化工学报 ›› 2022, Vol. 73 ›› Issue (8): 3720-3730.DOI: 10.11949/0438-1157.20220478

朱莲峰1,2,3( ), 王超1,2(

), 王超1,2( ), 张梦娟1,2, 刘方正1,2, 贾鑫1,2, 安萍1,2, 许光文1,2, 韩振南1,2(

), 张梦娟1,2, 刘方正1,2, 贾鑫1,2, 安萍1,2, 许光文1,2, 韩振南1,2( )

)

收稿日期:2022-04-06

修回日期:2022-05-10

出版日期:2022-08-05

发布日期:2022-09-06

通讯作者:

王超,韩振南

作者简介:朱莲峰(1997—),男,硕士研究生,zhulianfeng0724@163.com

基金资助:

Lianfeng ZHU1,2,3( ), Chao WANG1,2(

), Chao WANG1,2( ), Mengjuan ZHANG1,2, Fangzheng LIU1,2, Xin JIA1,2, Ping AN1,2, Guangwen XU1,2, Zhennan HAN1,2(

), Mengjuan ZHANG1,2, Fangzheng LIU1,2, Xin JIA1,2, Ping AN1,2, Guangwen XU1,2, Zhennan HAN1,2( )

)

Received:2022-04-06

Revised:2022-05-10

Online:2022-08-05

Published:2022-09-06

Contact:

Chao WANG, Zhennan HAN

摘要:

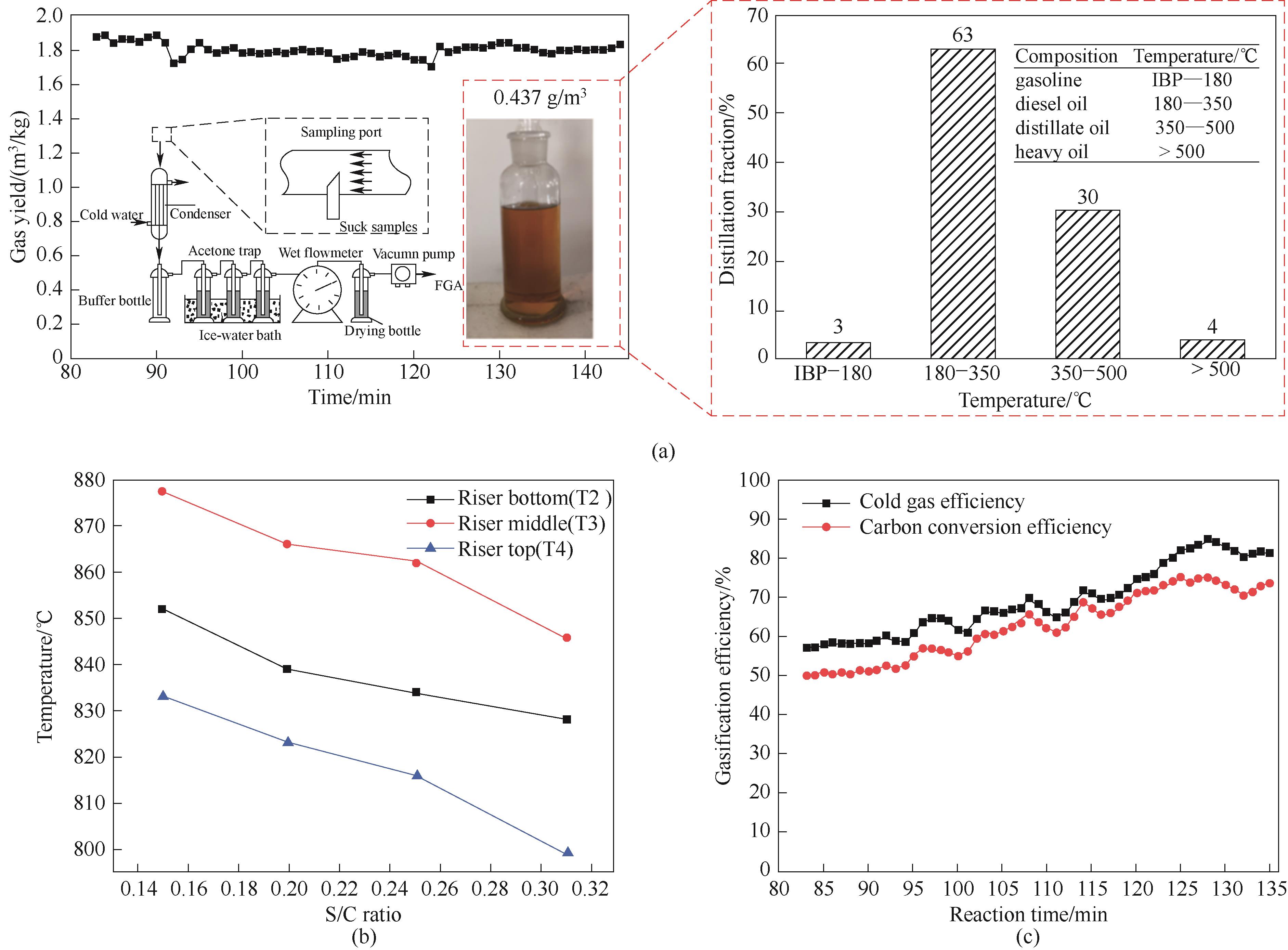

由下行床热解和提升管(或输送床)气化组合形成的流化床两段气化将煤气化反应过程解耦为煤热解和半焦气化两个反应阶段,热解产物完全进入气化反应器,利用其中的高温环境和输送的半焦催化作用分别实现焦油的热裂解与催化裂解,完成低焦油气化。利用该流化床两段气化的10 kg/h级实验室工艺实验装置,以榆林烟煤为原料、水蒸气/氧气作为气化剂,变化过量氧气系数ER、蒸汽炭比S/C、热解及气化温度等参数,研究水蒸气/氧流化床两段煤气化制备低焦油合成气的特性。结果表明,流化床两段气化系统可实现稳定运行(实验3 h以上),在ER=0.36和S/C=0.15时,热解和气化的代表温度分别稳定在735℃和877℃,合成气的CO、CO2、H2、CH4、C n H m 和N2含量分别为14.33%、10.07%、18.39%、9.89%、1.82%和45.50%,相应的合成气产量达到1.8 m3/kg,低位热值8.99 MJ/m3,焦油含量0.437 g/m3,展示了制备低焦油合成气的技术特征。对于实际的长时间连续运行,更高的气化温度将使流化床两段气化具有更好的低焦油特性。

中图分类号:

朱莲峰, 王超, 张梦娟, 刘方正, 贾鑫, 安萍, 许光文, 韩振南. 水蒸气/氧流化床两段煤气化制备低焦油合成气工艺实验[J]. 化工学报, 2022, 73(8): 3720-3730.

Lianfeng ZHU, Chao WANG, Mengjuan ZHANG, Fangzheng LIU, Xin JIA, Ping AN, Guangwen XU, Zhennan HAN. Fluidized bed two-stage gasification of coal with steam/O2 for production of low-tar syngas[J]. CIESC Journal, 2022, 73(8): 3720-3730.

图1 耦合下行床热解和提升管气化的两段流化床气化工艺原理示意图HCPs—heating carrier particles

Fig.1 A conceptual diagram of two-stage fluidized bed gasification coupling downer pyrolysis and riser gasification

| Industrial analysis/ %(mass,ad) | Elemental analysis/%(mass,ad) | |||||||

|---|---|---|---|---|---|---|---|---|

| M | A | V | FC | C | H | O① | N | S |

| 4.80 | 9.23 | 30.20 | 55.77 | 70.85 | 3.96 | 23.74 | 1.01 | 0.44 |

表1 实验原料烟煤工业分析和元素分析结果

Table 1 Industrial and elemental analyses of tested bituminous coal

| Industrial analysis/ %(mass,ad) | Elemental analysis/%(mass,ad) | |||||||

|---|---|---|---|---|---|---|---|---|

| M | A | V | FC | C | H | O① | N | S |

| 4.80 | 9.23 | 30.20 | 55.77 | 70.85 | 3.96 | 23.74 | 1.01 | 0.44 |

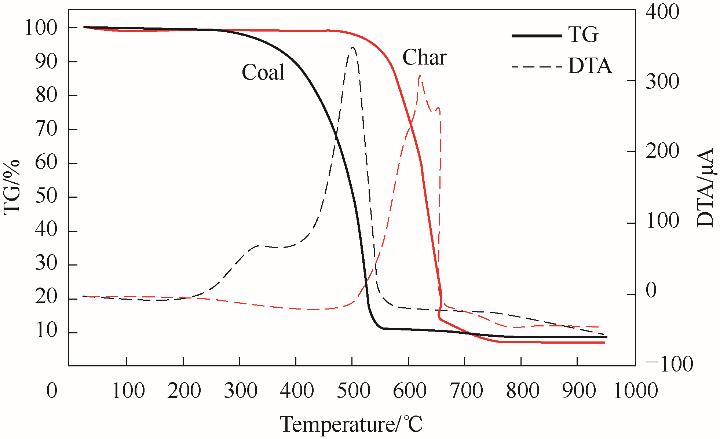

图4 原煤及其半焦在空气氛围中的失重特性(煤半焦样品对应气化条件为ER=0.36和S/C=0.15,下同)

Fig.4 Thermogravimetric analysis of tested coal and produced char in air atmosphere (char samples generated from coal gasification under ER=0.36 and S/C=0.15)

图9 稳定运行条件下:(a)气体收率、焦油含量和焦油模拟蒸馏结果;(b)随着水煤比增加气化反应器温度分布曲线;(c)冷态气化效率与碳转化率变化曲线

Fig.9 Gas yield, tar content and simulated distillation results of tar (a), the temperature variation with S/C ratio increasing (b), and the variations of cold gas efficiency and carbon conversion efficiency (c) at realized steady gasification test

| Typical applied gasifier name | Feedstock | Institute | Caloric value/ (MJ/m3) | Tar content/ (g/m3) | Ref. |

|---|---|---|---|---|---|

| downdraft gasifier | high ash biomass and high ash coal | Institute of Technology, Nirma University, Ahmedabad, India | 4.98—5.62 | 0.11—0.52 | [ |

| top-lit updraft gasifier (TLUD) | palm kernel shell, high-volatile bituminous coal | Department of Mechanical Engineering, Universidad del Norte, Colombia | 3.7—5.1 | 8.55—132.4 | [ |

| staged fixed-bed gasifier | wood, bark, and sunflower husk pellets | VTT Technical Research Centre of Finland Ltd., Finland | 2.4—12.1 | 0.01—0.254 | [ |

| bubbling fluidized bed | pinewood, maple-oak wood, seed corn | Department of Mechanical Engineering, Iowa State University, USA | 4.28—8.26 | 6.62—19.55 | [ |

| circulating fluidized bed | cypress, hemlock, cedar, spruce, pine, and mixed sawdust | The University of British Columbia, Canada | 2.43—6.13 | 0.4—15.2 | [ |

| dual fluidized bed | wood chips, coal, sewage sludge, and plastics | Vienna University of Technology, Austria | 12—14 | 0.5—20 | [ |

| two-stage fluidized bed | low-rank coal | IPE, China | 4.6 | 0.365—1.13 | [ |

| this work | bituminous coal | Shenyang University of Chemical Technology, China | 8.99 | 0.437 | — |

表2 文献中不同气化技术之间的对比

Table 2 Comparison of different gasification technologies in references

| Typical applied gasifier name | Feedstock | Institute | Caloric value/ (MJ/m3) | Tar content/ (g/m3) | Ref. |

|---|---|---|---|---|---|

| downdraft gasifier | high ash biomass and high ash coal | Institute of Technology, Nirma University, Ahmedabad, India | 4.98—5.62 | 0.11—0.52 | [ |

| top-lit updraft gasifier (TLUD) | palm kernel shell, high-volatile bituminous coal | Department of Mechanical Engineering, Universidad del Norte, Colombia | 3.7—5.1 | 8.55—132.4 | [ |

| staged fixed-bed gasifier | wood, bark, and sunflower husk pellets | VTT Technical Research Centre of Finland Ltd., Finland | 2.4—12.1 | 0.01—0.254 | [ |

| bubbling fluidized bed | pinewood, maple-oak wood, seed corn | Department of Mechanical Engineering, Iowa State University, USA | 4.28—8.26 | 6.62—19.55 | [ |

| circulating fluidized bed | cypress, hemlock, cedar, spruce, pine, and mixed sawdust | The University of British Columbia, Canada | 2.43—6.13 | 0.4—15.2 | [ |

| dual fluidized bed | wood chips, coal, sewage sludge, and plastics | Vienna University of Technology, Austria | 12—14 | 0.5—20 | [ |

| two-stage fluidized bed | low-rank coal | IPE, China | 4.6 | 0.365—1.13 | [ |

| this work | bituminous coal | Shenyang University of Chemical Technology, China | 8.99 | 0.437 | — |

| 1 | Xie K C, Li W Y, Zhao W. Coal chemical industry and its sustainable development in China[J]. Energy, 2010, 35(11): 4349-4355. |

| 2 | Guan G Q. Clean coal technologies in Japan: a review[J]. Chinese Journal of Chemical Engineering, 2017, 25(6): 689-697. |

| 3 | Wang Y, Dong W, Dong L, et al. Production of middle caloric fuel gas from coal by dual-bed gasification technology[J]. Energy & Fuels, 2010, 24(5): 2985-2990. |

| 4 | Zeng X, Ueki Y, Yoshiie R, et al. Recent progress in tar removal by char and the applications: a comprehensive analysis[J]. Carbon Resources Conversion, 2020, 3: 1-18. |

| 5 | Zhang J W, Wang Y, Dong L, et al. Decoupling gasification: approach principle and technology justification[J]. Energy & Fuels, 2010, 24(12): 6223-6232. |

| 6 | Chen Z H, Li Y J, Lai D G, et al. Coupling coal pyrolysis with char gasification in a multi-stage fluidized bed to co-produce high-quality tar and syngas[J]. Applied Energy, 2018, 215: 348-355. |

| 7 | Han Z N, Geng S L, Zeng X, et al. Reaction decoupling in thermochemical fuel conversion and technical progress based on decoupling using fluidized bed[J]. Carbon Resources Conversion, 2018, 1(2): 109-125. |

| 8 | Fan S M, Yuan X Z, Zhao L, et al. Experimental and kinetic study of catalytic steam gasification of low rank coal with an environmentally friendly, inexpensive composite K2CO3-eggshell derived CaO catalyst[J]. Fuel, 2016, 165: 397-404. |

| 9 | Hanchate N, Ramani S, Mathpati C S, et al. Biomass gasification using dual fluidized bed gasification systems: a review[J]. Journal of Cleaner Production, 2021, 280: 123148. |

| 10 | Berdugo Vilches T, Maric J, Knutsson P, et al. Bed material as a catalyst for char gasification: the case of ash-coated olivine activated by K and S addition[J]. Fuel, 2018, 224: 85-93. |

| 11 | Zhang Y M, Wang Y, Cai L G, et al. Dual bed pyrolysis gasification of coal: process analysis and pilot test[J]. Fuel, 2013, 112: 624-634. |

| 12 | Kern S, Pfeifer C, Hofbauer H. Gasification of lignite in a dual fluidized bed gasifier—influence of bed material particle size and the amount of steam [J]. Fuel Processing Technology, 2013, 111: 1-13. |

| 13 | Al-Rahbi A S, Williams P T. Hydrogen-rich syngas production and tar removal from biomass gasification using sacrificial tyre pyrolysis char[J]. Applied Energy, 2017, 190: 501-509. |

| 14 | Zeng X, Wang F, Han Z N, et al. Characterization and pilot scale test of a fluidized bed two-stage gasification process for the production of clean industrial fuel gas from low-rank coal[J]. Carbon Resources Conversion, 2018, 1(1): 73-80. |

| 15 | Li G Y, Wang L P, Wang C W, et al. Experimental study on coal gasification in a full-scale two-stage entrained-flow gasifier[J]. Energies, 2020, 13(18): 4937. |

| 16 | Wang Y, Yoshikawa K, Namioka T, et al. Performance optimization of two-staged gasification system for woody biomass[J]. Fuel Processing Technology, 2007, 88(3): 243-250. |

| 17 | Wang C, Zhang M J, Han Z N, et al. Pilot verification of a two-stage fluidized bed gasifier with a downer pyrolyzer using oxygen-rich air[J]. Fuel, 2022, 307: 121816. |

| 18 | Sarkar M, Kumar A, Tumuluru J S, et al. Gasification performance of switchgrass pretreated with torrefaction and densification[J]. Applied Energy, 2014, 127: 194-201. |

| 19 | 聂其红, 孙绍增, 李争起, 等. 褐煤混煤燃烧特性的热重分析法研究[J]. 燃烧科学与技术, 2001, 7(1): 72-76. |

| Nie Q H, Sun S Z, Li Z Q, et al. Thermogravimetric analysis on the combustion characteristics of brown coal blends[J].Journal of Combustion Science and Technology, 2001, 7(1): 72-76. | |

| 20 | 刘国伟, 董芃, 韩亚芬, 等. 富氧条件下煤燃烧特性的热重法实验研究 [J]. 哈尔滨工业大学学报, 2011, 43(1): 5. |

| Liu G W, Dong P, Han Y F, et al. Experimental study on combustion characteristics of coals under enrich-oxygen condition by thermo-gravimetric analysis [J] Journal of Harbin Institute of Technology, 2011, 43(1): 5. | |

| 21 | Li D B, Zhao N, Feng Y X, et al. Thermogravimetric analysis of coal semi-char co-firing with straw in O2/CO2 mixtures[J]. Processes, 2021, 9(8): 1421. |

| 22 | Wang F J, Zhang S, Chen Z D, et al. Tar reforming using char as catalyst during pyrolysis and gasification of Shengli brown coal[J]. Journal of Analytical and Applied Pyrolysis, 2014, 105: 269-275. |

| 23 | Zhang S, Chen Z D, Zhang H Y, et al. The catalytic reforming of tar from pyrolysis and gasification of brown coal: effects of parental carbon materials on the performance of char catalysts[J]. Fuel Processing Technology, 2018, 174: 142-148. |

| 24 | Zeng X, Wang F, Han Z N, et al. Assessment of char property on tar catalytic reforming in a fluidized bed reactor for adopting a two-stage gasification process[J]. Applied Energy, 2019, 248: 115-125. |

| 25 | Huynh C V, Kong S C. Performance characteristics of a pilot-scale biomass gasifier using oxygen-enriched air and steam[J]. Fuel, 2013, 103: 987-996. |

| 26 | Fu Q R, Huang Y J, Niu M M, et al. Experimental and predicted approaches for biomass gasification with enriched air-steam in a fluidised bed[J]. Waste Management & Research: the Journal of the International Solid Wastes and Public Cleansing Association, ISWA, 2014, 32(10): 988-996. |

| 27 | Huang W G, Wang Z T, Duan T H, et al. Effect of oxygen and steam on gasification and power generation in industrial tests of underground coal gasification[J]. Fuel, 2021, 289: 119855. |

| 28 | Aranda G, Grootjes A J, van der Meijden C M, et al. Conversion of high-ash coal under steam and CO2 gasification conditions [J]. Fuel Processing Technology, 2016, 141: 16-30. |

| 29 | Kuba M, Havlik F, Kirnbauer F, et al. Influence of bed material coatings on the water-gas-shift reaction and steam reforming of toluene as tar model compound of biomass gasification[J]. Biomass and Bioenergy, 2016, 89: 40-49. |

| 30 | An P, Han Z N, Wang K J, et al. Process analysis of a two-stage fluidized bed gasification system with and without pre-drying of high-water content coal[J]. The Canadian Journal of Chemical Engineering, 2021, 99(7): 1498-1509. |

| 31 | Umeki K, Namioka T, Yoshikawa K. The effect of steam on pyrolysis and char reactions behavior during rice straw gasification [J]. Fuel Processing Technology, 2012, 94(1): 53-60. |

| 32 | 周鸿刚, 孙小利. 高温模拟蒸馏法测定原油和常压渣油的馏分分布[J]. 石油化工应用, 2021, 40(10): 115-121. |

| Zhou H G, Sun X L.The determination of distillates distribution in crude oil and atmospheric residue by high temperature simulated distillation method[J]. Petrochemical Industry Application, 2021, 40(10): 115-121. | |

| 33 | 李斌, 黄亚继, 金保升, 等. 蒸汽煤比对湍动循环流化床煤气化的影响[J]. 东南大学学报(自然科学版), 2009, 39(5):998-1001. |

| Li B, Huang Y J, Jin B S, et al. Effect of steam/coal ratio on coal gasification in turbulent circulating fluidized bed [J]. Journal of Southeast University (Natural Science Edition), 2009, 39(5): 998-1001. | |

| 34 | Upadhyay D S, Panchal K R, Sakhiya A K V, et al. Air-steam gasification of lignite in a fixed bed gasifier: influence of steam to lignite ratio on performance of downdraft gasifier[J]. Energy, 2020, 211: 118187. |

| 35 | Quintero-Coronel D A, Lenis-Rodas Y A, Corredor L, et al. Co-gasification of biomass and coal in a top-lit updraft fixed bed gasifier: syngas composition and its interchangeability with natural gas for combustion applications[J]. Fuel, 2022, 316: 123394. |

| 36 | Kurkela E, Kurkela M, Hiltunen I. Pilot-scale development of pressurized fixed-bed gasification for synthesis gas production from biomass residues[J]. Biomass Conversion and Biorefinery, 2021, doi:10.1007/s13399-021-01554-2 . |

| 37 | Ju F D, Chen H P, Yang H P, et al. Experimental study of a commercial circulated fluidized bed coal gasifier[J]. Fuel Processing Technology, 2010, 91(8): 818-822. |

| 38 | Rapagná S, Provendier H, Petit C, et al. Development of catalysts suitable for hydrogen or syn-gas production from biomass gasification[J]. Biomass and Bioenergy, 2002, 22(5): 377-388. |

| [1] | 吴雷, 刘姣, 李长聪, 周军, 叶干, 刘田田, 朱瑞玉, 张秋利, 宋永辉. 低阶粉煤催化微波热解制备含碳纳米管的高附加值改性兰炭末[J]. 化工学报, 2023, 74(9): 3956-3967. |

| [2] | 何松, 刘乔迈, 谢广烁, 王斯民, 肖娟. 高浓度水煤浆管道气膜减阻两相流模拟及代理辅助优化[J]. 化工学报, 2023, 74(9): 3766-3774. |

| [3] | 陈哲文, 魏俊杰, 张玉明. 超临界水煤气化耦合SOFC发电系统集成及其能量转化机制[J]. 化工学报, 2023, 74(9): 3888-3902. |

| [4] | 赵佳佳, 田世祥, 李鹏, 谢洪高. SiO2-H2O纳米流体强化煤尘润湿性的微观机理研究[J]. 化工学报, 2023, 74(9): 3931-3945. |

| [5] | 韩晨, 司徒友珉, 朱斌, 许建良, 郭晓镭, 刘海峰. 协同处理废液的多喷嘴粉煤气化炉内反应流动研究[J]. 化工学报, 2023, 74(8): 3266-3278. |

| [6] | 倪文翔, 赵京, 李博, 魏小林, 吴东垠, 刘迪, 王强. 转炉煤气全干法显热回收工艺中余热锅炉积灰特性研究[J]. 化工学报, 2023, 74(8): 3485-3493. |

| [7] | 康超, 乔金鹏, 杨胜超, 彭超, 付元鹏, 刘斌, 刘建荣, Aleksandrova Tatiana, 段晨龙. 煤矸石中有价关键金属活化提取研究进展[J]. 化工学报, 2023, 74(7): 2783-2799. |

| [8] | 王光宇, 张锴, 张凯华, 张东柯. 微波加热干燥煤泥热质传递及其能耗特性分析[J]. 化工学报, 2023, 74(6): 2382-2390. |

| [9] | 张媛媛, 曲江源, 苏欣欣, 杨静, 张锴. 循环流化床燃煤机组SNCR脱硝过程气液传质和反应特性[J]. 化工学报, 2023, 74(6): 2404-2415. |

| [10] | 葛泽峰, 吴雨青, 曾名迅, 查振婷, 马宇娜, 侯增辉, 张会岩. 灰化学成分对生物质气化特性的影响规律[J]. 化工学报, 2023, 74(5): 2136-2146. |

| [11] | 黄磊, 孔令学, 白进, 李怀柱, 郭振兴, 白宗庆, 李平, 李文. 油页岩添加对准东高钠煤灰熔融行为影响的研究[J]. 化工学报, 2023, 74(5): 2123-2135. |

| [12] | 周必茂, 许世森, 王肖肖, 刘刚, 李小宇, 任永强, 谭厚章. 烧嘴偏转角度对气化炉渣层分布特性的影响[J]. 化工学报, 2023, 74(5): 1939-1949. |

| [13] | 白天昊, 王晓雯, 杨梦滋, 段新伟, 米杰, 武蒙蒙. 类水滑石衍生锌基氧化物高温煤气脱硫过程中COS释放行为及其抑制研究[J]. 化工学报, 2023, 74(4): 1772-1780. |

| [14] | 王倩, 李神勇, 康帅, 庞薇, 郝龙龙, 秦身钧. 粉煤灰分质高效利用预处理技术的研究进展[J]. 化工学报, 2023, 74(3): 1010-1032. |

| [15] | 彭晓婉, 郭笑楠, 邓春, 刘蓓, 孙长宇, 陈光进. ZIF-8浆液法分离CH4/N2的双吸收-吸附塔工艺流程建模与模拟[J]. 化工学报, 2023, 74(2): 784-795. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号