化工学报 ›› 2023, Vol. 74 ›› Issue (9): 3831-3840.DOI: 10.11949/0438-1157.20230341

收稿日期:2023-04-06

修回日期:2023-08-24

出版日期:2023-09-25

发布日期:2023-11-20

通讯作者:

郭航

作者简介:李艺彤(1996—),女,博士研究生,yitongli@emails.bjut.edu.cn

基金资助:

Yitong LI( ), Hang GUO(

), Hang GUO( ), Hao CHEN, Fang YE

), Hao CHEN, Fang YE

Received:2023-04-06

Revised:2023-08-24

Online:2023-09-25

Published:2023-11-20

Contact:

Hang GUO

摘要:

催化层中铂载量沿流道方向的梯度分布会影响反应物利用以及热量和物质的传递,而操作条件对铂载量梯度分布质子交换膜燃料电池电性能和传热传质的影响尚不明确。因此,基于二维、非等温、两相质子交换膜燃料电池模型探究了操作条件反应物流向和化学计量比对铂载量二梯度分布和多梯度分布中的三梯度分布质子交换膜燃料电池的影响。研究表明,反应物流向对铂载量梯度分布燃料电池的电性能和物质含量的影响较弱;化学计量比的增加可以提高铂载量梯度分布燃料电池的电性能,并且随着化学计量比的增加,铂载量梯度分布的燃料电池性能相对于均匀分布的燃料电池性能的提升效果增强。

中图分类号:

李艺彤, 郭航, 陈浩, 叶芳. 催化剂非均匀分布的质子交换膜燃料电池操作条件研究[J]. 化工学报, 2023, 74(9): 3831-3840.

Yitong LI, Hang GUO, Hao CHEN, Fang YE. Study on operating conditions of proton exchange membrane fuel cells with non-uniform catalyst distributions[J]. CIESC Journal, 2023, 74(9): 3831-3840.

| 参数 | 取值 |

|---|---|

| 铂载量/(mg/cm2) | 0.4 |

| 操作温度/K | 343.15 |

| 操作压力/MPa | 0.1 |

| 阳极氢气流量/(ml/min) | 600 |

| 质子交换膜厚度/m | 5.3×10-5 |

| 催化层厚度/m | 1.5×10-5 |

| 气体扩散层厚度/m | 3.75×10-4 |

| 流道宽度/m | 7.5×10-4 |

| 流道深度/m | 1.0×10-3 |

| 流道长度/m | 4.0×10-2 |

表1 文献[34]中的实验条件

Table 1 Experimental conditions in Ref. [34]

| 参数 | 取值 |

|---|---|

| 铂载量/(mg/cm2) | 0.4 |

| 操作温度/K | 343.15 |

| 操作压力/MPa | 0.1 |

| 阳极氢气流量/(ml/min) | 600 |

| 质子交换膜厚度/m | 5.3×10-5 |

| 催化层厚度/m | 1.5×10-5 |

| 气体扩散层厚度/m | 3.75×10-4 |

| 流道宽度/m | 7.5×10-4 |

| 流道深度/m | 1.0×10-3 |

| 流道长度/m | 4.0×10-2 |

| 流动方式 | 电流密度/(A/cm2) | |||

|---|---|---|---|---|

| 均匀分布 | 二梯度分布 | 三梯度分布 | ||

| 0.8 V | 顺流 | 0.0829 | 0.0860 | 0.0850 |

| 逆流 | 0.0834 | 0.0864 | 0.0854 | |

| 0.5 V | 顺流 | 0.9672 | 0.9735 | 0.9712 |

| 逆流 | 0.9715 | 0.9773 | 0.9749 | |

| 0.2 V | 顺流 | 1.3891 | 1.4474 | 1.4288 |

| 逆流 | 1.3897 | 1.4480 | 1.4292 | |

表2 顺流和逆流流动时的电流密度

Table 2 Current density for downstream and countercurrent flow

| 流动方式 | 电流密度/(A/cm2) | |||

|---|---|---|---|---|

| 均匀分布 | 二梯度分布 | 三梯度分布 | ||

| 0.8 V | 顺流 | 0.0829 | 0.0860 | 0.0850 |

| 逆流 | 0.0834 | 0.0864 | 0.0854 | |

| 0.5 V | 顺流 | 0.9672 | 0.9735 | 0.9712 |

| 逆流 | 0.9715 | 0.9773 | 0.9749 | |

| 0.2 V | 顺流 | 1.3891 | 1.4474 | 1.4288 |

| 逆流 | 1.3897 | 1.4480 | 1.4292 | |

| 铂载量分布方式 | 氧气浓度/(mol/m3) | 液态水饱和度 | ||

|---|---|---|---|---|

| 顺流 | 逆流 | 顺流 | 逆流 | |

| 均匀分布 | 3.24 | 3.23 | 0.0709 | 0.0712 |

| 二梯度分布 | 3.15 | 3.13 | 0.0746 | 0.0749 |

| 三梯度分布 | 3.16 | 3.15 | 0.0742 | 0.0744 |

表3 顺流和逆流流动时阴极催化层中平均氧气浓度和液态水饱和度

Table 3 The average oxygen concentration and liquid water saturation in the cathode catalyst layer for downstream and countercurrent flow

| 铂载量分布方式 | 氧气浓度/(mol/m3) | 液态水饱和度 | ||

|---|---|---|---|---|

| 顺流 | 逆流 | 顺流 | 逆流 | |

| 均匀分布 | 3.24 | 3.23 | 0.0709 | 0.0712 |

| 二梯度分布 | 3.15 | 3.13 | 0.0746 | 0.0749 |

| 三梯度分布 | 3.16 | 3.15 | 0.0742 | 0.0744 |

| 铂载量分布方式 | 平均温度/K | 温度标准差/K | ||

|---|---|---|---|---|

| 顺流 | 逆流 | 顺流 | 逆流 | |

| 均匀分布 | 348.38 | 348.64 | 0.9391 | 0.8945 |

| 二梯度分布 | 348.69 | 348.73 | 1.0605 | 1.1917 |

| 三梯度分布 | 348.66 | 348.71 | 0.9980 | 1.1351 |

表4 顺流和逆流流动时在0.5 V电压下膜电极组件内的温度

Table 4 Temperature in the membrane electrode assembly at 0.5 V for downstream and countercurrent flow

| 铂载量分布方式 | 平均温度/K | 温度标准差/K | ||

|---|---|---|---|---|

| 顺流 | 逆流 | 顺流 | 逆流 | |

| 均匀分布 | 348.38 | 348.64 | 0.9391 | 0.8945 |

| 二梯度分布 | 348.69 | 348.73 | 1.0605 | 1.1917 |

| 三梯度分布 | 348.66 | 348.71 | 0.9980 | 1.1351 |

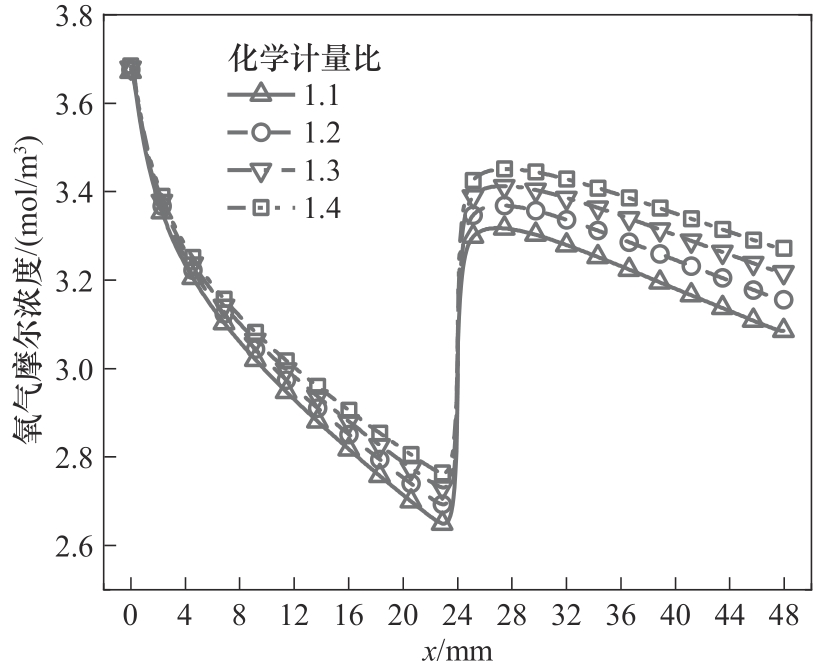

图6 化学计量比对铂载量二梯度分布时沿流道方向阴极催化层中线氧气浓度的影响

Fig.6 Effect of stoichiometric ratio on oxygen concentration on the cathode catalyst layer center line along the flow channel direction for two-gradient distribution of platinum loading

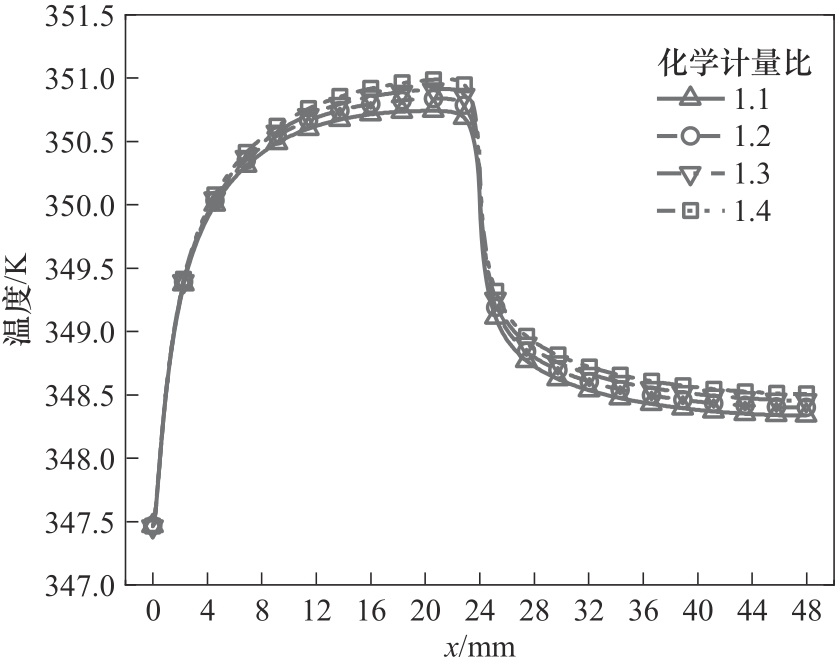

图7 化学计量比对铂载量二梯度分布时沿流道方向阴极催化层中线温度的影响

Fig.7 Effect of stoichiometric ratio on temperature on the cathode catalyst layer center line along the flow channel direction for two-gradient distribution of platinum loading

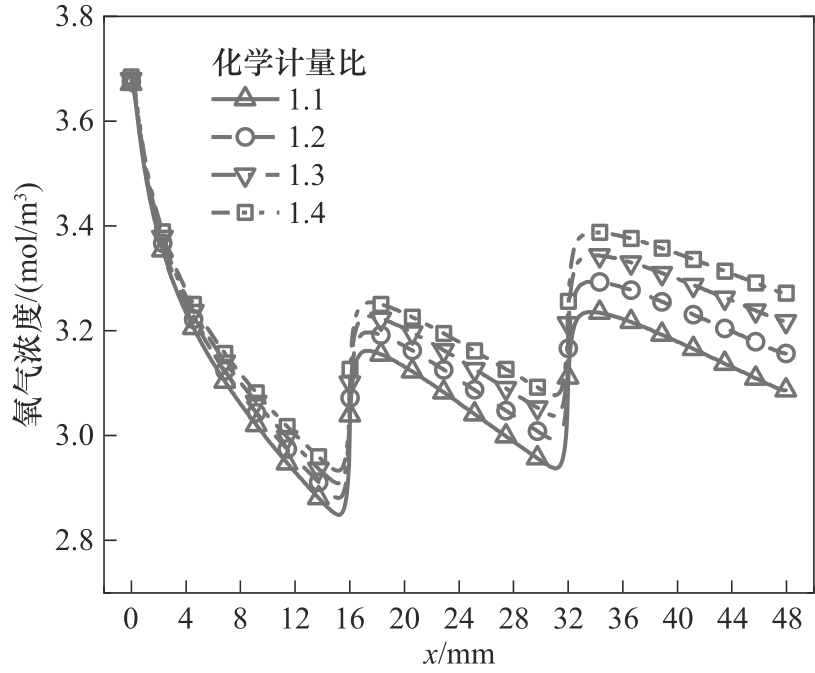

图9 化学计量比对铂载量三梯度分布时沿流道方向阴极催化层中线氧气浓度的影响

Fig.9 Effect of stoichiometric ratio on oxygen concentration on the cathode catalyst layer center line along the flow channel direction for three-gradient distribution of platinum loading

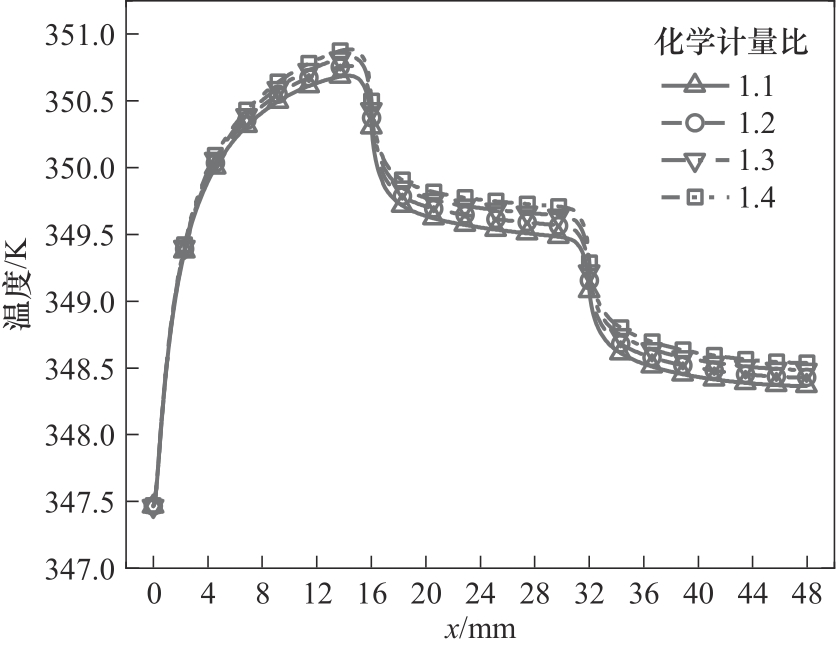

图10 化学计量比对铂载量三梯度分布时沿流道方向阴极催化层中线温度的影响

Fig.10 Effect of stoichiometric ratio on temperature on the cathode catalyst layer center line along the flow channel direction for three-gradient distribution of platinum loading

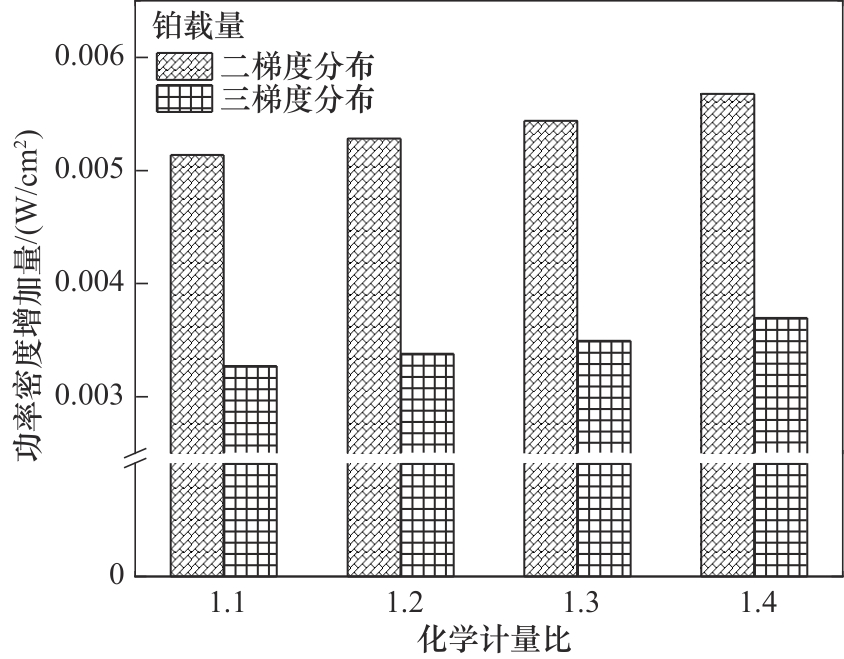

图12 不同化学计量比下铂载量梯度分布相比与均匀分布的最大功率密度增加量

Fig.12 Increment of maximum power density of gradient distribution compared to uniform distribution under different stoichiometric ratios

| 1 | 张诚, 檀志恒, 晁怀颇. “双碳”背景下数据中心氢能应用的可行性研究[J]. 太阳能学报, 2022, 43(6): 327-334. |

| Zhang C, Tan Z H, Chao H P. Feasibility study of hydrogen energy application on data center under “carbon peaking and neutralization” background[J]. Acta Energiae Solaris Sinica, 2022, 43(6): 327-334. | |

| 2 | Huang T M, Huang J, Feng M C, et al. Optimization of the thickness of catalytic layer for HT-PEMFCs based on genetic algorithm[J]. Energy Reports, 2022, 8: 12905-12915. |

| 3 | Zhu K Q, Ding Q, Xu J H, et al. Optimization of gas diffusion layer thickness for proton exchange membrane fuel cells under steady-state and load-varying conditions[J]. Energy Conversion and Management, 2022, 267: 115915. |

| 4 | Li X A, Tang F M, Li B, et al. (Digital presentation) effects of catalyst dimension parameters on local oxygen transport in cathode catalyst layer of proton exchange membrane fuel cell[J]. ECS Transactions, 2022, 108(7): 165-179. |

| 5 | Guo H, Zhao Q, Ye F. An experimental study on gas and liquid two-phase flow in orientated-type flow channels of proton exchange membrane fuel cells by using a side-view method[J]. Renewable Energy, 2022, 188: 603-618. |

| 6 | Chen X, Yang C, Sun Y, et al. Water management and structure optimization study of nickel metal foam as flow distributors in proton exchange membrane fuel cell[J]. Applied Energy, 2022, 309: 118448. |

| 7 | Havaej P, Kermani M J, Abdollahzadeh M, et al. A numerical modeling study on the influence of catalyst loading distribution on the performance of polymer electrolyte membrane fuel cell[J]. International Journal of Hydrogen Energy, 2018, 43(21): 10031-10047. |

| 8 | Li Y T, Guo H, Ye F. Heat and mass transfer in a proton exchange membrane fuel cell with gradient distribution of platinum loading along flow channel direction[J]. International Journal of Energy Research, 2022, 46(7): 8872-8890. |

| 9 | Xing L, Wang Y, Das P K, et al. Homogenization of current density of PEM fuel cells by in-plane graded distributions of platinum loading and GDL porosity[J]. Chemical Engineering Science, 2018, 192: 699-713. |

| 10 | Xing L, Xu Y X, Penga Ž, et al. A segmented fuel cell unit with functionally graded distributions of platinum loading and operating temperature[J]. Chemical Engineering Journal, 2021, 406: 126889. |

| 11 | Schwarz D H, Djilali N. Three-dimensional modelling of catalyst layers in PEM fuel cells: effects of non-uniform catalyst loading[J]. International Journal of Energy Research, 2009, 33(7): 631-644. |

| 12 | Yang L, Fu K H, Jin X S, et al. Catalyst layer design with inhomogeneous distribution of platinum and ionomer optimal for proton exchange membrane fuel cell cold-start[J]. Chemical Engineering Science, 2022, 263: 118132. |

| 13 | Lei H H, Xing L, Jiang H, et al. Designing graded fuel cell electrodes for proton exchange membrane (PEM) fuel cells with recurrent neural network (RNN) approaches[J]. Chemical Engineering Science, 2023, 267: 118350. |

| 14 | Yu R J, Guo H, Ye F, et al. Multi-parameter optimization of stepwise distribution of parameters of gas diffusion layer and catalyst layer for PEMFC peak power density[J]. Applied Energy, 2022, 324: 119764. |

| 15 | Lin G Y, He W S, van Nguyen T. Modeling liquid water effects in the gas diffusion and catalyst layers of the cathode of a PEM fuel cell[J]. Journal of the Electrochemical Society, 2004, 151(12): A1999. |

| 16 | Dannenberg K, Ekdunge P, Lindbergh G. Mathematical model of the PEMFC[J]. Journal of Applied Electrochemistry, 2000, 30(12): 1377-1387. |

| 17 | Darling R. Modeling air electrodes with low platinum loading[J]. Journal of the Electrochemical Society, 2019, 166(7): F3058-F3064. |

| 18 | Xing L, Das P K, Song X G, et al. Numerical analysis of the optimum membrane/ionomer water content of PEMFCs: the interaction of Nafion® ionomer content and cathode relative humidity[J]. Applied Energy, 2015, 138: 242-257. |

| 19 | Hu G L, Li G N, Zheng Y Q, et al. Optimization and parametric analysis of PEMFC based on an agglomerate model for catalyst layer[J]. Journal of the Energy Institute, 2014, 87(2): 163-174. |

| 20 | Moein-Jahromi M, Kermani M J. Performance prediction of PEM fuel cell cathode catalyst layer using agglomerate model[J]. International Journal of Hydrogen Energy, 2012, 37(23): 17954-17966. |

| 21 | Jung C Y, Shim H S, Koo S M, et al. Investigations of the temperature distribution in proton exchange membrane fuel cells[J]. Applied Energy, 2012, 93: 733-741. |

| 22 | Srinivasarao M, Bhattacharyya D, Rengaswamy R, et al. Parametric study of the cathode and the role of liquid saturation on the performance of a polymer electrolyte membrane fuel cell—a numerical approach[J]. Journal of Power Sources, 2010, 195(19): 6782-6794. |

| 23 | Rao R M, Bhattacharyya D, Rengaswamy R, et al. A two-dimensional steady state model including the effect of liquid water for a PEM fuel cell cathode[J]. Journal of Power Sources, 2007, 173(1): 375-393. |

| 24 | Xing L, Liu X T, Alaje T, et al. A two-phase flow and non-isothermal agglomerate model for a proton exchange membrane (PEM) fuel cell[J]. Energy, 2014, 73: 618-634. |

| 25 | Hosseini M, Afrouzi H H, Arasteh H, et al. Energy analysis of a proton exchange membrane fuel cell (PEMFC) with an open-ended anode using agglomerate model: a CFD study[J]. Energy, 2019, 188: 116090. |

| 26 | Chen H, Guo H, Ye F, et al. A numerical study of baffle height and location effects on mass transfer of proton exchange membrane fuel cells with orientated-type flow channels[J]. International Journal of Hydrogen Energy, 2021, 46(10): 7528-7545. |

| 27 | Li S A, Yuan J L, Xie G N, et al. Effects of agglomerate model parameters on transport characterization and performance of PEM fuel cells[J]. International Journal of Hydrogen Energy, 2018, 43(17): 8451-8463. |

| 28 | Li X, Tang F M, Wang Q Q, et al. Simulation on cathode catalyst layer in proton exchange membrane fuel cell: sensitivity of design parameters to cell performance and oxygen distribution[J]. International Journal of Hydrogen Energy, 2022, 47(58): 24452-24463. |

| 29 | Kulkarni N, Cho J I S, Jervis R, et al. The effect of non-uniform compression on the performance of polymer electrolyte fuel cells[J]. Journal of Power Sources, 2022, 521: 230973. |

| 30 | Yu R J, Guo H, Ye F. Study on transmission coefficients anisotropy of gas diffusion layer in a proton exchange membrane fuel cell[J]. Electrochimica Acta, 2022, 414: 140163. |

| 31 | Choi J, Kim E, Cha Y, et al. Probing the influence of nonuniform Pt particle size distribution using a full three-dimensional, multiscale, multiphase polymer electrolyte membrane fuel cell model[J]. Electrochimica Acta, 2022, 405: 139811. |

| 32 | Wang N, Qu Z G, Jiang Z Y, et al. A unified catalyst layer design classification criterion on proton exchange membrane fuel cell performance based on a modified agglomerate model[J]. Chemical Engineering Journal, 2022, 447: 137489. |

| 33 | Chen H, Guo H, Ye F, et al. Forchheimer’s inertial effect on liquid water removal in proton exchange membrane fuel cells with baffled flow channels[J]. International Journal of Hydrogen Energy, 2021, 46(3): 2990-3007. |

| 34 | 孙红, 吴玉厚. 反应气体流量和背压对PEM燃料电池性能的影响[J]. 沈阳建筑大学学报(自然科学版), 2006, 22(6): 1034-1037. |

| Sun H, Wu Y H. Effects of reactant flow rate and backpressure on the performance of PEM fuel cells[J]. Journal of Shenyang Jianzhu University(Natural Science), 2006, 22(6): 1034-1037. |

| [1] | 晁京伟, 许嘉兴, 李廷贤. 基于无管束蒸发换热强化策略的吸附热池的供热性能研究[J]. 化工学报, 2023, 74(S1): 302-310. |

| [2] | 程成, 段钟弟, 孙浩然, 胡海涛, 薛鸿祥. 表面微结构对析晶沉积特性影响的格子Boltzmann模拟[J]. 化工学报, 2023, 74(S1): 74-86. |

| [3] | 张双星, 刘舫辰, 张义飞, 杜文静. R-134a脉动热管相变蓄放热实验研究[J]. 化工学报, 2023, 74(S1): 165-171. |

| [4] | 张义飞, 刘舫辰, 张双星, 杜文静. 超临界二氧化碳用印刷电路板式换热器性能分析[J]. 化工学报, 2023, 74(S1): 183-190. |

| [5] | 陈爱强, 代艳奇, 刘悦, 刘斌, 吴翰铭. 基板温度对HFE7100液滴蒸发过程的影响研究[J]. 化工学报, 2023, 74(S1): 191-197. |

| [6] | 刘明栖, 吴延鹏. 导光管直径和长度对传热影响的模拟分析[J]. 化工学报, 2023, 74(S1): 206-212. |

| [7] | 王志国, 薛孟, 董芋双, 张田震, 秦晓凯, 韩强. 基于裂隙粗糙性表征方法的地热岩体热流耦合数值模拟与分析[J]. 化工学报, 2023, 74(S1): 223-234. |

| [8] | 王玉兵, 李杰, 詹宏波, 朱光亚, 张大林. R134a在菱形离散肋微小通道内的流动沸腾换热实验研究[J]. 化工学报, 2023, 74(9): 3797-3806. |

| [9] | 陈杰, 林永胜, 肖恺, 杨臣, 邱挺. 胆碱基碱性离子液体催化合成仲丁醇性能研究[J]. 化工学报, 2023, 74(9): 3716-3730. |

| [10] | 杨学金, 杨金涛, 宁平, 王访, 宋晓双, 贾丽娟, 冯嘉予. 剧毒气体PH3的干法净化技术研究进展[J]. 化工学报, 2023, 74(9): 3742-3755. |

| [11] | 齐聪, 丁子, 余杰, 汤茂清, 梁林. 基于选择吸收纳米薄膜的太阳能温差发电特性研究[J]. 化工学报, 2023, 74(9): 3921-3930. |

| [12] | 李科, 文键, 忻碧平. 耦合蒸气冷却屏的真空多层绝热结构对液氢储罐自增压过程的影响机制研究[J]. 化工学报, 2023, 74(9): 3786-3796. |

| [13] | 杨越, 张丹, 郑巨淦, 涂茂萍, 杨庆忠. NaCl水溶液喷射闪蒸-掺混蒸发的实验研究[J]. 化工学报, 2023, 74(8): 3279-3291. |

| [14] | 陈天华, 刘兆轩, 韩群, 张程宾, 李文明. 喷雾冷却换热强化研究进展及影响因素[J]. 化工学报, 2023, 74(8): 3149-3170. |

| [15] | 陈国泽, 卫东, 郭倩, 向志平. 负载跟踪状态下的铝空气电池堆最优功率点优化方法[J]. 化工学报, 2023, 74(8): 3533-3542. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号