化工学报 ›› 2025, Vol. 76 ›› Issue (12): 6257-6267.DOI: 10.11949/0438-1157.20250245

收稿日期:2025-03-12

修回日期:2025-04-30

出版日期:2025-12-31

发布日期:2026-01-23

通讯作者:

马学虎

作者简介:汪嘉辉(1999—),男,硕士研究生,wjhdlut2022@163.com

基金资助:

Jiahui WANG1( ), Xu LIU1, Nan ZHANG1, Yi ZHENG2, Xuehu MA1(

), Xu LIU1, Nan ZHANG1, Yi ZHENG2, Xuehu MA1( )

)

Received:2025-03-12

Revised:2025-04-30

Online:2025-12-31

Published:2026-01-23

Contact:

Xuehu MA

摘要:

随着工业的发展,液化石油气储存的安全问题越来越重要。油气球形储罐泄漏以沸腾液体膨胀蒸汽爆炸(BLEVE)为主,严重影响着工作人员的安全。因此研究不同曲率曲面沸腾过程,快速降低传热系数(HTC)十分关键。研究了四种不同曲率曲面对沸腾的影响,并对气泡的传热特性和动力学进行讨论。研究结果表明,除了曲率为47-1 mm-1的表面,其余表面传热系数随着曲率的增大不断增大。相较于平面沸腾,曲面沸腾实现了气泡的定向输运,加快了表面气泡的更新速率,从而提高了沸腾过程中的临界热通量(CHF)和传热系数,其中曲率为47-1 mm-1的曲面圆心角0°处CHF最高,为138.8 W/cm2,相较于光滑平表面升高了26.2%,其对应的表面温度为111.4℃。

中图分类号:

汪嘉辉, 刘旭, 张楠, 郑毅, 马学虎. 弯曲表面核沸腾气泡特性与传热研究[J]. 化工学报, 2025, 76(12): 6257-6267.

Jiahui WANG, Xu LIU, Nan ZHANG, Yi ZHENG, Xuehu MA. Research on the characteristics and heat transfer of nucleate boiling bubbles on curved surfaces[J]. CIESC Journal, 2025, 76(12): 6257-6267.

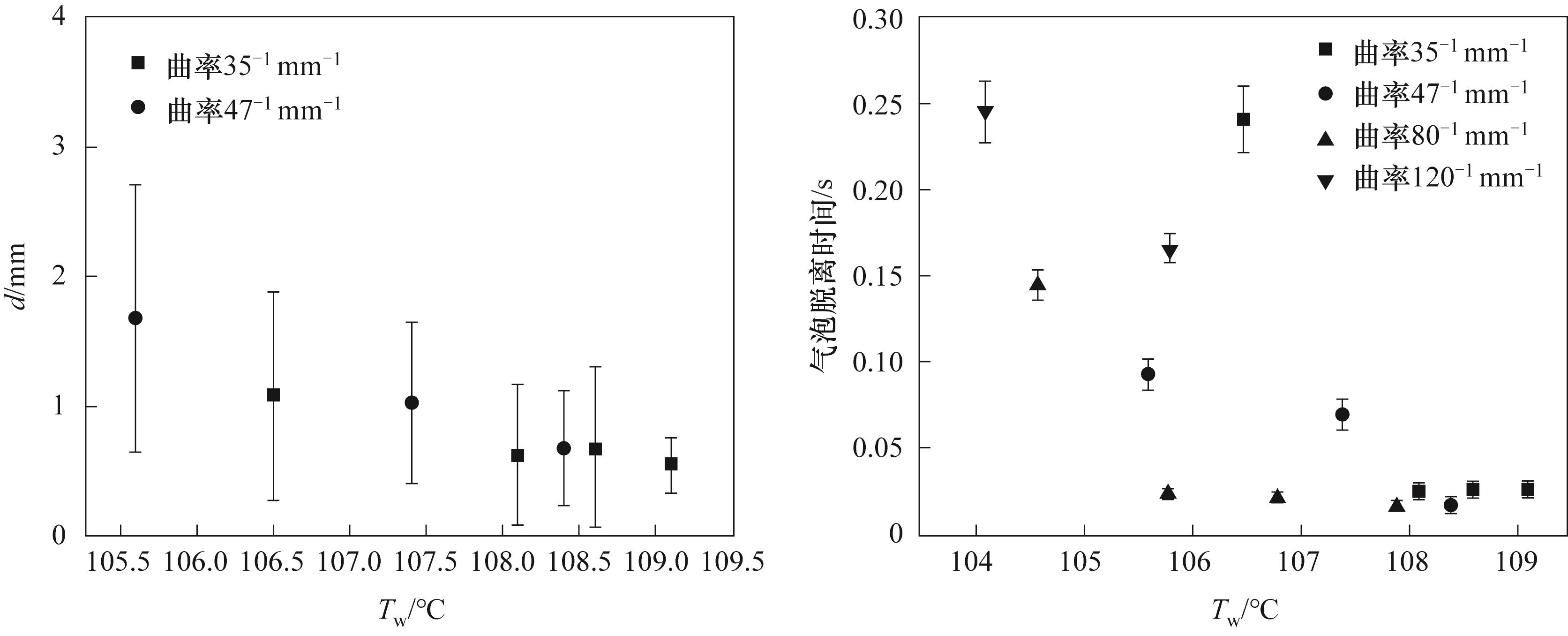

图9 不同曲率曲面气泡滑移距离和不同曲率曲面气泡脱离时间

Fig.9 Bubble slip distance on surfaces with different curvatures and bubble detachment time on surfaces with different curvatures

| [1] | CCPS. Guidelines for Evaluating the Characteristics of Vapor Cloud Explosions, Flash Fires and BLEVE's, Center for Chemical Process Safety[M]. New York: American Institute of Chemical Engineers, 1994: 1-402. |

| [2] | Walls W L. The BLEVE-part 1[J]. Fire Command, 1979, 17: 35-37. |

| [3] | Ibrahim Mohamed Shaluf. An overview on BLEVE[J]. Disaster Prevention and Management, 2007, 16(5): 740-754. |

| [4] | CCPS. Guidelines for Consequence Analysis of Chemical Releases[M]. New York: American Institute of Chemical Engineers, 1999: 1-346. |

| [5] | Birk A M, Cunningham M H. The boiling liquid expanding vapor explosion[J]. Journal of Loss Prevention in the Process Industries, 1994, 7(6): 474-480. |

| [6] | van den Berg A C, van der Voort M M, Weerheijm J, et al. BLEVE blast by expansion-controlled evaporation[J]. Process Safety Progress, 2006, 25(1): 44-51. |

| [7] | Bourdon B, Di Marco P, Rioboo R, et al. Enhancing the onset of pool boiling by wettability modification on nanometrically smooth surfaces[J]. International Communications in Heat and Mass Transfer, 2013, 45: 11-15. |

| [8] | Phan H T, Caney N, Marty P, et al. Surface wettability control by nanocoating: the effects on pool boiling heat transfer and nucleation mechanism[J]. International Journal of Heat and Mass Transfer, 2009, 52(23/24): 5459-5471. |

| [9] | Bourdon B, Bertrand E, Di Marco P, et al. Wettability influence on the onset temperature of pool boiling: experimental evidence onto ultra-smooth surfaces[J]. Advances in Colloid and Interface Science, 2015, 221: 34-40. |

| [10] | Takata Y, Hidaka S, Kohno M. Effect of surface wettability on pool boiling: enhancement by hydrophobic coating[J]. International Journal of Air-Conditioning and Refrigeration, 2012, 20(1): 1150003. |

| [11] | Shi J, Jia X, Feng D Y, et al. Wettability effect on pool boiling heat transfer using a multiscale copper foam surface[J]. International Journal of Heat and Mass Transfer, 2020, 146: 118726. |

| [12] | Jung J Y, Kwak H Y. Effect of surface condition on boiling heat transfer from silicon chip with submicron-scale roughness [J]. International Journal of Heat and Mass Transfer, 2006, 49(23/24): 4543-4551. |

| [13] | Kim J, Jun S, Laksnarain R, et al. Effect of surface roughness on pool boiling heat transfer at a heated surface having moderate wettability[J]. International Journal of Heat and Mass Transfer, 2016, 101: 992-1002. |

| [14] | Honda H, Takamastu H, Wei J J. Enhanced Boiling of FC-72 on silicon chips with micro-pin-fins and submicron-scale roughness[J]. Journal of Heat Transfer, 2002, 124(2): 383-390. |

| [15] | O'Hanley H, Coyle C, Buongiorno J, et al. Separate effects of surface roughness, wettability, and porosity on the boiling critical heat flux[J]. Applied Physics Letters, 2013, 103(2): 024102. |

| [16] | Zou Y, Li J Y, Li T Y, et al. Experimental study of the effect of surface roughness on the heat transfer characteristics of subcooled flow boiling in a narrow rectangular channel[J]. Annals of Nuclear Energy, 2025, 210: 110842. |

| [17] | Sun Y L, Tang Y, Zhang S W, et al. A review on fabrication and pool boiling enhancement of three-dimensional complex structures[J]. Renewable and Sustainable Energy Reviews, 2022, 162: 112437. |

| [18] | Liu Y, Tang J Q, Li L X, et al. Design of Cassie-wetting nucleation sites in pool boiling[J]. International Journal of Heat and Mass Transfer, 2019, 132: 25-33. |

| [19] | 纪献兵, 王野, 代超, 等. 乳突状多尺度结构表面的池沸腾传热特性[J]. 高校化学工程学报,2018, 32(2): 312-318. |

| Ji X B, Wang Y, Dai C, et al. Pool boiling heat transfer characteristics on mastoid surface with multiscale structures[J]. Journal of Chemical Engineering of Chinese Universities, 2018, 32(2): 312-318. | |

| [20] | Gouda R K, Pathak M, Khan M K. Pool boiling heat transfer enhancement with segmented finned microchannels structured surface[J]. International Journal of Heat and Mass Transfer, 2018, 127: 39-50. |

| [21] | 柴永志, 张伟, 赵亚东, 等. 润湿性对微纳复合结构表面池沸腾换热的影响[J]. 高校化学工程学报, 2017, 31(4): 984-990. |

| Chai Y Z, Zhang W, Zhao Y D, et al. Effects of wettability on pool boiling heat transfer of micro/nano-composite surface[J]. Journal of Chemical Engineering of Chinese Universities, 2017, 31(4): 984-990. | |

| [22] | Choi H, Aziz F, Shin Y, et al. Effects of super-hydrophilicity and orientation of heater surface on bubble behavior and the critical heat flux in pool boiling[J]. Annals of Nuclear Energy, 2023, 186: 109762. |

| [23] | Xie S Z, Jiang M N, Kong H J, et al. An experimental investigation on the pool boiling of multi-orientated hierarchical structured surfaces[J]. International Journal of Heat and Mass Transfer, 2021, 164: 120595. |

| [24] | Ferng Y M, Tseng Y L. Investigating effects of heating orientations on boiling heat transfer and bubble dynamics for pool boiling on downward facing heating surface[J]. Nuclear Engineering and Design, 2023, 406: 112230. |

| [25] | Li Q, Kang Q J, Francois M M, et al. Lattice Boltzmann modeling of boiling heat transfer: The boiling curve and the effects of wettability[J]. International Journal of Heat and Mass Transfer, 2015, 85: 787-796. |

| [26] | Jo H, Ahn H S, Kang S, et al. A study of nucleate boiling heat transfer on hydrophilic, hydrophobic and heterogeneous wetting surfaces[J]. International Journal of Heat and Mass Transfer, 2011, 54(25/26): 5643-5652. |

| [27] | Ahn H S, Lee C, Kim H, et al. Pool boiling CHF enhancement by micro/nanoscale modification of zircaloy-4 surface[J]. Nuclear Engineering and Design, 2010, 240(10): 3350-3360. |

| [28] | Hui L F, Liu M Y, Cai Y W, et al. Fouling resistance on chemically etched hydrophobic surfaces in nucleate pool boiling[J]. Chemical Engineering & Technology, 2015, 38(3): 416-422. |

| [29] | Rohsenow W M. A method of correlating heat-transfer data for surface boiling of liquids[J]. Journal of Fluids Engineering, 1952, 74(6): 969-975. |

| [1] | 任现超, 谷雅秀, 段少斌, 贾文竹, 李汉林. 翅片式椭圆套管蒸发式冷凝器传热传质性能实验研究[J]. 化工学报, 2025, 76(S1): 75-83. |

| [2] | 吴馨, 龚建英, 李祥宇, 王宇涛, 杨小龙, 蒋震. 超声波激励疏水表面液滴运动的实验研究[J]. 化工学报, 2025, 76(S1): 133-139. |

| [3] | 袁琳慧, 王瑜. 单服务器浸没射流式液冷系统散热性能[J]. 化工学报, 2025, 76(S1): 160-169. |

| [4] | 赵子祥, 段钟弟, 孙浩然, 薛鸿祥. 大温差两相流动诱导水锤冲击的数值模型[J]. 化工学报, 2025, 76(S1): 170-180. |

| [5] | 黄博, 黄灏, 王文, 贺隆坤. 薄膜型LNG船液货舱温度场计算分析[J]. 化工学报, 2025, 76(S1): 195-204. |

| [6] | 汪思远, 刘国强, 熊通, 晏刚. 窗式空调器轴流风机的风速非均匀分布特性及其对冷凝器流路优化设计的影响规律[J]. 化工学报, 2025, 76(S1): 205-216. |

| [7] | 曹庆泰, 郭松源, 李建强, 蒋赞, 汪彬, 耑锐, 吴静怡, 杨光. 负过载下多孔隔板对液氧贮箱蓄液性能的影响研究[J]. 化工学报, 2025, 76(S1): 217-229. |

| [8] | 孔俊龙, 毕扬, 赵耀, 代彦军. 储能电池直冷热管理系统的模拟实验[J]. 化工学报, 2025, 76(S1): 289-296. |

| [9] | 罗海梅, 王泓, 孙照明, 尹艳华. 同向双螺杆传热系数计算模型的分析与验证[J]. 化工学报, 2025, 76(9): 4809-4823. |

| [10] | 胡金琦, 闵春华, 李小龙, 范元鸿, 王坤. 振动叶片耦合柔性板强化流体混沌混合与传热研究[J]. 化工学报, 2025, 76(9): 4824-4837. |

| [11] | 邹家庆, 张肇钰, 张建国, 张博宇, 刘定胜, 毛庆, 王挺, 李建军. 碱水制氢电解槽极板通道中气泡的生成及演化性质[J]. 化工学报, 2025, 76(9): 4786-4799. |

| [12] | 贾志勇, 沈宪琨, 蓝晓程, 王铁峰. 气体密度对高压流态化影响的CFD-DEM模拟[J]. 化工学报, 2025, 76(9): 4383-4397. |

| [13] | 曾宁, 郭振江, 陈建华, 张子轩, 曾玉娇, 肖炘, 刘松林, 薛绍秀, 周智武, 卢振明, 王利民. 二水湿法磷酸工艺中非水溶磷的分子动力学模拟[J]. 化工学报, 2025, 76(9): 4539-4550. |

| [14] | 徐佳琪, 张文君, 余燕萍, 苏宝根, 任其龙, 杨启炜. 热等离子体重整炼厂气制合成气过程数值模拟与实验研究[J]. 化工学报, 2025, 76(9): 4462-4473. |

| [15] | 佘海龙, 胡光忠, 崔晓钰, 柳忠彬, 彭帝, 李航. 不同节流工质下叠层微通道分布式节流制冷器性能研究[J]. 化工学报, 2025, 76(8): 4017-4029. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号