97 | 408.1 | 263.0 |

| n-C4H10 | 2.75 | 2.73 | 2.71 | 425.2 | 255.0 |

| i-C5H12 | 1.71 | 1.71 | 1.71 | 460.4 | 308.0 |

| n-C5H12 | 1.44 | 1.44 | 1.44 | 469.7 | 311.0 |

| C6H14 | 0.50 | 0.50 | 0.50 | 507.9 | 368.0 |

| C7H16 | 0.21 | 0.21 | 0.21 | 540.2 | 426.0 |

| CO2 | 2.56 | 2.21 | 1.92 | 304.2 | 93.9 |

| H2S | 0.85 | 0.78 | 0.72 | 373.7 | 98.0 |

| H2O | 0.41 | 0.42 | 0.42 | 647.3 | 57.1 |

| Cases | P/MPa(表压) | T/ °C | Composition/%(mol) | |||

|---|---|---|---|---|---|---|

| N2 | CH4 | C2H6 | C3H8 | |||

| MG-1 | 1.50 | 30 | 13.6 | 68.6 | 11.6 | 6.2 |

| MG-2 | 1.50 | 30 | 28.0 | 55.3 | 10.6 | 6.1 |

| MG-3 | 1.50 | 30 | 37.9 | 45.3 | 10.8 | 6.0 |

| MG-4 | 1.50 | 30 | 16.0 | 76.6 | 6.5 | 0.9 |

| MG-5 | 1.50 | 30 | 32.0 | 60.7 | 6.4 | 0.9 |

| MG-6 | 1.50 | 30 | 43.7 | 49.4 | 6.0 | 0.9 |

| MG-7 | 1.50 | 30 | 43.0 | 56.8 | 0.2 | 0 |

| MG-8 | 1.50 | 30 | 50.9 | 48.9 | 0.2 | 0 |

| MG-9 | 1.50 | 30 | 58.2 | 41.7 | 0.1 | 0 |

| MG-10 | 1.50 | 30 | 67.5 | 32.4 | 0.1 | 0 |

表2 测试PDMS涂层复合膜性能的系列含氮冷凝尾气

Table 2 Diversified natural gases after condensation for testing PDMS membrane’s performance

| Cases | P/MPa(表压) | T/ °C | Composition/%(mol) | |||

|---|---|---|---|---|---|---|

| N2 | CH4 | C2H6 | C3H8 | |||

| MG-1 | 1.50 | 30 | 13.6 | 68.6 | 11.6 | 6.2 |

| MG-2 | 1.50 | 30 | 28.0 | 55.3 | 10.6 | 6.1 |

| MG-3 | 1.50 | 30 | 37.9 | 45.3 | 10.8 | 6.0 |

| MG-4 | 1.50 | 30 | 16.0 | 76.6 | 6.5 | 0.9 |

| MG-5 | 1.50 | 30 | 32.0 | 60.7 | 6.4 | 0.9 |

| MG-6 | 1.50 | 30 | 43.7 | 49.4 | 6.0 | 0.9 |

| MG-7 | 1.50 | 30 | 43.0 | 56.8 | 0.2 | 0 |

| MG-8 | 1.50 | 30 | 50.9 | 48.9 | 0.2 | 0 |

| MG-9 | 1.50 | 30 | 58.2 | 41.7 | 0.1 | 0 |

| MG-10 | 1.50 | 30 | 67.5 | 32.4 | 0.1 | 0 |

| Main components | Permeation rate/GPU | Selectivity | |||||

|---|---|---|---|---|---|---|---|

| N2 | CH4 | C2H6 | C3H8 | CH4/N2 | C2H6/N2 | C3H8/N2 | |

| N2+CH4+C2H6+C3H8 | 151 | 518 | 1059 | 2208 | 3.4 | 7.0 | 14.6 |

| N2+CH4+C2H6 | 132 | 422 | 966 | 2005 | 3.2 | 7.3 | 15.2 |

| N2+CH4 | 119 | 358 | 911 | 1855 | 3.0 | 7.7 | 15.6 |

表3 用于流程设计优化的PDMS涂层复合膜性能参数

Table 3 Data about PDMS membrane’s performance for process simulation and optimization

| Main components | Permeation rate/GPU | Selectivity | |||||

|---|---|---|---|---|---|---|---|

| N2 | CH4 | C2H6 | C3H8 | CH4/N2 | C2H6/N2 | C3H8/N2 | |

| N2+CH4+C2H6+C3H8 | 151 | 518 | 1059 | 2208 | 3.4 | 7.0 | 14.6 |

| N2+CH4+C2H6 | 132 | 422 | 966 | 2005 | 3.2 | 7.3 | 15.2 |

| N2+CH4 | 119 | 358 | 911 | 1855 | 3.0 | 7.7 | 15.6 |

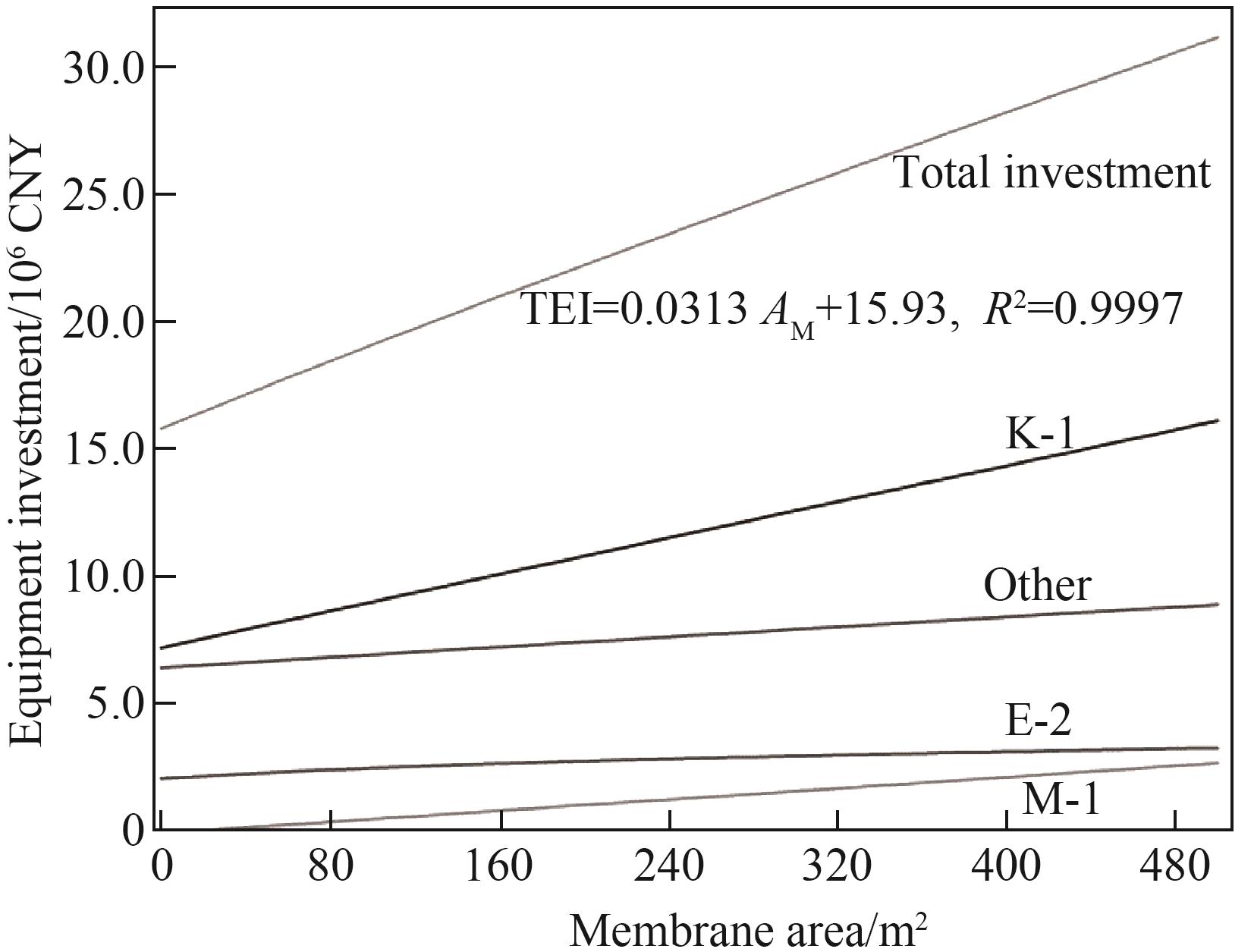

图6 膜面积对膜耦合强化浅冷加工流程CASE-2设备投资的影响TEI—total equipment investment; AM—membrane area

Fig.6 Effects of PDMS membrane area on equipment investment for CASE-2

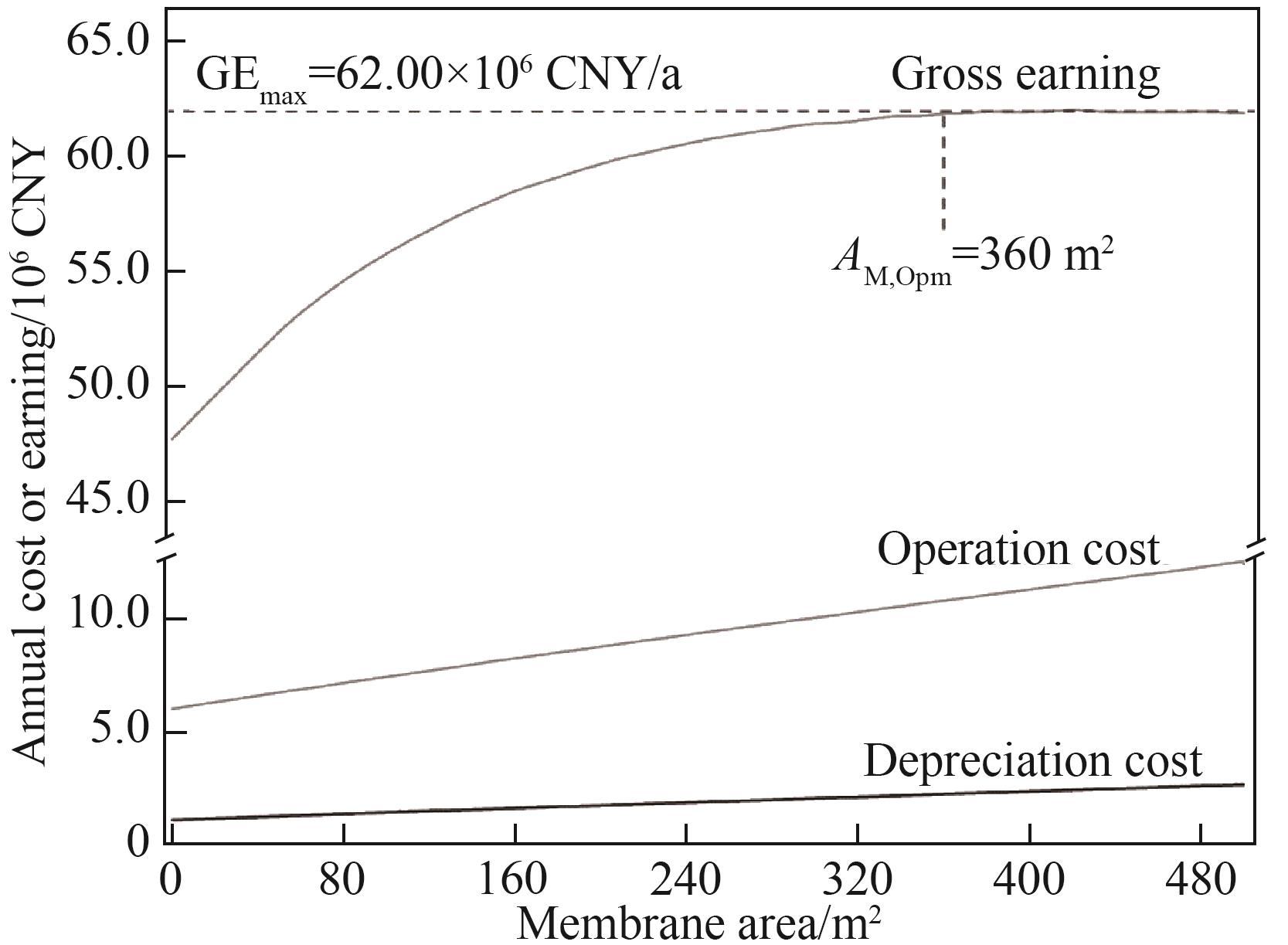

图8 膜面积对膜耦合强化浅冷加工流程CASE-2年费用及收益的影响GEmax—maximum gross earning; AM,Opm—optimized membrane area

Fig.8 Effects of PDMS membrane area on the annual cost and earning for CASE-2

| Parameter | CASE-1 | CASE-2 | CASE-3 |

|---|---|---|---|

| investment/106 CNY | 15.93 | 27.19 | 38.68 |

| depreciation/(106 CNY/a) | 1.12 | 2.27 | 3.40 |

| operation cost/(106 CNY/a) | 6.03 | 10.82 | 14.93 |

| gross profit/(106 CNY/a) | 47.67 | 61.90 | 79.00 |

| NGL yield/(t/a) | 16296 | 22092 | 23604 |

| NGL recovery/%(mass) | 53.4 | 74.5 | 77.6 |

| NG yield/(106 m3/a, standard condition) | — | — | 18.03 |

| NG recovery/% | — | — | 54.4 |

| poor NG yield/(106 m3/a,standard condition) | 49.87 | 46.10 | 27.79 |

表4 三种含氮天然气资源化分离流程的经济性对比

Table 4 Comparative analysis of economic parameters for three separation systems

| Parameter | CASE-1 | CASE-2 | CASE-3 |

|---|---|---|---|

| investment/106 CNY | 15.93 | 27.19 | 38.68 |

| depreciation/(106 CNY/a) | 1.12 | 2.27 | 3.40 |

| operation cost/(106 CNY/a) | 6.03 | 10.82 | 14.93 |

| gross profit/(106 CNY/a) | 47.67 | 61.90 | 79.00 |

| NGL yield/(t/a) | 16296 | 22092 | 23604 |

| NGL recovery/%(mass) | 53.4 | 74.5 | 77.6 |

| NG yield/(106 m3/a, standard condition) | — | — | 18.03 |

| NG recovery/% | — | — | 54.4 |

| poor NG yield/(106 m3/a,standard condition) | 49.87 | 46.10 | 27.79 |

| 1 | 陈平, 樊洪, 漆明勇. 川中低渗油田开发后期伴生气增压开采技术[J]. 天然气工业, 2003, 23(S1):136-138, 17. |

| Chen P, Fan H, Qi M Y. Accompanying gas recovering techniques with booster for late development of low permeability oil fields in middle Sichuan area[J]. Natural Gas Industry, 2003, 23(S1):136-138, 17. | |

| 2 | 赵春鹏. 特低渗透油藏渗流及开采特性实验研究[D]. 北京: 中国石油大学(北京), 2007. |

| Zhao C P. Experimental study on seepage and production characteristics of ultra-low permeability reservoir[D]. Beijing: China University of Petroleum, 2007. | |

| 3 | 刘继伟, 王刘琦, 肖世鑫, 等. 稠油区块氮气泡沫辅助蒸汽驱技术[J]. 油气田地面工程, 2013, 32(12): 6-7. |

| Liu J W, Wang L Q, Xiao S X, et al. Nitrogen foam assisted steam flooding technology in heavy oil block[J]. Oil-Gasfield Surface Engineering, 2013, 32(12): 6-7. | |

| 4 | Han D K, Yang C Z, Zhang Z Q, et al. Recent development of enhanced oil recovery in China[J]. Journal of Petroleum Science and Engineering, 1999, 22(1/2/3): 181-188. |

| 5 | Gbadamosi A O, Junin R, Manan M A, et al. An overview of chemical enhanced oil recovery: recent advances and prospects[J]. International Nano Letters, 2019, 9(3): 171-202. |

| 6 | 付洪涛, 王世栋, 潘一, 等. 气体驱油的研究现状[J]. 能源化工, 2015, 36(5): 44-48. |

| Fu H T, Wang S D, Pan Y, et al. Research status of gas flooding[J]. Energy Chemical Industry, 2015, 36(5): 44-48. | |

| 7 | 侯焜 译. 塔河油田规模氮气驱地面配套方案研究[D]. 北京: 中国石油大学(北京), 2019. |

| Hou K Y. Study on surface matching scheme of large-scale nitrogen flooding in Tahe oilfield[D]. Beijing: China University of Petroleum, 2019. | |

| 8 | 任增泉. 塔河油田注气开发地面配套技术研究[D]. 东营: 中国石油大学(华东), 2016. |

| Ren Z Q. Study on surface supporting technology of gas injection development in Tahe oilfield[D]. Dongying: China University of Petroleum, 2016. | |

| 9 | Wei P, Pu W F, Sun L, et al. Research on nitrogen foam for enhancing oil recovery in harsh reservoirs[J]. Journal of Petroleum Science and Engineering, 2017, 157: 27-38. |

| 10 | Fahandezhsaadi M, Amooie M A, Hemmati-Sarapardeh A, et al. Laboratory evaluation of nitrogen injection for enhanced oil recovery: effects of pressure and induced fractures[J]. Fuel, 2019, 253: 607-614. |

| 11 | Sun L, Wei P, Pu W F, et al. The oil recovery enhancement by nitrogen foam in high-temperature and high-salinity environments[J]. Journal of Petroleum Science and Engineering, 2016, 147: 485-494. |

| 12 | 中国国家市场监督管理总局, 中国国家标准化管理委员会. 天然气: [S]. 北京: 中国标准出版社, 2018. |

| China’s State Administration for Market Regulation, Standardization Administration of China. Natural gas: [S]. Beijing: China Standard Press, 2018. | |

| 13 | 顾晓峰, 王日生, 吴宝清, 等. 天然气脱氮工艺评述[J]. 石油与天然气化工, 2019, 48(1): 12-17. |

| Gu X F, Wang R S, Wu B Q, et al. Review on natural gas denitrification process[J]. Chemical Engineering of Oil and Gas, 2019, 48(1): 12-17. | |

| 14 | 韩治洋, 丁兆阳, 韩旸湲, 等. 真空变压吸附分离氮气甲烷的模拟与控制[J]. 化工学报, 2018, 69(2): 750-758. |

| Han Z Y, Ding Z Y, Han Y Y, et al. Simulation and control of vacuum pressure swing adsorption for N2/CH4 separation[J]. CIESC Journal, 2018, 69(2): 750-758. | |

| 15 | 于喆淼, 王志, 生梦龙, 等. 界面聚合法制备用于脱氮提纯CH4的N2优先渗透ZIF-90/聚酰胺混合基质膜[J]. 化工学报, 2022, 73(7): 3273-3286. |

| Yu Z M, Wang Z, Sheng M L, et al. Preparation of ZIF-90/polyamide mixed matrix membrane with N2 preferential permeation for CH4 purification based on interfacial polymerization[J]. CIESC Journal, 2022, 73(7): 3273-3286. | |

| 16 | 王少靖, 刘琳琳, 张磊, 等. 集成NGL回收的新型天然气液化系统AP-XTM的概念设计与模拟分析[J]. 化工学报, 2019, 70(2): 508-515. |

| Wang S J, Liu L L, Zhang L, et al. Conceptual design, simulation and analysis of novel AP-XTM system integrated with NGL recovery process for large-scale LNG plant[J]. CIESC Journal, 2019, 70(2): 508-515. | |

| 17 | 孙伟娜, 阎海宇, 张东辉. 真空变压吸附分离氮气甲烷流程灵敏度分析与优化[J]. 化工学报, 2016, 67(2): 598-605. |

| Sun W N, Yan H Y, Zhang D H. Sensitivity analysis and optimization of vacuum pressure swing adsorption process for N2/CH4 separation[J]. CIESC Journal, 2016, 67(2): 598-605. | |

| 18 | Baker R W. Future directions of membrane gas separation technology[J]. Industrial & Engineering Chemistry Research, 2002, 41(6): 1393-1411. |

| 19 | Merkel T C, Bondar V I, Nagai K, et al. Gas sorption, diffusion, and permeation in poly(dimethylsiloxane)[J]. Journal of Polymer Science Part B: Polymer Physics, 2000, 38(3): 415-434. |

| 20 | Cecopieri-Gómez M L, Palacios-Alquisira J, Domínguez J M. On the limits of gas separation in CO2/CH4, N2/CH4 and CO2/N2 binary mixtures using polyimide membranes[J]. Journal of Membrane Science, 2007, 293(1/2): 53-65. |

| 21 | Wu T, Diaz M C, Zheng Y H, et al. Influence of propane on CO2/CH4 and N2/CH4 separations in CHA zeolite membranes[J]. Journal of Membrane Science, 2015, 473: 201-209. |

| 22 | Zhou R F, Pan Y C, Xing W H, et al. Advanced microporous membranes for H2/CH4 separation: challenges and perspectives[J]. Advanced Membranes, 2021, 1: 100011. |

| 23 | Baker R W, Lokhandwala K. Natural gas processing with membranes: an overview[J]. Industrial & Engineering Chemistry Research, 2008, 47(7): 2109-2121. |

| 24 | Lokhandwala K A, Pinnau I, He Z J, et al. Membrane separation of nitrogen from natural gas: a case study from membrane synthesis to commercial deployment[J]. Journal of Membrane Science, 2010, 346(2): 270-279. |

| 25 | 李雯, 王志, 李潘源, 等. 用于甲烷-氮气体系分离的膜技术研究进展[J]. 化工学报, 2016, 67(2): 404-415. |

| Li W, Wang Z, Li P Y, et al. Progress in membrane technology for CH4-N2 separation[J]. CIESC Journal, 2016, 67(2): 404-415. | |

| 26 | 陈雷, 李东泽, 刘刚, 等. 甲烷-氮气分离膜研究进展及展望[J]. 天然气工业, 2022, 42(5): 120-130. |

| Chen L, Li D Z, Liu G, et al. Research progress and prospect of CH4/N2 separation membranes[J]. Natural Gas Industry, 2022, 42(5): 120-130. | |

| 27 | 李鹏, 赵德银, 张健, 等. 油田伴生气净化工艺优化研究及工业应用[J]. 石油与天然气化工, 2021, 50(2): 17-22. |

| Li P, Zhao D Y, Zhang J, et al. Optimization study and industrial application of oilfield associated gas purification process[J]. Chemical Engineering of Oil and Gas, 2021, 50(2): 17-22. | |

| 28 | Koros W J, Fleming G K, Jordan S M, et al. Polymeric membrane materials for solution-diffusion based permeation separations[J]. Progress in Polymer Science, 1988, 13(4): 339-401. |

| 29 | Wijmans J G, Baker R W. The solution-diffusion model: a review[J]. Journal of Membrane Science, 1995, 107(1/2): 1-21. |

| 30 | Pandey P, Chauhan R S. Membranes for gas separation[J]. Progress in Polymer Science, 2001, 26(6): 853-893. |

| 31 | Katoh T, Tokumura M, Yoshikawa H, et al. Dynamic simulation of multicomponent gas separation by hollow-fiber membrane module: nonideal mixing flows in permeate and residue sides using the tanks-in-series model[J]. Separation and Purification Technology, 2011, 76(3): 362-372. |

| 32 | Ruan X H, He G H, Li B J, et al. Chemical potential analysis for directing the optimal design of gas membrane separation frameworks[J]. Chemical Engineering Science, 2014, 107: 245-255. |

| 33 | Ruan X H, Dai Y, Du L, et al. Further separation of HFC-23 and HCFC-22 by coupling multi-stage PDMS membrane unit to cryogenic distillation[J]. Separation and Purification Technology, 2015, 156: 673-682. |

| 34 | Chen B, Ruan X H, Xiao W, et al. Synergy of CO2 removal and light hydrocarbon recovery from oil-field associated gas by dual-membrane process[J]. Journal of Natural Gas Science and Engineering, 2015, 26: 1254-1263. |

| 35 | Chen B, Ruan X H, Jiang X B, et al. Dual-membrane module and its optimal flow pattern for H2/CO2 separation[J]. Industrial & Engineering Chemistry Research, 2016, 55(4): 1064-1075. |

| 36 | 阮雪华. 气体膜分离及其梯级耦合流程的设计与优化[D]. 大连: 大连理工大学, 2014. |

| Ruan X H. Design and optimization of gas membrane separation and its cascade coupling process[D]. Dalian: Dalian University of Technology, 2014. | |

| 37 | 阮雪华, 贺高红, 肖武, 等. 生物甲烷膜分离提纯系统的设计与优化[J]. 化工学报, 2014, 65(5): 1688-1695. |

| Ruan X H, He G H, Xiao W, et al. Design and optimization of membrane-based system for bio-methane purification[J]. CIESC Journal, 2014, 65(5): 1688-1695. | |

| 38 | Ruan X H, Xiao H Y, Jiang X B, et al. Graphic synthesis method for multi-technique integration separation sequences of multi-input refinery gases[J]. Separation and Purification Technology, 2019, 214: 187-195. |

| [1] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [2] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [3] | 张瑞航, 曹潘, 杨锋, 李昆, 肖朋, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8纳米流体天然气乙烷回收工艺的产品纯度关键影响因素分析[J]. 化工学报, 2023, 74(8): 3386-3393. |

| [4] | 文兆伦, 李沛睿, 张忠林, 杜晓, 侯起旺, 刘叶刚, 郝晓刚, 官国清. 基于自热再生的隔壁塔深冷空分工艺设计及优化[J]. 化工学报, 2023, 74(7): 2988-2998. |

| [5] | 江锦波, 彭新, 许文烜, 门日秀, 刘畅, 彭旭东. 泵出型螺旋槽油气密封泄漏特性及参数影响研究[J]. 化工学报, 2023, 74(6): 2538-2554. |

| [6] | 刘尚豪, 贾胜坤, 罗祎青, 袁希钢. 基于梯度提升决策树的三组元精馏流程结构最优化[J]. 化工学报, 2023, 74(5): 2075-2087. |

| [7] | 周必茂, 许世森, 王肖肖, 刘刚, 李小宇, 任永强, 谭厚章. 烧嘴偏转角度对气化炉渣层分布特性的影响[J]. 化工学报, 2023, 74(5): 1939-1949. |

| [8] | 王泽栋, 石至平, 刘丽艳. 考虑气泡非均匀耗散的矩形反应器声流场数值模拟及结构优化[J]. 化工学报, 2023, 74(5): 1965-1973. |

| [9] | 许文烜, 江锦波, 彭新, 门日秀, 刘畅, 彭旭东. 宽速域三种典型型槽油气密封泄漏与成膜特性对比研究[J]. 化工学报, 2023, 74(4): 1660-1679. |

| [10] | 李纪元, 李金旺, 周刘伟. 不同扰流结构冷板传热性能研究[J]. 化工学报, 2023, 74(4): 1474-1488. |

| [11] | 李明川, 樊栓狮, 徐赋海, 卢惠东, 李晓军. 水合物热分解Stefan相变模型解的存在性及Laplace变换求解[J]. 化工学报, 2023, 74(4): 1746-1754. |

| [12] | 陈号, 田仪娟, 全学军, 蒋子文, 李纲. 铬铁矿在HCl-HF体系中的分解行为[J]. 化工学报, 2023, 74(3): 1161-1174. |

| [13] | 陈俊先, 姬忠礼, 赵瑜, 张倩, 周岩, 刘猛, 刘震. 基于微波技术的天然气管道内颗粒物在线检测方法研究[J]. 化工学报, 2023, 74(3): 1042-1053. |

| [14] | 刘倩, 曹禹, 周琦, 穆景山, 历伟. 孔道结构修饰的Ziegler-Natta催化剂设计与高抗冲低缠结UHMWPE的制备[J]. 化工学报, 2023, 74(3): 1092-1101. |

| [15] | 魏进家, 刘蕾, 杨小平. 面向高热流电子器件散热的环路热管研究进展[J]. 化工学报, 2023, 74(1): 60-73. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号