化工学报 ›› 2022, Vol. 73 ›› Issue (8): 3518-3528.DOI: 10.11949/0438-1157.20220609

收稿日期:2022-04-29

修回日期:2022-07-05

出版日期:2022-08-05

发布日期:2022-09-06

通讯作者:

辛忠

作者简介:姚翰林(1993—),男,博士研究生,18818205845@163.com

基金资助:Received:2022-04-29

Revised:2022-07-05

Online:2022-08-05

Published:2022-09-06

Contact:

Zhong XIN

摘要:

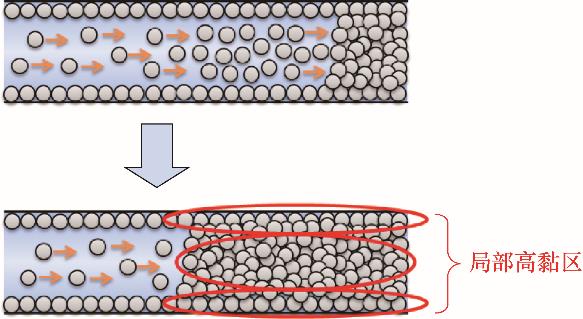

以碳酸钙水相合成为模型反应,借助对流动反应过程的放大观测,从沉淀悬浮液的流变特性分析了液相沉淀反应在毫米级管式微通道中的流动行为特征以及通道堵塞的过程机理。结果表明,碳酸钙-水悬浮体系的黏度在低剪切速率下随固含率的增加而飙升,而反应通道堵塞的本质可归因于在壁面和流动主体区形成了固含率较高的局部高黏区,使流动性严重恶化。提高反应的流速加快了壁面沉积层和沉淀颗粒团聚体的形成,反而加快了堵塞;其中团聚体的形成远快于沉积层的积累,使团聚体的“架桥”虽晚于沉积层出现,却成为管路堵塞的主要因素。基于破坏流动壁面和主体的局部高黏区,设计了两种新型的微通道反应器模型,有可能为解决反应通道堵塞这一难题提供新的思路。

中图分类号:

姚翰林, 辛忠. 液相沉淀反应在管式微通道反应器中的流动行为研究[J]. 化工学报, 2022, 73(8): 3518-3528.

Hanlin YAO, Zhong XIN. Research on flow behavior of liquid-phase precipitation reaction in the tubular microchannel reactor[J]. CIESC Journal, 2022, 73(8): 3518-3528.

图11 沉淀颗粒的惯性运动对空隙中液相的挤压作用以及局部高黏区的形成

Fig.11 Extrusion of liquid phase in interspace by inertial motion of precipitation particles and formation of local high viscosity area

图13 壁面附近存在液层时沉淀颗粒团聚体的流动(管内径:4 mm;流量:50.000 ml/min)

Fig.13 Flow of precipitation particle aggregates when liquid layers exist near the wall surface (tube inner diameter: 4 mm; flow: 50.000 ml/min)

| 优/劣势 | 外环液层式微通道反应器 | 套管式微通道反应器 | |

|---|---|---|---|

| 外环液层与反应溶剂不互溶 | 外环液层与反应溶剂相同 | ||

| 优势 | 1. 对反应沉淀和流动壁面的阻隔作用更加明显 2. 可保持反应物浓度和反应速率不被降低 | 1. 可保持反应器本身的传热性能 2. 不存在液液两相的分离问题 | 1. 射流速度高,可有效破坏沉积层和团聚体 2. 混合效果好 |

| 劣势 | 1. 增加了对反应物料的传热阻力 2. 增加了反应容积(管长) 3. 增加了分离难度和原料成本 | 1. 降低了反应物浓度和反应速率,增加了反应容积(管长) 2. 均匀混合后反应沉淀仍可能在壁面沉积 | 1. 内管压力大 2. 微孔加工精度要求高 3. 反应物的物质的量比可能失准,需要通过实验验证 |

表1 两种新型静态混合式微通道反应器模型的潜在优劣势分析

Table 1 Analysis of potential superiorities and flaws of two novel static mixing microchannel reactor models

| 优/劣势 | 外环液层式微通道反应器 | 套管式微通道反应器 | |

|---|---|---|---|

| 外环液层与反应溶剂不互溶 | 外环液层与反应溶剂相同 | ||

| 优势 | 1. 对反应沉淀和流动壁面的阻隔作用更加明显 2. 可保持反应物浓度和反应速率不被降低 | 1. 可保持反应器本身的传热性能 2. 不存在液液两相的分离问题 | 1. 射流速度高,可有效破坏沉积层和团聚体 2. 混合效果好 |

| 劣势 | 1. 增加了对反应物料的传热阻力 2. 增加了反应容积(管长) 3. 增加了分离难度和原料成本 | 1. 降低了反应物浓度和反应速率,增加了反应容积(管长) 2. 均匀混合后反应沉淀仍可能在壁面沉积 | 1. 内管压力大 2. 微孔加工精度要求高 3. 反应物的物质的量比可能失准,需要通过实验验证 |

| 4 | Coley C W, Thomas D A, Lummiss J A M, et al. A robotic platform for flow synthesis of organic compounds informed by AI planning[J]. Science, 2019, 365(6453): eaax1566. |

| 5 | Lin H K, Dai C H, Jamison T F, et al. A rapid total synthesis of ciprofloxacin hydrochloride in continuous flow[J]. Angewandte Chemie International Edition, 2017, 56(30): 8870-8873. |

| 6 | Luo L M, Yang M, Chen G W. Continuous synthesis of reduced graphene oxide-supported bimetallic NPs in liquid-liquid segmented flow[J]. Industrial & Engineering Chemistry Research, 2020, 59(17): 8456-8468. |

| 7 | Onisuru O R, Alimi O A, Potgieter K, et al. Continuous-flow catalytic degradation of hexacyanoferrate ion through electron transfer induction in a 3D-printed flow reactor[J]. Journal of Materials Engineering and Performance, 2021, 30(7): 4891-4901. |

| 8 | Wang K, Luo G S. Microflow extraction: a review of recent development[J]. Chemical Engineering Science, 2017, 169(21): 18-33. |

| 9 | Yang L, Ładosz A, Jensen K F. Analysis and simulation of multiphase hydrodynamics in capillary microseparators[J]. Lab on a Chip, 2019, 19(4): 706-715. |

| 10 | Zhu K, Yao C Q, Liu Y Y, et al. Using expansion units to improve CO2 absorption for natural gas purification — a study on the hydrodynamics and mass transfer[J]. Chinese Journal of Chemical Engineering, 2021, 29(1): 35-46. |

| 11 | Zhang L, Bo X F, Yao H L, et al. Zinc-catalyzed alkylation of aromatic amines in continuous flow[J]. Organic Process Research & Development, 2020, 24(10): 2078-2084. |

| 12 | Zhao F, Cambié D, Janse J, et al. Scale-up of a luminescent solar concentrator-based photomicroreactor via numbering-up[J]. ACS Sustainable Chemistry & Engineering, 2018, 6(1): 422-429. |

| 13 | Dong Z Y, Delacour C, Mc Carogher K, et al. Continuous ultrasonic reactors: design, mechanism and application[J]. Materials (Basel, Switzerland), 2020, 13(2): 344-368. |

| 14 | Dong Z Y, Fernandez R D, Kuhn S. Acoustophoretic focusing effects on particle synthesis and clogging in microreactors[J]. Lab on a Chip, 2019, 19(2): 316-327. |

| 15 | Hartman R L. Managing solids in microreactors for the upstream continuous processing of fine chemicals[J]. Organic Process Research & Development, 2012, 16(5): 870-887. |

| 16 | Mao M M, Zhang L, Yao H L, et al. Development and scale-up of the rapid synthesis of triphenyl phosphites in continuous flow[J]. ACS Omega, 2020, 5(16): 9503-9509. |

| 17 | Yao H L, Wan L, Zhao X Y, et al. Effective phosphorylation of 2,2'-methylene-bis(4,6-di-tert-butyl) phenol in continuous flow reactors[J]. Organic Process Research & Development, 2021, 25(9): 2060-2070. |

| 18 | Tamaki T, Nagaki A. Flash production of organophosphorus compounds in flow[J]. Tetrahedron Letters, 2021, 81: 153364. |

| 19 | Dong X R, Wang K, Luo G S. Microreaction continuous synthesis of gold nanoparticles[J]. Chinese Journal of Chemical Engineering, 2021, 72(7): 3823-3831. |

| 20 | Nagasawa H, Mae K. Development of a new microreactor based on annular microsegments for fine particle production[J]. Industrial & Engineering Chemistry Research, 2006, 45(7): 2179-2186. |

| 21 | Nagasawa H, Tsujiuchi T, Maki T, et al. Controlling fine particle formation processes using a concentric microreactor[J]. AIChE Journal, 2007, 53(1): 196-206. |

| 22 | Cruz P C, Silva C R, Rocha F A, et al. Mixing performance of planar oscillatory flow reactors with liquid solutions and solid suspensions[J]. Industrial & Engineering Chemistry Research, 2021, 60(6): 2663-2676. |

| 23 | Ley S V, Fitzpatrick D E, Myers R M, et al. Machine-assisted organic synthesis[J]. Angewandte Chemie International Edition, 2015, 54(35): 10122-10136. |

| 24 | Sleveland D, Bjørsvik H R. Synthesis of phenylboronic acids in continuous flow by means of a multijet oscillating disc reactor system operating at cryogenic temperatures[J]. Organic Process Research & Development, 2012, 16(5): 1121-1130. |

| 25 | Mo Y M, Lin H K, Jensen K F. High-performance miniature CSTR for biphasic C—C bond-forming reactions[J]. Chemical Engineering Journal, 2018, 335: 936-944. |

| 26 | Kern D Q, Seaton R A. A theoretical analysis of thermal surface fouling[J]. British Chemical Engineering, 1959, 4(5): 258-262. |

| 27 | Trofa M, D'Avino G, Sicignano L, et al. CFD-DEM simulations of particulate fouling in microchannels[J]. Chemical Engineering Journal, 2019, 358: 91-100. |

| 28 | Hartman R L, Naber J R, Zaborenko N, et al. Overcoming the challenges of solid bridging and constriction during Pd-catalyzed C—N bond formation in microreactors[J]. Organic Process Research & Development, 2010, 14(6): 1347-1357. |

| 29 | Sicignano L, Tomaiuolo G, Perazzo A, et al. The effect of shear flow on microreactor clogging[J]. Chemical Engineering Journal, 2018, 341: 639-647. |

| 30 | Hsu C P, Ramakrishna S N, Zanini M, et al. Roughness-dependent tribology effects on discontinuous shear thickening[J]. Proceedings of the National Academy of Sciences of the United States of America, 2018, 115(20): 5117-5122. |

| 31 | 杨红娟, 韦方强, 胡凯衡, 等. 不同上限粒径泥石流浆体的流变参数变化规律[J]. 水利学报, 2016, 47(7): 884-890. |

| Yang H J, Wei F Q, Hu K H, et al. Rheological parameters of debris flow slurries with different maximum grain sizes[J]. Journal of Hydraulic Engineering, 2016, 47(7): 884-890. | |

| 1 | Adamo A, Beingessner R L, Behnam M, et al. On-demand continuous-flow production of pharmaceuticals in a compact, reconfigurable system[J]. Science, 2016, 352(6281): 61-67. |

| 2 | Bogdan A, Poe S, Kubis D, et al. The continuous-flow synthesis of ibuprofen[J]. Angewandte Chemie International Edition, 2009, 48(45): 8547-8550. |

| 3 | Cambié D, Bottecchia C, Straathof N J W, et al. Applications of continuous-flow photochemistry in organic synthesis, material science, and water treatment[J]. Chemical Reviews, 2016, 116(17): 10276-10341. |

| 32 | 茅梦梅, 万力, 辛忠. 抗氧剂168的连续流高效制备[J]. 精细化工, 2019, 36(10): 2151-2154. |

| Mao M M, Wan L, Xin Z. Highly efficient synthesis of antioxidant 168 in continuous flow[J]. Fine Chemicals, 2019, 36(10): 2151-2154. | |

| 33 | Boylu F, Dinçer H, Ateşok G. Effect of coal particle size distribution, volume fraction and rank on the rheology of coal-water slurries[J]. Fuel Processing Technology, 2004, 85(4): 241-250. |

| 34 | Singh H, Kumar S, Mohapatra S K, et al. Slurryability and flowability of coal water slurry: effect of particle size distribution[J]. Journal of Cleaner Production, 2021, 323: 129183. |

| 35 | Guillot P, Colin A. Determination of the flow curve of complex fluids using the Rabinowitsch-Mooney equation in sensorless microrheometer[J]. Microfluidics and Nanofluidics, 2014, 17(3): 605-611. |

| 36 | Levenspiel O. Chemical Reaction Engineering[M]. New York: Wiley-VCH, 1999. |

| 37 | Foust A S. Principles of Unit Operations[M]. New York: John Willey and Sons Inc., 1980. |

| [1] | 宋瑞涛, 王派, 王云鹏, 李敏霞, 党超镔, 陈振国, 童欢, 周佳琦. 二氧化碳直接蒸发冰场排管内流动沸腾换热数值模拟分析[J]. 化工学报, 2023, 74(S1): 96-103. |

| [2] | 周绍华, 詹飞龙, 丁国良, 张浩, 邵艳坡, 刘艳涛, 郜哲明. 短管节流阀内流动噪声的实验研究及降噪措施[J]. 化工学报, 2023, 74(S1): 113-121. |

| [3] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [4] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [5] | 郑玉圆, 葛志伟, 韩翔宇, 王亮, 陈海生. 中高温钙基材料热化学储热的研究进展与展望[J]. 化工学报, 2023, 74(8): 3171-3192. |

| [6] | 刘爽, 张霖宙, 许志明, 赵锁奇. 渣油及其组分黏度的分子层次组成关联研究[J]. 化工学报, 2023, 74(8): 3226-3241. |

| [7] | 段重达, 姚小伟, 朱家华, 孙静, 胡南, 李广悦. 环境因素对克雷白氏杆菌诱导碳酸钙沉淀的影响[J]. 化工学报, 2023, 74(8): 3543-3553. |

| [8] | 杨峥豪, 何臻, 常玉龙, 靳紫恒, 江霞. 生物质快速热解下行式流化床反应器研究进展[J]. 化工学报, 2023, 74(6): 2249-2263. |

| [9] | 周小文, 杜杰, 张战国, 许光文. 基于甲烷脉冲法的Fe2O3-Al2O3载氧体还原特性研究[J]. 化工学报, 2023, 74(6): 2611-2623. |

| [10] | 张兰河, 赖青燚, 王铁铮, 关潇卓, 张明爽, 程欣, 徐小惠, 贾艳萍. H2O2对SBR脱氮效率和污泥性能的影响[J]. 化工学报, 2023, 74(5): 2186-2196. |

| [11] | 赵健, 周兴超, 夏丹, 董航. 机械搅拌对原油储罐射流加热过程传热特性的影响规律研究[J]. 化工学报, 2023, 74(5): 1982-1999. |

| [12] | 雷博雯, 吴建华, 吴启航. R290低压比热泵高补气过热度循环研究[J]. 化工学报, 2023, 74(5): 1875-1883. |

| [13] | 周必茂, 许世森, 王肖肖, 刘刚, 李小宇, 任永强, 谭厚章. 烧嘴偏转角度对气化炉渣层分布特性的影响[J]. 化工学报, 2023, 74(5): 1939-1949. |

| [14] | 王泽栋, 石至平, 刘丽艳. 考虑气泡非均匀耗散的矩形反应器声流场数值模拟及结构优化[J]. 化工学报, 2023, 74(5): 1965-1973. |

| [15] | 何汉兵, 刘真, 陈勇, 王小锋, 曾婧. 直写成型电极锰氧化物粉末的合成与浆料调控[J]. 化工学报, 2023, 74(5): 2239-2247. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号