化工学报 ›› 2022, Vol. 73 ›› Issue (6): 2690-2697.DOI: 10.11949/0438-1157.20220150

王婵1,2( ),肖国锡1,郭小雪1,徐人威3,岳源源1,2(

),肖国锡1,郭小雪1,徐人威3,岳源源1,2( ),鲍晓军1,2

),鲍晓军1,2

收稿日期:2022-01-25

修回日期:2022-04-08

出版日期:2022-06-05

发布日期:2022-06-30

通讯作者:

岳源源

作者简介:王婵(1987—),女,博士,讲师,基金资助:

Chan WANG1,2( ),Guoxi XIAO1,Xiaoxue GUO1,Renwei XU3,Yuanyuan YUE1,2(

),Guoxi XIAO1,Xiaoxue GUO1,Renwei XU3,Yuanyuan YUE1,2( ),Xiaojun BAO1,2

),Xiaojun BAO1,2

Received:2022-01-25

Revised:2022-04-08

Online:2022-06-05

Published:2022-06-30

Contact:

Yuanyuan YUE

摘要:

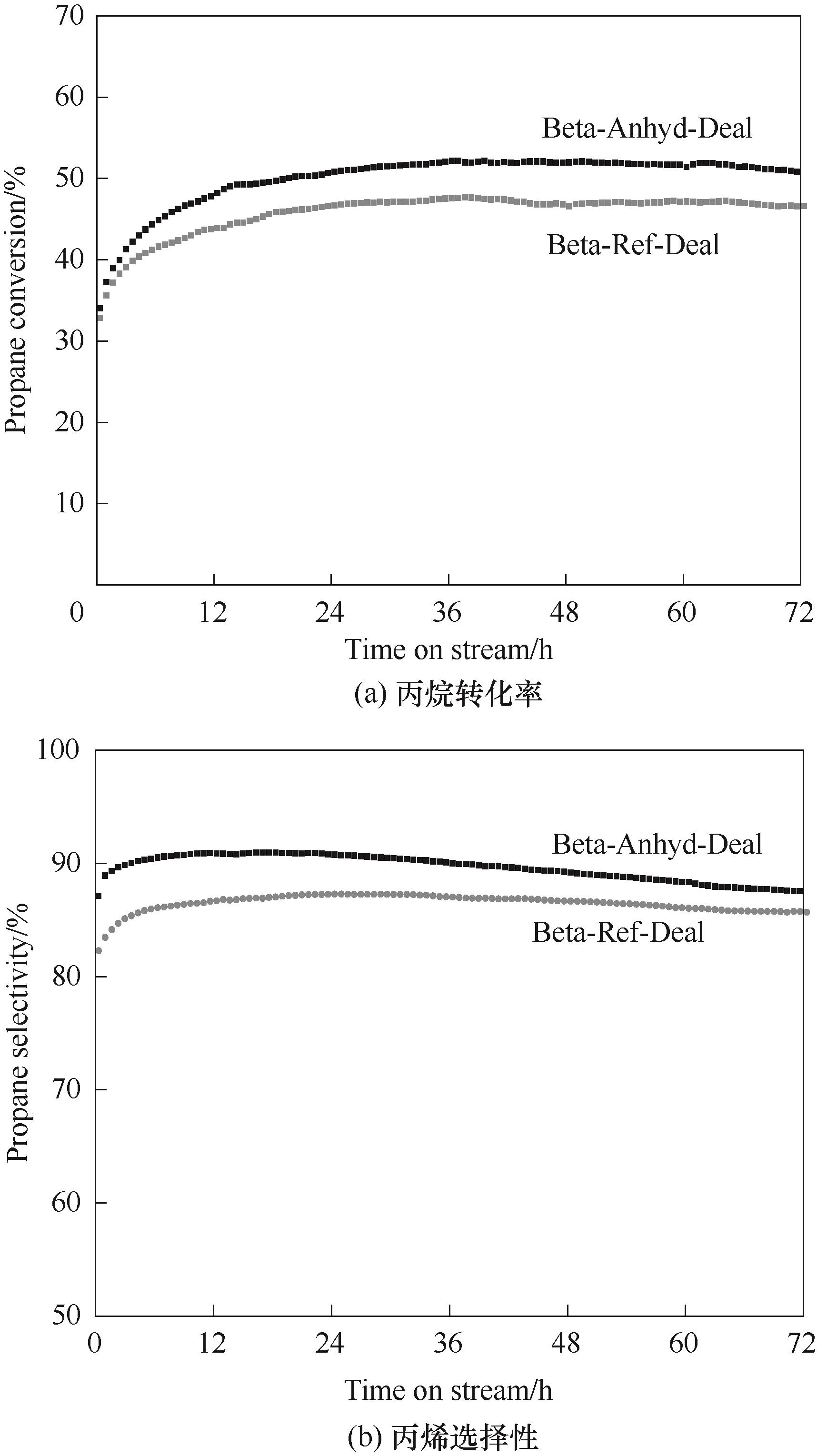

Beta分子筛作为一种重要的催化材料,被广泛应用于石油化工、煤化工及环境保护等领域,但其常规的水热合成过程存在成本高、单釜产率低和废水排放量大等问题。本研究提出了一条基于天然矿物介尺度结构解聚-重组装的无溶剂绿色合成Beta分子筛的新路线,采用该路线所合成的Beta分子筛(Beta-Anhyd)含有丰富的介孔和大孔结构,且具有较商业Beta分子筛(Beta-Ref)更高的比表面积和更低的酸量,以其为载体,通过脱Al补Sn制备的Sn-Beta催化剂(Beta-Anhyd-Deal)在丙烷脱氢反应中表现出较参比催化剂(Beta-Ref-Deal)更加优异的催化性能。

中图分类号:

王婵, 肖国锡, 郭小雪, 徐人威, 岳源源, 鲍晓军. 基于介尺度结构解聚-重组装的Beta分子筛的绿色合成及应用[J]. 化工学报, 2022, 73(6): 2690-2697.

Chan WANG, Guoxi XIAO, Xiaoxue GUO, Renwei XU, Yuanyuan YUE, Xiaojun BAO. Green synthesis and application of Beta zeolite prepared via mesoscale depolymerization-reorganization strategy[J]. CIESC Journal, 2022, 73(6): 2690-2697.

| Sample | SBET①/ (m2/g) | Smicro②/ (m2/g) | Sext②/ (m2/g) | Vtotal①/ (cm3/g) | Vmicro②/ (cm3/g) | Vmeso③/ (cm3/g) |

|---|---|---|---|---|---|---|

| Beta-Ref | 461 | 344 | 117 | 0.33 | 0.18 | 0.15 |

| Beta-Anhyd | 586 | 379 | 207 | 0.50 | 0.20 | 0.30 |

表1 Beta-Anhyd和Beta-Ref的孔结构参数

Table 1 Textural characteristics of Beta-Anhyd and Beta-Ref

| Sample | SBET①/ (m2/g) | Smicro②/ (m2/g) | Sext②/ (m2/g) | Vtotal①/ (cm3/g) | Vmicro②/ (cm3/g) | Vmeso③/ (cm3/g) |

|---|---|---|---|---|---|---|

| Beta-Ref | 461 | 344 | 117 | 0.33 | 0.18 | 0.15 |

| Beta-Anhyd | 586 | 379 | 207 | 0.50 | 0.20 | 0.30 |

| Samples | Amount of acid sites/(μmol/g) | ||||||

|---|---|---|---|---|---|---|---|

| 200℃ | 350℃ | ||||||

| B | L | Total | B | L | Total | ||

| Beta-Ref | 182.37 | 176.01 | 358.38 | 84.73 | 112.56 | 197.28 | |

| Beta-Anhyd | 143.76 | 87.57 | 231.34 | 97.29 | 62.92 | 160.24 | |

| Beta-Ref-Deal | 31.94 | 175.84 | 207.78 | 15.37 | 8.59 | 23.96 | |

| Beta-Anhyd-Deal | 22.74 | 153.06 | 175.80 | 6.97 | 45.04 | 52.00 | |

表2 Beta-Anhyd-Deal和Beta-Ref-Deal的酸量

Table 2 Acid sites amount of Beta-Anhyd-Deal and Beta-Ref-Deal

| Samples | Amount of acid sites/(μmol/g) | ||||||

|---|---|---|---|---|---|---|---|

| 200℃ | 350℃ | ||||||

| B | L | Total | B | L | Total | ||

| Beta-Ref | 182.37 | 176.01 | 358.38 | 84.73 | 112.56 | 197.28 | |

| Beta-Anhyd | 143.76 | 87.57 | 231.34 | 97.29 | 62.92 | 160.24 | |

| Beta-Ref-Deal | 31.94 | 175.84 | 207.78 | 15.37 | 8.59 | 23.96 | |

| Beta-Anhyd-Deal | 22.74 | 153.06 | 175.80 | 6.97 | 45.04 | 52.00 | |

图8 Beta-Anhyd-Deal和Beta-Ref-Deal在常压、630℃、质量空速为3.02 h-1下的丙烷脱氢催化性能

Fig.8 The catalytic performance of Beta-Anhyd-Deal and Beta-Ref-Deal in propylene dehydrogenation at atmospheric pressure, 630℃ and WHSV of 3.02 h-1

| 1 | 徐如人, 庞文琴, 霍启升, 等. 分子筛与多孔材料化学[M]. 2版. 北京: 科学出版社, 2015. |

| Xu R R, Pang W Q, Huo Q S, et al. Molecular Sieves and Porous Materials Chemistry[M]. Beijing: Science Press, 2015. | |

| 2 | Liu B Y, Chen Z P, Huang J J, et al. Development of iron encapsulated hollow beta zeolites for ammonia selective catalytic reduction[J]. Industrial & Engineering Chemistry Research, 2019, 58(8): 2914-2923. |

| 3 | Wu Q, Li Y Y, Hou Z G, et al. Synthesis and characterization of Beta-FDU-12 and the hydrodesulfurization performance of FCC gasoline and diesel[J]. Fuel Processing Technology, 2018, 172: 55-64. |

| 4 | Soltanali S, Darian J T. Synthesis of mesoporous beta catalysts in the presence of carbon nanostructures as hard templates in MTO process[J]. Microporous and Mesoporous Materials, 2019, 286: 169-175. |

| 5 | Cheng Z L, Li Y X, Liu Z. Novel adsorption materials based on graphene oxide/Beta zeolite composite materials and their adsorption performance for rhodamine B[J]. Journal of Alloys and Compounds, 2017, 708: 255-263. |

| 6 | 尚茜子, 张宝泉, 李雲. 不锈钢网负载Al-beta分子筛涂层的制备及其在油水分离中的应用[J]. 化工学报, 2019, 70(10): 3994-4001. |

| Shang X Z, Zhang B Q, Li Y. Fabrication of stainless steel mesh supported zeolite Al-beta coatings for oil/water separation[J]. CIESC Journal, 2019, 70(10): 3994-4001. | |

| 7 | Balomenos E, Panias D, Paspaliaris I. Energy and exergy analysis of the primary aluminum production processes: a review on current and future sustainability[J]. Mineral Processing and Extractive Metallurgy Review, 2011, 32(2): 69-89. |

| 8 | 郑涛, 刘海燕, 张睿, 等. 基于分子筛绿色合成的天然硅铝矿物介尺度活化研究进展[J]. 化工学报, 2022, 73(6): 2334-2351. |

| Zheng T, Liu H Y, Zhang R, et al. Research progress on mesoscale activation of natural aluminosilicate minerals based on green synthesis of molecular sieve[J]. CIESC Journal, 2022, 73(6): 2334-2351. | |

| 9 | Yue Y, Liu H, Yuan P, et al. One-pot synthesis of hierarchical FeZSM-5 zeolites from natural aluminosilicates for selective catalytic reduction of NO by NH3 [J]. Scientific Reports, 2015, 5: 9270. |

| 10 | Yue Y Y, Hu Y, Dong P, et al. Mesoscale depolymerization of natural rectorite mineral via a quasi-solid-phase approach for zeolite synthesis[J]. Chemical Engineering Science, 2020, 220: 115635. |

| 11 | Yue Y Y, Gu L L, Zhou Y N, et al. Template-free synthesis and catalytic applications of microporous and hierarchical ZSM-5 zeolites from natural aluminosilicate minerals[J]. Industrial & Engineering Chemistry Research, 2017, 56(36): 10069-10077. |

| 12 | Li T S, Liu H Y, Fan Y, et al. Synthesis of zeolite Y from natural aluminosilicate minerals for fluid catalytic cracking application[J]. Green Chemistry, 2012, 14(12): 3255-3259. |

| 13 | Yue Y Y, Liu H Y, Zhou Y N, et al. Pure-phase zeolite beta synthesized from natural aluminosilicate minerals and its catalytic application for esterification[J]. Applied Clay Science, 2016, 126: 1-6. |

| 14 | Yue Y Y, Liu B, Qin P, et al. One-pot synthesis of FeCu-SSZ-13 zeolite with superior performance in selective catalytic reduction of NO by NH3 from natural aluminosilicates[J]. Chemical Engineering Journal, 2020, 398: 125515. |

| 15 | Yue Y Y, Liu B, Lv N G, et al. Direct synthesis of hierarchical FeCu-ZSM-5 zeolite with wide temperature window in selective catalytic reduction of NO by NH3 [J]. ChemCatChem, 2019, 11(19): 4744-4754. |

| 16 | Yue Y Y, Guo X X, Liu T, et al. Template free synthesis of hierarchical porous zeolite Beta with natural Kaolin clay as alumina source[J]. Microporous and Mesoporous Materials, 2020, 293: 109772. |

| 17 | Wu Q M, Wang X, Qi G D, et al. Sustainable synthesis of zeolites without addition of both organotemplates and solvents[J]. Journal of the American Chemical Society, 2014, 136(10): 4019-4025. |

| 18 | Wu Q M, Liu X L, Zhu L F, et al. Solvent-free synthesis of zeolites from anhydrous starting raw solids[J]. Journal of the American Chemical Society, 2015, 137(3): 1052-1055. |

| 19 | Khan N A, Yoo D K, Bhadra B N, et al. Preparation of SSZ-13 zeolites from beta zeolite and their application in the conversion of ethylene to propylene[J]. Chemical Engineering Journal, 2019, 377: 119546. |

| 20 | Wang Y Q, Ding G Q, Yang X H, et al. Selectively convert fructose to furfural or hydroxymethylfurfural on Beta zeolite: the manipulation of solvent effects[J]. Applied Catalysis B: Environmental, 2018, 235: 150-157. |

| 21 | Manrique C, Guzmán A, Pérez-Pariente J, et al. Vacuum gas-oil hydrocracking performance of Beta zeolite obtained by hydrothermal synthesis using carbon nanotubes as mesoporous template[J]. Fuel, 2016, 182: 236-247. |

| 22 | Soy E, Arkhypova V, Soldatkin O, et al. Investigation of characteristics of urea and butyrylcholine chloride biosensors based on ion-selective field-effect transistors modified by the incorporation of heat-treated zeolite Beta crystals[J]. Materials Science and Engineering: C, 2012, 32(7): 1835-1842. |

| 23 | Abraham A, Lee S H, Shin C H, et al. Influence of framework silicon to aluminium ratio on aluminium coordination and distribution in zeolite Beta investigated by 27Al MAS and 27Al MQ MAS NMR[J]. Physical Chemistry Chemical Physics, 2004, 6(11): 3031. |

| 24 | Kao H M, Chen Y C. 27Al and 19F solid-state NMR studies of zeolite H-β dealuminated with ammonium hexafluorosilicate[J]. The Journal of Physical Chemistry B, 2003, 107(15): 3367-3375. |

| 25 | Tang B, Dai W L, Wu G J, et al. Improved postsynthesis strategy to Sn-beta zeolites as Lewis acid catalysts for the ring-opening hydration of epoxides[J]. ACS Catalysis, 2014, 4(8): 2801-2810. |

| 26 | Pachamuthu M P, Shanthi K, Luque R, et al. SnTUD-1: a solid acid catalyst for three component coupling reactions at room temperature[J]. Green Chemistry, 2013, 15(8): 2158. |

| 27 | 辛勤. 固体催化剂研究方法[M]. 北京: 科学出版社, 2004. |

| Xin Q. Research Methods for Solid Catalysts [M]. Beijing: Science Press, 2004. | |

| 28 | Verboekend D, Pérez-Ramírez J. Desilication mechanism revisited: highly mesoporous all-silica zeolites enabled through pore-directing agents[J]. Chemistry — A European Journal, 2011, 17(4): 1137-1147. |

| 29 | Boddenberg B. High-resolution solid-state NMR of silicates and zeolites[J]. Applied Catalysis, 1988, 42(1): 187-188. |

| 30 | de Baerdemaeker T, Yilmaz B, Müller U, et al. Catalytic applications of OSDA-free beta zeolite[J]. Journal of Catalysis, 2013, 308: 73-81. |

| 31 | Ding J J, Liu H Y, Yuan P, et al. Catalytic properties of a hierarchical zeolite synthesized from a natural aluminosilicate mineral without the use of a secondary mesoscale template[J]. ChemCatChem, 2013, 5(8): 2258-2269. |

| 32 | Emeis C A. Determination of integrated molar extinction coefficients for infrared absorption bands of pyridine adsorbed on solid acid catalysts[J]. Journal of Catalysis, 1993, 141(2): 347-354. |

| 33 | González F, Pesquera C, Perdigón A, et al. Synthesis, characterization and catalytic performance of Al-MCM-41 mesoporous materials[J]. Applied Surface Science, 2009, 255(17): 7825-7830. |

| 34 | Yue Y Y, Fu J, Wang C M, et al. Propane dehydrogenation catalyzed by single Lewis acid site in Sn-Beta zeolite[J]. Journal of Catalysis, 2021, 395: 155-167. |

| 35 | Katranas T K, Vlessidis A G, Tsiatouras V A, et al. Dehydrogenation of propane over natural clinoptilolite zeolites[J]. Microporous and Mesoporous Materials, 2003, 61(1/2/3): 189-198. |

| [1] | 李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840. |

| [2] | 杨学金, 杨金涛, 宁平, 王访, 宋晓双, 贾丽娟, 冯嘉予. 剧毒气体PH3的干法净化技术研究进展[J]. 化工学报, 2023, 74(9): 3742-3755. |

| [3] | 陈杰, 林永胜, 肖恺, 杨臣, 邱挺. 胆碱基碱性离子液体催化合成仲丁醇性能研究[J]. 化工学报, 2023, 74(9): 3716-3730. |

| [4] | 杨菲菲, 赵世熙, 周维, 倪中海. Sn掺杂的In2O3催化CO2选择性加氢制甲醇[J]. 化工学报, 2023, 74(8): 3366-3374. |

| [5] | 李凯旋, 谭伟, 张曼玉, 徐志豪, 王旭裕, 纪红兵. 富含零价钴活性位点的钴氮碳/活性炭设计及甲醛催化氧化应用研究[J]. 化工学报, 2023, 74(8): 3342-3352. |

| [6] | 杨欣, 彭啸, 薛凯茹, 苏梦威, 吴燕. 分子印迹-TiO2光电催化降解增溶PHE废水性能研究[J]. 化工学报, 2023, 74(8): 3564-3571. |

| [7] | 余娅洁, 李静茹, 周树锋, 李清彪, 詹国武. 基于天然生物模板构建纳米材料及集成催化剂研究进展[J]. 化工学报, 2023, 74(7): 2735-2752. |

| [8] | 李盼, 马俊洋, 陈志豪, 王丽, 郭耘. Ru/α-MnO2催化剂形貌对NH3-SCO反应性能的影响[J]. 化工学报, 2023, 74(7): 2908-2918. |

| [9] | 涂玉明, 邵高燕, 陈健杰, 刘凤, 田世超, 周智勇, 任钟旗. 钙基催化剂的设计合成及应用研究进展[J]. 化工学报, 2023, 74(7): 2717-2734. |

| [10] | 张琦钰, 高利军, 苏宇航, 马晓博, 王翊丞, 张亚婷, 胡超. 碳基催化材料在电化学还原二氧化碳中的研究进展[J]. 化工学报, 2023, 74(7): 2753-2772. |

| [11] | 张希庆, 王琰婷, 徐彦红, 常淑玲, 孙婷婷, 薛定, 张立红. Mg量影响的纳米片负载Pt-In催化异丁烷脱氢性能[J]. 化工学报, 2023, 74(6): 2427-2435. |

| [12] | 周继鹏, 何文军, 李涛. 异形催化剂上乙烯催化氧化失活动力学反应工程计算[J]. 化工学报, 2023, 74(6): 2416-2426. |

| [13] | 张谭, 刘光, 李晋平, 孙予罕. Ru基氮还原电催化剂性能调控策略[J]. 化工学报, 2023, 74(6): 2264-2280. |

| [14] | 韩奎奎, 谭湘龙, 李金芝, 杨婷, 张春, 张永汾, 刘洪全, 于中伟, 顾学红. 四通道中空纤维MFI分子筛膜用于二甲苯异构体分离[J]. 化工学报, 2023, 74(6): 2468-2476. |

| [15] | 王辰, 史秀锋, 武鲜凤, 魏方佳, 张昊虹, 车寅, 吴旭. 氧化还原法制备Mn3O4催化剂及其甲苯催化氧化性能与机理研究[J]. 化工学报, 2023, 74(6): 2447-2457. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号