化工学报 ›› 2021, Vol. 72 ›› Issue (11): 5770-5778.DOI: 10.11949/0438-1157.20211028

王文燕1,3( ),张光义2,3(

),张光义2,3( ),孟辉波1,朱新宇1,3,张建岭3,许光文1

),孟辉波1,朱新宇1,3,张建岭3,许光文1

收稿日期:2021-07-23

修回日期:2021-09-06

出版日期:2021-11-05

发布日期:2021-11-12

通讯作者:

张光义

作者简介:王文燕(1995—),女,硕士研究生,基金资助:

Wenyan WANG1,3( ),Guangyi ZHANG2,3(

),Guangyi ZHANG2,3( ),Huibo MENG1,Xinyu ZHU1,3,Jianling ZHANG3,Guangwen XU1

),Huibo MENG1,Xinyu ZHU1,3,Jianling ZHANG3,Guangwen XU1

Received:2021-07-23

Revised:2021-09-06

Online:2021-11-05

Published:2021-11-12

Contact:

Guangyi ZHANG

摘要:

通常,具有高含氮资源禀赋生物质在能源化利用过程中需控制NOx排放。解耦燃烧是可适用于高含水、高含氮燃料的低NOx燃烧技术,其对NOx生成的抑制效果优于其他燃烧技术。为揭示解耦燃烧中热解挥发产物的原位控氮潜力、发展双流化床解耦燃烧技术,以糠醛渣为原料,借助固定床装置和双流化床装置,分别开展其热解特性和双流化床解耦燃烧近实际工况模拟研究。具体地,首先在固定床反应器中考察糠醛渣在不同温度下的热解产物分布,继而借助双流化床反应器考察了热解在线挥发产物对热解半焦同步燃烧烟气中NOx的还原效果。结果表明:在500~700℃热解温度区间内,随温度的升高,半焦产率逐渐减少,从45.2%下降到39.8%;气体产率呈明显上升趋势,从12.4%上升到22.5%,CO、CH4、H2等还原性组分产率增加显著;焦油产率略有降低,从15.9%降低到12.9%;水分产率变化不大。双流化床解耦燃烧实验中,糠醛渣热解挥发产物对热解半焦同步燃烧所产烟气控氮效果良好,热解挥发产物对半焦燃烧烟气NOx减排效果主要受热解温度、二次风占比影响,总过量空气系数ER=1.3,热解温度600℃、二次风过量空气系数ER2=0.5时,糠醛渣热解挥发产物对相同热解条件下生成的半焦燃烧(900℃,过量空气系数ER1=0.8)所产烟气原位控氮效果达到最优,NOx减排率为54.80%。这表明,可通过控制热解挥发分产物产率、氧化程度,充分发挥挥发分的NOx还原能力,从而明显改善解耦燃烧原位控氮效果。

中图分类号:

王文燕, 张光义, 孟辉波, 朱新宇, 张建岭, 许光文. 糠醛渣热解特性及热解挥发产物对其燃烧烟气原位控氮作用[J]. 化工学报, 2021, 72(11): 5770-5778.

Wenyan WANG, Guangyi ZHANG, Huibo MENG, Xinyu ZHU, Jianling ZHANG, Guangwen XU. Furfural residue pyrolysis characteristics and the effect of its pyrolysis products on in-situ control of NOx emission from its combustion flue gas[J]. CIESC Journal, 2021, 72(11): 5770-5778.

| Proximate analysis/%(mass, dry) | Ultimate analysis/%(mass, dry) | ||||||

|---|---|---|---|---|---|---|---|

| Ash | Volatile | Fixed carbon | C | H | O① | N | S |

| 21.93 | 64.61 | 13.46 | 42.74 | 4.46 | 38.23 | 0.58 | 0.53 |

表1 糠醛渣的工业分析和元素分析

Table 1 Proximate and ultimate analyses of furfural residues

| Proximate analysis/%(mass, dry) | Ultimate analysis/%(mass, dry) | ||||||

|---|---|---|---|---|---|---|---|

| Ash | Volatile | Fixed carbon | C | H | O① | N | S |

| 21.93 | 64.61 | 13.46 | 42.74 | 4.46 | 38.23 | 0.58 | 0.53 |

图1 糠醛渣固定床热解装置流程图1—high pressure nitrogen cylinder; 2—pressure reducing valve; 3—pressure gauge; 4—mass flowmeter; 5—temperature transmitter; 6—temperature controller; 7—fixed bed gold furnace; 8—condenser; 9—temperature circulator; 10—filter flask; 11—cold trap tank; 12—tar collecting bottle; 13—saturated sodium bicarbonate bottle; 14—color-changing silicone bottle; 15—wet flowmeter; 16—gas bag

Fig.1 Schematic diagram of the fixed bed reactor for furfural residue pyrolysis

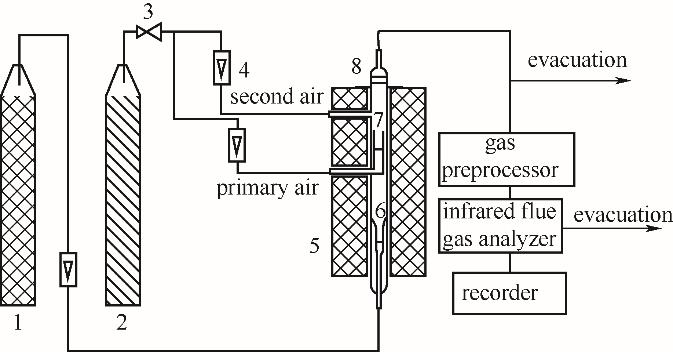

图2 双流化床燃烧装置流程示意图1—high pressure nitrogen cylinder; 2—high pressure air cylinder; 3—pressure reducing valve; 4—rotor flow meter;5—two-stage electric heating furnace; 6—lower fluidized bed; 7—upper fluidized bed; 8—feed inlet

Fig.2 Flow diagram of the dual fluidized bed combustion apparatus

图6 糠醛渣不同温度热解挥发分在900℃燃烧烟气NOx排放浓度和N转化率

Fig.6 NOx emission concentration and the N conversion rate during/after combustion (at 900℃) of the volatiles from furfural residue pyrolysis at different temperatures

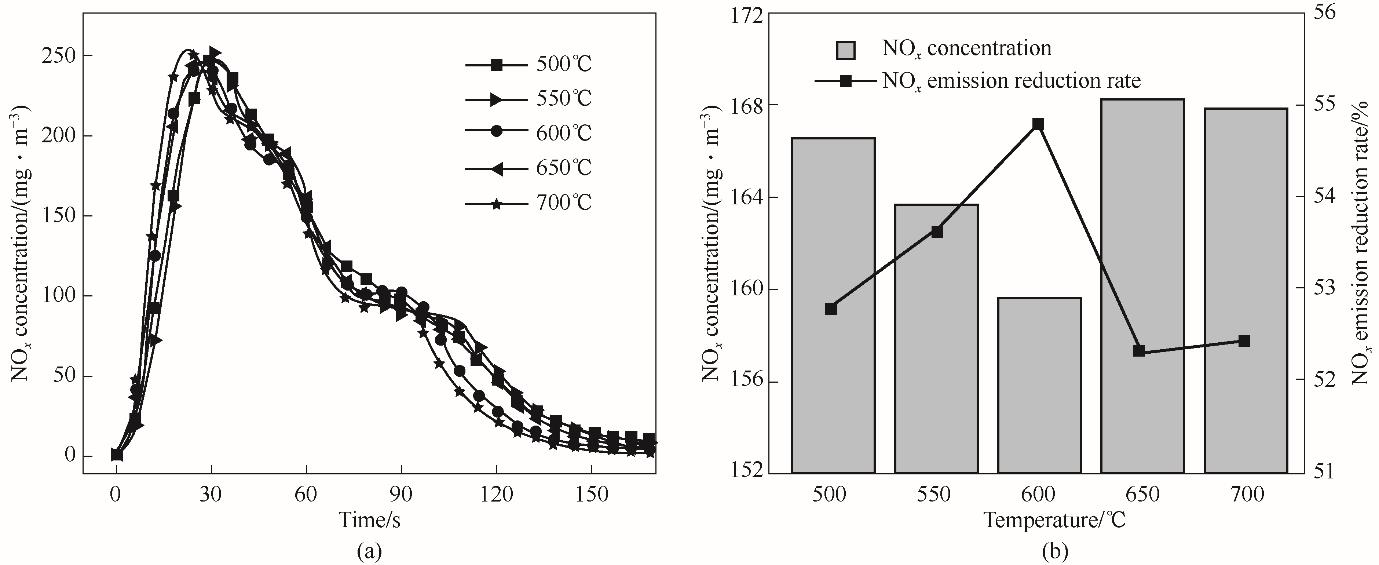

图8 不同热解温度挥发分与半焦耦合燃烧NOx排放浓度与减排率

Fig.8 NOx emission concentration and NOx reduction rate during coupled combustion of volatiles and semi-cokes prepared at different pyrolysis temperatures

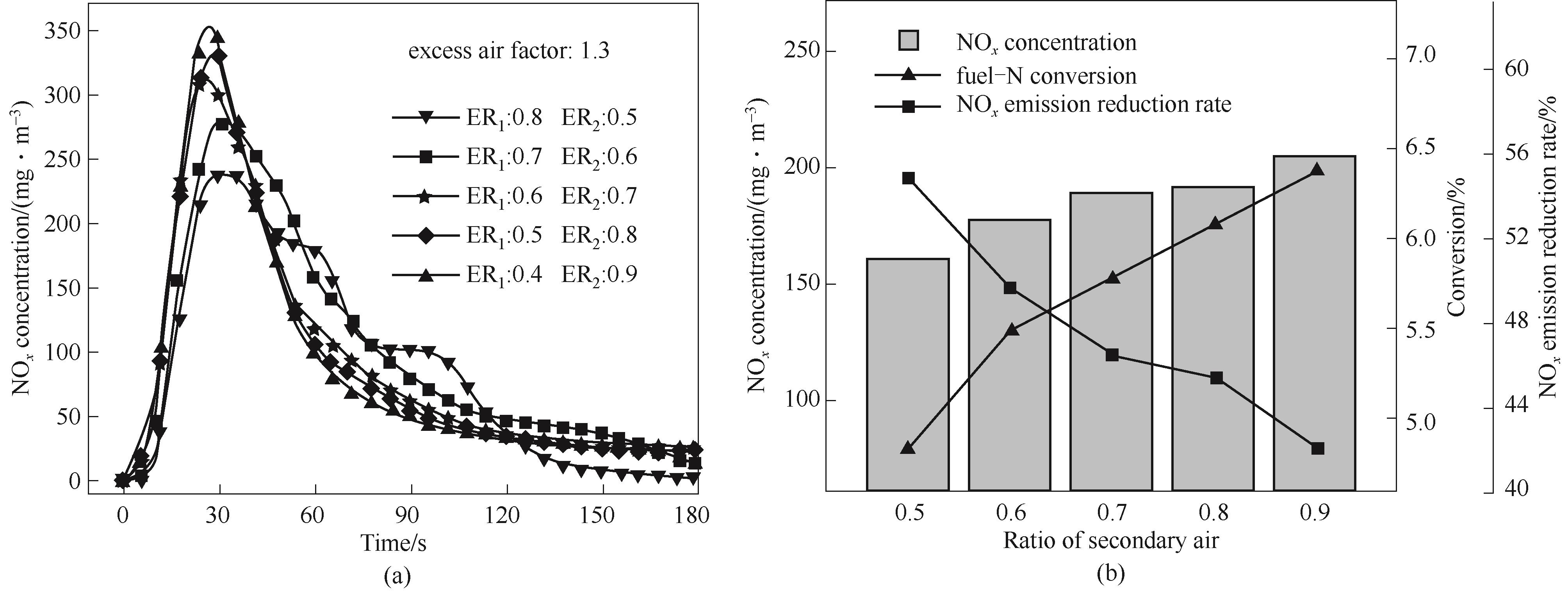

图9 一、二次风比对挥发分与半焦耦合燃烧NOx排放浓度、N转化率及NOx减排率的影响

Fig.9 Effects of the primary and secondary air ratios on the NOx emission concentration, the N conversion rate and the NOx reduction rate for coupled combustion of volatiles and semi-coke

| 1 | Nishiguchi S, Tabata T. Assessment of social, economic, and environmental aspects of woody biomass energy utilization: direct burning and wood pellets[J]. Renewable and Sustainable Energy Reviews, 2016, 57: 1279-1286. |

| 2 | 滕海鹏, 李诗媛, 吕清刚, 等. 生物质流态化燃烧黏结失流特性分析[J]. 中国电机工程学报, 2010, 30(S1): 138-143. |

| Teng H P, Li S Y, Lyu Q G, et al. Defluidization of biomass combustion in fluidized bed[J]. Proceedings of the CSEE, 2010, 30(S1): 138-143. | |

| 3 | 李诗媛, 吕清刚, 矫维红, 等. 生物质成型燃料循环流化床燃烧试验研究[J]. 燃烧科学与技术, 2009, 15(1): 54-58. |

| Li S Y, Lyu Q G, Jiao W H, et al. Experimental study on biomass briquette fuels combustion in circulating fluidized bed[J]. Journal of Combustion Science and Technology, 2009, 15(1): 54-58. | |

| 4 | 苏亚欣, 毛玉如, 徐璋. 燃煤氮氧化物排放控制技术[M]. 北京: 化学工业出版社, 2005: 70-118. |

| Su Y X, Mao Y R, Xu Z. Control Technology of NOx Emission from Coal Combustion[M]. Beijing: Chemical Industry Press, 2005: 70-118. | |

| 5 | 尚校, 高士秋, 汪印, 等. 不同煤燃烧方式降低NOx排放比较及解耦燃烧应用[J]. 燃料化学学报, 2012, 40(6): 672-679. |

| Shang X, Gao S Q, Wang Y, et al. Comparison of NOx reduction among different coal combustion methods and the application of decoupling combustion[J]. Journal of Fuel Chemistry and Technology, 2012, 40(6): 672-679. | |

| 6 | 李静海, 许光文, 杨励丹, 等. 一种抑制氮氧化物的无烟燃煤方法及燃煤炉与应用: 1110776A[P]. 1995-10-25. |

| Li J H, Xu G W, Yang L D, et al. A method of coal-fired smokeless combustion for NOx suppression as well as its application in household stoves: 1110776A[P]. 1995-10-25. | |

| 7 | Chen H F, Zhao P T, Wang Y, et al. NO emission control during the decoupling combustion of industrial biomass wastes with a high nitrogen content[J]. Energy & Fuels, 2013, 27(6): 3186-3193. |

| 8 | Dong L, Gao S Q, Song W L, et al. NO reduction in decoupling combustion of biomass and biomass-coal blend[J]. Energy & Fuels, 2009, 23(1): 224-228. |

| 9 | Xu G W, Yao C B, Dong L. Spirits lees utilization via circulating fluidized bed decoupling combustion[C]//BIT's 3rd World Congress of Industrial Biotechnology. 2010: 311-312. |

| 10 | Yao C B, Dong L, Wang Y, et al. Fluidized bed pyrolysis of distilled spirits lees for adapting to its circulating fluidized bed decoupling combustion[J]. Fuel Processing Technology, 2011, 92(12): 2312-2319. |

| 11 | 韩振南. 高含水含氮生物质废弃物双流化床解耦燃烧基础及工业应用[D]. 北京: 中国科学院过程工程研究所, 2017. |

| Han Z N. Fundamentals and industrial application of dual fluidized bed decoupling combustion of biomass waste with high water and nitrogen content[D]. Beijing: Institute of Process Engineering, Chinese Academy of Sciences, 2017. | |

| 12 | 杨武, 汪印, 宋扬, 等. 沉降炉中生物质热解产物的脱硝特性[J]. 过程工程学报, 2013, 13(2): 191-196. |

| Yang W, Wang Y, Song Y, et al. NO reduction characteristics of biomass pyrolysis products in a drop-tube reactor [J]. The Chinese Journal of Process Engineering, 2013, 13(2): 191-196. | |

| 13 | Song Y, Wang Y, Yang W, et al. Reduction of NO over biomass tar in micro-fluidized bed[J]. Fuel Processing Technology, 2014, 118: 270-277. |

| 14 | Bunman Y, Do H S, Zeng X, et al. NO reduction by different tar agents and model compounds in a drop-tube reactor[J]. Fuel Processing Technology, 2018, 172: 187-194. |

| 15 | Dong L, Gao S Q, Song W L, et al. Experimental study of NO reduction over biomass char[J]. Fuel Processing Technology, 2007, 88(7): 707-715. |

| 16 | 张晔, 陈明强, 李峰, 等. 常压下硫酸催化玉米芯制备糠醛的实验研究[J]. 林产化学与工业, 2013, 33(5): 77-82. |

| Zhang Y, Chen M Q, Li F, et al. Conversion of corncob into furfural with sulfuric acid at atmospheric pressure[J]. Chemistry and Industry of Forest Products, 2013, 33(5): 77-82. | |

| 17 | Sun Y, Wang Z, Liu Y, et al. A review on the transformation of furfural residue for value-added products[J]. Energies, 2019, 13(1): 21. |

| 18 | Xing Y, Bu L X, Sun D F, et al. High glucose recovery from direct enzymatic hydrolysis of bisulfite-pretreatment on non-detoxified furfural residues[J]. Bioresource Technology, 2015, 193: 401-407. |

| 19 | Yu H L, Tang Y, Xing Y, et al. Improvement of the enzymatic hydrolysis of furfural residues by pretreatment with combined green liquor and hydrogen peroxide[J]. Bioresource Technology, 2013, 147: 29-36. |

| 20 | 何志鹏, 刘周恩, 李文松, 等. 粒径对弱黏结性煤与非黏结性煤共热解特性的影响[J]. 煤炭转化, 2020, 43(6): 9-16. |

| He Z P, Liu Z E, Li W S, et al. Effect of particle sizes on co-pyrolysis characteristics of weak caking coal and non-caking coal[J]. Coal Conversion, 2020, 43(6): 9-16. | |

| 21 | 詹昊, 张晓鸿, 阴秀丽, 等. 生物质热化学转化过程含N污染物形成研究[J]. 化学进展, 2016, 28(12): 1880-1890. |

| Zhan H, Zhang X H, Yin X L, et al. Formation of nitrogenous pollutants during biomass thermo-chemical conversion[J]. Progress in Chemistry, 2016, 28(12): 1880-1890. | |

| 22 | Baumlin S, Broust F, Ferrer M, et al. The continuous self stirred tank reactor: measurement of the cracking kinetics of biomass pyrolysis vapours[J]. Chemical Engineering Science, 2005, 60(1): 41-55. |

| 23 | 王琼, 刘云云, 叶三成, 等. 玉米芯产糠醛残渣的热解利用分析[J]. 新能源进展, 2018, 6(5): 346-352. |

| Wang Q, Liu Y Y, Ye S C, et al. Pyrolysis analysis of furfural residue from corncob[J]. Advances in New and Renewable Energy, 2018, 6(5): 346-352. | |

| 24 | Zhang R Z, Liu C Y, Yin R H, et al. Experimental and kinetic study of the NO-reduction by tar formed from biomass gasification, using benzene as a tar model component[J]. Fuel Processing Technology, 2011, 92(1): 132-138. |

| 25 | 牛欣, 肖军. 污泥化学链燃烧过程中氮迁移转化特性研究[J]. 燃料化学学报, 2017, 45(4): 505-512. |

| Niu X, Xiao J. Nitrogen transformation in chemical looping combustion of sewage sludge[J]. Journal of Fuel Chemistry and Technology, 2017, 45(4): 505-512. | |

| 26 | Scappin F, Stefansson S H, Haglind F, et al. Validation of a zero-dimensional model for prediction of NOx and engine performance for electronically controlled marine two-stroke diesel engines[J]. Applied Thermal Engineering, 2012, 37: 344-352. |

| 27 | 葛亚昕, 张光义, 崔丽杰, 等. 高含水菌渣流化床燃烧NOx、SO2排放特性[J]. 化工学报, 2017, 68(8): 3250-3257. |

| Ge Y X, Zhang G Y, Cui L J, et al. Characteristics of NOx and SO2 emission from combustion of antibiotic mycelial residue with high water content in fluidized bed reactor[J]. CIESC Journal, 2017, 68(8): 3250-3257. | |

| 28 | Teng H, Suuberg E M. Chemisorption of nitric oxide on char (1): Reversible nitric oxide sorption[J]. The Journal of Physical Chemistry, 1993, 97(2): 478-483. |

| 29 | Teng H, Suuberg E M. Chemisorption of nitric oxide on char (2): Irreversible carbon oxide formation[J]. Industrial & Engineering Chemistry Research, 1993, 32(3): 416-423. |

| 30 | 周志军, 周宁, 陈瑶姬, 等. 低挥发分煤燃烧特性及NOx生成规律的试验研究[J]. 中国电机工程学报, 2010, 30(29): 55-61. |

| Zhou Z J, Zhou N, Chen Y J, et al. Experimental research on the combustion and NOx generation characteristics of low volatile coal[J]. Proceedings of the CSEE, 2010, 30(29): 55-61. | |

| 31 | 余岳溪, 高正阳, 季鹏, 等. 煤焦异相还原N2O的反应机理[J]. 化工学报, 2017, 68(1): 369-374. |

| Yu Y X, Gao Z Y, Ji P, et al. Heterogeneous reduction reaction of N2O by char[J]. CIESC Journal, 2017, 68(1): 369-374. | |

| 32 | 方晓晴, 范垂钢, 都林, 等. 煤焦直接还原脱除烟道气氮氧化物[J]. 化工学报, 2014, 65(6): 2249-2255. |

| Fang X Q, Fan C G, Du L, et al. Reduction of nitric oxide in flue gas by coal char[J]. CIESC Journal, 2014, 65(6): 2249-2255. | |

| 33 | Zhang G Y, Liu H, Ge Y X, et al. Gaseous emission and ash characteristics from combustion of high ash content antibiotic mycelial residue in fluidized bed and the impact of additional water vapor[J]. Fuel, 2017, 202: 66-77. |

| 34 | 温宏炎, 张光义, 纪德馨, 等.油泥焦流化床燃烧NOx释放特性及控制[J]. 燃料化学学报, 2019, 47(11): 1401-1408. |

| Wen H Y, Zhang G Y, Ji D X, et al. Emission characteristics and control of NOx from oil sludge char fluidized bed combustion[J]. Journal of Fuel Chemistry and Technology, 2019, 47(11): 1401-1408. |

| [1] | 吴雷, 刘姣, 李长聪, 周军, 叶干, 刘田田, 朱瑞玉, 张秋利, 宋永辉. 低阶粉煤催化微波热解制备含碳纳米管的高附加值改性兰炭末[J]. 化工学报, 2023, 74(9): 3956-3967. |

| [2] | 杨峥豪, 何臻, 常玉龙, 靳紫恒, 江霞. 生物质快速热解下行式流化床反应器研究进展[J]. 化工学报, 2023, 74(6): 2249-2263. |

| [3] | 衣思敏, 马亚丽, 刘伟强, 张金帅, 岳岩, 郑强, 贾松岩, 李雪. 微晶菱镁矿蒸氨及水化动力学研究[J]. 化工学报, 2023, 74(4): 1578-1586. |

| [4] | 陈瑞哲, 程磊磊, 顾菁, 袁浩然, 陈勇. 纤维增强树脂复合材料化学回收技术研究进展[J]. 化工学报, 2023, 74(3): 981-994. |

| [5] | 张娜, 潘鹤林, 牛波, 张亚运, 龙东辉. 酚醛树脂热裂解反应机理的密度泛函理论研究[J]. 化工学报, 2023, 74(2): 843-860. |

| [6] | 陈晨, 杨倩, 陈云, 张睿, 刘冬. 不同氧浓度下煤挥发分燃烧的化学动力学研究[J]. 化工学报, 2022, 73(9): 4133-4146. |

| [7] | 郝泽光, 张乾, 高增林, 张宏文, 彭泽宇, 杨凯, 梁丽彤, 黄伟. 生物质与催化裂化油浆共热解协同作用研究[J]. 化工学报, 2022, 73(9): 4070-4078. |

| [8] | 邵健, 冯军宗, 柳凤琦, 姜勇刚, 李良军, 冯坚. 酚醛树脂基炭微球结构调控与功能化制备研究进展[J]. 化工学报, 2022, 73(9): 3787-3801. |

| [9] | 刘新华, 韩振南, 韩健, 梁斌, 张楠, 胡善伟, 白丁荣, 许光文. 基于热解与燃烧反应重构的低NO x 解耦燃烧原理与技术[J]. 化工学报, 2022, 73(8): 3355-3368. |

| [10] | 肖皓宇, 杨海平, 张雄, 陈应泉, 王贤华, 陈汉平. 塑料催化热解制备高附加值产品的研究进展[J]. 化工学报, 2022, 73(8): 3461-3471. |

| [11] | 唐恺鸿, 何晓峰, 徐桂秋, 于洋, 刘啸凤, 葛铁军, 张爱玲. 酚醛泡沫的燃烧行为及阻燃研究进展[J]. 化工学报, 2022, 73(8): 3483-3500. |

| [12] | 陈玉弓, 陈昊, 黄耀松. 基于分子反应动力学模拟的六甲基二硅氧烷热解机理研究[J]. 化工学报, 2022, 73(7): 2844-2857. |

| [13] | 陈永安, 周安宁, 李云龙, 石智伟, 贺新福, 焦卫红. 磁性MgFe2O4及其核壳催化剂制备与煤热解性能研究[J]. 化工学报, 2022, 73(7): 3026-3037. |

| [14] | 郑默, 李晓霞. ReaxFF MD模拟揭示的煤热解挥发分自由基反应的竞争与协调[J]. 化工学报, 2022, 73(6): 2732-2741. |

| [15] | 陈冠益, 童图军, 李瑞, 王燕杉, 颜蓓蓓, 李宁, 侯立安. 热解时间对污泥生物炭活化过硫酸盐的影响研究[J]. 化工学报, 2022, 73(5): 2111-2119. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号