化工学报 ›› 2022, Vol. 73 ›› Issue (8): 3355-3368.DOI: 10.11949/0438-1157.20220716

刘新华1( ), 韩振南2, 韩健1, 梁斌1, 张楠1, 胡善伟1, 白丁荣2, 许光文2(

), 韩振南2, 韩健1, 梁斌1, 张楠1, 胡善伟1, 白丁荣2, 许光文2( )

)

收稿日期:2022-05-19

修回日期:2022-06-22

出版日期:2022-08-05

发布日期:2022-09-06

通讯作者:

刘新华,许光文

作者简介:刘新华(1974—),男,博士,研究员,xhliu@ipe.ac.cn

基金资助:

Xinhua LIU1( ), Zhennan HAN2, Jian HAN1, Bin LIANG1, Nan ZHANG1, Shanwei HU1, Dingrong BAI2, Guangwen XU2(

), Zhennan HAN2, Jian HAN1, Bin LIANG1, Nan ZHANG1, Shanwei HU1, Dingrong BAI2, Guangwen XU2( )

)

Received:2022-05-19

Revised:2022-06-22

Online:2022-08-05

Published:2022-09-06

Contact:

Xinhua LIU, Guangwen XU

摘要:

解耦燃烧原理最早于1995年被用于烟煤的低氮无烟燃烧,其通过分离燃料热解与半焦燃烧,打破两反应在传统燃烧方式中的耦合作用,并通过重构热解挥发分与半焦的燃烧反应,实现挥发分完全燃烧的同时有效还原燃烧生成的NO x。基于此方法的燃烧技术在1997年被定义为“解耦燃烧”。本文围绕固体燃料解耦燃烧高效低氮化原理、燃烧过程反应重构原则和反应过程定向调控关键要素,综合总结近三十年在煤炭与生物质解耦燃烧基础研究、技术开发、民用及工业燃烧典型应用及其实现的燃烧强化效果等方面取得的主要进展。解耦燃烧耦合其他诸如燃料再燃、燃料或空气分级燃烧、流态重构燃烧等先进燃烧技术可以进一步提高燃烧效率,降低空气污染物排放。解耦燃烧技术特别适合高含水燃料,对创新低阶煤和有机废弃物等的高效低氮燃烧新技术具有重要的科学意义和应用价值。

中图分类号:

刘新华, 韩振南, 韩健, 梁斌, 张楠, 胡善伟, 白丁荣, 许光文. 基于热解与燃烧反应重构的低NO x 解耦燃烧原理与技术[J]. 化工学报, 2022, 73(8): 3355-3368.

Xinhua LIU, Zhennan HAN, Jian HAN, Bin LIANG, Nan ZHANG, Shanwei HU, Dingrong BAI, Guangwen XU. Principle and technology of low-NO x decoupling combustion based on restructuring reactions[J]. CIESC Journal, 2022, 73(8): 3355-3368.

图3 不同热解产物还原NO能力对比(NO还原效率代表NO还原能力)[25]

Fig.3 NO reduction capabilities of pyrolysis products (NO reduction efficiency represents NO reduction capability) [25]

图9 传统链条炉和解耦链条炉典型结构及原理

Fig.9 Typical structures and principles of the traditional grate-firing boiler and the decoupling combustion grate-firing boiler

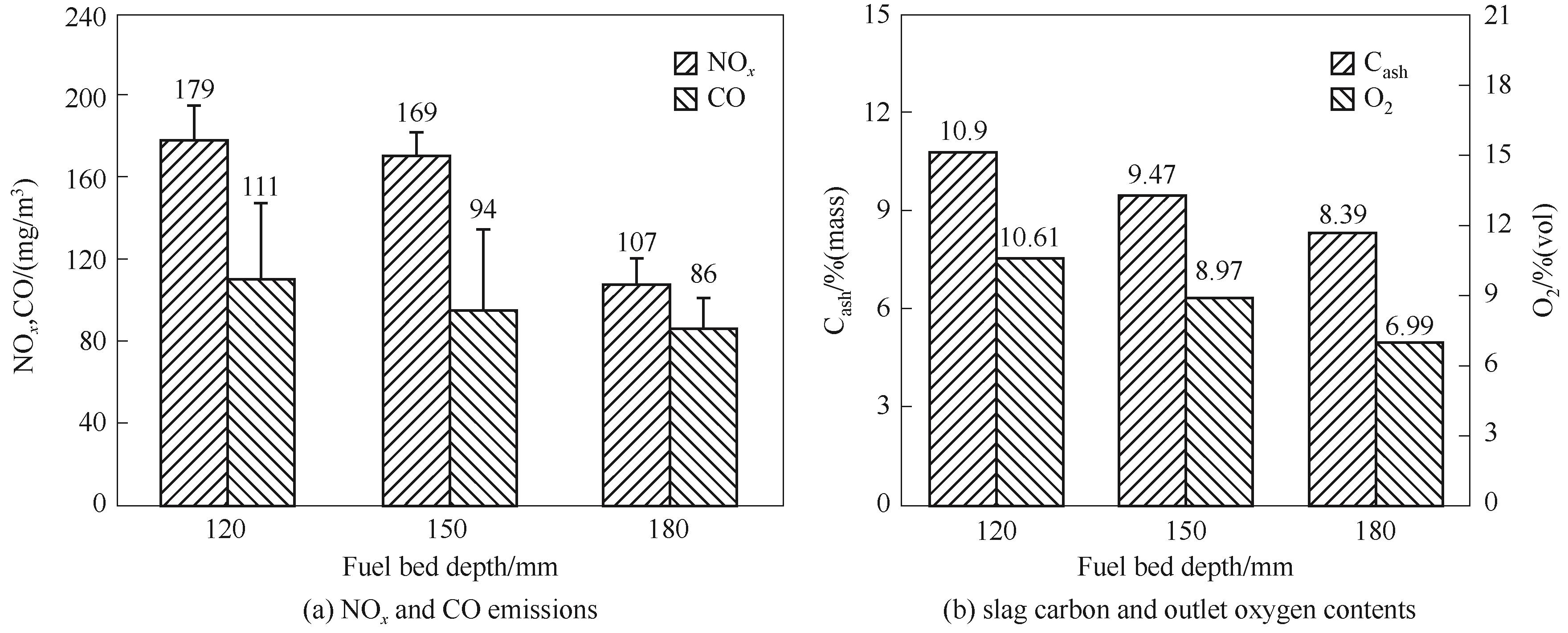

图10 燃料层厚度对污染物排放和解耦燃烧效率的影响

Fig.10 Effect of fuel bed depth on pollutant emission and combustion efficiency in the decoupling combustion grate-firing boiler

图11 热解-燃烧过程匹配对污染物排放和解耦燃烧效率的影响

Fig.11 Effect of pyrolysis-combustion combination on pollutant emission and combustion efficiency in the decoupling combustion grate-firing boiler

Mode of combustion | NO x emissions/ (mg/m3) | Outlet oxygen content/% (vol) | LOI of slag/ % (mass) |

|---|---|---|---|

| TC | 284.9 | 14.1 | 23.0 |

| DC | 180.4 | 10.7 | 9.8 |

| improvement | decreased by 36.7% | decreased by 24.1% | decreased by 57.4% |

表1 传统链条炉的解耦燃烧改造效果[44]

Table 1 Improvement of traditional grate-firing boilers by using decoupling combustion technology[44]

Mode of combustion | NO x emissions/ (mg/m3) | Outlet oxygen content/% (vol) | LOI of slag/ % (mass) |

|---|---|---|---|

| TC | 284.9 | 14.1 | 23.0 |

| DC | 180.4 | 10.7 | 9.8 |

| improvement | decreased by 36.7% | decreased by 24.1% | decreased by 57.4% |

| 1 | Yang H R, Yue G X, Lv J F, et al. An update of circulating fluidized bed combustion (CFBC) technology in China [J]. VGB PowerTech, 2012, 12: 1-5. |

| 2 | 许光文, 高士秋, 余剑, 等. 解耦热化学转化基础与技术[M]. 北京: 科学出版社, 2016. |

| Xu G W, Gao S Q, Yu J, et al. Fundamentals and Technologies of Decoupling Thermochemical Conversion [M]. Beijing: Science Press, 2016. | |

| 3 | 李静海, 许光文, 杨励丹, 等. 一种抑制氮氧化物的无烟燃煤方法及燃煤炉: 95102081.1 [P]. 1995-10-25. |

| Li J H, Xu G W, Yang L D, et al. A NO x -suppressed smokeless coal-fired method as well as corresponding stove: 95102081.1 [P]. 1995-10-25. | |

| 4 | Li J H, Bai Y R, Song W L. NO x -suppressed smokeless coal combustion technique [C]//Proceedings of International Symposium on Clean Coal Technology. Xiamen, China, 1997: 344-349. |

| 5 | 李静海, 郭慕孙, 白蕴茹, 等. 解耦循环流化床燃烧系统及其脱硫与脱硝方法: 97112562.7 [P]. 1997-06-25. |

| Li J H, Kwauk M, Bai Y R, et al. Decoupling circulating fluidized bed combustion system as well as its DeSO x and DeNO x methods: 97112562.7 [P]. 1997-06-25. | |

| 6 | He J D, Song W L, Gao S Q, et al. Experimental study of the reduction mechanisms of NO emission in decoupling combustion of coal[J]. Fuel Processing Technology, 2006, 87(9): 803-810. |

| 7 | 郝江平, 高士秋, 孙广藩, 等. 燃煤工业锅炉的发展与解耦燃烧技术的开发[J]. 工业锅炉, 2014(4): 7-11. |

| Hao J P, Gao S Q, Sun G F, et al. Status of coal-fired industrial boilers and development of decoupling combustion technique[J]. Industrial Boiler, 2014(4): 7-11. | |

| 8 | 郝江平, 孙广藩, 李静海, 等. 一种燃煤解耦燃烧装置及燃烧方法: 201310381626.7 [P]. 2016-06-29. |

| Hao J P, Sun G F, Li J H, et al. A decoupling coal-fired appliance as well as its combustion method: 201310381626.7 [P]. 2016-06-29. | |

| 9 | 刘新华, 郝江平, 张楠, 等. 一种解耦燃烧装置及燃烧方法: 201710512563.2[P]. 2017-06-29 |

| Liu X H, Hao J P, Zhang N, et al. A decoupling combustion appliance as well as its combustion method: 2017105112563.2 [P]. 2017-06-29. | |

| 10 | 刘新华, 郝江平, 张楠. 一种生物质解耦燃烧装置及方法: 202010454344.5 [P]. 2021-12-06. |

| Liu X H, Hao J P, Zhang N. A decoupling biomass-fired appliance as well as its combustion method: 202010454344.5 [P]. 2021-12-06. | |

| 11 | 郝江平, 高士秋, 李静海, 等. 一种预燃式机械炉排解耦燃烧炉及其燃烧方法: 201110322136.0 [P]. 2015-02-18. |

| Hao J P, Gao S Q, Li J H, et al. A pre-burning decoupling grate-firing boiler as well as its combustion method: 201110322136.0 [P]. 2015-02-18. | |

| 12 | 郝江平, 刘新华, 李静海, 等. 一种空气分级解耦燃烧机械炉排燃烧炉及其燃烧方法: 201710102625.2 [P]. 2017-02-24. |

| Hao J P, Liu X H, Li J H, et al. An air-staged decoupling grate-firing boiler as well as its combustion method: 201710102625.2 [P]. 2017-02-24. | |

| 13 | 郝江平, 刘新华, 高士秋, 等. 一种解耦燃烧机械炉排炉及其燃烧方法: 202010468258.X [P]. 2021-12-09. |

| Hao J P, Liu X H, Gao S Q, et al. A decoupling grate-firing boiler as well as its combustion method: 202010468258.X [P]. 2021-12-09. | |

| 14 | 姚常斌, 董利, 李强, 等. 一种高含水固体废弃物的解耦燃烧方法和装置: 201010218118.3 [P]. 2010-06-24. |

| Yao C B, Dong L, Li Q, et al. A decoupling combustion method of high-moisture content solid wastes as well as corresponding combustion appliance: 201010218118.3 [P]. 2010-06-24. | |

| 15 | Klein F, Platt S M, Farren N J, et al. Characterization of gas-phase organics using proton transfer reaction time-of-flight mass spectrometry: cooking emissions[J]. Environmental Science & Technology, 2016, 50(3): 1243-1250. |

| 16 | Glarborg P, Miller J A, Ruscic B, et al. Modeling nitrogen chemistry in combustion[J]. Progress in Energy and Combustion Science, 2018, 67: 31-68. |

| 17 | Johnsson J E. Formation and reduction of nitrogen oxides in fluidized-bed combustion[J]. Fuel, 1994, 73(9): 1398-1415. |

| 18 | Miller J A, Bowman C T. Mechanism and modeling of nitrogen chemistry in combustion[J]. Progress in Energy and Combustion Science, 1989, 15(4): 287-338. |

| 19 | Visona S P, Stanmore B R. Modeling NO x release from a single coal particle(Ⅱ): Formation of NO from char-nitrogen[J]. Combustion and Flame, 1996, 106(3): 207-218. |

| 20 | Liu S Y, Wang Y, Wu R C, et al. Fundamentals of catalytic tar removal over in situ and ex situ chars in two-stage gasification of coal[J]. Energy & Fuels, 2014, 28(1): 58-66. |

| 21 | Dong L, Gao S Q, Song W L, et al. Experimental study of NO reduction over biomass char[J]. Fuel Processing Technology, 2007, 88(7): 707-715. |

| 22 | Molina A, Eddings E G, Pershing D W, et al. Char nitrogen conversion: implications to emissions from coal-fired utility boilers[J]. Progress in Energy and Combustion Science, 2000, 26(4/5/6): 507-531. |

| 23 | Li H L, Han J, Zhang N, et al. Effects of high-temperature char layer and pyrolysis gas on NO x reduction in a typical decoupling combustion coal-fired stove[J]. Journal of Thermal Science, 2019, 28(1): 40-50. |

| 24 | Vilas E, Skifter U, Jensen A D, et al. Experimental and modeling study of biomass reburning[J]. Energy & Fuels, 2004, 18(5): 1442-1450. |

| 25 | Ballester J, Ichaso R, Pina A, et al. Experimental evaluation and detailed characterisation of biomass reburning[J]. Biomass and Bioenergy, 2008, 32(10): 959-970. |

| 26 | Munir S, Nimmo W, Gibbs B M. The effect of air staged, co-combustion of pulverised coal and biomass blends on NO x emissions and combustion efficiency[J]. Fuel, 2011, 90(1): 126-135. |

| 27 | Song Y, Wang Y, Yang W, et al. Reduction of NO over biomass tar in micro-fluidized bed[J]. Fuel Processing Technology, 2014, 118: 270-277. |

| 28 | Do H S, Bunman Y, Gao S Q, et al. Reduction of NO by biomass pyrolysis products in an experimental drop-tube[J]. Energy & Fuels, 2017, 31(4): 4499-4506. |

| 29 | Cai L G, Shang X, Gao S Q, et al. Low-NO x coal combustion via combining decoupling combustion and gas reburning[J]. Fuel, 2013, 112: 695-703. |

| 30 | Duan J, Luo Y H, Yan N Q, et al. Effect of biomass gasification tar on NO reduction by biogas reburning[J]. Energy & Fuels, 2007, 21(3): 1511-1516. |

| 31 | Liu C Y, Luo Y H, Duan J, et al. Experimental study on the effect of NO reduction by tar model compounds[J]. Energy & Fuels, 2009, 23(8): 4099-4104. |

| 32 | Zhang R Z, Liu C Y, Yin R H, et al. Experimental and kinetic study of the NO-reduction by tar formed from biomass gasification, using benzene as a tar model component[J]. Fuel Processing Technology, 2011, 92(1): 132-138. |

| 33 | Liang B, Bai H L, Bai D R, et al. Emissions of non-methane hydrocarbons and typical volatile organic compounds from various grate-firing coal furnaces[J]. Atmospheric Pollution Research, 2022, 13(4): 101380. |

| 34 | 韩健, 刘新华, 何京东, 等. 民用解耦燃煤炉中的NO x 和CO同时减排[J]. 化工学报, 2019, 70(5): 1991-1998. |

| Han J, Liu X H, He J D, et al. Simultaneous reduction of NO x and CO emissions in domestic decoupling coal-fired stoves[J]. CIESC Journal, 2019, 70(5): 1991-1998. | |

| 35 | 韩健, 刘新华, 何京东. 典型煤炭燃料在民用解耦炉中的燃烧实验研究[J]. 过程工程学报, 2020, 20(6): 728-736. |

| Han J, Liu X H, He J D. Experimental study on the combustion of typical coal fuels in domestic decoupling stoves[J]. The Chinese Journal of Process Engineering, 2020, 20(6): 728-736. | |

| 36 | Jin N N, Guo L, Liu X H. Machine learning-aided optimization of coal decoupling combustion for lowering NO and CO emissions simultaneously[J]. Computers & Chemical Engineering, 2022, 162: 107822. |

| 37 | 梁斌, 白浩隆, 冯强, 等. 民用燃煤颗粒物及多环芳烃排放特性[J]. 化工学报, 2019, 70(8): 2888-2897. |

| Liang B, Bai H L, Feng Q, et al. Emissions of particulate matter and polycyclic aromatic hydrocarbons from household coal combustions[J]. CIESC Journal, 2019, 70(8): 2888-2897. | |

| 38 | Dong L, Gao S Q, Song W L, et al. NO reduction in decoupling combustion of biomass and biomass-coal blend[J]. Energy & Fuels, 2009, 23(1): 224-228. |

| 39 | Li H J, Chi H Y, Han H D, et al. Comprehensive study on co-combustion behavior of pelletized coal-biomass mixtures in a concentrating photothermal reactor[J]. Fuel Processing Technology, 2021, 211: 106596. |

| 40 | Rajh B, Yin C G, Samec N, et al. Advanced CFD modelling of air and recycled flue gas staging in a waste wood-fired grate boiler for higher combustion efficiency and greater environmental benefits[J]. Journal of Environmental Management, 2018, 218: 200-208. |

| 41 | Xu L, Zhao G B, Gao J M, et al. Effect of flue gas recirculation on nitric oxide (NO) emissions during the coal grate-fired process[J]. Toxicological & Environmental Chemistry, 2017, 99(5/6): 783-794. |

| 42 | Du H L, Zhang M, Zhang Y L, et al. Characteristics of NO reduction by char layer in fixed-bed coal combustion[J]. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2017, 39(10): 963-970. |

| 43 | Jiao L, Kuang M, Chen Y Y, et al. Detailed measurements of in-furnace gas temperature and species concentration distribution regarding the primary-air distribution mode in a spreader and reversal chain-grate furnace[J]. Energy, 2021, 235: 121384. |

| 44 | 王海苗, 宋令坡, 杨晓辉, 等. 预燃低氮燃烧技术在燃煤工业链条排炉中的应用[J]. 煤炭加工与综合利用, 2019(6): 83-87. |

| Wang H M, Song L P, Yang X H, et al. Application of low-nitrogen pre-combustion technology in coal-fired industrial chain boiler[J]. Coal Processing & Comprehensive Utilization, 2019(6): 83-87. | |

| 45 | Yao C B, Dong L, Wang Y, et al. Fluidized bed pyrolysis of distilled spirits lees for adapting to its circulating fluidized bed decoupling combustion[J]. Fuel Processing Technology, 2011, 92(12): 2312-2319. |

| 46 | Han Z N, Geng S L, Zeng X, et al. Reaction decoupling in thermochemical fuel conversion and technical progress based on decoupling using fluidized bed[J]. Carbon Resources Conversion, 2018, 1(2): 109-125. |

| 47 | 姚常斌. 白酒糟双流化床解耦燃烧研究[D]. 北京: 中国科学院研究生院, 2011. |

| Yao C B. Dual fluidized bed decoupling combustion of distilled spirits lees [D]. Beijing: Graduate University of Chinese Academy of Sciences, 2011. | |

| 48 | Han Z N, Zeng X, Yao C B, et al. Comparison of direct combustion in a circulating fluidized bed system and decoupling combustion in a dual fluidized bed system for distilled spirit lees[J]. Energy & Fuels, 2016, 30(3): 1693-1700. |

| 49 | Zhang J W, Wu R C, Zhang G Y, et al. Technical review on thermochemical conversion based on decoupling for solid carbonaceous fuels[J]. Energy & Fuels, 2013, 27(4): 1951-1966. |

| 50 | Zhang C, Wu R C, Xu G W. Coal pyrolysis for high-quality tar in a fixed-bed pyrolyzer enhanced with internals[J]. Energy & Fuels, 2014, 28(1): 236-244. |

| 51 | Lin L X, Zhang C, Li H J, et al. Pyrolysis in indirectly heated fixed bed with internals: the first application to oil shale[J]. Fuel Processing Technology, 2015, 138: 147-155. |

| 52 | Zeng X, Ueki Y, Yoshiie R, et al. Recent progress in tar removal by char and the applications: a comprehensive analysis[J]. Carbon Resources Conversion, 2020, 3: 1-18. |

| 53 | Zeng X, Wang F, Han Z N, et al. Assessment of char property on tar catalytic reforming in a fluidized bed reactor for adopting a two-stage gasification process[J]. Applied Energy, 2019, 248: 115-125. |

| 54 | Zeng X, Wang F, Han Z N, et al. Characterization and pilot scale test of a fluidized bed two-stage gasification process for the production of clean industrial fuel gas from low-rank coal[J]. Carbon Resources Conversion, 2018, 1(1): 73-80. |

| [1] | 郑佳丽, 李志会, 赵新强, 王延吉. 离子液体催化合成2-氰基呋喃反应动力学研究[J]. 化工学报, 2023, 74(9): 3708-3715. |

| [2] | 陈佳起, 赵万玉, 姚睿充, 侯道林, 董社英. 开心果壳基碳点的合成及其对Q235碳钢的缓蚀行为研究[J]. 化工学报, 2023, 74(8): 3446-3456. |

| [3] | 吴文涛, 褚良永, 张玲洁, 谭伟民, 沈丽明, 暴宁钟. 腰果酚生物基自愈合微胶囊的高效制备工艺研究[J]. 化工学报, 2023, 74(7): 3103-3115. |

| [4] | 杨峥豪, 何臻, 常玉龙, 靳紫恒, 江霞. 生物质快速热解下行式流化床反应器研究进展[J]. 化工学报, 2023, 74(6): 2249-2263. |

| [5] | 陈巨辉, 张谦, 舒崚峰, 李丹, 徐鑫, 刘晓刚, 赵晨希, 曹希峰. 基于DEM方法的旋转流化床纳米颗粒流动特性研究[J]. 化工学报, 2023, 74(6): 2374-2381. |

| [6] | 董茂林, 陈李栋, 黄六莲, 吴伟兵, 戴红旗, 卞辉洋. 酸性助水溶剂制备木质纳米纤维素及功能应用研究进展[J]. 化工学报, 2023, 74(6): 2281-2295. |

| [7] | 张媛媛, 曲江源, 苏欣欣, 杨静, 张锴. 循环流化床燃煤机组SNCR脱硝过程气液传质和反应特性[J]. 化工学报, 2023, 74(6): 2404-2415. |

| [8] | 袁子涵, 王淑彦, 邵宝力, 谢磊, 陈曦, 马一玫. 基于幂律液固曳力模型流化床内湿颗粒流动特性的研究[J]. 化工学报, 2023, 74(5): 2000-2012. |

| [9] | 葛泽峰, 吴雨青, 曾名迅, 查振婷, 马宇娜, 侯增辉, 张会岩. 灰化学成分对生物质气化特性的影响规律[J]. 化工学报, 2023, 74(5): 2136-2146. |

| [10] | 刘海芹, 李博文, 凌喆, 刘亮, 俞娟, 范一民, 勇强. 羟基-炔点击化学改性半乳甘露聚糖薄膜的制备及性能研究[J]. 化工学报, 2023, 74(3): 1370-1378. |

| [11] | 祖凌鑫, 胡荣庭, 李鑫, 陈余道, 陈广林. 木质生物质化学组分的碳释放产物特征和反硝化利用程度[J]. 化工学报, 2023, 74(3): 1332-1342. |

| [12] | 郑杰元, 张先伟, 万金涛, 范宏. 丁香酚环氧有机硅树脂的制备及其固化动力学研究[J]. 化工学报, 2023, 74(2): 924-932. |

| [13] | 陈健鑫, 朱瑞杰, 盛楠, 朱春宇, 饶中浩. 纤维素基生物质多孔炭的制备及其超级电容器性能研究[J]. 化工学报, 2022, 73(9): 4194-4206. |

| [14] | 郝泽光, 张乾, 高增林, 张宏文, 彭泽宇, 杨凯, 梁丽彤, 黄伟. 生物质与催化裂化油浆共热解协同作用研究[J]. 化工学报, 2022, 73(9): 4070-4078. |

| [15] | 张东旺, 杨海瑞, 周托, 黄中, 李诗媛, 张缦. 生物质锅炉对流受热面积灰冷态模拟实验研究[J]. 化工学报, 2022, 73(8): 3731-3738. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号