化工学报 ›› 2023, Vol. 74 ›› Issue (2): 953-967.DOI: 10.11949/0438-1157.20221046

周培旭1( ), 李亚伦1, 叶恭然1, 庄园1, 吴曦蕾1, 郭智恺2, 韩晓红1(

), 李亚伦1, 叶恭然1, 庄园1, 吴曦蕾1, 郭智恺2, 韩晓红1( )

)

收稿日期:2022-07-06

修回日期:2023-01-26

出版日期:2023-02-05

发布日期:2023-03-21

通讯作者:

韩晓红

作者简介:周培旭(1998—),男,硕士研究生,22027101@zju.edu.cn

基金资助:

Peixu ZHOU1( ), Yalun LI1, Gongran YE1, Yuan ZHUANG1, Xilei WU1, Zhikai GUO2, Xiaohong HAN1(

), Yalun LI1, Gongran YE1, Yuan ZHUANG1, Xilei WU1, Zhikai GUO2, Xiaohong HAN1( )

)

Received:2022-07-06

Revised:2023-01-26

Online:2023-02-05

Published:2023-03-21

Contact:

Xiaohong HAN

摘要:

新一代环境友好型工质如R290、R32等由于其燃爆特性,一旦发生泄漏会造成一定的安全隐患,而仍使用较为广泛的工质如R22等一旦发生泄漏同样会加剧温室效应,从而造成全球气候环境恶化。开展工质的泄漏扩散沉积等相关特性的研究十分必要。针对工质在泄漏扩散过程中由于物性的差异造成的泄漏扩散开展了数值模拟研究,模拟中采用Species组分输运模型,考虑密度、黏度等工质物性参数的差异,对工质在泄漏孔下方、泄漏有限空间内的浓度变化,以及密度、黏度等物性对泄漏扩散过程的影响进行了研究。结果表明:泄漏孔下方区域,密度对工质的浓度分布影响较大,其次是黏度;密度越大,工质在泄漏孔下方区域质量分数越大;黏度越大,工质流动性越差,在泄漏孔下方区域质量分数越大。整个有限空间内,工质的密度越大,越易于向空间的中下部区域扩散并形成较高的质量分数;工质的黏度越大,越易于与周围空气发生卷吸作用。

中图分类号:

周培旭, 李亚伦, 叶恭然, 庄园, 吴曦蕾, 郭智恺, 韩晓红. 有限空间内工质物性对制冷剂泄漏扩散特性的影响[J]. 化工学报, 2023, 74(2): 953-967.

Peixu ZHOU, Yalun LI, Gongran YE, Yuan ZHUANG, Xilei WU, Zhikai GUO, Xiaohong HAN. Influence of physical properties of working fluids on leakage and diffusion characteristics of refrigerant in limited space[J]. CIESC Journal, 2023, 74(2): 953-967.

| 工质 | 泄漏压力/MPa | 泄漏速率/(g/s) |

|---|---|---|

| R717 | 0.998 | 1.308 |

| R290 | 0.948 | 2.018 |

| R1234yf | 0.68 | 3.191 |

| R22 | 1.04 | 2.902 |

| R32 | 1.68 | 2.394 |

| R744 | 6.41 | 2.001 |

表1 常见工质在泄漏孔径3 mm室温工况下(25℃)临界流的质量流量

Table 1 Critical flow mass flow rates of common working fluids at room temperature(25℃) with leakage aperture of 3 mm

| 工质 | 泄漏压力/MPa | 泄漏速率/(g/s) |

|---|---|---|

| R717 | 0.998 | 1.308 |

| R290 | 0.948 | 2.018 |

| R1234yf | 0.68 | 3.191 |

| R22 | 1.04 | 2.902 |

| R32 | 1.68 | 2.394 |

| R744 | 6.41 | 2.001 |

| 泄漏孔尺寸/m | 空间尺寸/m | 网格质量 | 网格数/个 |

|---|---|---|---|

| 0.0005 | 0.2 | 0.835 | 66469 |

| 0.0005 | 0.1 | 0.845 | 301558 |

| 0.0001 | 0.08 | 0.847 | 600119 |

| 0.0001 | 0.06 | 0.849 | 1324453 |

| 0.0001 | 0.05 | 0.850 | 2232378 |

表2 网格尺寸设置

Table 2 Grid size settings

| 泄漏孔尺寸/m | 空间尺寸/m | 网格质量 | 网格数/个 |

|---|---|---|---|

| 0.0005 | 0.2 | 0.835 | 66469 |

| 0.0005 | 0.1 | 0.845 | 301558 |

| 0.0001 | 0.08 | 0.847 | 600119 |

| 0.0001 | 0.06 | 0.849 | 1324453 |

| 0.0001 | 0.05 | 0.850 | 2232378 |

| 工质 | T/K | p/MPa | 密度/ (kg/m³) | 比定压热容/ (kJ/(kg·K)) | 热导率/ (mW/(m·K)) | 黏度/ (μPa·s) | 动量扩散 系数μ/ρ | 热扩散系数λ/(ρcp ) |

|---|---|---|---|---|---|---|---|---|

| R717 (7664-41-7) | 298 | 0.1 | 0.69 | 2.16 | 25.16 | 10.08 | 14.52 | 16.75 |

| R290 (74-98-6) | 298 | 0.1 | 1.81 | 1.68 | 18.29 | 8.12 | 4.49 | 6.01 |

| R1234yf (754-12-1) | 298 | 0.1 | 4.71 | 0.90 | 13.83 | 11.46 | 2.44 | 3.25 |

| R22 (75-45-6) | 298 | 0.1 | 3.54 | 0.66 | 10.57 | 12.62 | 3.56 | 2.13 |

| R32 (75-10-5) | 298 | 0.1 | 2.13 | 0.85 | 12.51 | 12.61 | 5.93 | 6.95 |

| R744 (14485-07-5) | 298 | 0.1 | 1.79 | 0.85 | 16.62 | 14.91 | 8.35 | 10.95 |

表3 常见工质在室温常压下(25℃,0.1 MPa)的物性参数

Table 3 Physical properties of common working fluids at room temperature and pressure (25℃,0.1 MPa)

| 工质 | T/K | p/MPa | 密度/ (kg/m³) | 比定压热容/ (kJ/(kg·K)) | 热导率/ (mW/(m·K)) | 黏度/ (μPa·s) | 动量扩散 系数μ/ρ | 热扩散系数λ/(ρcp ) |

|---|---|---|---|---|---|---|---|---|

| R717 (7664-41-7) | 298 | 0.1 | 0.69 | 2.16 | 25.16 | 10.08 | 14.52 | 16.75 |

| R290 (74-98-6) | 298 | 0.1 | 1.81 | 1.68 | 18.29 | 8.12 | 4.49 | 6.01 |

| R1234yf (754-12-1) | 298 | 0.1 | 4.71 | 0.90 | 13.83 | 11.46 | 2.44 | 3.25 |

| R22 (75-45-6) | 298 | 0.1 | 3.54 | 0.66 | 10.57 | 12.62 | 3.56 | 2.13 |

| R32 (75-10-5) | 298 | 0.1 | 2.13 | 0.85 | 12.51 | 12.61 | 5.93 | 6.95 |

| R744 (14485-07-5) | 298 | 0.1 | 1.79 | 0.85 | 16.62 | 14.91 | 8.35 | 10.95 |

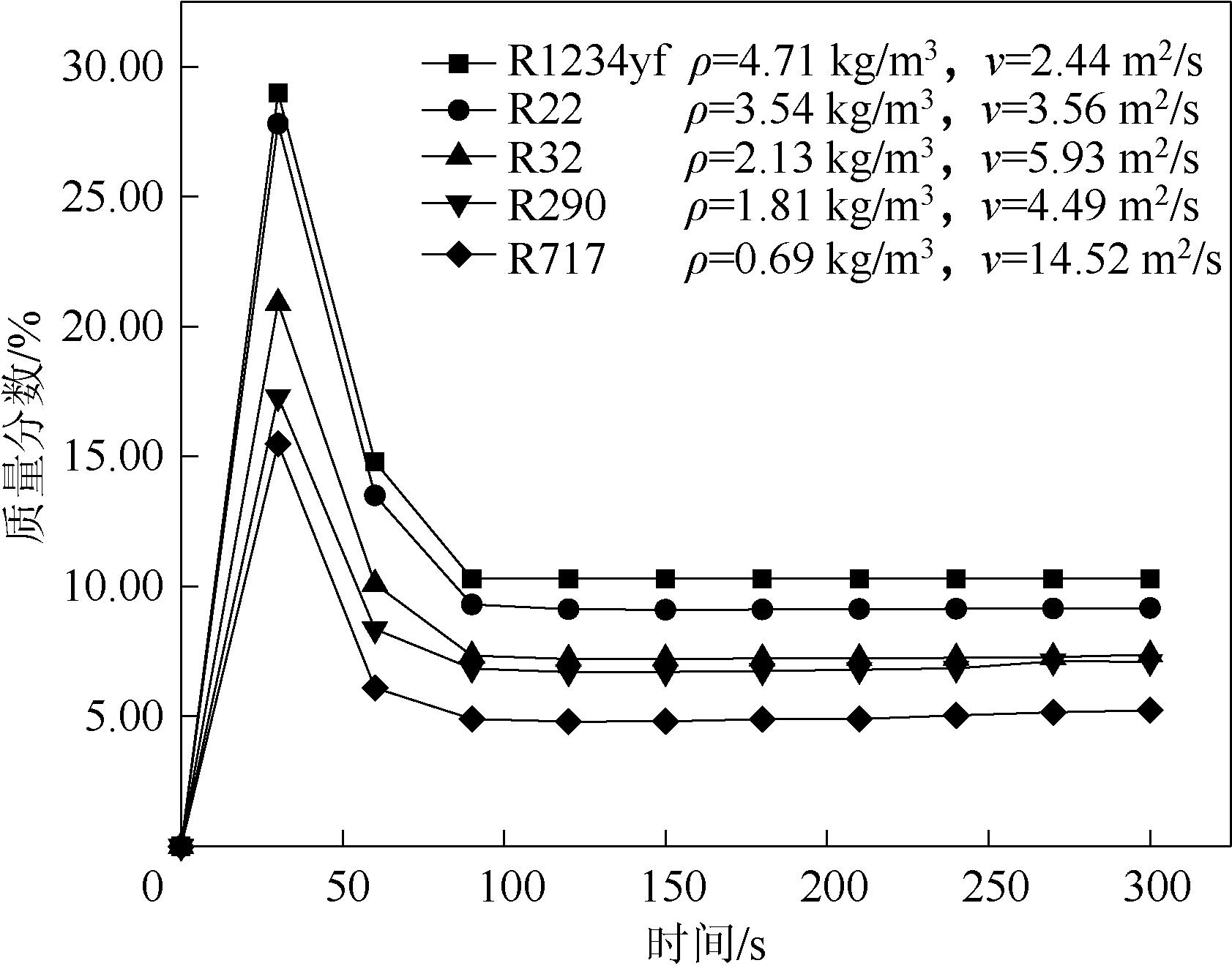

图9 密度差异较大的工质在泄漏孔下方测点处的浓度分布

Fig.9 Concentration distribution of working fluids with large density difference at the monitor points under the leakage hole

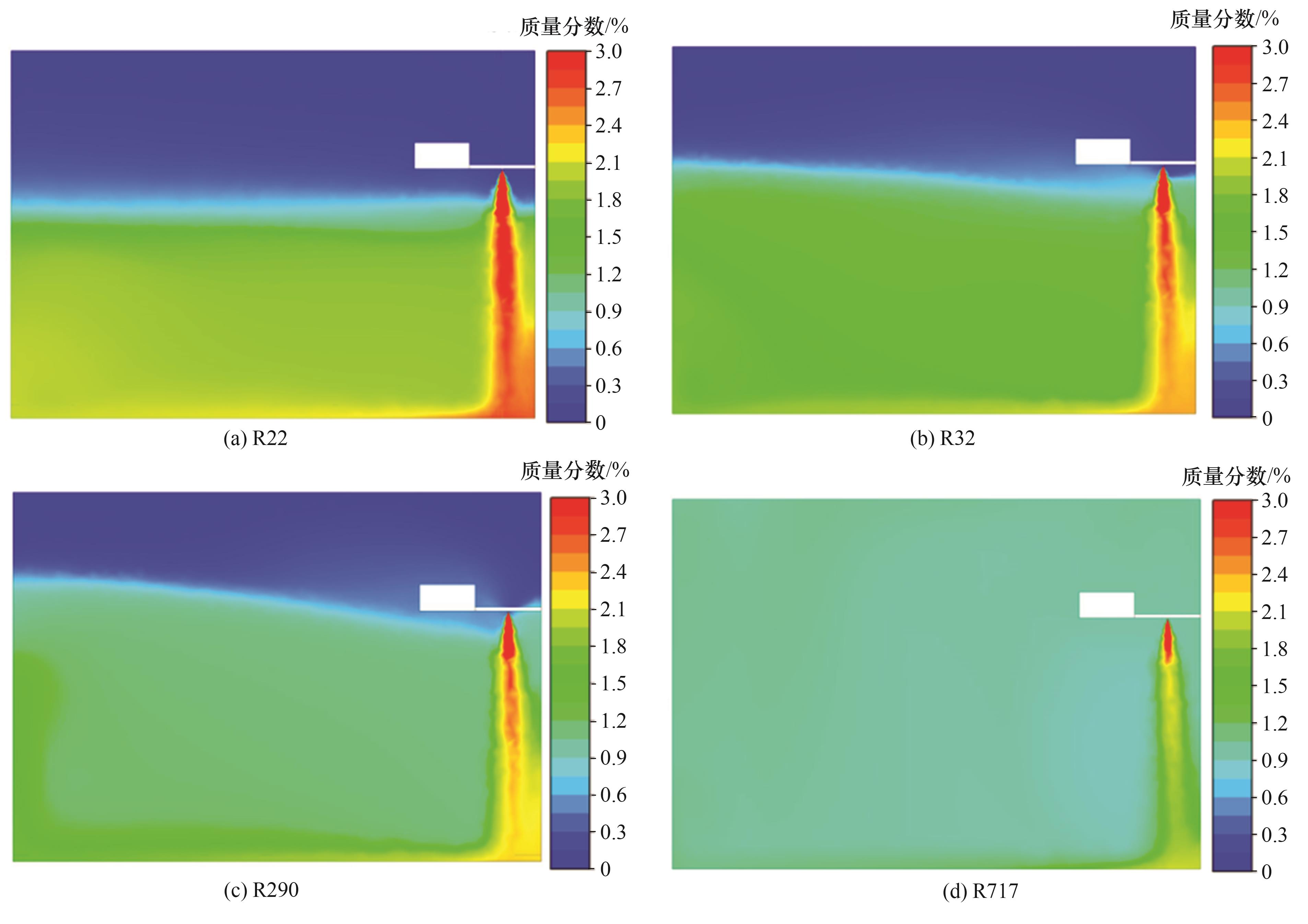

图12 扩散阶段不同工质在泄漏孔中心所在截面(Z=0.115 m)处的浓度分布云图

Fig.12 Contours of concentration distribution of different working fluids at the intersecting surface of the center of the leakage hole (Z=0.115 m) during diffusion process

| 序号 | X/m | Y/m | Z/m | 序号 | X/m | Y/m | Z/m | 序号 | X/m | Y/m | Z/m |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 点1 | 1.0 | 0.7 | 0.7 | 点10 | 2.0 | 0.7 | 0.7 | 点19 | 3.0 | 0.7 | 0.7 |

| 点2 | 1.0 | 0.7 | 1.4 | 点11 | 2.0 | 0.7 | 1.4 | 点20 | 3.0 | 0.7 | 1.4 |

| 点3 | 1.0 | 0.7 | 2.1 | 点12 | 2.0 | 0.7 | 2.1 | 点21 | 3.0 | 0.7 | 2.1 |

| 点4 | 1.0 | 1.4 | 0.7 | 点13 | 2.0 | 1.4 | 0.7 | 点22 | 3.0 | 1.4 | 0.7 |

| 点5 | 1.0 | 1.4 | 1.4 | 点14 | 2.0 | 1.4 | 1.4 | 点23 | 3.0 | 1.4 | 1.4 |

| 点6 | 1.0 | 1.4 | 2.1 | 点15 | 2.0 | 1.4 | 2.1 | 点24 | 3.0 | 1.4 | 2.1 |

| 点7 | 1.0 | 2.1 | 0.7 | 点16 | 2.0 | 2.1 | 0.7 | 点25 | 3.0 | 2.1 | 0.7 |

| 点8 | 1.0 | 2.1 | 1.4 | 点17 | 2.0 | 2.1 | 1.4 | 点26 | 3.0 | 2.1 | 1.4 |

| 点9 | 1.0 | 2.1 | 2.1 | 点18 | 2.0 | 2.1 | 2.1 | 点27 | 3.0 | 2.1 | 2.1 |

表4 测点布置坐标

Table 4 Layouts of monitoring points

| 序号 | X/m | Y/m | Z/m | 序号 | X/m | Y/m | Z/m | 序号 | X/m | Y/m | Z/m |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 点1 | 1.0 | 0.7 | 0.7 | 点10 | 2.0 | 0.7 | 0.7 | 点19 | 3.0 | 0.7 | 0.7 |

| 点2 | 1.0 | 0.7 | 1.4 | 点11 | 2.0 | 0.7 | 1.4 | 点20 | 3.0 | 0.7 | 1.4 |

| 点3 | 1.0 | 0.7 | 2.1 | 点12 | 2.0 | 0.7 | 2.1 | 点21 | 3.0 | 0.7 | 2.1 |

| 点4 | 1.0 | 1.4 | 0.7 | 点13 | 2.0 | 1.4 | 0.7 | 点22 | 3.0 | 1.4 | 0.7 |

| 点5 | 1.0 | 1.4 | 1.4 | 点14 | 2.0 | 1.4 | 1.4 | 点23 | 3.0 | 1.4 | 1.4 |

| 点6 | 1.0 | 1.4 | 2.1 | 点15 | 2.0 | 1.4 | 2.1 | 点24 | 3.0 | 1.4 | 2.1 |

| 点7 | 1.0 | 2.1 | 0.7 | 点16 | 2.0 | 2.1 | 0.7 | 点25 | 3.0 | 2.1 | 0.7 |

| 点8 | 1.0 | 2.1 | 1.4 | 点17 | 2.0 | 2.1 | 1.4 | 点26 | 3.0 | 2.1 | 1.4 |

| 点9 | 1.0 | 2.1 | 2.1 | 点18 | 2.0 | 2.1 | 2.1 | 点27 | 3.0 | 2.1 | 2.1 |

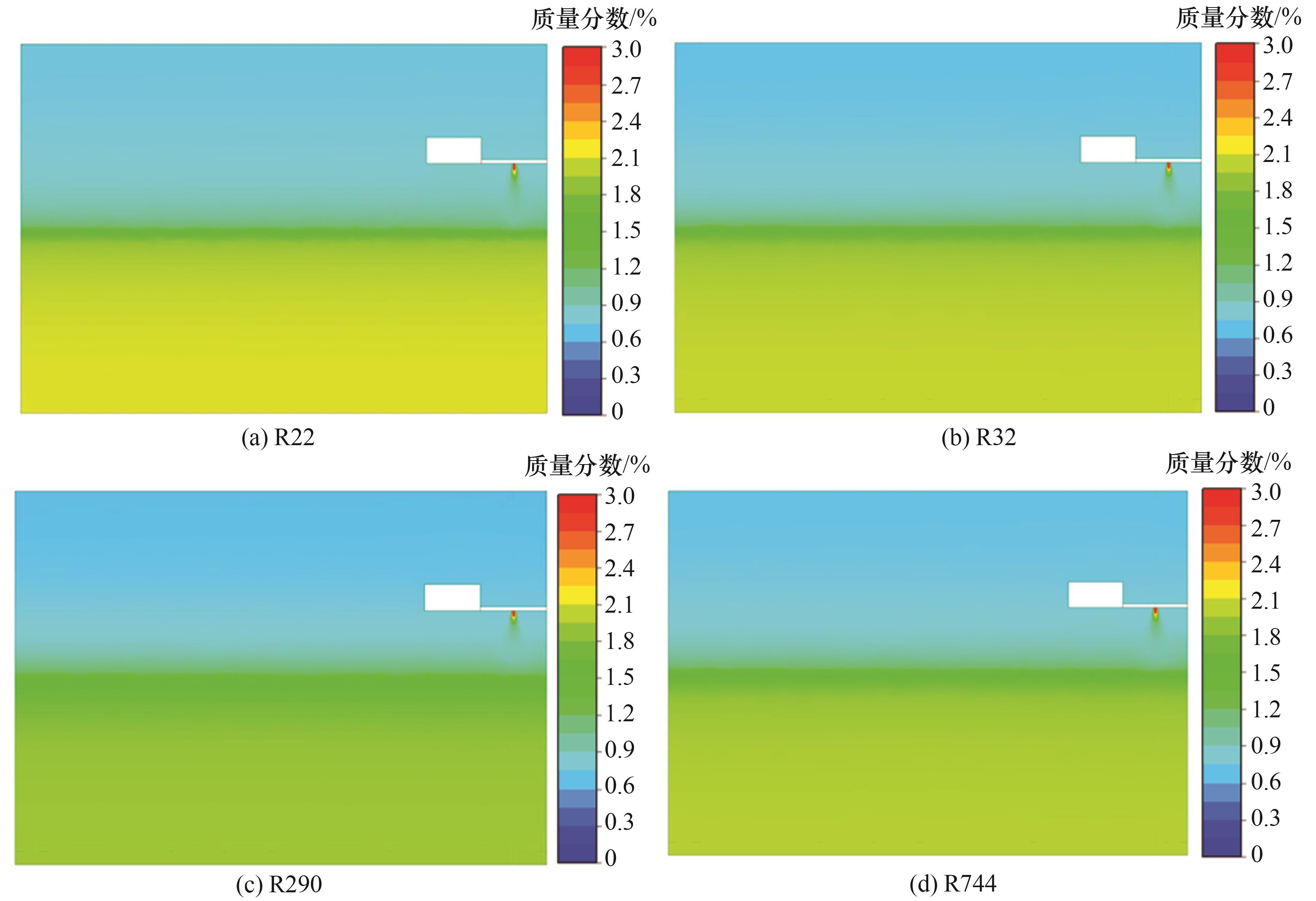

图19 沉积阶段不同工质在泄漏孔中心所在截面(Z=0.115 m)处的浓度分布云图

Fig.19 Contours of concentration distribution of different working fluids at the intersecting surface of the center of the leakage hole (Z=0.115 m) during deposition process

| 1 | National Oceanic and Atmospheric Administration. Climate Change: global temperature[EB/OL]. . |

| 2 | United States Environmental Protection Agency. Greenhouse gas emissions and sinks: 1990-2019 [EB/OL]. . |

| 3 | Levenspiel O. Engineering Flow and Heat Exchange[M]. Boston, MA: Springer, 1984. |

| 4 | Li Y L, Zhou P X, Zhuang Y, et al. An improved gas leakage model and research on the leakage field strength characteristics of R290 in limited space[J]. Applied Sciences, 2022, 12(11): 5657. |

| 5 | Hu M J, Li J B, Liu Z, et al. Experimental and numerical simulation analysis of R-290 air conditioner leak[J]. International Journal of Refrigeration, 2018, 90: 163-173. |

| 6 | Muliawan R, Pasek A D, Lukitobudi A R, et al. Effect of leakage on refrigerant distribution in an air conditioned room using propane as working fluid[J]. IOP Conference Series: Materials Science and Engineering, 2020, 830(4): 042023. |

| 7 | 陆毅. 制冷系统R290泄漏扩散机理及安全评估[D]. 南京: 南京理工大学, 2018. |

| Lu Y. Leakage and diffusion mechanism of R290 in refrigeration system and safety assessment[D]. Nanjing: Nanjing University of Science and Technology, 2018. | |

| 8 | Tang W E, He G G, Sun W, et al. Assessment of leakage and risk reduction of R290 in a split type household air conditioner[J]. International Journal of Refrigeration, 2018, 89: 70-82. |

| 9 | Tang W E, He G G, Cai D H, et al. The experimental investigation of refrigerant distribution and leaking characteristics of R290 in split type household air conditioner[J]. Applied Thermal Engineering, 2017, 115: 72-80. |

| 10 | Tang W E, He G G, Zhou S, et al. The experimental study of R290 mass distribution and indoor leakage of 2 HP and 3 HP split type household air conditioner[J]. International Journal of Refrigeration, 2019, 100: 246-254. |

| 11 | Zhang Y, Liu C C, Wang T Y, et al. Leakage analysis and concentration distribution of flammable refrigerant R290 in the automobile air conditioner system[J]. International Journal of Refrigeration, 2020, 110: 286-294. |

| 12 | 郭春辉, 刘知新, 徐永恩. 泄漏管直径对R290空调器使用安全性的影响[J]. 制冷与空调, 2014, 14(12): 66-68, 137. |

| Guo C H, Liu Z X, Xu Y E. Impacts of leakage pipe's diameter on safety application of R290 air-conditioner[J]. Refrigeration and Air-Conditioning, 2014, 14(12): 66-68, 137. | |

| 13 | Liang J R, Li T X. Detailed dynamic refrigerant migration characteristics in room air-conditioner with R290[J]. International Journal of Refrigeration, 2018, 88: 108-116. |

| 14 | 张网, 张欣, 慕洋洋. R717和R290爆炸参数实验研究[J]. 消防科学与技术, 2016, 35(6): 737-740. |

| Zhang W, Zhang X, Mu Y Y. Experimental study on the explosion characteristics of R717 and R290[J]. Fire Science and Technology, 2016, 35(6): 737-740. | |

| 15 | Li K, Wang J W, Luo S X, et al. Experimental investigation on combustion characteristics of flammable refrigerant R290/R1234yf leakage from heat pump system for electric vehicles[J]. Royal Society Open Science, 2020, 7(4): 191478. |

| 16 | Elatar A, Abu-Heiba A, Patel V, et al. Evaluation of flammable volume in the case of a catastrophic leak of R-32 from a rooftop unit[J]. International Journal of Refrigeration, 2018, 91: 39-45. |

| 17 | Li Y N, Tao J J, Han Y C, et al. Numerical and experimental study on the diffusion property of difluoromethane (HFC-32) in leakage[J]. Procedia Engineering, 2014, 71: 34-43. |

| 18 | Jia L Z, Jin W F, Zhang Y. Analysis of indoor environment safety with R32 leaking from a running air conditioner[J]. Procedia Engineering, 2015, 121: 1605-1612. |

| 19 | Jia L Z, Jin W F, Zhang Y. Experimental study on R32 leakage and diffusion characteristic of wall-mounted air conditioners under different operating conditions[J]. Applied Energy, 2017, 185: 2127-2133. |

| 20 | 金梧凤, 薛探栋, 袁小勇, 等. R32制冷剂泄漏位置对浓度分布与室内安全性的实验研究[J]. 制冷学报, 2022, 43(5): 114-121. |

| Jin W F, Xue T D, Yuan X Y, et al. Experimental study on concentration distribution and indoor safety of R32 refrigerant leakage location[J]. Journal of Re Frige Ration, 2022, 43(5): 114-121. | |

| 21 | Tan W, Du H, Liu L Y, et al. Experimental and numerical study of ammonia leakage and dispersion in a food factory[J]. Journal of Loss Prevention in the Process Industries, 2017, 47: 129-139. |

| 22 | Ji J, Chen X X, Han X F. Rapid simulation and visualization analysis of liquid ammonia tank leakage risk[J]. Procedia Engineering, 2014, 84: 682-688. |

| 23 | 田华, 马一太, 刘圣春, 等. CO2双级滚动转子压缩机泄漏分析[J]. 工程热物理学报, 2009, 30(6): 905-910. |

| Tian H, Ma Y T, Liu S C, et al. Leakage analysis of CO2 two stage rolling piston compressor[J]. Journal of Engineering Thermophysics, 2009, 30(6): 905-910. | |

| 24 | Tong X, Wang Z R, Cheng Z, et al. A modeling method for predicting the concentration of indoor carbon dioxide leakage and dispersion based on similarity theory[J]. Energy and Buildings, 2017, 151: 585-591. |

| 25 | 李康. 小尺度超临界二氧化碳泄漏过程物理机理研究[D]. 合肥: 中国科学技术大学, 2016. |

| Li K. The physical mechanism of the supercritical CO2 leakage process in small scale laboratory conditions[D]. Hefei: University of Science and Technology of China, 2016. | |

| 26 | Oreilly H, Crombie D, Monaghan R, et al. An experimental and numerical study of refrigerant leaks in refrigerated transport containers[C]// 1st IIR International Conference on the Application of HFO Refrigerants. Birmingham, UK: Proceedings of IIR Conferences, 2018. |

| 27 | Oreilly H, Crombie D, Monaghan R. Towards a comprehensive modelling framework for flammable refrigerant leaks in transport containers[C]// 25th IIR International Congress of Refrigeration. Montreal, Canada: Proceedings of IIR Conferences, 2019. |

| 28 | Papas P, Zhang S L, Jiang H, et al. Computational fluid dynamics modeling of flammable refrigerant leaks inside machine rooms: evaluation of ventilation mitigation requirements[J]. Science and Technology for the Built Environment, 2016, 22(4): 463-471. |

| 29 | Li Y L, Yang J L, Wu X L, et al. Explosion risk analysis of R290 leakage into a limited external space[J]. Applied Thermal Engineering, 2023, 225: 120122. |

| 30 | Lemmon E W, Bell I H, Huber M L, et al. NIST standard reference database 23: reference fluid thermodynamic and transport properties-REFPROP, version 10.0[DS]. National Institute of Standards and Technology, 2018. |

| 31 | 张网, 杨昭, 王婕, 等. 分体式空调器使用R290作为制冷剂的泄漏研究[J]. 制冷学报, 2013, 34(6): 42-47. |

| Zhang W, Yang Z, Wang J, et al. Leakage research of split-type air-conditioner using R290 as refrigerant[J]. Journal of Refrigeration, 2013, 34(6): 42-47. |

| [1] | 金伟其, 吴月荣, 王霞, 李力, 裘溯, 袁盼, 王铭赫. 化工园区工业气体泄漏气云红外成像检测技术与国产化装备进展[J]. 化工学报, 2023, 74(S1): 32-44. |

| [2] | 吴曦, 区祖迪, 张鑫杰, 徐士鸣, 朱晓静. HFO-1243zf爆燃特性实验研究[J]. 化工学报, 2023, 74(S1): 346-352. |

| [3] | 高润淼, 宋孟杰, 高恩元, 张龙, 张旋, 邵苛苛, 甄泽康, 江正勇. 冷链装备制冷剂相关温室气体减排研究进展[J]. 化工学报, 2023, 74(S1): 1-7. |

| [4] | 尹刚, 李伊惠, 何飞, 曹文琦, 王民, 颜非亚, 向禹, 卢剑, 罗斌, 卢润廷. 基于KPCA和SVM的铝电解槽漏槽事故预警方法[J]. 化工学报, 2023, 74(8): 3419-3428. |

| [5] | 周继鹏, 何文军, 李涛. 异形催化剂上乙烯催化氧化失活动力学反应工程计算[J]. 化工学报, 2023, 74(6): 2416-2426. |

| [6] | 李辰鑫, 潘艳秋, 何流, 牛亚宾, 俞路. 基于碳微晶结构的炭膜模型及其气体分离模拟[J]. 化工学报, 2023, 74(5): 2057-2066. |

| [7] | 胡香凝, 尹渊博, 袁辰, 是赟, 刘翠伟, 胡其会, 杨文, 李玉星. 成品油在土壤中运移可视化的实验研究[J]. 化工学报, 2023, 74(4): 1827-1835. |

| [8] | 明迁, 高逸, 胡剑, 李盛杰, 王金江. 热交换器泄漏故障虚拟感知方法研究[J]. 化工学报, 2023, 74(4): 1836-1846. |

| [9] | 吴选军, 王超, 曹子健, 蔡卫权. 数据与物理信息混合驱动的固定床吸附穿透深度学习模型[J]. 化工学报, 2023, 74(3): 1145-1160. |

| [10] | 武子超, 汪志雷, 李荣业, 李可昕, 华敏, 潘旭海, 王三明, 蒋军成. 点火方式对欠膨胀氢气射流爆炸超压影响规律研究[J]. 化工学报, 2023, 74(3): 1409-1418. |

| [11] | 陈晨, 杨倩, 陈云, 张睿, 刘冬. 不同氧浓度下煤挥发分燃烧的化学动力学研究[J]. 化工学报, 2022, 73(9): 4133-4146. |

| [12] | 曹健, 叶南南, 蒋管聪, 覃瑶, 王士博, 朱家华, 陆小华. 基于微量热法对多孔碳与双氧水相互作用过程的传质阻力分析[J]. 化工学报, 2022, 73(6): 2543-2551. |

| [13] | 李文怀, 周嵬. 高氧离子电导钙钛矿的影响因素分析和设计策略[J]. 化工学报, 2022, 73(4): 1455-1471. |

| [14] | 孙裕坤, 杨焘, 吴江涛. R32+R1234yf+R1234ze(E)混合制冷剂气液相平衡实验研究[J]. 化工学报, 2022, 73(3): 1063-1071. |

| [15] | 闫帅, 杨家宝, 龚岩, 郭庆华, 于广锁. CO2稀释对甲烷反扩散火焰结构的影响研究[J]. 化工学报, 2022, 73(3): 1335-1342. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号