化工学报 ›› 2021, Vol. 72 ›› Issue (11): 5607-5619.DOI: 10.11949/0438-1157.20210762

收稿日期:2021-06-08

修回日期:2021-08-09

出版日期:2021-11-05

发布日期:2021-11-12

通讯作者:

许细薇

作者简介:孙焱(1989—),男,博士,基金资助:

Yan SUN( ),Xiaowen SHEN,Xiwei XU(

),Xiaowen SHEN,Xiwei XU( ),Enchen JIANG,Xuecong LIU

),Enchen JIANG,Xuecong LIU

Received:2021-06-08

Revised:2021-08-09

Online:2021-11-05

Published:2021-11-12

Contact:

Xiwei XU

摘要:

生物油重整制合成气不仅能充分利用生物油中的成分,同时也展现了生物油转化为化学品的高值利用潜能。将载氧体NiFe2O4和Ni基催化剂耦合得到催化耦合化学链反应体系,为了比较催化剂的影响机制,分别构建了Ni/Si-NiFe和Ni/VR-NiFe催化耦合化学链反应体系,并以愈创木酚、乙酸和乙醇的纯物质及其混合液作为生物质热解液的模拟物,通过水蒸气重整实验考察了催化剂配比、反应温度、水碳比和反应时间对重整产物分布的影响。基于反应条件的筛选进一步通过寿命试验和BET、SEM表征,验证了反应体系的稳定性。最后,通过单组分及混合液体重整反应系统分析了化学链耦合催化反应体系的重整机制,为生物质热转化制备化学品提供了重要的理论支撑。

中图分类号:

孙焱, 沈晓文, 许细薇, 蒋恩臣, 刘雪聪. 化学链耦合催化重整热解生物油制备合成气[J]. 化工学报, 2021, 72(11): 5607-5619.

Yan SUN, Xiaowen SHEN, Xiwei XU, Enchen JIANG, Xuecong LIU. Coupled chemical looping and catalytic reforming to produce syngas from pyrolysis bio-oil[J]. CIESC Journal, 2021, 72(11): 5607-5619.

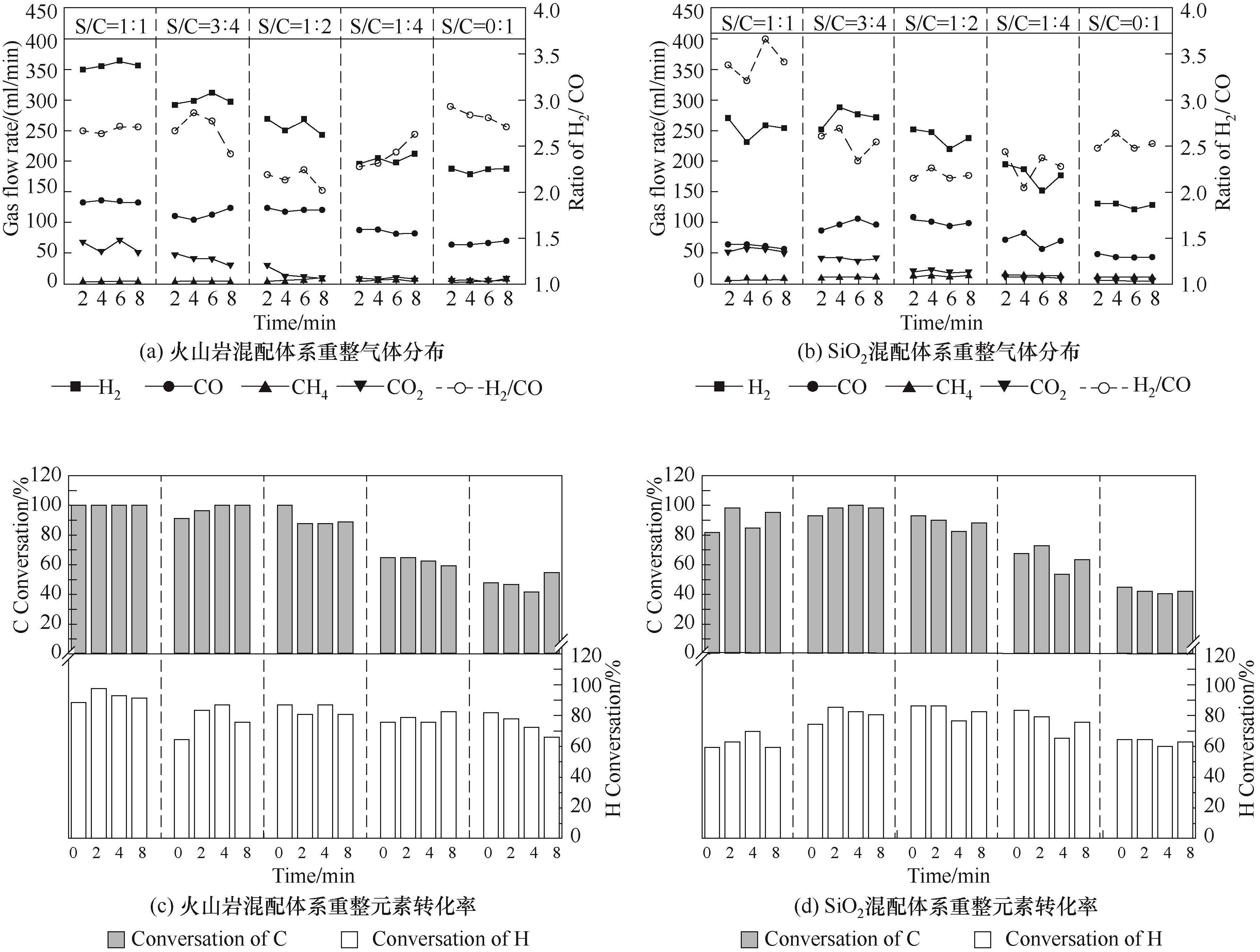

图4 不同耦合体系在不同水碳比条件下重整产物分布及元素的转化变化情况

Fig.4 Effect of different water carbon ratio on reforming performance of mixed liquid with different reaction system

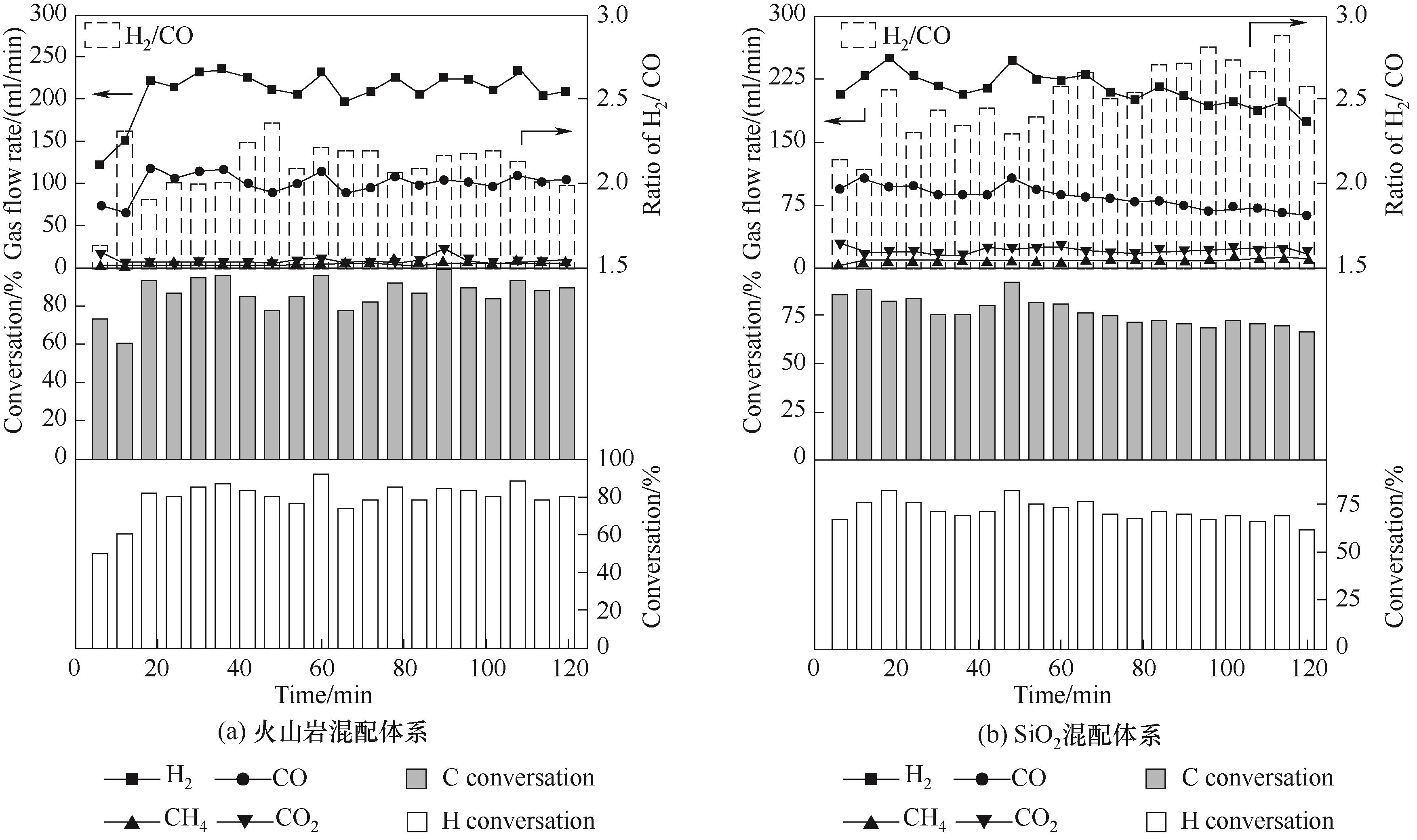

图5 两种耦合体系在相同条件下重整产物分布及木质素的转化随时间变化情况

Fig.5 The distribution of reforming products and the transformation of lignin with time in the two coupling systems under the same conditions

| 样品名称 | 比表面积/(m2/g) | 平均孔径/nm | 孔容/(cm3/g) |

|---|---|---|---|

| VR-NiFe原样 | 1.8554 | 19.6952 | 0. 132 ×10-3 |

| VR-NiFe反应后 | 1.7037 | 21.5902 | 0.032 ×10-3 |

| Si-NiFe原样 | 23.5204 | 26.1521 | 0. 846 ×10-3 |

| Si-NiFe反应后 | 17.2746 | 26.5620 | 0. 260 ×10-3 |

表1 反应前后载氧体的孔隙结构参数

Table 1 Pore structure parameters of the spend and fresh OCs

| 样品名称 | 比表面积/(m2/g) | 平均孔径/nm | 孔容/(cm3/g) |

|---|---|---|---|

| VR-NiFe原样 | 1.8554 | 19.6952 | 0. 132 ×10-3 |

| VR-NiFe反应后 | 1.7037 | 21.5902 | 0.032 ×10-3 |

| Si-NiFe原样 | 23.5204 | 26.1521 | 0. 846 ×10-3 |

| Si-NiFe反应后 | 17.2746 | 26.5620 | 0. 260 ×10-3 |

| 1 |

Balasundram V, Ibrahim N, Kasmani R M, et al. Catalytic upgrading of biomass-derived pyrolysis vapour over metal-modified HZSM-5 into BTX: a comprehensive review[J]. Biomass Conversion and Biorefinery, 2020. doi: 10.1007/s13399-020-00909-5.

DOI URL |

| 2 | Bohre A, Alam M I, Avasthi K, et al. Low temperature transformation of lignocellulose derived bioinspired molecules to aviation fuel precursor over magnesium-lanthanum mixed oxide catalyst[J]. Applied Catalysis B: Environmental, 2020, 276: 119069. |

| 3 | Liu W, You W Q, Gong Y T, et al. High-efficiency electrochemical hydrodeoxygenation of bio-phenols to hydrocarbon fuels by a superacid-noble metal particle dual-catalyst system[J]. Energy & Environmental Science, 2020, 13(3): 917-927. |

| 4 | 罗泽军, 胡永华, 王雨松, 等. 重质生物油理化性质及其热解特性研究[J]. 化工学报, 2019, 70(8): 3196-3201. |

| Luo Z J, Hu Y H, Wang Y S, et al. Physicochemical properties and pyrolysis characteristics of heavy biooil[J]. CIESC Journal, 2019, 70(8): 3196-3201. | |

| 5 | Shu R Y, Li R X, Lin B Q, et al. A review on the catalytic hydrodeoxygenation of lignin-derived phenolic compounds and the conversion of raw lignin to hydrocarbon liquid fuels[J]. Biomass and Bioenergy, 2020, 132: 105432. |

| 6 | Ouedraogo A S, Bhoi P R. Recent progress of metals supported catalysts for hydrodeoxygenation of biomass derived pyrolysis oil[J]. Journal of Cleaner Production, 2020, 253: 119957. |

| 7 | 张帆, 殷实, 冷富荣, 等. 基于生物炭载体催化剂的生物油重整制氢研究[J]. 工程热物理学报, 2016, 37(5): 1123-1128. |

| Zhang F, Yin S, Leng F R, et al. Study on hydrogen production from bio oil reforming based on biochar supported catalyst [J]. Journal of Engineering Thermophysics, 2016, 37 (5): 1123-1128. | |

| 8 | 仉利, 姚宗路, 赵立欣, 等. 生物质热化学转化提质及其催化剂研究进展[J]. 化工学报, 2020, 71(8): 3416-3427. |

| Zhang L, Yao Z L, Zhao L X, et al. Research progress of biomass thermochemical conversion and upgrading and its catalysts [J]. CIESC Journal, 2020, 71 (8): 3416-3427. | |

| 9 | 赵文祥, 杨双霞, 陈雷, 等. 生物质热化学催化转化制富氢合成气研究进展[J]. 现代化工, 2021, 41(4): 38-42. |

| Zhao W X, Yang S X, Chen L, et al. Research progress of biomass thermochemical catalytic conversion to hydrogen rich syngas [J]. Modern Chemical Industry, 2021, 41 (4): 38-42. | |

| 10 | Valle B, García-Gómez N, Remiro A, et al. Dual catalyst-sorbent role of dolomite in the steam reforming of raw bio-oil for producing H2-rich syngas[J]. Fuel Processing Technology, 2020, 200: 106316. |

| 11 | Kang Y, Han Y J, Tian M, et al. Promoted methane conversion to syngas over Fe-based garnets via chemical looping[J]. Applied Catalysis B: Environmental, 2020, 278: 119305. |

| 12 | Liu C L, Chen D, Ashok J, et al. Chemical looping steam reforming of bio-oil for hydrogen-rich syngas production: effect of doping on LaNi0.8Fe0.2O3 perovskite[J]. International Journal of Hydrogen Energy, 2020, 45(41): 21123-21137. |

| 13 | Zhao K, He F, Huang Z, et al. Perovskite-type oxides LaFe1-xCoxO3 for chemical looping steam methane reforming to syngas and hydrogen co-production[J]. Applied Energy, 2016, 168: 193-203. |

| 14 | Jin Z, Yi X F, Wang L, et al. Metal-acid interfaces enveloped in zeolite crystals for cascade biomass hydrodeoxygenation[J]. Applied Catalysis B: Environmental, 2019, 254: 560-568. |

| 15 | 颜蓓蓓, 王建, 刘彬, 等.生物油金属水热原位加氢提质技术研究进展[J]. 化工学报, 2021, 72(4): 1783-1795. |

| Yan B B, Wang J, Liu B, et al. Research progress of bio-oil metal hydrothermal in-situ hydrogenation technology[J]. CIESC Journal, 2021, 72(4): 1783-1795. | |

| 16 | Mehla S, Kukade S, Kumar P, et al. Fine tuning H-transfer and β-scission reactions in VGO FCC using metal promoted dual functional ZSM-5[J]. Fuel, 2019, 242: 487-495. |

| 17 | Zhou H B, Zhang T T, Sui Z J, et al. A single source method to generate Ru-Ni-MgO catalysts for methane dry reforming and the kinetic effect of Ru on carbon deposition and gasification[J]. Applied Catalysis B: Environmental, 2018, 233: 143-159. |

| 18 | Gomes J F, Frasson D, Pereira J L, et al. Ecotoxicity variation through parabens degradation by single and catalytic ozonation using volcanic rock[J]. Chemical Engineering Journal, 2019, 360: 30-37. |

| 19 | Gomes J, Frasson D, Quinta-Ferreira R, et al. Removal of enteric pathogens from real wastewater using single and catalytic ozonation[J]. Water, 2019, 11(1): 127. |

| 20 | Li Z, Yan Q H, Jiang Q, et al. Oxygen vacancy mediated CuyCo3-yFe1Ox mixed oxide as highly active and stable toluene oxidation catalyst by multiple phase interfaces formation and metal doping effect[J]. Applied Catalysis B: Environmental, 2020, 269: 118827. |

| 21 | 孙焱. 松子壳生物油制备和催化改性试验研究[D]. 哈尔滨: 东北农业大学, 2014. |

| Sun Y. Study on the preparation and catalytic upgrading of pine-nut shell bio-oil[D]. Harbin: Northeast Agricultural University, 2014. | |

| 22 | Li M R, Wang G C. The mechanism of ethanol steam reforming on the Co0 and Co2+ sites: a DFT study[J]. Journal of Catalysis, 2018, 365: 391-404. |

| 23 | Badawi M, Paul J F, Cristol S, et al. Guaiacol derivatives and inhibiting species adsorption over MoS2 and CoMoS catalysts under HDO conditions: a DFT study[J]. Catalysis Communications, 2011, 12(10): 901-905. |

| 24 | Li X B, Xue L J, Zhu Y Y, et al. Mechanistic study of bio-oil catalytic steam reforming for hydrogen production: acetic acid decomposition[J]. International Journal of Hydrogen Energy, 2018, 43(29): 13212-13224. |

| 25 | Lee D K, Ahn S J, Kim D S. Mechanistic studies of formation of carbon deposits on supported Pt catalysts during wet oxidation of phenol [C]//Proceedings of the 9th International Symposium. Amsterdam: Elsevier, 2001: 69-76. |

| 26 | 方修忠.高效抗积炭Ni基甲烷重整制氢催化剂的制备和性能研究[D].南昌: 南昌大学, 2016. |

| Fang X Z. Preparation and performance of high efficiency carbon deposition resistant Ni based catalyst for hydrogen production from methane reforming [D]. Nanchang: Nanchang University, 2016. | |

| 27 | 郎林, 李键铭, 杨文申, 等. Ni/KZSM-5催化剂的生物乙醇水蒸气重整制氢催化性能[J]. 可再生能源, 2017, 35(2): 185-191. |

| Lang L, Li J M, Yang W S, et al. Bio-ethanol catalytic steam reforming over Ni/KZSM-5 catalysts[J]. Renewable Energy Resources, 2017, 35(2): 185-191. | |

| 28 | 梅占强, 何素芳, 陈柯臻, 等. 乙醇水蒸气重整制氢催化剂的研究进展[J]. 环境化学, 2017, 36(10): 2126-2139. |

| Mei Z Q, He S F, Chen K Z, et al. Research progress of catalysts for hydrogen production from ethanol steam reforming [J]. Environmental Chemistry, 2017, 36 (10): 2126-2139. | |

| 29 | 冉艳雄. Ni基催化剂上乙酸蒸汽重整反应机理研究[D]. 太原: 太原理工大学, 2017. |

| Ran Y X. DFT studies of acetic acid steam reforming over Ni-based catalysts[D]. Taiyuan: Taiyuan University of Technology, 2017. | |

| 30 | 吴国鹏. 光催化重整甲醇及生物质衍生物制氢[D]. 大连: 大连理工大学, 2007. |

| Wu G P. H2 prodution via photocatalytic reforming of methanol and biomass-derived compounds[D]. Dalian: Dalian University of Technology, 2007. | |

| 31 | 郑朝霞.不同钌基催化剂在水相中催化愈创木酚选择性加氢脱氧到苯的研究[D].上海: 华东师范大学, 2018. |

| Zheng Z X. Study on selective hydrodeoxygenation of guaiacol to benzene catalyzed by different ruthenium based catalysts in aqueous phase [D]. Shanghai: East China Normal University, 2018. | |

| 32 | Shi D M, Vohs J M. Lignin-derived oxygenate reforming on a bimetallic surface: the reaction of benzaldehyde on Zn/Pt(111)[J]. Surface Science, 2016, 650: 161-166. |

| 33 | Du Z Y, Zhang Z H, Xu C, et al. Low-temperature steam reforming of toluene and biomass tar over biochar-supported Ni nanoparticles[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(3): 3111-3119. |

| [1] | 宋嘉豪, 王文. 斯特林发动机与高温热管耦合运行特性研究[J]. 化工学报, 2023, 74(S1): 287-294. |

| [2] | 王阳, 戴永强, 曾炜. 2,5-二羟基苯磺酸增强离子水凝胶材料热电性能的研究[J]. 化工学报, 2023, 74(9): 3946-3955. |

| [3] | 毕恩哲, 李双喜, 沙廉翔, 刘登宇, 陈凯放. 高温动压涨圈密封结构参数多目标优化分析[J]. 化工学报, 2023, 74(6): 2565-2579. |

| [4] | 葛泽峰, 吴雨青, 曾名迅, 查振婷, 马宇娜, 侯增辉, 张会岩. 灰化学成分对生物质气化特性的影响规律[J]. 化工学报, 2023, 74(5): 2136-2146. |

| [5] | 顾浩, 张福建, 刘珍, 周文轩, 张鹏, 张忠强. 力电耦合作用下多孔石墨烯膜时间维度的脱盐性能及机理研究[J]. 化工学报, 2023, 74(5): 2067-2074. |

| [6] | 范坤阳, 杨景兴, 许海波, 连兴容, 何凤梅, 陈聪慧, 李增耀. 遮光剂掺杂SiO2气凝胶传热的统一格子Boltzmann模型研究[J]. 化工学报, 2023, 74(5): 1974-1981. |

| [7] | 任金胜, 刘克润, 焦志伟, 刘家祥, 于源. 涡流空气分级机近导叶处团聚体解团机理研究[J]. 化工学报, 2023, 74(4): 1528-1538. |

| [8] | 肖川宝, 李林洋, 刘武锋, 钟年丙, 解泉华, 钟登杰, 常海星. 光催化与离子交换吸附耦合有效去除2,4,6-三氯苯酚[J]. 化工学报, 2023, 74(4): 1587-1597. |

| [9] | 李雨萧, 王青月, Ho Lim Khak, 李晓辉, Erlita Mastan, 彭博, 王文俊. 自由基聚合反应动力学常数测定技术[J]. 化工学报, 2023, 74(2): 559-570. |

| [10] | 范怡平, 卢春喜. 离心力场-移动床耦合气固分离装备的研究进展[J]. 化工学报, 2023, 74(1): 157-169. |

| [11] | 李鑫, 曾少娟, 彭奎霖, 袁磊, 张香平. CO2电催化还原制合成气研究进展及趋势[J]. 化工学报, 2023, 74(1): 313-329. |

| [12] | 刘振宇. 煤地下气化低效的化学反应工程根源:滞留层及通道中的传质与反应[J]. 化工学报, 2022, 73(8): 3299-3306. |

| [13] | 朱莲峰, 王超, 张梦娟, 刘方正, 贾鑫, 安萍, 许光文, 韩振南. 水蒸气/氧流化床两段煤气化制备低焦油合成气工艺实验[J]. 化工学报, 2022, 73(8): 3720-3730. |

| [14] | 王佳铭, 阮雪华, 贺高红. 面向不同工业二氧化碳分离体系的膜材料研究进展[J]. 化工学报, 2022, 73(8): 3417-3432. |

| [15] | 王悦琳, 晁伟, 蓝晓程, 莫志朋, 佟淑环, 王铁峰. 合成气生物发酵法制乙醇的研究进展[J]. 化工学报, 2022, 73(8): 3448-3460. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号