化工学报 ›› 2024, Vol. 75 ›› Issue (7): 2505-2521.DOI: 10.11949/0438-1157.20231375

董可豪1,2( ), 周敬之3,4(

), 周敬之3,4( ), 周峰3,4, 陈海家3, 淮秀兰3,4(

), 周峰3,4, 陈海家3, 淮秀兰3,4( ), 李栋1

), 李栋1

收稿日期:2023-12-26

修回日期:2024-05-09

出版日期:2024-07-25

发布日期:2024-08-09

通讯作者:

周敬之,淮秀兰

作者简介:董可豪(1999—),男,硕士研究生,2210451373@qq.com

基金资助:

Kehao DONG1,2( ), Jingzhi ZHOU3,4(

), Jingzhi ZHOU3,4( ), Feng ZHOU3,4, Haijia CHEN3, Xiulan HUAI3,4(

), Feng ZHOU3,4, Haijia CHEN3, Xiulan HUAI3,4( ), Dong LI1

), Dong LI1

Received:2023-12-26

Revised:2024-05-09

Online:2024-07-25

Published:2024-08-09

Contact:

Jingzhi ZHOU, Xiulan HUAI

摘要:

随着超薄热管等元件进一步超薄化,蒸汽腔厚度减小导致蒸汽流动压降急剧增大,传热热阻增加,传输极限降低。搭建了超薄受限空间气体流动压降实验装置,开展空气流动实验,获得了不同通道高度(0.1~0.5 mm)、不同表面丝网孔径(0.036~0.104 mm)和不同流速(1~10 m/s)下的压降变化。结果表明:通道高度和流速对压降产生显著影响,而表面丝网孔径并不会;3个影响因素按显著程度依次为通道高度、流速、表面丝网孔径;随表面丝网孔径的减小,压降逐渐增大;随通道高度的减小,压降先缓慢增大,在减至0.3 mm后压降开始剧烈上升;随流速的增加,压降增大且近似呈正比例变化关系。最后基于实验数据修正了微通道层流情况下沿程阻力系数相关性预测关联式,以便更准确地预测气体压降。

中图分类号:

董可豪, 周敬之, 周峰, 陈海家, 淮秀兰, 李栋. 超薄空间复杂边界条件下气体流动压降实验[J]. 化工学报, 2024, 75(7): 2505-2521.

Kehao DONG, Jingzhi ZHOU, Feng ZHOU, Haijia CHEN, Xiulan HUAI, Dong LI. Experiment of gas flow pressure drop under complex boundary conditions in ultra-thin space[J]. CIESC Journal, 2024, 75(7): 2505-2521.

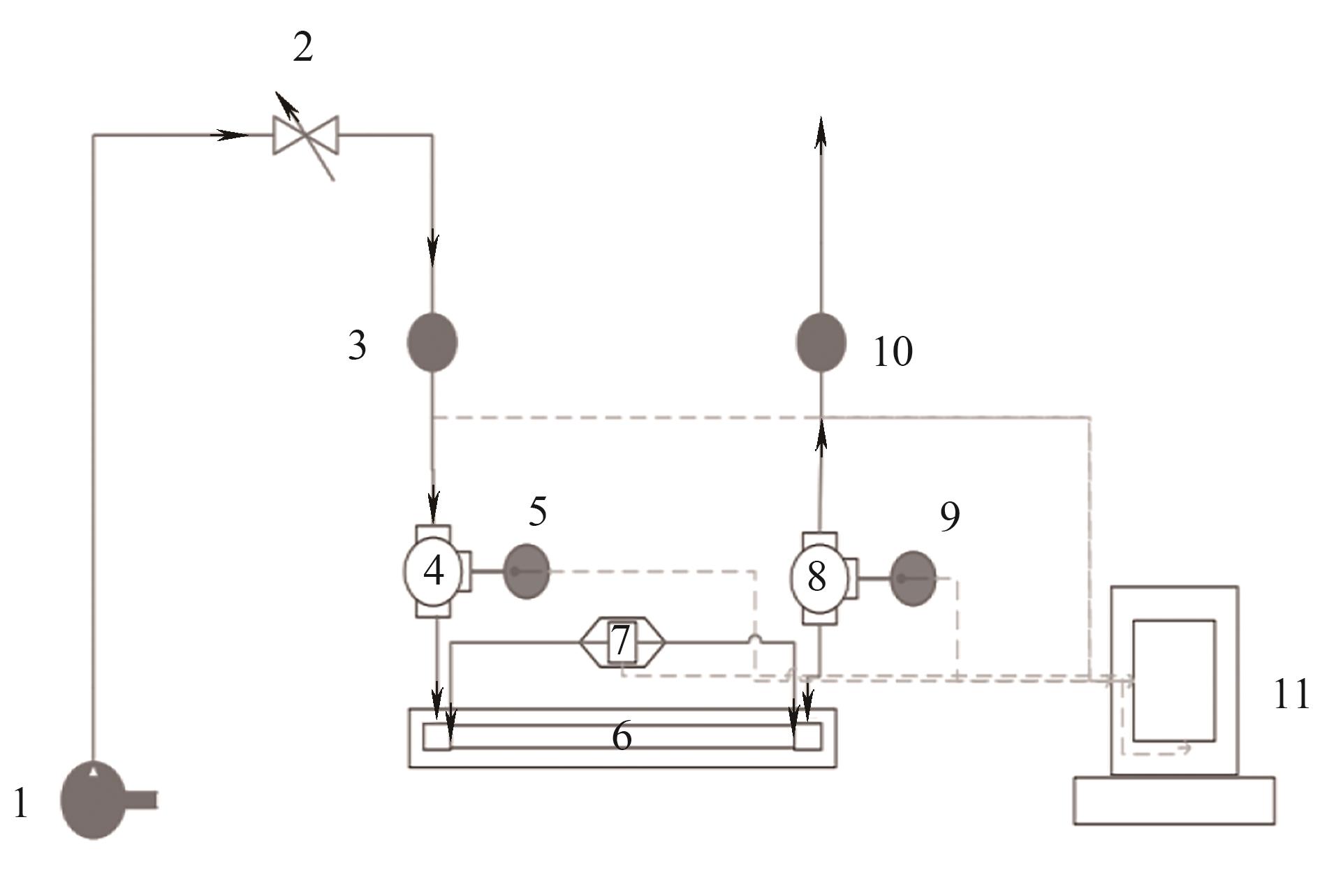

图1 超薄受限空间气体流动实验装置设计系统1—无油空气压缩机;2—针阀;3,10—流量计; 4,8—三通;5,9—温度传感器;6—实验段;7—差压变送器;11—数据采集装置

Fig.1 Flowchart of ultra-thin space gas flow experimental system

| 设 备 | 参 数 | 精 度 |

|---|---|---|

| 智能数字压力表 | 通道压力(-0.1~0.1 MPa) | ±0.5 kPa |

| 玻璃转子流量计 | 进出口体积流量(ml/min,L/h) | ±4%F.S. |

| PT100热电偶 | 进出口温度(℃) | (0.15±0.002)℃ |

| 差压变送器 | 进出口压差(0~10 kPa) | ±0.1%F.S. |

表1 实验设备测量精度

Table 1 Uncertainty of experimental equipment

| 设 备 | 参 数 | 精 度 |

|---|---|---|

| 智能数字压力表 | 通道压力(-0.1~0.1 MPa) | ±0.5 kPa |

| 玻璃转子流量计 | 进出口体积流量(ml/min,L/h) | ±4%F.S. |

| PT100热电偶 | 进出口温度(℃) | (0.15±0.002)℃ |

| 差压变送器 | 进出口压差(0~10 kPa) | ±0.1%F.S. |

图3 实验段4—实验段;401—引流管;402—引压管;403—不锈钢上盖板;404—不锈钢凹槽基座;405—螺栓;406—螺母;407—密封圈;408—盖板安装通孔;409—基座安装通孔;410—不锈钢上盖板凸台;411—粗糙表面铜板;412—口字形不锈钢限位片;413—进气孔;414—稳流腔;415—测压孔;416—出气孔;417—环形槽;418—流动连接槽

Fig.3 Test section

| A通道高度b/mm | B流速u/(m/s) | C表面丝网孔径w/mm |

|---|---|---|

| 0.1 | 1 | 光滑铜板 |

| 0.2 | 2 | 0.036 |

| 0.3 | 3 | 0.041 |

| 0.4 | 4 | 0.053 |

| 0.5 | 5 | 0.063 |

| — | 6 | 0.104 |

表2 实验测试参数水平

Table 2 Experimental test parameter level

| A通道高度b/mm | B流速u/(m/s) | C表面丝网孔径w/mm |

|---|---|---|

| 0.1 | 1 | 光滑铜板 |

| 0.2 | 2 | 0.036 |

| 0.3 | 3 | 0.041 |

| 0.4 | 4 | 0.053 |

| 0.5 | 5 | 0.063 |

| — | 6 | 0.104 |

| 样品 | 长度L/mm | 宽度W/mm | 表面情况 | 丝径d/mm | 孔径w/mm |

|---|---|---|---|---|---|

| 1 | 160 | 10 | — | — | — |

| 2 | 160 | 10 | 100目铜丝网 | 0.150 | 0.104 |

| 3 | 160 | 10 | 150目铜丝网 | 0.106 | 0.063 |

| 4 | 160 | 10 | 200目铜丝网 | 0.074 | 0.053 |

| 5 | 160 | 10 | 250目铜丝网 | 0.061 | 0.041 |

| 6 | 160 | 10 | 300目铜丝网 | 0.048 | 0.036 |

表3 铜丝网铜板样品参数

Table 3 Copper wire mesh copper plate sample parameter

| 样品 | 长度L/mm | 宽度W/mm | 表面情况 | 丝径d/mm | 孔径w/mm |

|---|---|---|---|---|---|

| 1 | 160 | 10 | — | — | — |

| 2 | 160 | 10 | 100目铜丝网 | 0.150 | 0.104 |

| 3 | 160 | 10 | 150目铜丝网 | 0.106 | 0.063 |

| 4 | 160 | 10 | 200目铜丝网 | 0.074 | 0.053 |

| 5 | 160 | 10 | 250目铜丝网 | 0.061 | 0.041 |

| 6 | 160 | 10 | 300目铜丝网 | 0.048 | 0.036 |

| 参数 | 不确定度 |

|---|---|

| 温度/℃ | ±0.152℃ |

| 压力/kPa | ±0.5kPa |

| 压降/kPa | ±0.1%F.S. |

| 体积流量/(ml/min) | ±4%F.S. |

| 宽度/mm | 0.05 mm |

| 高度/mm | 0.05 mm |

| 流速/(m/s) | 4.04% |

| f | 16.86% |

表4 实验中测量参数和计算参数的不确定度

Table 4 Uncertainties of measured and calculated parameters in experiment

| 参数 | 不确定度 |

|---|---|

| 温度/℃ | ±0.152℃ |

| 压力/kPa | ±0.5kPa |

| 压降/kPa | ±0.1%F.S. |

| 体积流量/(ml/min) | ±4%F.S. |

| 宽度/mm | 0.05 mm |

| 高度/mm | 0.05 mm |

| 流速/(m/s) | 4.04% |

| f | 16.86% |

| 编号 | 通道高度b/mm | 流速u/(m/s) | 表面丝网孔径w/mm |

|---|---|---|---|

| 1 | 0.1 | 5 | 0.041 |

| 2 | 0.2 | 1 | 光滑 |

| 3 | 0.3 | 3 | 0.063 |

| 4 | 0.4 | 10 | 0.036 |

| 5 | 0.5 | 2 | 0.104 |

| 6 | 0.1 | 4 | 0.053 |

| 7 | 0.4 | 1 | 0.053 |

| 8 | 0.5 | 3 | 0.036 |

| 9 | 0.2 | 5 | 0.104 |

| 10 | 0.1 | 10 | 0.104 |

| 11 | 0.2 | 2 | 0.053 |

| 12 | 0.3 | 4 | 0.036 |

| 13 | 0.4 | 5 | 0.063 |

| 14 | 0.5 | 1 | 0.041 |

| 15 | 0.3 | 3 | 光滑 |

| 16 | 0.1 | 4 | 光滑 |

| 17 | 0.2 | 10 | 0.063 |

| 18 | 0.3 | 2 | 0.041 |

| 19 | 0.1 | 1 | 0.063 |

| 20 | 0.2 | 3 | 0.041 |

| 21 | 0.3 | 5 | 光滑 |

| 22 | 0.1 | 2 | 0.036 |

| 23 | 0.2 | 4 | 0.104 |

| 24 | 0.3 | 10 | 0.053 |

| 25 | 0.4 | 4 | 0.041 |

| 26 | 0.5 | 10 | 光滑 |

| 27 | 0.4 | 2 | 0.063 |

| 28 | 0.4 | 3 | 0.104 |

| 29 | 0.5 | 5 | 0.053 |

| 30 | 0.5 | 1 | 0.036 |

| 31 | 0.4 | 2 | 光滑 |

| 32 | 0.5 | 4 | 0.063 |

| 33 | 0.1 | 10 | 0.041 |

| 34 | 0.1 | 3 | 0.053 |

| 35 | 0.2 | 5 | 0.036 |

| 36 | 0.3 | 1 | 0.104 |

表5 正交设计

Table 5 Orthogonal designs

| 编号 | 通道高度b/mm | 流速u/(m/s) | 表面丝网孔径w/mm |

|---|---|---|---|

| 1 | 0.1 | 5 | 0.041 |

| 2 | 0.2 | 1 | 光滑 |

| 3 | 0.3 | 3 | 0.063 |

| 4 | 0.4 | 10 | 0.036 |

| 5 | 0.5 | 2 | 0.104 |

| 6 | 0.1 | 4 | 0.053 |

| 7 | 0.4 | 1 | 0.053 |

| 8 | 0.5 | 3 | 0.036 |

| 9 | 0.2 | 5 | 0.104 |

| 10 | 0.1 | 10 | 0.104 |

| 11 | 0.2 | 2 | 0.053 |

| 12 | 0.3 | 4 | 0.036 |

| 13 | 0.4 | 5 | 0.063 |

| 14 | 0.5 | 1 | 0.041 |

| 15 | 0.3 | 3 | 光滑 |

| 16 | 0.1 | 4 | 光滑 |

| 17 | 0.2 | 10 | 0.063 |

| 18 | 0.3 | 2 | 0.041 |

| 19 | 0.1 | 1 | 0.063 |

| 20 | 0.2 | 3 | 0.041 |

| 21 | 0.3 | 5 | 光滑 |

| 22 | 0.1 | 2 | 0.036 |

| 23 | 0.2 | 4 | 0.104 |

| 24 | 0.3 | 10 | 0.053 |

| 25 | 0.4 | 4 | 0.041 |

| 26 | 0.5 | 10 | 光滑 |

| 27 | 0.4 | 2 | 0.063 |

| 28 | 0.4 | 3 | 0.104 |

| 29 | 0.5 | 5 | 0.053 |

| 30 | 0.5 | 1 | 0.036 |

| 31 | 0.4 | 2 | 光滑 |

| 32 | 0.5 | 4 | 0.063 |

| 33 | 0.1 | 10 | 0.041 |

| 34 | 0.1 | 3 | 0.053 |

| 35 | 0.2 | 5 | 0.036 |

| 36 | 0.3 | 1 | 0.104 |

| 项目 | 平方和 | df | 均方 | F | p |

|---|---|---|---|---|---|

| 截距 | 401795343.4 | 1 | 401795343.4 | 28.505 | 0.000** |

| 丝网孔径 | 56616500.81 | 5 | 11323300.16 | 0.803 | 0.561 |

| 流速 | 220820030.8 | 5 | 44164006.16 | 3.133 | 0.030* |

| 通道高度 | 249658457.5 | 5 | 49931691.49 | 3.542 | 0.019* |

| 残差 | 281915550.6 | 20 | 14095777.53 |

表6 多因素方差分析结果

Table 6 Results of multivariate analysis of variance

| 项目 | 平方和 | df | 均方 | F | p |

|---|---|---|---|---|---|

| 截距 | 401795343.4 | 1 | 401795343.4 | 28.505 | 0.000** |

| 丝网孔径 | 56616500.81 | 5 | 11323300.16 | 0.803 | 0.561 |

| 流速 | 220820030.8 | 5 | 44164006.16 | 3.133 | 0.030* |

| 通道高度 | 249658457.5 | 5 | 49931691.49 | 3.542 | 0.019* |

| 残差 | 281915550.6 | 20 | 14095777.53 |

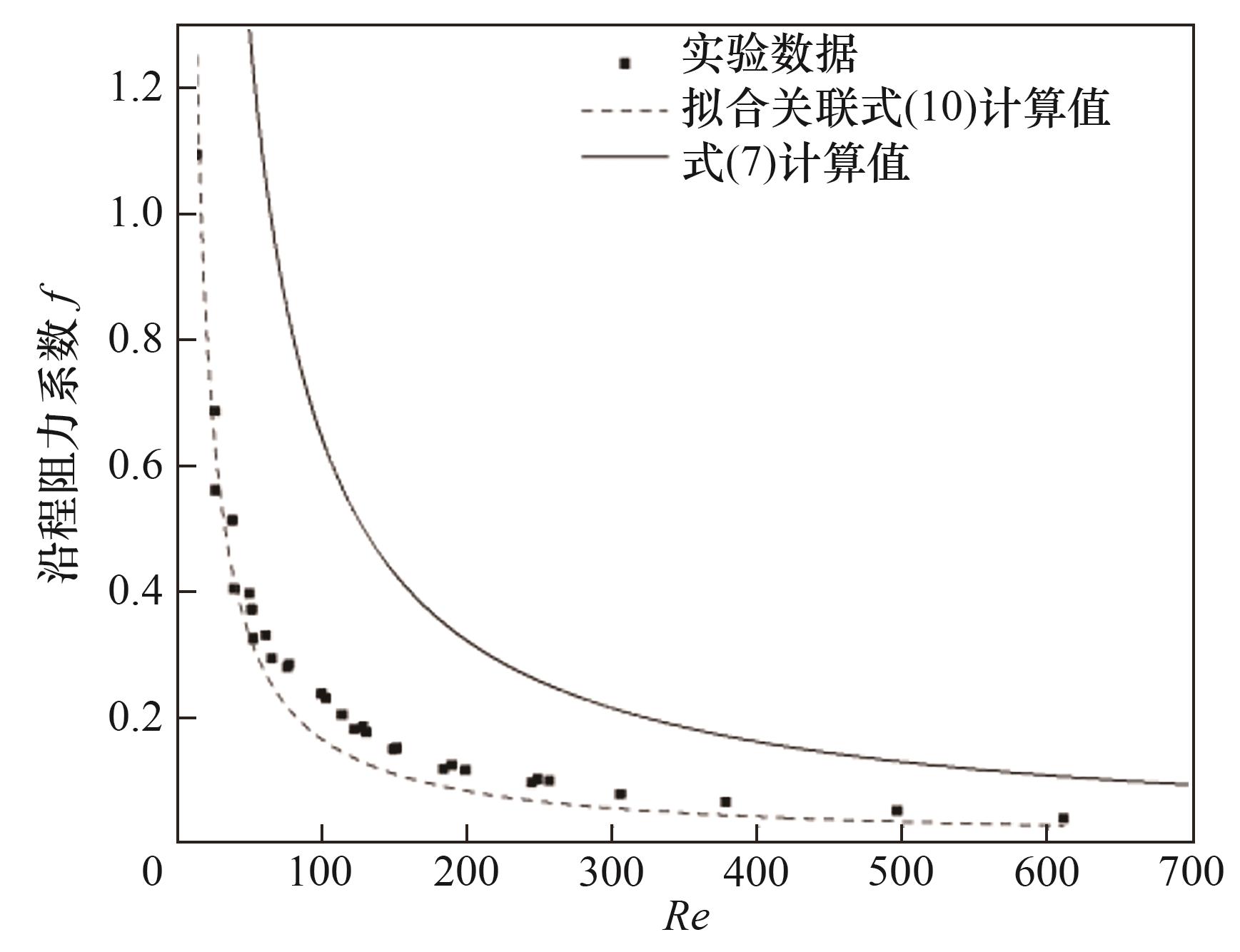

图14 微通道内摩擦系数修正关联式计算值与实验值对比

Fig.14 Comparison of calculated and experimental values of microchannel internal friction coefficient by modified correlation formula

| Reynolds数 | f计算值 | |||||

|---|---|---|---|---|---|---|

| 光滑铜板 | 0.036 mm孔径丝网 | 0.041 mm孔径丝网 | 0.053 mm孔径丝网 | 0.063 mm孔径丝网 | 0.104 mm孔径丝网 | |

| 13.02 | 1.49 | 1.64 | 1.08 | 1.40 | 0.62 | 0.33 |

| 26.05 | 0.75 | 0.84 | 0.61 | 0.70 | 0.29 | 0.18 |

| 39.07 | 0.53 | 0.61 | 0.40 | 0.53 | 0.22 | 0.13 |

| 52.10 | 0.42 | 0.49 | 0.32 | 0.42 | 0.19 | 0.11 |

| 65.12 | 0.38 | 0.46 | 0.28 | 0.37 | 0.17 | 0.10 |

| 130.25 | 0.21 | 0.27 | 0.17 | 0.22 | 0.11 | 0.06 |

| 25.63 | 0.74 | 0.80 | 0.64 | 0.80 | 0.68 | 0.45 |

| 51.26 | 0.39 | 0.45 | 0.36 | 0.42 | 0.33 | 0.26 |

| 76.89 | 0.33 | 0.34 | 0.27 | 0.32 | 0.25 | 0.19 |

| 102.52 | 0.24 | 0.28 | 0.21 | 0.26 | 0.22 | 0.16 |

| 128.15 | 0.20 | 0.22 | 0.17 | 0.22 | 0.17 | 0.13 |

| 256.29 | 0.10 | 0.12 | 0.09 | 0.11 | 0.09 | 0.07 |

| 37.83 | 0.52 | 0.56 | 0.62 | 0.52 | 0.48 | 0.37 |

| 75.67 | 0.30 | 0.30 | 0.25 | 0.32 | 0.29 | 0.21 |

| 113.50 | 0.22 | 0.23 | 0.20 | 0.21 | 0.20 | 0.16 |

| 151.33 | 0.16 | 0.16 | 0.14 | 0.16 | 0.15 | 0.12 |

| 189.17 | 0.13 | 0.14 | 0.12 | 0.13 | 0.12 | 0.10 |

| 378.34 | 0.07 | 0.07 | 0.06 | 0.07 | 0.07 | 0.05 |

| 49.66 | 0.46 | 0.43 | 0.38 | 0.39 | 0.38 | 0.33 |

| 99.31 | 0.25 | 0.25 | 0.23 | 0.25 | 0.24 | 0.20 |

| 148.97 | 0.15 | 0.16 | 0.14 | 0.16 | 0.15 | 0.13 |

| 198.63 | 0.12 | 0.12 | 0.11 | 0.12 | 0.11 | 0.10 |

| 248.28 | 0.10 | 0.11 | 0.10 | 0.11 | 0.10 | 0.09 |

| 496.57 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.04 |

| 61.12 | 0.33 | 0.37 | 0.31 | 0.32 | 0.34 | 0.30 |

| 122.23 | 0.19 | 0.20 | 0.16 | 0.18 | 0.18 | 0.16 |

| 183.35 | 0.12 | 0.13 | 0.10 | 0.12 | 0.12 | 0.10 |

| 244.46 | 0.10 | 0.11 | 0.08 | 0.09 | 0.10 | 0.09 |

| 305.58 | 0.08 | 0.09 | 0.07 | 0.08 | 0.08 | 0.07 |

| 611.16 | 0.04 | 0.04 | 0.03 | 0.04 | 0.04 | 0.03 |

表7 实验结果基于Fanning公式[式(6)]计算值

Table 7 Experimental results calculated based on Fanning formula [Eq. (6)]

| Reynolds数 | f计算值 | |||||

|---|---|---|---|---|---|---|

| 光滑铜板 | 0.036 mm孔径丝网 | 0.041 mm孔径丝网 | 0.053 mm孔径丝网 | 0.063 mm孔径丝网 | 0.104 mm孔径丝网 | |

| 13.02 | 1.49 | 1.64 | 1.08 | 1.40 | 0.62 | 0.33 |

| 26.05 | 0.75 | 0.84 | 0.61 | 0.70 | 0.29 | 0.18 |

| 39.07 | 0.53 | 0.61 | 0.40 | 0.53 | 0.22 | 0.13 |

| 52.10 | 0.42 | 0.49 | 0.32 | 0.42 | 0.19 | 0.11 |

| 65.12 | 0.38 | 0.46 | 0.28 | 0.37 | 0.17 | 0.10 |

| 130.25 | 0.21 | 0.27 | 0.17 | 0.22 | 0.11 | 0.06 |

| 25.63 | 0.74 | 0.80 | 0.64 | 0.80 | 0.68 | 0.45 |

| 51.26 | 0.39 | 0.45 | 0.36 | 0.42 | 0.33 | 0.26 |

| 76.89 | 0.33 | 0.34 | 0.27 | 0.32 | 0.25 | 0.19 |

| 102.52 | 0.24 | 0.28 | 0.21 | 0.26 | 0.22 | 0.16 |

| 128.15 | 0.20 | 0.22 | 0.17 | 0.22 | 0.17 | 0.13 |

| 256.29 | 0.10 | 0.12 | 0.09 | 0.11 | 0.09 | 0.07 |

| 37.83 | 0.52 | 0.56 | 0.62 | 0.52 | 0.48 | 0.37 |

| 75.67 | 0.30 | 0.30 | 0.25 | 0.32 | 0.29 | 0.21 |

| 113.50 | 0.22 | 0.23 | 0.20 | 0.21 | 0.20 | 0.16 |

| 151.33 | 0.16 | 0.16 | 0.14 | 0.16 | 0.15 | 0.12 |

| 189.17 | 0.13 | 0.14 | 0.12 | 0.13 | 0.12 | 0.10 |

| 378.34 | 0.07 | 0.07 | 0.06 | 0.07 | 0.07 | 0.05 |

| 49.66 | 0.46 | 0.43 | 0.38 | 0.39 | 0.38 | 0.33 |

| 99.31 | 0.25 | 0.25 | 0.23 | 0.25 | 0.24 | 0.20 |

| 148.97 | 0.15 | 0.16 | 0.14 | 0.16 | 0.15 | 0.13 |

| 198.63 | 0.12 | 0.12 | 0.11 | 0.12 | 0.11 | 0.10 |

| 248.28 | 0.10 | 0.11 | 0.10 | 0.11 | 0.10 | 0.09 |

| 496.57 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.04 |

| 61.12 | 0.33 | 0.37 | 0.31 | 0.32 | 0.34 | 0.30 |

| 122.23 | 0.19 | 0.20 | 0.16 | 0.18 | 0.18 | 0.16 |

| 183.35 | 0.12 | 0.13 | 0.10 | 0.12 | 0.12 | 0.10 |

| 244.46 | 0.10 | 0.11 | 0.08 | 0.09 | 0.10 | 0.09 |

| 305.58 | 0.08 | 0.09 | 0.07 | 0.08 | 0.08 | 0.07 |

| 611.16 | 0.04 | 0.04 | 0.03 | 0.04 | 0.04 | 0.03 |

| Reynolds数 | 式(7)的计算值与实验计算值误差 | |||||

|---|---|---|---|---|---|---|

| 光滑铜板 | 0.036 mm孔径丝网 | 0.041 mm孔径丝网 | 0.053 mm孔径丝网 | 0.063 mm孔径丝网 | 0.104 mm孔径丝网 | |

| 13.02 | 230.57% | 198.90% | 355.70% | 252.03% | 691.03% | 1368.23% |

| 26.05 | 228.95% | 194.15% | 301.32% | 253.06% | 746.66% | 1269.68% |

| 39.07 | 206.61% | 169.14% | 314.11% | 209.76% | 636.51% | 1176.27% |

| 52.10 | 189.76% | 151.24% | 285.82% | 191.58% | 561.33% | 1046.62% |

| 65.12 | 160.28% | 114.99% | 247.80% | 164.95% | 482.63% | 913.43% |

| 130.25 | 130.38% | 84.09% | 186.50% | 119.70% | 339.05% | 665.68% |

| 25.63 | 237.97% | 210.32% | 291.61% | 210.94% | 269.28% | 455.24% |

| 51.26 | 216.96% | 177.62% | 249.37% | 193.89% | 274.62% | 378.36% |

| 76.89 | 153.62% | 145.48% | 208.27% | 163.51% | 230.78% | 330.66% |

| 102.52 | 158.04% | 125.64% | 194.45% | 138.91% | 181.01% | 288.67% |

| 128.15 | 153.21% | 122.93% | 198.86% | 132.04% | 195.57% | 288.67% |

| 256.29 | 142.16% | 115.03% | 176.14% | 118.35% | 170.38% | 242.97% |

| 37.83 | 222.82% | 199.76% | 174.40% | 227.27% | 254.95% | 351.54% |

| 75.67 | 184.24% | 181.44% | 231.83% | 165.22% | 195.42% | 296.36% |

| 113.50 | 153.59% | 141.30% | 186.52% | 170.24% | 179.42% | 262.77% |

| 151.33 | 157.10% | 156.86% | 195.42% | 162.54% | 185.09% | 258.06% |

| 189.17 | 156.26% | 141.84% | 187.91% | 165.42% | 174.82% | 243.66% |

| 378.34 | 145.76% | 131.71% | 187.91% | 149.02% | 156.36% | 222.68% |

| 49.66 | 181.74% | 202.30% | 239.47% | 228.69% | 236.71% | 287.06% |

| 99.31 | 155.65% | 154.08% | 185.62% | 158.84% | 169.81% | 230.00% |

| 148.97 | 179.20% | 161.57% | 199.39% | 176.10% | 192.34% | 241.33% |

| 198.63 | 162.95% | 169.81% | 189.62% | 159.25% | 183.18% | 230.00% |

| 248.28 | 150.39% | 137.20% | 162.12% | 144.19% | 156.28% | 199.24% |

| 496.57 | 151.15% | 140.09% | 163.45% | 147.70% | 148.29% | 202.74% |

| 61.12 | 217.91% | 184.80% | 233.42% | 225.48% | 207.20% | 246.08% |

| 122.23 | 173.40% | 160.39% | 227.43% | 187.79% | 183.32% | 225.48% |

| 183.35 | 190.86% | 161.21% | 243.19% | 192.93% | 183.81% | 233.42% |

| 244.46 | 162.89% | 143.03% | 213.36% | 176.17% | 161.63% | 206.34% |

| 305.58 | 157.44% | 144.11% | 209.28% | 173.40% | 158.91% | 206.51% |

| 611.16 | 157.93% | 143.46% | 208.93% | 168.04% | 171.50% | 207.20% |

表8 基于式(7)的计算值与实验计算值误差

Table 8 Error between calculated value and experimental value based on Eq. (7)

| Reynolds数 | 式(7)的计算值与实验计算值误差 | |||||

|---|---|---|---|---|---|---|

| 光滑铜板 | 0.036 mm孔径丝网 | 0.041 mm孔径丝网 | 0.053 mm孔径丝网 | 0.063 mm孔径丝网 | 0.104 mm孔径丝网 | |

| 13.02 | 230.57% | 198.90% | 355.70% | 252.03% | 691.03% | 1368.23% |

| 26.05 | 228.95% | 194.15% | 301.32% | 253.06% | 746.66% | 1269.68% |

| 39.07 | 206.61% | 169.14% | 314.11% | 209.76% | 636.51% | 1176.27% |

| 52.10 | 189.76% | 151.24% | 285.82% | 191.58% | 561.33% | 1046.62% |

| 65.12 | 160.28% | 114.99% | 247.80% | 164.95% | 482.63% | 913.43% |

| 130.25 | 130.38% | 84.09% | 186.50% | 119.70% | 339.05% | 665.68% |

| 25.63 | 237.97% | 210.32% | 291.61% | 210.94% | 269.28% | 455.24% |

| 51.26 | 216.96% | 177.62% | 249.37% | 193.89% | 274.62% | 378.36% |

| 76.89 | 153.62% | 145.48% | 208.27% | 163.51% | 230.78% | 330.66% |

| 102.52 | 158.04% | 125.64% | 194.45% | 138.91% | 181.01% | 288.67% |

| 128.15 | 153.21% | 122.93% | 198.86% | 132.04% | 195.57% | 288.67% |

| 256.29 | 142.16% | 115.03% | 176.14% | 118.35% | 170.38% | 242.97% |

| 37.83 | 222.82% | 199.76% | 174.40% | 227.27% | 254.95% | 351.54% |

| 75.67 | 184.24% | 181.44% | 231.83% | 165.22% | 195.42% | 296.36% |

| 113.50 | 153.59% | 141.30% | 186.52% | 170.24% | 179.42% | 262.77% |

| 151.33 | 157.10% | 156.86% | 195.42% | 162.54% | 185.09% | 258.06% |

| 189.17 | 156.26% | 141.84% | 187.91% | 165.42% | 174.82% | 243.66% |

| 378.34 | 145.76% | 131.71% | 187.91% | 149.02% | 156.36% | 222.68% |

| 49.66 | 181.74% | 202.30% | 239.47% | 228.69% | 236.71% | 287.06% |

| 99.31 | 155.65% | 154.08% | 185.62% | 158.84% | 169.81% | 230.00% |

| 148.97 | 179.20% | 161.57% | 199.39% | 176.10% | 192.34% | 241.33% |

| 198.63 | 162.95% | 169.81% | 189.62% | 159.25% | 183.18% | 230.00% |

| 248.28 | 150.39% | 137.20% | 162.12% | 144.19% | 156.28% | 199.24% |

| 496.57 | 151.15% | 140.09% | 163.45% | 147.70% | 148.29% | 202.74% |

| 61.12 | 217.91% | 184.80% | 233.42% | 225.48% | 207.20% | 246.08% |

| 122.23 | 173.40% | 160.39% | 227.43% | 187.79% | 183.32% | 225.48% |

| 183.35 | 190.86% | 161.21% | 243.19% | 192.93% | 183.81% | 233.42% |

| 244.46 | 162.89% | 143.03% | 213.36% | 176.17% | 161.63% | 206.34% |

| 305.58 | 157.44% | 144.11% | 209.28% | 173.40% | 158.91% | 206.51% |

| 611.16 | 157.93% | 143.46% | 208.93% | 168.04% | 171.50% | 207.20% |

| Reynolds数 | 式(10)的计算值与实验计算值误差 | |||||

|---|---|---|---|---|---|---|

| 光滑铜板 | 0.036 mm孔径丝网 | 0.041 mm孔径丝网 | 0.053 mm孔径丝网 | 0.063 mm孔径丝网 | 0.104 mm孔径丝网 | |

| 13.02 | 15.81% | 23.88% | 16.06% | 10.34% | 101.47% | 273.94% |

| 26.05 | 16.22% | 25.08% | 2.21% | 10.08% | 115.63% | 248.84% |

| 39.07 | 21.91% | 31.45% | 5.47% | 21.11% | 87.58% | 225.05% |

| 52.10 | 26.20% | 36.01% | 1.74% | 25.74% | 68.43% | 192.03% |

| 65.12 | 33.71% | 45.24% | 11.42% | 32.52% | 48.39% | 158.11% |

| 130.25 | 41.33% | 53.11% | 27.03% | 44.05% | 11.82% | 95.01% |

| 25.63 | 13.92% | 20.97% | 0.26% | 20.81% | 5.95% | 41.41% |

| 51.26 | 19.27% | 29.29% | 11.02% | 25.15% | 4.59% | 21.83% |

| 76.89 | 35.41% | 37.48% | 21.49% | 32.89% | 15.75% | 9.68% |

| 102.52 | 34.28% | 42.53% | 25.01% | 39.15% | 28.43% | 1.01% |

| 128.15 | 35.51% | 43.22% | 23.88% | 40.90% | 24.72% | 1.01% |

| 256.29 | 38.32% | 45.23% | 29.67% | 44.39% | 31.14% | 12.65% |

| 37.83 | 17.78% | 23.65% | 30.11% | 16.65% | 9.60% | 15.00% |

| 75.67 | 27.61% | 28.32% | 15.49% | 32.45% | 24.76% | 0.95% |

| 113.50 | 35.41% | 38.54% | 27.03% | 31.17% | 28.84% | 7.61% |

| 151.33 | 34.52% | 34.58% | 24.76% | 33.14% | 27.39% | 8.81% |

| 189.17 | 34.73% | 38.41% | 26.67% | 32.40% | 30.01% | 12.47% |

| 378.34 | 37.41% | 40.99% | 26.67% | 36.58% | 34.71% | 17.82% |

| 49.66 | 28.25% | 23.01% | 13.54% | 16.29% | 14.24% | 1.42% |

| 99.31 | 34.89% | 35.29% | 27.26% | 34.08% | 31.28% | 15.95% |

| 148.97 | 28.89% | 33.38% | 23.75% | 29.68% | 25.54% | 13.07% |

| 198.63 | 33.03% | 31.28% | 26.24% | 33.97% | 27.88% | 15.95% |

| 248.28 | 36.23% | 39.59% | 33.24% | 37.81% | 34.73% | 23.79% |

| 496.57 | 36.03% | 38.85% | 32.90% | 36.91% | 36.76% | 22.90% |

| 61.12 | 19.03% | 27.47% | 15.08% | 17.10% | 21.76% | 11.86% |

| 122.23 | 30.37% | 33.68% | 16.61% | 26.70% | 27.84% | 17.10% |

| 183.35 | 25.92% | 33.47% | 12.59% | 25.39% | 27.72% | 15.08% |

| 244.46 | 33.05% | 38.10% | 20.19% | 29.66% | 33.37% | 21.98% |

| 305.58 | 34.43% | 37.83% | 21.23% | 30.37% | 34.06% | 21.94% |

| 611.16 | 34.31% | 37.99% | 21.32% | 31.73% | 30.85% | 21.76% |

表9 基于式(10)的计算值与实验计算值误差

Table 9 Error between calculated value and experimental value based on Eq. (10)

| Reynolds数 | 式(10)的计算值与实验计算值误差 | |||||

|---|---|---|---|---|---|---|

| 光滑铜板 | 0.036 mm孔径丝网 | 0.041 mm孔径丝网 | 0.053 mm孔径丝网 | 0.063 mm孔径丝网 | 0.104 mm孔径丝网 | |

| 13.02 | 15.81% | 23.88% | 16.06% | 10.34% | 101.47% | 273.94% |

| 26.05 | 16.22% | 25.08% | 2.21% | 10.08% | 115.63% | 248.84% |

| 39.07 | 21.91% | 31.45% | 5.47% | 21.11% | 87.58% | 225.05% |

| 52.10 | 26.20% | 36.01% | 1.74% | 25.74% | 68.43% | 192.03% |

| 65.12 | 33.71% | 45.24% | 11.42% | 32.52% | 48.39% | 158.11% |

| 130.25 | 41.33% | 53.11% | 27.03% | 44.05% | 11.82% | 95.01% |

| 25.63 | 13.92% | 20.97% | 0.26% | 20.81% | 5.95% | 41.41% |

| 51.26 | 19.27% | 29.29% | 11.02% | 25.15% | 4.59% | 21.83% |

| 76.89 | 35.41% | 37.48% | 21.49% | 32.89% | 15.75% | 9.68% |

| 102.52 | 34.28% | 42.53% | 25.01% | 39.15% | 28.43% | 1.01% |

| 128.15 | 35.51% | 43.22% | 23.88% | 40.90% | 24.72% | 1.01% |

| 256.29 | 38.32% | 45.23% | 29.67% | 44.39% | 31.14% | 12.65% |

| 37.83 | 17.78% | 23.65% | 30.11% | 16.65% | 9.60% | 15.00% |

| 75.67 | 27.61% | 28.32% | 15.49% | 32.45% | 24.76% | 0.95% |

| 113.50 | 35.41% | 38.54% | 27.03% | 31.17% | 28.84% | 7.61% |

| 151.33 | 34.52% | 34.58% | 24.76% | 33.14% | 27.39% | 8.81% |

| 189.17 | 34.73% | 38.41% | 26.67% | 32.40% | 30.01% | 12.47% |

| 378.34 | 37.41% | 40.99% | 26.67% | 36.58% | 34.71% | 17.82% |

| 49.66 | 28.25% | 23.01% | 13.54% | 16.29% | 14.24% | 1.42% |

| 99.31 | 34.89% | 35.29% | 27.26% | 34.08% | 31.28% | 15.95% |

| 148.97 | 28.89% | 33.38% | 23.75% | 29.68% | 25.54% | 13.07% |

| 198.63 | 33.03% | 31.28% | 26.24% | 33.97% | 27.88% | 15.95% |

| 248.28 | 36.23% | 39.59% | 33.24% | 37.81% | 34.73% | 23.79% |

| 496.57 | 36.03% | 38.85% | 32.90% | 36.91% | 36.76% | 22.90% |

| 61.12 | 19.03% | 27.47% | 15.08% | 17.10% | 21.76% | 11.86% |

| 122.23 | 30.37% | 33.68% | 16.61% | 26.70% | 27.84% | 17.10% |

| 183.35 | 25.92% | 33.47% | 12.59% | 25.39% | 27.72% | 15.08% |

| 244.46 | 33.05% | 38.10% | 20.19% | 29.66% | 33.37% | 21.98% |

| 305.58 | 34.43% | 37.83% | 21.23% | 30.37% | 34.06% | 21.94% |

| 611.16 | 34.31% | 37.99% | 21.32% | 31.73% | 30.85% | 21.76% |

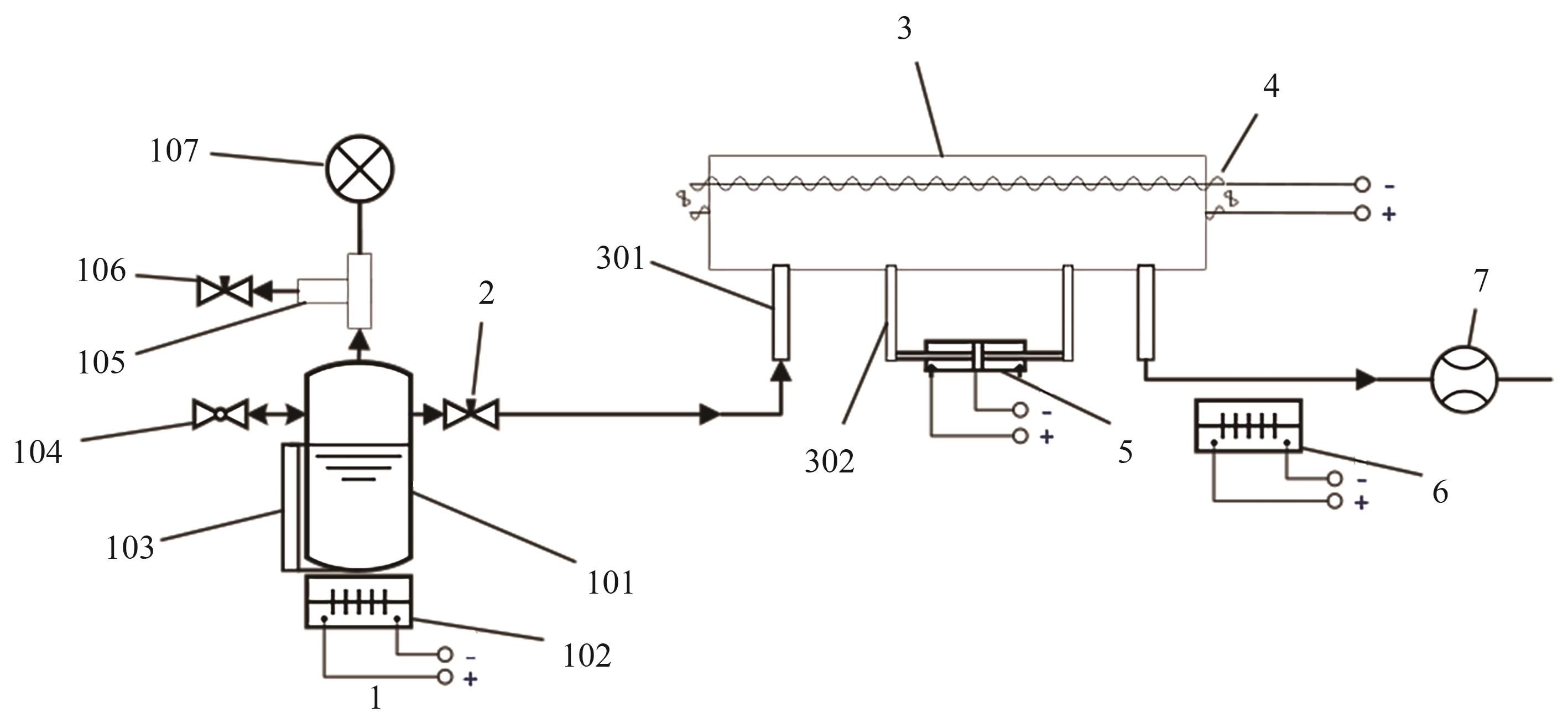

图15 实验装置流程图1—水蒸气发生装置;101—圆柱不锈钢水罐;102—电加热炉;103—液位计;104—球阀;105—三通;106—安全阀;107—压力表;2—流量调节阀;3—第一涡街流量计;4—实验装置;5—电加热带温控装置;6—差压变送器;7—流量计

Fig.15 Flow chart of experimental device

| 1 | Chen Y T, Kang S W, Hung Y H, et al. Feasibility study of an aluminum vapor chamber with radial grooved and sintered powders wick structures[J]. Applied Thermal Engineering, 2013, 51(1/2): 864-870. |

| 2 | 王辉, 汤勇, 余建军. 相变传热微通道技术的研究进展[J]. 机械工程学报, 2010, 46(24): 101-106. |

| Wang H, Tang Y, Yu J J. Recent advances of the phase change micro-channel cooling structure[J]. Journal of Mechanical Engineering, 2010, 46(24): 101-106. | |

| 3 | Chen X P, Ye H Y, Fan X J, et al. A review of small heat pipes for electronics[J]. Applied Thermal Engineering, 2016, 96: 1-17. |

| 4 | Abdulshaheed A A, Wang P T, Huang G H, et al. High performance copper-water heat pipes with nanoengineered evaporator sections[J]. International Journal of Heat and Mass Transfer, 2019, 133: 474-486. |

| 5 | 李健, 杨殷创, 许传龙, 等. 具有纳米结构吸液芯的超薄平面热管传热特性[J]. 工程热物理学报,2020, 41(11): 2762-2766. |

| Li J, Yang Y C, Xu C L, et al. Thermal performance of ultrathin flat heat pipe with nanostructured wick[J]. Journal of Engineering Thermophysics, 2020, 41(11): 2762-2766. | |

| 6 | Wang C, Liu Z L, Zhang G M, et al. Experimental investigations of flat plate heat pipes with interlaced narrow grooves or channels as capillary structure[J]. Experimental Thermal and Fluid Science, 2013, 48: 222-229. |

| 7 | Putra N, Yanuar, Iskandar F N. Application of nanofluids to a heat pipe liquid-block and the thermoelectric cooling of electronic equipment[J]. Experimental Thermal and Fluid Science, 2011, 35(7): 1274-1281. |

| 8 | Yakomaskin A, Afanasiev V, Zubkov N, et al. Investigation of heat transfer in evaporator of microchannel loop heat pipe[J]. Journal of Heat Transfer-Transactions of the ASME, 2013, 135(10): 101-106. |

| 9 | Chen G, Tang Y, Duan L H, et al. Thermal performance enhancement of micro-grooved aluminum flat plate heat pipes applied in solar collectors[J]. Renewable Energy, 2020, 146: 2234-2242. |

| 10 | Koukoravas T P, Damoulakis G, Megaridis C M. Experimental investigation of a vapor chamber featuring wettability-patterned surfaces[J]. Applied Thermal Engineering, 2020, 178: 115522. |

| 11 | Huang J L, Zhou W, Xiang J H, et al. Development of novel flexible heat pipe with multistage design inspired by structure of human spine[J]. Applied Thermal Engineering, 2020, 175: 115392. |

| 12 | Ling W S, Zhou W, Yu W, et al. Thermal performance of loop heat pipes with smooth and rough porous copper fiber sintered sheets[J]. Energy Conversion and Management, 2017, 153: 323-334. |

| 13 | 汤勇, 唐恒, 万珍平,等. 超薄微热管的研究现状及发展趋势[J]. 机械工程学报, 2017, 53(20): 131-144 |

| Tang Y, Tang H, Wan Z P, et al. Development status and perspective trend of ultra-thin micro heat pipe[J]. Journal of Mechanical Engineering, 2017, 53(20): 131-144. | |

| 14 | Qu J, Wu H Y, Cheng P, et al. Recent advances in MEMS-based micro heat pipes[J]. International Journal of Heat and Mass Transfer, 2017, 110: 294-313. |

| 15 | Luo Y Q, Liu W Y, Gou J R. Multiscale simulation of a novel leaf-vein-inspired gradient porous wick structure[J]. Journal of Bionic Engineering, 2019, 16(5): 828-841. |

| 16 | Aoki H, Shioya N, Ikeda M, et al. Development of ultra thin plate-type heat pipe with less than 1 mm thickness[C]// 2010 26th Annual IEEE Semiconductor Thermal Measurement and Management Symposium (SEMI-THERM). Santa Clara, CA, USA: IEEE, 2010: 217-222. |

| 17 | Ding C S, Soni G, Bozorgi P, et al. A flat heat pipe architecture based on nanostructured titania[J]. Journal of Microelectromechanical Systems, 2010, 1(4): 878-884. |

| 18 | Oshman C, Shi B, Li C, et al. The development of polymer-based flat heat pipes[J]. Journal of Microelectromechanical Systems, 2011, 20(2): 410-417. |

| 19 | Lewis R, Xu S S, Liew L A, et al. Thin flexible thermal ground planes: fabrication and scaling characterization[J]. Journal of Microelectromechanical Systems, 2015, 24(6): 2040-2048. |

| 20 | Struss Q, Coudrain P, Colonna J P, et al. Design and fabrication of an ultra-thin silicon vapor chamber for compact electronic cooling[C]//2020 IEEE 70th Electronic Components and Technology Conference (ECTC). Orlando, FL, USA: IEEE, 2020: 2259-2265. |

| 21 | Huang G W, Liu W Y, Luo Y Q, et al. Research and optimization design of limited internal cavity of ultra-thin vapor chamber[J]. International Journal of Heat and Mass Transfer, 2020, 148: 119101. |

| 22 | Zeng J, Chen C, Tang Y, et al. Effect of powder size on capillary and two-phase heat transfer performance for porous interconnected microchannel nets as enhanced wick for two-phase heat transfer devices[J]. Applied Thermal Engineering, 2016, 104: 668-677. |

| 23 | 钱文瑛, 孙志坚, 程攻, 等. 弯折和倾角对微槽道扁平热管传热特性的影响[J]. 能源工程, 2020(4):6-12. |

| Qian W Y, Sun Z J, Cheng G, et al. Effect of bending and inclination on heat transfer characteristics of flat heat pipe with micro-grooves[J]. Energy Engineering, 2020(4): 6-12. | |

| 24 | Chang S W, Chiang K F, Cai W L. Thermal performance evaluation of thin vapor chamber[J]. Applied Thermal Engineering, 2019, 149: 220-230. |

| 25 | 李聪. 基于不同热负荷的超薄均热板传热传质特性研究[D]. 广州: 华南理工大学, 2018. |

| Li C. Analysis on heat and mass transfer characteristic of ultra-thin vapor chamber based on different heat loads[D]. Guangzhou: South China University of Technology, 2018. | |

| 26 | Patankar G, Weibel J A, Garimella S V. Patterning the condenser-side wick in ultra-thin vapor chamber heat spreaders to improve skin temperature uniformity of mobile devices[J]. International Journal of Heat and Mass Transfer, 2016, 101: 927-936. |

| 27 | Patankar G, Weibel J A, Garimella S V. Working-fluid selection for minimized thermal resistance in ultra-thin vapor chambers[J]. International Journal of Heat and Mass Transfer, 2017, 106: 648-654. |

| 28 | Koito Y. Numerical analyses on vapor pressure drop in a centered-wick ultra-thin heat pipe [J]. Frontiers in Heat and Mass Transfer, 2019, 13(1):1-6. |

| 29 | 熊瑭. 结构参数对复合吸液芯超薄热管传热性能影响分析[D]. 广州: 华南理工大学, 2022. |

| Xiong T. Analysis on the effect of structural parameters on the thermal performance of ultra-thin heat pipes with composite wick [D]. Guangzhou: South China University of Technology, 2022. | |

| 30 | Moffat R J. Describing the uncertainties in experimental results[J]. Experimental Thermal and Fluid Science, 1988, 1(1): 3-17. |

| 31 | 刘浩. 基于CFD的透平机械叶片气动性能优化研究[D]. 长春: 吉林大学, 2016. |

| Liu H. Study on aerodynamic performance optimization of turbine machinery blades based on CFD[D]. Changchun: Jilin University, 2016. |

| [1] | 罗小平, 侯云天, 范一杰. 逆流相分离结构微细通道流动沸腾传热与均温性[J]. 化工学报, 2024, 75(7): 2474-2485. |

| [2] | 方立昌, 李梓龙, 陈博, 苏政, 贾莉斯, 王智彬, 陈颖. 基于相变微胶囊悬浮液的芯片阵列冷却特性研究[J]. 化工学报, 2024, 75(7): 2455-2464. |

| [3] | 余清杰, 杨洪海, 刘玉浩, 方海洲, 何伟琪, 王军, 卢心诚. 脉动热管温度信号的小波分析及流型识别[J]. 化工学报, 2024, 75(7): 2497-2504. |

| [4] | 吴邦汉, 林定标, 陆海峰, 郭晓镭, 刘海峰. 竖直管气动物流传输系统管道压降和传送瓶输送特性[J]. 化工学报, 2024, 75(7): 2465-2473. |

| [5] | 赵赫, 费滢洁, 朱春英, 付涛涛, 马友光. 高黏体系中纳米颗粒稳定气泡的形变及破裂行为[J]. 化工学报, 2024, 75(6): 2180-2189. |

| [6] | 徐嘉宇, 陈飞国, 徐骥, 葛蔚. 颗粒体系的多尺度混合指数[J]. 化工学报, 2024, 75(6): 2214-2221. |

| [7] | 刘礼豪, 黄婷, 雍宇, 罗昕浩, 赵泽明, 宋尚飞, 史博会, 陈光进, 宫敬. 含粉砂盐水体系甲烷水合物生成与固相沉积规律[J]. 化工学报, 2024, 75(5): 1987-2000. |

| [8] | 李娟, 曹耀文, 朱章钰, 石雷, 李佳. 仿生正形尾鳍结构微通道流动与传热特性数值研究及结构优化[J]. 化工学报, 2024, 75(5): 1802-1815. |

| [9] | 刘帆, 张芫通, 陶成, 胡成玉, 杨小平, 魏进家. 歧管式射流微通道液冷散热性能[J]. 化工学报, 2024, 75(5): 1777-1786. |

| [10] | 吉笑盈, 郑园, 李晓鹏, 杨振, 张维, 邱诗蕊, 张倩颖, 罗沧海, 孙东鹏, 陈东, 李东亮. 微流控可控制备液滴、颗粒和胶囊及其应用[J]. 化工学报, 2024, 75(4): 1455-1468. |

| [11] | 陈彦松, 阮达, 刘渊博, 郑通, 张帅帅, 马学虎. 微通道换热器拓扑结构优化与性能研究[J]. 化工学报, 2024, 75(3): 823-835. |

| [12] | 陈饶, 赵鑫, 陈戴欣, 姜圣坤, 廉应江, 王金波, 杨梅, 陈光文. 微反应器内甲苯连续二硝化制备二硝基甲苯[J]. 化工学报, 2024, 75(3): 867-876. |

| [13] | 宋仕容, 刘宏臣, 米晓天, 许超, 杨梅, 尧超群. 同轴微通道内管结构对液滴生成的影响规律研究[J]. 化工学报, 2024, 75(2): 566-574. |

| [14] | 郑雨婷, 方冠东, 张梦波, 张浩淼, 王靖岱, 阳永荣. 微化工精馏分离技术研究进展[J]. 化工学报, 2024, 75(1): 47-59. |

| [15] | 温唯谷, 袁志宏, 王凯, 骆广生. 微分散液滴的光纤检测研究[J]. 化工学报, 2024, 75(1): 211-220. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号