化工学报 ›› 2021, Vol. 72 ›› Issue (8): 4239-4254.DOI: 10.11949/0438-1157.20210407

收稿日期:2021-03-22

修回日期:2021-04-22

出版日期:2021-08-05

发布日期:2021-08-05

通讯作者:

江锦波

作者简介:江鹏(1997—),男,硕士研究生,基金资助:

Peng JIANG( ),Jinbo JIANG(

),Jinbo JIANG( ),Xudong PENG,Xiangkai MENG,Yi MA

),Xudong PENG,Xiangkai MENG,Yi MA

Received:2021-03-22

Revised:2021-04-22

Online:2021-08-05

Published:2021-08-05

Contact:

Jinbo JIANG

摘要:

干气密封流体膜与密封环间传热模型的合理选取对于准确求解密封温压分布和稳态性能至关重要。在CO2近临界工况下,对比研究了密封环等温模型、绝热模型和共轭热传递模型对超临界CO2干气密封端面温度、压力分布和开启力、泄漏率等稳态性能的影响,探讨了不同膜厚和转速条件下密封环等温模型和绝热模型的适用性,并基于共轭热传递模型研究了超临界CO2和空气介质干气密封的温压分布和稳态性能差异。结果表明:以共轭热传递模型计算结果为基准,密封环等温模型假设适用于小膜厚低速流动工况,不过开启力偏低而泄漏率偏高,绝热模型假设适用于大膜厚高速流动工况;相较于空气介质干气密封,超临界CO2干气密封在小膜厚下的温度分布和大膜厚下的压力分布基本接近,不过小膜厚下的温度更低,而在大膜厚下的压力更高。

中图分类号:

江鹏, 江锦波, 彭旭东, 孟祥铠, 马艺. 传热模型对近临界工况CO2干气密封温压分布和稳态性能影响[J]. 化工学报, 2021, 72(8): 4239-4254.

Peng JIANG, Jinbo JIANG, Xudong PENG, Xiangkai MENG, Yi MA. Influence of heat transfer model on temperature and pressure distribution and steady state performance of CO2 dry gas seal under near critical condition[J]. CIESC Journal, 2021, 72(8): 4239-4254.

| 工况及参数 | 数值 |

|---|---|

| 槽根半径rg/mm | 69 |

| 槽数 | 12 |

| 槽深hg/μm | 5 |

| 螺旋角β/(°) | 15 |

| 周向槽宽比α | 0.5 |

| 进口压力pin/MPa | 8 |

| 进口温度T/K | 360 |

| 动环转速n/(kr/min) | 10 |

| 膜厚h0/μm | 6 |

表1 干气密封运行工况及型槽结构参数

Table 1 Dry gas seal operating conditions and structural parameters of type groove

| 工况及参数 | 数值 |

|---|---|

| 槽根半径rg/mm | 69 |

| 槽数 | 12 |

| 槽深hg/μm | 5 |

| 螺旋角β/(°) | 15 |

| 周向槽宽比α | 0.5 |

| 进口压力pin/MPa | 8 |

| 进口温度T/K | 360 |

| 动环转速n/(kr/min) | 10 |

| 膜厚h0/μm | 6 |

| 参数 | 数值 |

|---|---|

| 外径ro/mm | 77.78 |

| 内径ri/mm | 58.42 |

| 静环外周与密封腔内壁间隙δs/mm | 20 |

| 动环外周与密封腔内壁间隙δr/mm | 20 |

| 热导率k/(W/(m·K)) | 57 |

| 密度ρ/(kg/m3) | 3150 |

| 比定压热容cp/ (J/(kg·K)) | 710 |

表2 干气密封环结构和材料参数

Table2 Dry gas seal ring structure and material parameters

| 参数 | 数值 |

|---|---|

| 外径ro/mm | 77.78 |

| 内径ri/mm | 58.42 |

| 静环外周与密封腔内壁间隙δs/mm | 20 |

| 动环外周与密封腔内壁间隙δr/mm | 20 |

| 热导率k/(W/(m·K)) | 57 |

| 密度ρ/(kg/m3) | 3150 |

| 比定压热容cp/ (J/(kg·K)) | 710 |

| 转速n/ (r/min) | 对流传热系数/(W/(m2·K)) | |||

|---|---|---|---|---|

| 动环 | 静环 | |||

| 空气 | CO2 | 空气 | CO2 | |

| 2000 | — | 3683 | — | 2876 |

| 6000 | — | 6014 | — | 2876 |

| 10000 | 5078 | 8188 | 1556 | 2876 |

表3 不同转速下动静环外周面对流传热系数

Table 3 The heat transfer coefficient of the circumferential face of the rotor and stator ring at different rotational speeds

| 转速n/ (r/min) | 对流传热系数/(W/(m2·K)) | |||

|---|---|---|---|---|

| 动环 | 静环 | |||

| 空气 | CO2 | 空气 | CO2 | |

| 2000 | — | 3683 | — | 2876 |

| 6000 | — | 6014 | — | 2876 |

| 10000 | 5078 | 8188 | 1556 | 2876 |

图6 干气密封径向压力和温度分布计算值与文献值对比

Fig.6 Comparison of radial pressure and temperature distribution of dry gas seal between calculated results and literature values

图10 不同膜厚下两种介质干气密封径向温度和压力分布

Fig.10 Radial temperature and pressure distribution of dry gas seal lubricated with two kinds of gas under different film thickness

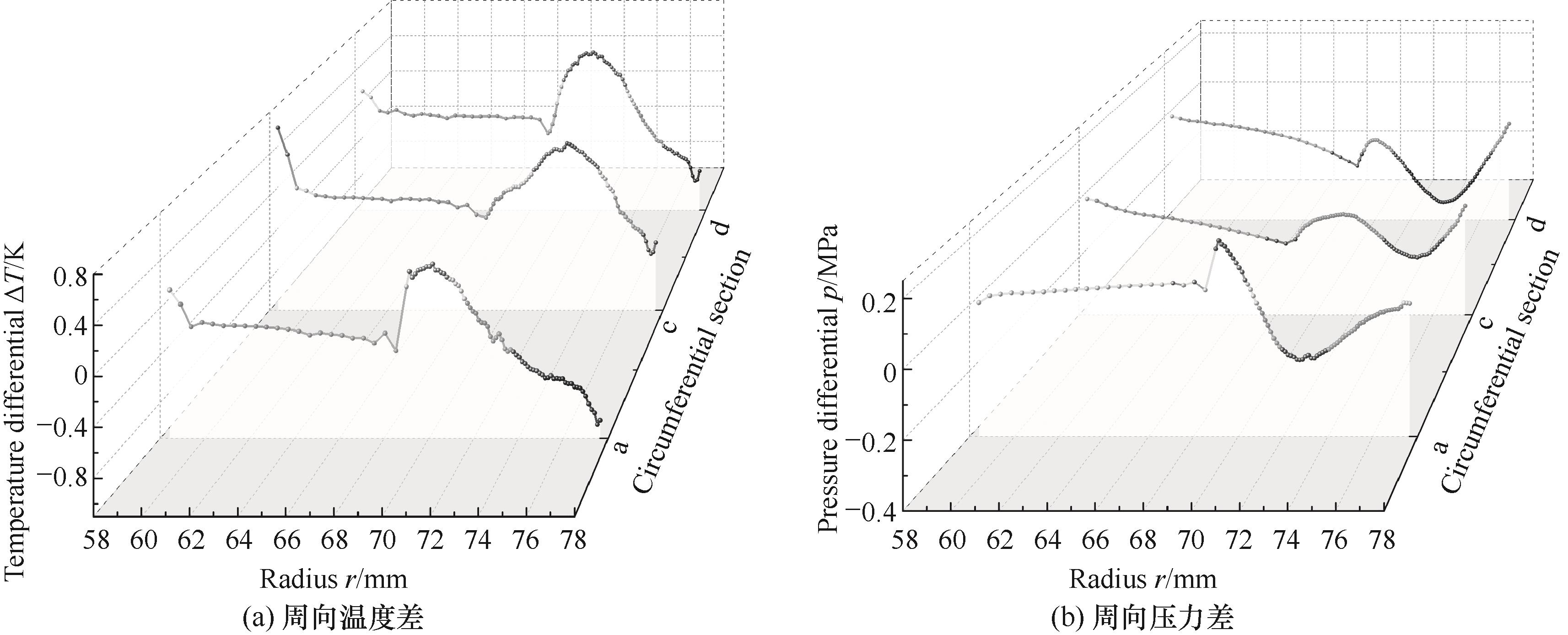

图13 sCO2干气密封不同周向切面处的温差和压差径向分布

Fig.13 Radial distribution of temperature and pressure differential at different circumferential sections of sCO2 dry gas seal

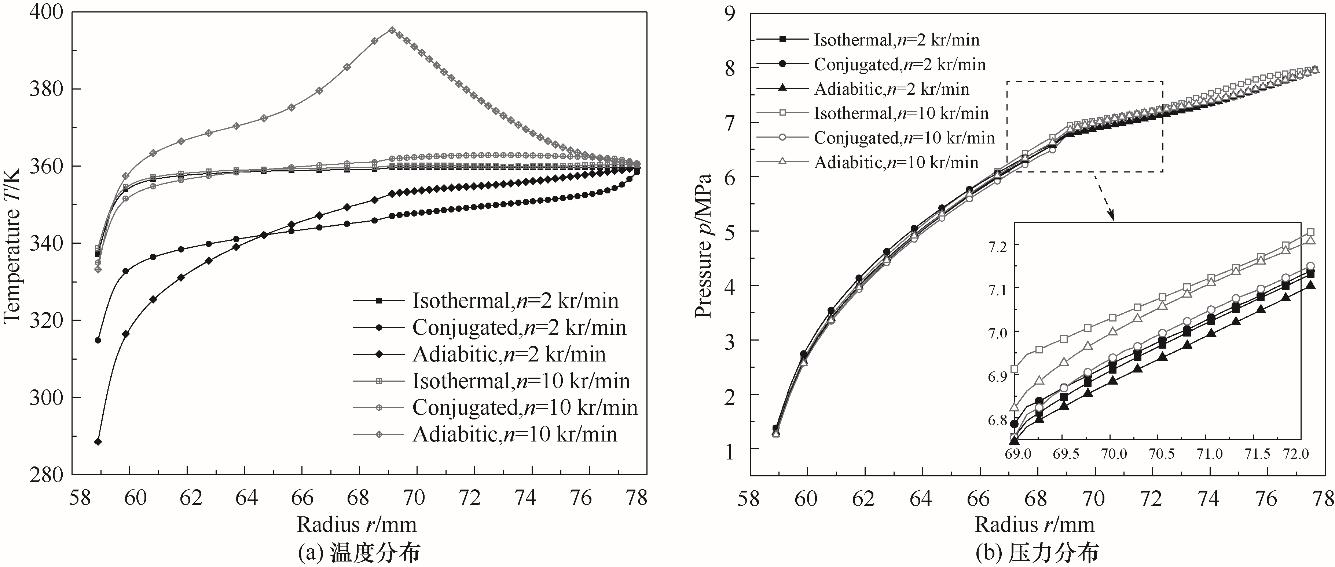

图14 不同传热模型和转速下sCO2干气密封径向温度和压力分布

Fig.14 Radial temperature and pressure distribution of sCO2 dry gas seal under different heat transfer models and rotating speed

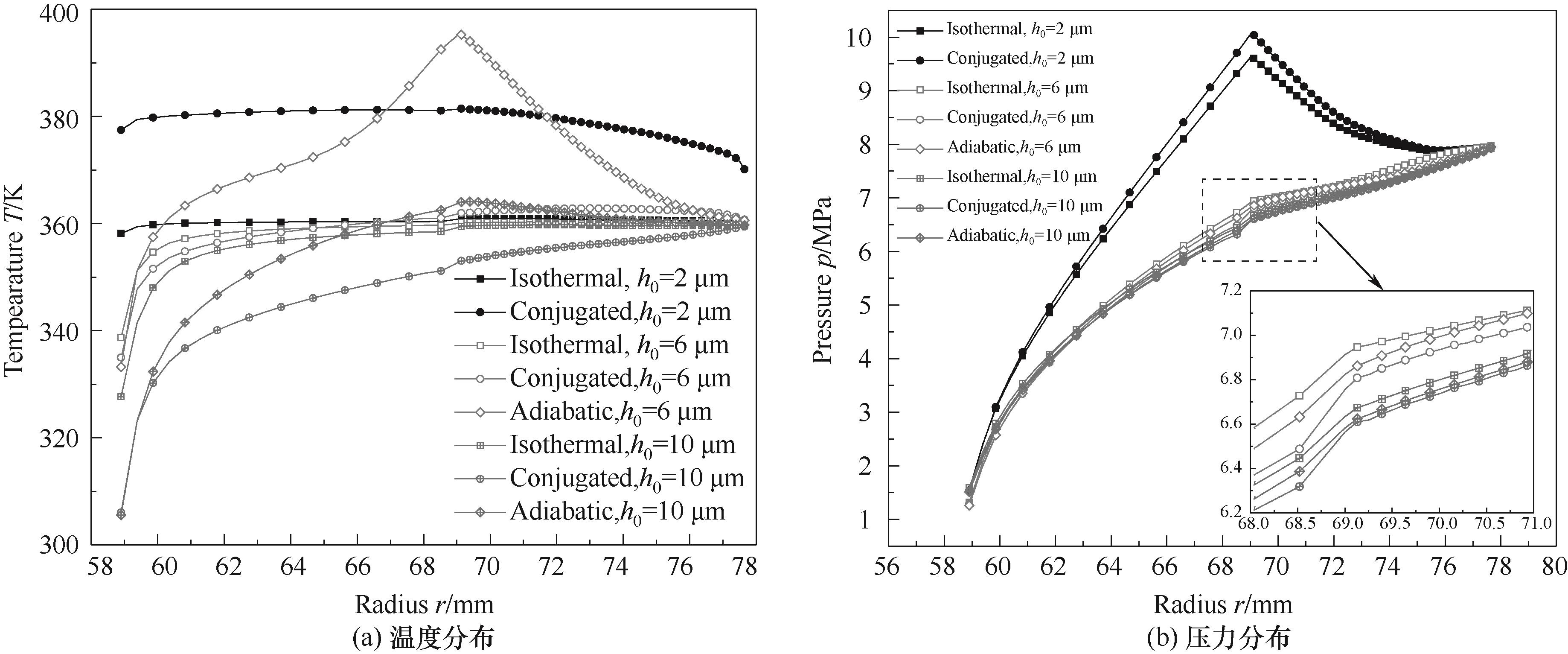

图15 不同传热模型和膜厚下sCO2干气密封径向温度和压力分布

Fig.15 Radial temperature and pressure distribution of sCO2 dry gas seal under different heat transfer models and film thickness

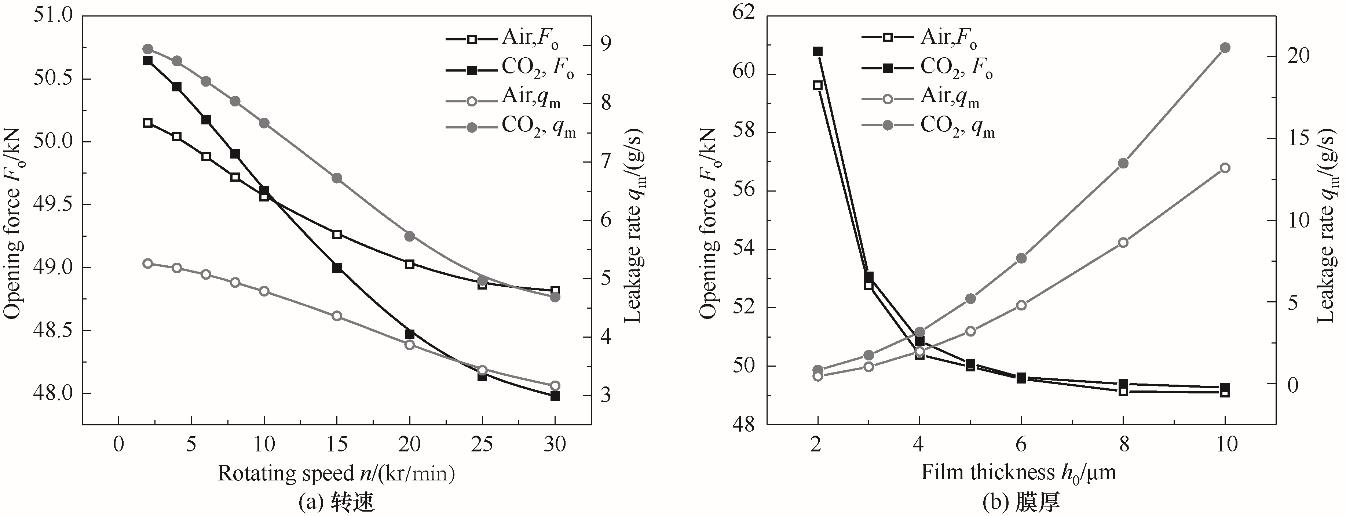

图17 转速和膜厚对两种介质干气密封的开启力和泄漏率影响

Fig.17 Influence of rotating speed and film thickness on opening force and leakage rate of dry gas seal lubricated with two kinds of gas

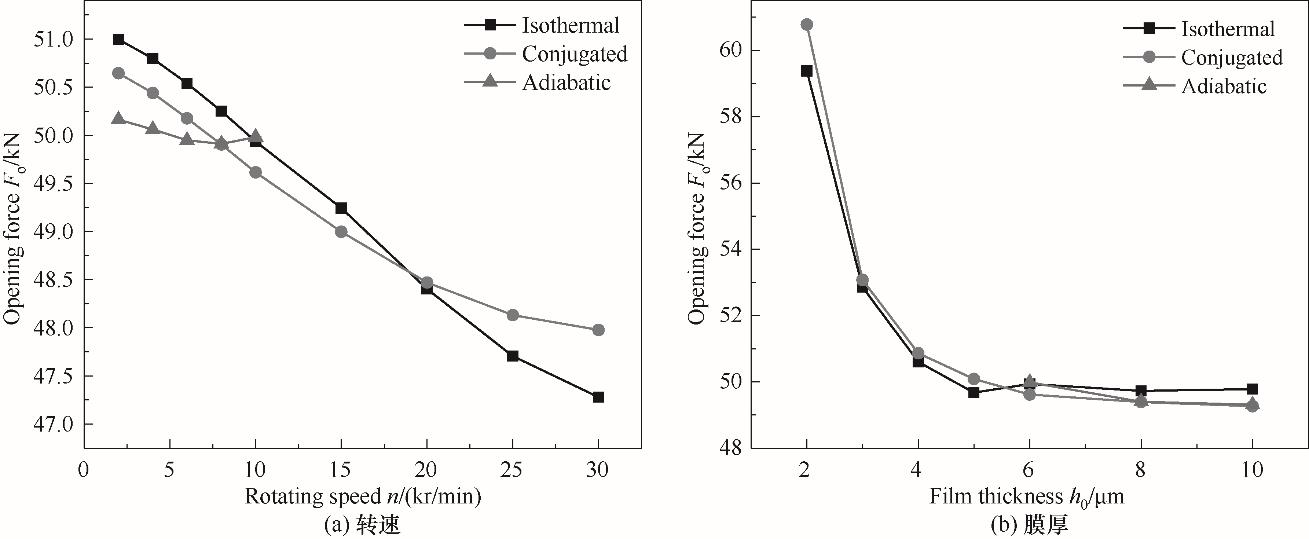

图18 不同传热模型下sCO2干气密封开启力随转速和膜厚变化规律

Fig.18 The opening force of sCO2 dry gas seal with rotating speed and film thickness under different heat transfer models

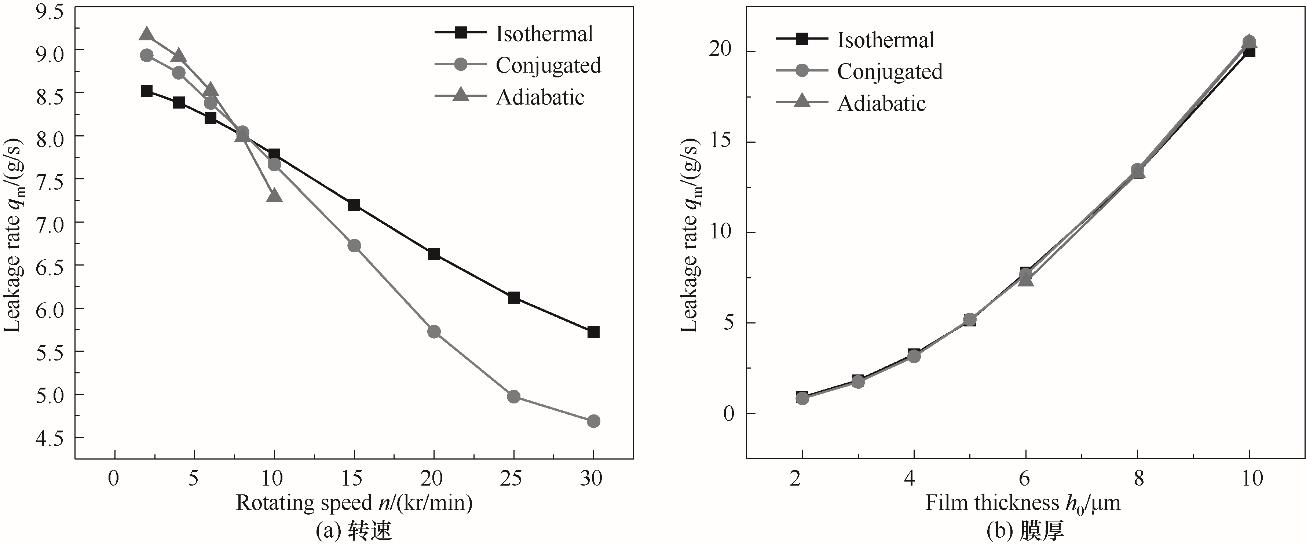

图19 不同传热模型下sCO2干气密封泄漏率随转速和膜厚变化规律

Fig.19 The leakage rate of sCO2 dry gas seal with film thickness and rotating speed under different heat transfer models

| 1 | 李志刚, 袁韬, 方志, 等. 超临界二氧化碳旋转机械动密封技术研究进展[J]. 热力透平, 2019, 48(3): 166-174, 191. |

| Li Z G, Yuan T, Fang Z, et al. A review on dynamic sealing technology of supercritical carbon dioxide rotating machinery[J]. Thermal Turbine, 2019, 48(3): 166-174, 191. | |

| 2 | 沈伟, 彭旭东, 江锦波, 等. 高速超临界二氧化碳干气密封实际效应影响分析[J]. 化工学报, 2019, 70(7): 2645-2659. |

| Shen W, Peng X D, Jiang J B, et al. Analysis on real effect of supercritical carbon dioxide dry gas seal at high speed[J]. CIESC Journal, 2019, 70(7): 2645-2659. | |

| 3 | 陈维, 宋鹏云, 许恒杰, 等. 含杂质二氧化碳实际气体干气密封性能研究[J]. 化工学报, 2020, 71(5): 2215-2229. |

| Chen W, Song P Y, Xu H J, et al. Effects of the real-gas characteristics of carbon dioxide with impurities on the dry gas seal performance[J]. CIESC Journal, 2020, 71(5): 2215-2229. | |

| 4 | 邓成香, 宋鹏云, 马爱琳. 干气密封的实际气体焦耳-汤姆逊效应分析[J]. 化工学报, 2016, 67(9): 3833-3842. |

| Deng C X, Song P Y, Ma A L. Analysis of Joule-Thomson effect of real gas system sealed by dry gas[J]. CIESC Journal, 2016, 67(9): 3833-3842. | |

| 5 | Bidkar R A, Sevincer E, Wang J F, et al. Low-leakage shaft-end seals for utility-scale supercritical CO2 turboexpanders[J]. Journal of Engineering for Gas Turbines and Power, 2017, 139(2): 022503-1-8. |

| 6 | Fairuz Z M, Jahn I, Abdul-Rahman R. The effect of convection area on the deformation of dry gas seal operating with supercritical CO2[J]. Tribology International, 2019, 137: 349-365. |

| 7 | 江锦波, 滕黎明, 孟祥铠, 等. 基于多变量摄动的超临界CO2干气密封动态特性[J].化工学报,2021,72(4):2190-2202. |

| Jiang J B, Teng L M, Meng X K, et al. Dynamic characteristics of supercritical CO2 dry gas seal based on multi variables perturbation[J]. CIESC Journal, 2021,72(4):2190-2202. | |

| 8 | 严如奇, 丁雪兴, 徐洁, 等. 离心惯性力效应对超临界二氧化碳干气密封流场与密封特性影响分析[J]. 摩擦学学报, 2020, 40(6): 781-791. |

| Yan R Q, Ding X X, Xu J, et al. The influence analysis of centrifugal inertia force effect on the flow field and sealing characteristics of supercritical carbon dioxide dry gas seal[J]. Tribology, 2020, 40(6): 781-791. | |

| 9 | 杜秋晚, 张荻, 谢永慧. 串联式干气密封对超临界二氧化碳轴流透平气动性能的影响[J]. 中国电机工程学报, 2021, 41(13): 4576-4584. |

| Du QW, Zhang D, Xie Y H. Effect of series dry gas seal on the aerodynamic performance of a supercritical carbon dioxide axial-inflow turbine[J]. Proceedings of The Chinese Society for Electrical Engineering, 2021, 41(13): 4576-4584. | |

| 10 | Du Q W, Zhang L, Zhang D, et al. Numerical investigation on flow characteristics and aerodynamic performance of shroud seal in a supercritical CO2 axial-flow turbine[J]. Applied Thermal Engineering, 2020, 169: 114960. |

| 11 | 蒋雪峰, 田勇, 邵卫卫, 等. 超临界二氧化碳压缩机特性数值模拟[J]. 航空动力学报, 2018, 33(7): 1685-1694. |

| Jiang X F, Tian Y, Shao W W, et al. Numerical simulation of supercritical CO2 compressors characteristics[J]. Journal of Aerospace Power, 2018, 33(7): 1685-1694. | |

| 12 | 许恒杰, 宋鹏云, 毛文元, 等. 层流状态下高压高转速二氧化碳干气密封的惯性效应分析[J]. 化工学报, 2018, 69(10): 4311-4323. |

| Xu H J, Song P Y, Mao W Y, et al. Analysis on inertia effect of carbon dioxide dry gas seal at high speed and pressure under laminar condition[J]. CIESC Journal, 2018, 69(10): 4311-4323. | |

| 13 | 刘柯炜, 李振涛, 王昕, 等. 超临界二氧化碳干气密封稳态性能研究[J]. 润滑与密封, 2020, 45(9): 71-77. |

| Liu K W, Li Z T, Wang X, et al. Study on steady-state performance of supercritical carbon dioxide dry gas seal[J]. Lubrication Engineering, 2020, 45(9): 71-77. | |

| 14 | Fairuz Z M, Jahn I. The influence of real gas effects on the performance of supercritical CO2 dry gas seals[J]. Tribology International, 2016, 102: 333-347. |

| 15 | Zakariya M F, Jahn I H J. Performance of supercritical CO2 dry gas seals near the critical point[C]//Proceedings of ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition. Seoul, South Korea,2016. |

| 16 | 马润梅, 朱鑫磊, 张楠楠, 等. 超临界二氧化碳气体端面密封阻塞效应研究[J]. 润滑与密封, 2020, 45(1): 16-22. |

| Ma R M, Zhu X L, Zhang N N, et al. Study on blocking effect supercritical carbon dioxide of dry gas seal[J]. Lubrication Engineering, 2020, 45(1): 16-22. | |

| 17 | Thatte A, Zheng X Q. Hydrodynamics and sonic flow transition in dry gas seals[C]//Proceedings of ASME Turbo Expo 2014: Turbine Technical Conference and Exposition. Düsseldorf, Germany, 2014 |

| 18 | Xu H J, Song P Y, Mao W Y, et al. The performance of spiral groove dry gas seal under choked flow condition considering the real gas effect[J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2020, 234(4): 554-566. |

| 19 | Du Q W, Gao K K, Zhang D, et al. Effects of grooved ring rotation and working fluid on the performance of dry gas seal[J]. International Journal of Heat and Mass Transfer, 2018, 126: 1323-1332. |

| 20 | Du Q W, Zhang D. Research on the performance of supercritical CO2 dry gas seal with different deep spiral groove[J]. Journal of Thermal Science, 2019, 28(3): 547-558. |

| 21 | Thomas S, Brunetière N, Tournerie B. Thermoelastohydrodynamic behavior of mechanical gas face seals operating at high pressure[J]. Journal of Tribology, 2007, 129(4): 841-850. |

| 22 | Bai S X, Ma C H, Peng X D, et al. Thermoelastohydrodynamic behavior of gas spiral groove face seals operating at high pressure and speed[J]. Journal of Tribology, 2015, 137(2): 021502. |

| 23 | Wang H, Zhu B S, Lin J S, et al. A thermohydrodynamic analysis of dry gas seals for high-temperature gas-cooled reactor[J]. Journal of Tribology, 2013, 135(2): 021701. |

| 24 | Brunetie`re N, Tournerie B, Fre^ne J. Influence of fluid flow regime on performances of non-contacting liquid face seals[J]. Journal of Tribology, 2002, 124(3): 515-523. |

| 25 | Xu J, Peng X D, Bai S X, et al. CFD simulation of microscale flow field in spiral groove dry gas seal[C]//Proceedings of 2012 IEEE/ASME 8th IEEE/ASME International Conference on Mechatronic and Embedded Systems and Applications. Suzhou, China, 2012: 211-217. |

| 26 | 彭旭东, 谢友柏, 顾永泉. 机械密封端面温度的确定[J]. 化工机械, 1996, 23(6):25-28, 21,58. |

| Peng X D, Xie Y B, Gu Y Q. Determination of the end face temperature of mechanical seal[J]. Chemical Engineering & Machnery, 1996, 23(6): 25-28, 21,58. | |

| 27 | Gabriel R P. Fundamentals of spiral groove non-contacting face seals[J]. Lubrication Engineering, 1994, 50(3): 215-224. |

| 28 | Laxander A, Fesl A, Hellmig B. Development and testing of dry gas seals for turbomachinery in multiphase CO2 applications[C]// 3rd European Supercritical CO2 Conference. Paris, France, 2019. |

| [1] | 丁俊华, 俞树荣, 王世鹏, 洪先志, 包鑫, 丁雪兴. 多重效应下超高速干气密封流场模拟及密封性能试验[J]. 化工学报, 2023, 74(5): 2088-2099. |

| [2] | 何洋, 高森虎, 吴青云, 张明理, 龙涛, 牛佩, 高景辉, 孟颖琪. 析湿工况下平直开缝翅片传热传质特性的数值研究[J]. 化工学报, 2023, 74(3): 1073-1081. |

| [3] | 孙雪剑, 宋鹏云, 毛文元, 邓强国, 许恒杰, 陈维. 考虑密封环材料属性和表面形貌干气密封启停阶段的动态接触特性分析[J]. 化工学报, 2021, 72(8): 4279-4291. |

| [4] | 严如奇, 丁雪兴, 徐洁, 洪先志, 包鑫. 基于湍流模型的S-CO2干气密封流场与稳态性能分析[J]. 化工学报, 2021, 72(8): 4292-4303. |

| [5] | 江锦波, 滕黎明, 孟祥铠, 李纪云, 彭旭东. 基于多变量摄动的超临界CO2干气密封动态特性[J]. 化工学报, 2021, 72(4): 2190-2202. |

| [6] | 商浩, 陈源, 李孝禄, 王冰清, 李运堂, 彭旭东. 膜厚扰动下的非线性效应对干气密封性能影响研究[J]. 化工学报, 2021, 72(4): 2213-2222. |

| [7] | 乔国岳, 刘居陶, 孙剑飞, 徐琴琴, 银建中. 超临界CO2脱附作用调控负载纳米颗粒结晶动力学研究[J]. 化工学报, 2021, 72(11): 5849-5857. |

| [8] | 于辰,江锦波,赵文静,李纪云,彭旭东,王玉明. 基于微段组合的干气密封端面型槽结构模型及其参数影响[J]. 化工学报, 2021, 72(10): 5294-5309. |

| [9] | 吕义高, 李庆, 文哲希. 正弦波纹流道印刷电路板换热器热工水力性能[J]. 化工学报, 2020, 71(S2): 142-151. |

| [10] | 严如奇, 洪先志, 包鑫, 徐洁, 丁雪兴. 超临界二氧化碳干气密封相态分布规律与密封性能研究[J]. 化工学报, 2020, 71(8): 3681-3690. |

| [11] | 范瑜, 宋鹏云, 许恒杰. 水蒸气润滑干气密封启动过程研究[J]. 化工学报, 2020, 71(8): 3671-3680. |

| [12] | 陈维, 宋鹏云, 许恒杰, 孙雪剑. 含杂质二氧化碳实际气体干气密封性能研究[J]. 化工学报, 2020, 71(5): 2215-2229. |

| [13] | 车健, 江锦波, 李纪云, 彭旭东, 马艺, 王玉明. 节流孔出气模式对静压干气密封稳态性能影响[J]. 化工学报, 2020, 71(4): 1734-1743. |

| [14] | 刘占斌, 何雅玲, 王坤, 马朝, 姜涛. 泡沫填充方式对管内超临界CO2流动换热的影响研究[J]. 化工学报, 2019, 70(9): 3329-3336. |

| [15] | 沈伟, 彭旭东, 江锦波, 李纪云. 高速超临界二氧化碳干气密封实际效应影响分析[J]. 化工学报, 2019, 70(7): 2645-2659. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号