化工学报 ›› 2022, Vol. 73 ›› Issue (7): 3078-3089.DOI: 10.11949/0438-1157.20220177

孙国鑫1( ),苟萌萱1,周诚2,常佩2,贺高红1,姜晓滨1(

),苟萌萱1,周诚2,常佩2,贺高红1,姜晓滨1( )

)

收稿日期:2022-02-10

修回日期:2022-03-21

出版日期:2022-07-05

发布日期:2022-08-01

通讯作者:

姜晓滨

作者简介:孙国鑫(1996—),男,硕士,基金资助:

Guoxin SUN1( ),Mengxuan GOU1,Cheng ZHOU2,Pei CHANG2,Gaohong HE1,Xiaobin JIANG1(

),Mengxuan GOU1,Cheng ZHOU2,Pei CHANG2,Gaohong HE1,Xiaobin JIANG1( )

)

Received:2022-02-10

Revised:2022-03-21

Online:2022-07-05

Published:2022-08-01

Contact:

Xiaobin JIANG

摘要:

煤化工、含能材料等工业领域产生的富含硝酸盐、硫酸盐的高浓废水排放量巨大、环境危害严重。高浓度复合盐水低能耗处理的同时实现高品质结晶过程调控,已经成为一个重要的研究方向。针对典型的高浓度Na+//NO

中图分类号:

孙国鑫, 苟萌萱, 周诚, 常佩, 贺高红, 姜晓滨. 高浓度Na+//NO

Guoxin SUN, Mengxuan GOU, Cheng ZHOU, Pei CHANG, Gaohong HE, Xiaobin JIANG. Membrane distillation crystallization coupling process for the treatment of high concentration Na+//NO

| 名称 | 规格 | 厂家 |

|---|---|---|

| 硝酸钠 | 分析纯 | 天津市大茂化学试剂厂 |

| 无水硫酸钠 | 分析纯 | 天津市科密欧化学试剂有限公司 |

| 超纯水 | 离子含量<0.1 μg/L | 莱特莱德环境工程有限公司 |

表1 实验药品与试剂

Table 1 Drugs and reagents used in the experiment

| 名称 | 规格 | 厂家 |

|---|---|---|

| 硝酸钠 | 分析纯 | 天津市大茂化学试剂厂 |

| 无水硫酸钠 | 分析纯 | 天津市科密欧化学试剂有限公司 |

| 超纯水 | 离子含量<0.1 μg/L | 莱特莱德环境工程有限公司 |

| 膜材料 | 外径/μm | 内径/μm | 纯水接触角/(°) | 体积空隙率 |

|---|---|---|---|---|

| PTFE | 2110±50 | 1200±35 | 120±2 | 0.53±0.01 |

表2 中空纤维膜材料的结构参数

Table 2 Membrane structure parameters of hollow fiber membrane

| 膜材料 | 外径/μm | 内径/μm | 纯水接触角/(°) | 体积空隙率 |

|---|---|---|---|---|

| PTFE | 2110±50 | 1200±35 | 120±2 | 0.53±0.01 |

| 名称 | 规格 | 厂家 |

|---|---|---|

| 中空纤维膜组件 | 内径20 mm,高150 mm, 装填密度454.0、340.5、227.0 m2/m3 | 自制 |

| 电子天平 | Adventurer AR | 奥豪斯仪器有限公司 |

| 蠕动泵 | BT100-2J | 保定兰格恒流泵有限公司 |

| 隔膜真空泵 | N820 | 优莱博技术有限公司 |

| 真空控制器 | NVC-3000 | 东京理化器械 株式会社 |

| 恒温水浴 | CF41 | 优莱博技术有限公司 |

| 玻璃夹套反应釜 | 500 ml | 优莱博技术有限公司 |

表3 实验中使用的仪器

Table 3 Apparatus used during the experiment

| 名称 | 规格 | 厂家 |

|---|---|---|

| 中空纤维膜组件 | 内径20 mm,高150 mm, 装填密度454.0、340.5、227.0 m2/m3 | 自制 |

| 电子天平 | Adventurer AR | 奥豪斯仪器有限公司 |

| 蠕动泵 | BT100-2J | 保定兰格恒流泵有限公司 |

| 隔膜真空泵 | N820 | 优莱博技术有限公司 |

| 真空控制器 | NVC-3000 | 东京理化器械 株式会社 |

| 恒温水浴 | CF41 | 优莱博技术有限公司 |

| 玻璃夹套反应釜 | 500 ml | 优莱博技术有限公司 |

图2 减压蒸发结晶装置示意图① 天平数据记录计算机;②天平;③结晶釜;④加热水浴;⑤冷却水浴;⑥热电偶;⑦真空控制器;⑧真空泵

Fig.2 Schematic diagram of the experimental device for vacuum evaporative crystallization

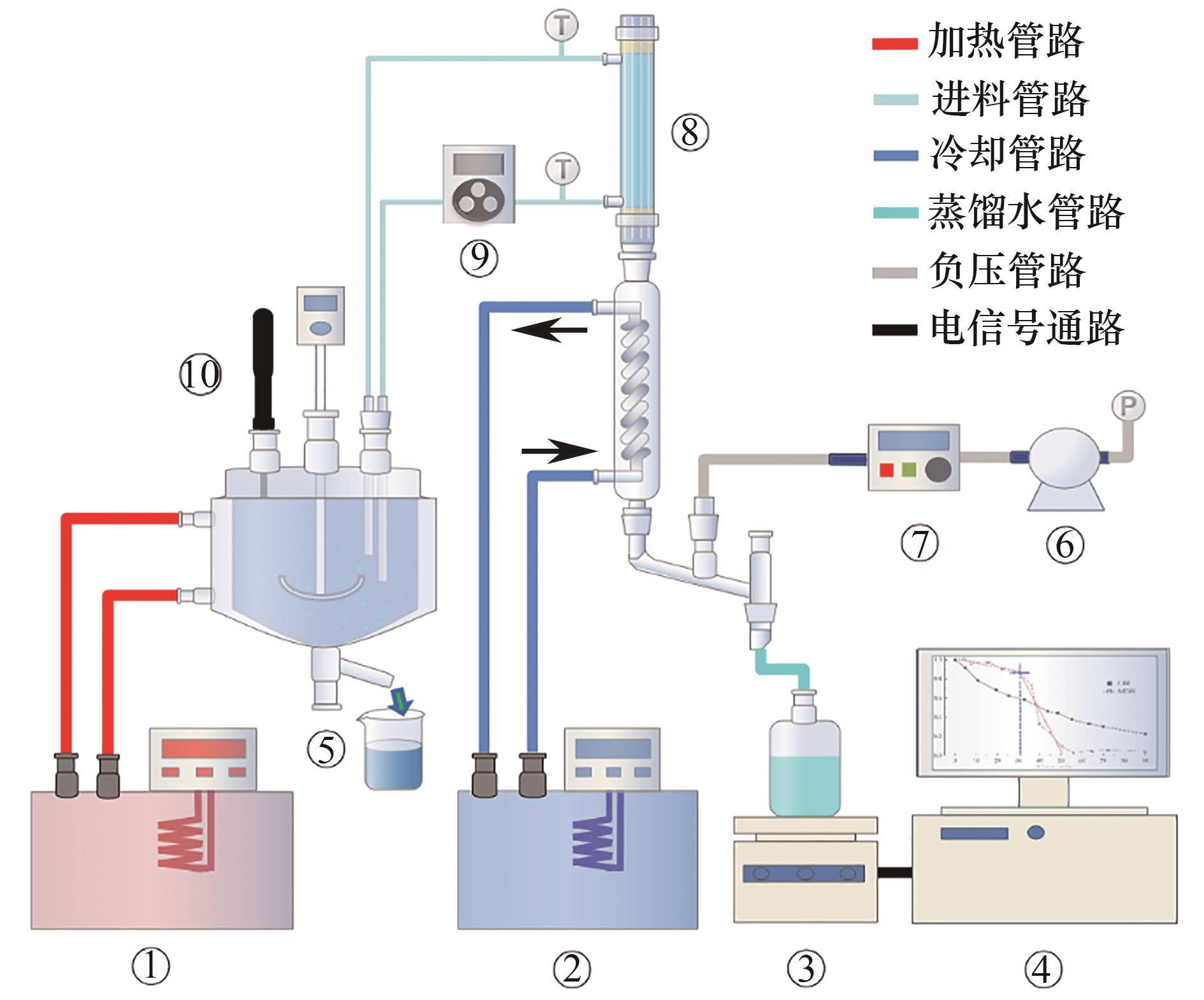

图3 真空膜蒸馏结晶装置示意图① 加热水浴;②冷却水浴;③天平;④天平数据记录计算机;⑤结晶釜;⑥真空泵;⑦真空控制器;⑧膜组件;⑨蠕动泵;⑩热电偶

Fig.3 Schematic diagram of the experimental device for vacuum membrane distillation crystallization

| 点 | w(NaNO3)/% | w(Na2SO4)/% |

|---|---|---|

| 固相Q | 57.143 | 42.857 |

| 液相E | 57.804 | 1.790 |

| 液相M | 18.182 | 13.636 |

| 液相N | 20.122 | 15.096 |

表4 353.15 K 三元体系Na+//NO3-, SO42--H2O 稳定相图数据

Table 4 Stable phase diagram data of the ternary system Na+//NO3-,SO42--H2O at 353.15 K

| 点 | w(NaNO3)/% | w(Na2SO4)/% |

|---|---|---|

| 固相Q | 57.143 | 42.857 |

| 液相E | 57.804 | 1.790 |

| 液相M | 18.182 | 13.636 |

| 液相N | 20.122 | 15.096 |

| 点 | w(NaNO3)/% | w(Na2SO4)/% |

|---|---|---|

| 液相P3 | 48.970 | 2.480 |

| 液相E1 | 57.804 | 1.790 |

表5 313.15 K 三元体系Na+//NO3-, SO42--H2O 稳定相图数据

Table 5 Stable phase diagram data of the ternary system Na+//NO3-, SO42--H2O at 313.15 K

| 点 | w(NaNO3)/% | w(Na2SO4)/% |

|---|---|---|

| 液相P3 | 48.970 | 2.480 |

| 液相E1 | 57.804 | 1.790 |

| 编号 | 纯度/% (质量分数) |

|---|---|

| 1# | 97.900 |

| 2# | 96.380 |

| 3# | 95.960 |

| 4# | 96.160 |

| 5# | 95.630 |

| 6# | 98.700 |

| 7# | 96.660 |

| 平均值 | 96.770 |

表6 膜蒸馏结晶产品纯度

Table 6 Purity of membrane distillation crystallization products

| 编号 | 纯度/% (质量分数) |

|---|---|

| 1# | 97.900 |

| 2# | 96.380 |

| 3# | 95.960 |

| 4# | 96.160 |

| 5# | 95.630 |

| 6# | 98.700 |

| 7# | 96.660 |

| 平均值 | 96.770 |

图15 膜蒸馏过程的典型膜通量(a)和阶段性变化原理示意图(b)

Fig.15 Schematic diagram of typical membrane flux (a) and step-by-step change principle of membrane distillation process (b)

| 实验编号 | 晶体收率/% | 总蒸发量/ml | 纯度/% (质量分数) |

|---|---|---|---|

| 1# | 76.310 | 214.21 | 96.060 |

| 2# | 79.340 | 220.23 | 94.110 |

| 3# | 78.890 | 221.45 | 94.860 |

| 4# | 78.320 | 218.54 | 93.760 |

| 平均值 | 78.220 | 218.61 | 94.700 |

表7 MDC-VEC耦合过程晶体收率、总蒸发量及纯度

Table 7 Crystal yield, total evaporation and purity during MDC-VEC coupling process

| 实验编号 | 晶体收率/% | 总蒸发量/ml | 纯度/% (质量分数) |

|---|---|---|---|

| 1# | 76.310 | 214.21 | 96.060 |

| 2# | 79.340 | 220.23 | 94.110 |

| 3# | 78.890 | 221.45 | 94.860 |

| 4# | 78.320 | 218.54 | 93.760 |

| 平均值 | 78.220 | 218.61 | 94.700 |

| 1 | 高姣丽, 李恩泽, 康锦, 等. 盐湖老卤动态变温分离高纯结晶硫酸镁[J]. 化工学报, 2021, 72(6): 3022-3030. |

| Gao J L, Li E Z, Kang J, et al. Separation of high purity magnesium sulfate hydrates from salt lake tail brine in a dynamic temperature-changing process[J]. CIESC Journal, 2021, 72(6): 3022-3030. | |

| 2 | 刘威. 煤制烯烃含盐废水近零排放技术的应用[J]. 化工进展, 2020, 39(11): 4643-4650. |

| Liu W. Application of near-zero liquid discharge technology of brine wastewater in coal to olefin industry[J]. Chemical Industry and Engineering Progress, 2020, 39(11): 4643-4650. | |

| 3 | Tong T Z, Elimelech M. The global rise of zero liquid discharge for wastewater management: drivers, technologies, and future directions[J]. Environmental Science & Technology, 2016, 50(13): 6846-6855. |

| 4 | Panagopoulos A, Haralambous K J, Loizidou M. Desalination brine disposal methods and treatment technologies—a review[J]. The Science of the Total Environment, 2019, 693: 133545. |

| 5 | Ghaffour N, Soukane S, Lee J G, et al. Membrane distillation hybrids for water production and energy efficiency enhancement: a critical review[J]. Applied Energy, 2019, 254: 113698. |

| 6 | Khayet M. Solar desalination by membrane distillation: dsispersion in energy consumption analysis and water production costs (a review)[J]. Desalination, 2013, 308: 89-101. |

| 7 | 姜晓滨, 孙国鑫, 贺高红. 高效膜蒸馏结晶过程的研究进展[J]. 化工学报, 2020, 71(9): 3905-3918. |

| Jiang X B, Sun G X, He G H. Research progress of high-efficiency membrane distillation crystallization process[J]. CIESC Journal, 2020, 71(9): 3905-3918. | |

| 8 | 张洪. 多级闪蒸在水处理及工业废液蒸发方面的应用[J]. 水处理技术, 1984, 10(4): 18-22. |

| Zhang H. Application of MSF process in water treatment and evaporation of industrial waste solutions[J]. Technology of Water Treatment, 1984, 10(4): 18-22. | |

| 9 | 解利昕, 李凭力, 王世昌. 海水淡化技术现状及各种淡化方法评述[J]. 化工进展, 2003, 22(10): 1081-1084. |

| Xie L X, Li P L, Wang S C. A review of seawater desalination and comparison of desalting processes[J]. Chemical Industry and Engineering Progress, 2003, 22(10): 1081-1084. | |

| 10 | Das P, Dutta S, Singh K K. Insights into membrane crystallization: a sustainable tool for value added product recovery from effluent streams[J]. Separation and Purification Technology, 2021, 257: 117666. |

| 11 | 熊日华. 常温结晶分盐零排放脱硫废水处理技术[J]. 水处理技术, 2019, 45(6): 10-14. |

| Xiong R H. Ambient temperature crystallization assisted zero liquid discharge and pure salt recovery process for flue gas desulfurization wastewater treatment[J]. Technology of Water Treatment, 2019, 45(6): 10-14. | |

| 12 | 谢绍雷, 张超, 纪律, 等. 硫酸镁亚型盐田卤水低温冷冻结晶规律的研究[J]. 无机盐工业, 2015, 47(2): 35-38. |

| Xie S L, Zhang C, Ji L, et al. Research on freezing crystalization behavior of magnesium sulfate subtypes brine at low temperature[J]. Inorganic Chemicals Industry, 2015, 47(2): 35-38. | |

| 13 | Lu K J, Cheng Z L, Chang J, et al. Design of zero liquid discharge desalination (ZLDD) systems consisting of freeze desalination, membrane distillation, and crystallization powered by green energies[J]. Desalination, 2019, 458: 66-75. |

| 14 | 李柄缘, 刘光全, 王莹, 等. 高盐废水的形成及其处理技术进展[J]. 化工进展, 2014, 33(2): 493-497, 515. |

| Li B Y, Liu G Q, Wang Y, et al. Formation and treatment of high-salt wastewater[J]. Chemical Industry and Engineering Progress, 2014, 33(2): 493-497, 515. | |

| 15 | 李冠男, 贺高红, 姜晓滨. 膜结晶处理高浓度Na+、Mg2+//Cl--H2O溶液的结晶调控[J]. 化工学报, 2019, 70(9): 3412-3420. |

| Li G N, He G H, Jiang X B. Treatment of high concentration Na+, Mg2+// Cl--H2O solution and crystallization control via membrane distillation crystallization[J]. CIESC Journal, 2019, 70(9): 3412-3420. | |

| 16 | Guan G Q, Wang R, Wicaksana F, et al. Analysis of membrane distillation crystallization system for high salinity brine treatment with zero discharge using aspen flowsheet simulation[J]. Industrial & Engineering Chemistry Research, 2012, 51(41): 13405-13413. |

| 17 | Quist-Jensen C A, Macedonio F, Horbez D, et al. Reclamation of sodium sulfate from industrial wastewater by using membrane distillation and membrane crystallization[J]. Desalination, 2017, 401: 112-119. |

| 18 | Edwie F, Chung T S. Development of simultaneous membrane distillation-crystallization (SMDC) technology for treatment of saturated brine[J]. Chemical Engineering Science, 2013, 98: 160-172. |

| 19 | Naidu G, Tijing L, Johir M A H, et al. Hybrid membrane distillation: resource, nutrient and energy recovery[J]. Journal of Membrane Science, 2020, 599: 117832. |

| 20 | Lakerveld R, Verzijden N G, Kramer H, et al. Application of ultrasound for start-up of evaporative batch crystallization of ammonium sulfate in a 75-L crystallizer[J]. AIChE Journal, 2011, 57(12): 3367-3377. |

| 21 | Jiang X B, Tuo L H, Lu D P, et al. Progress in membrane distillation crystallization: process models, crystallization control and innovative applications[J]. Frontiers of Chemical Science and Engineering, 2017, 11(4): 647-662. |

| 22 | Meng S W, Hsu Y C, Ye Y, et al. Submerged membrane distillation for inland desalination applications[J]. Desalination, 2015, 361: 72-80. |

| 23 | Drioli E, di Profio G, Curcio E. Progress in membrane crystallization[J]. Current Opinion in Chemical Engineering, 2012, 1(2): 178-182. |

| 24 | Kim J H, Park S H, Lee M J, et al. Thermally rearranged polymer membranes for desalination[J]. Energy & Environmental Science, 2016, 9(3): 878-884. |

| 25 | Ji Z G, Wang J, Yin Z F, et al. Effect of microwave irradiation on typical inorganic salts crystallization in membrane distillation process[J]. Journal of Membrane Science, 2014, 455: 24-30. |

| 26 | Cao J, Ren Y S, Zhu Q N, et al. Investigation of solid-liquid equilibria on the Na+//CI-, NO 3 - , SO 4 2 - -H2O system and the Na+//NO 3 - , SO 4 2 - -H2O system at 313.15 K[J]. Journal of Chemical and Engineering Data, 2019, 64(3): 1209-1221. |

| 27 | Chen H, Bian C, Bian J W, et al. Stable solid-liquid equilibrium of the quaternary system Na+// Cl-, NO 3 - , and SO 4 2 - -H2O at 333.15 K[J]. Journal of Chemical & Engineering Data, 2019, 64(8): 3569-3575. |

| 28 | Bian C, Chen H, Song X F, et al. Stable phase equilibria of the quaternary system Na+// Cl–, NO 3 - , SO 4 2 - -H2O at 353.15 K[J]. Journal of Chemical & Engineering Data, 2018, 63(9): 3305-3314. |

| 29 | Zhou W Z. Reversed crystal growth: implications for crystal engineering[J]. Advanced Materials, 2010, 22(28): 3086-3092. |

| 30 | Self K, Zhou H J, Greer H F, et al. Reversed crystal growth of ZnO microdisks[J]. Chemical Communications (Cambridge, England), 2013, 49(47): 5411-5413. |

| 31 | Li P Y, Li G N, Xiao W, et al. Na+/Mg2+ interactions on membrane distillation permeation flux and crystallization performance during high saline solution treatment[J]. Separation and Purification Technology, 2021, 259: 118191. |

| 32 | Jiang X B, Lu D P, Xiao W, et al. Interface-based crystal particle autoselection via membrane crystallization: from scaling to process control[J]. AIChE Journal, 2019, 65(2): 723-733. |

| [1] | 于宏鑫, 邵双全. 水结晶过程的分子动力学模拟分析[J]. 化工学报, 2023, 74(S1): 250-258. |

| [2] | 傅予, 刘兴翀, 王瀚雨, 李海敏, 倪亚飞, 邹文静, 雷月, 彭永姗. F3EACl修饰层对钙钛矿太阳能电池性能提升的研究[J]. 化工学报, 2023, 74(8): 3554-3563. |

| [3] | 苏晓丹, 朱干宇, 李会泉, 郑光明, 孟子衡, 李防, 杨云瑞, 习本军, 崔玉. 湿法磷酸半水工艺考察与石膏结晶过程研究[J]. 化工学报, 2023, 74(4): 1805-1817. |

| [4] | 周璇, 李孟亚, 孙杰, 岑振凯, 吕强三, 周立山, 王海涛, 韩丹丹, 龚俊波. 添加剂对氨基酸晶体生长的影响[J]. 化工学报, 2023, 74(2): 500-510. |

| [5] | 陈毓明, 历伟, 严翔, 王靖岱, 阳永荣. 初生态聚乙烯聚集态结构调控研究进展[J]. 化工学报, 2023, 74(2): 487-499. |

| [6] | 苏伟怡, 丁佳慧, 李春利, 王洪海, 姜艳军. 酶促反应结晶研究进展[J]. 化工学报, 2023, 74(2): 617-629. |

| [7] | 乃学瑛, 吴鹏, 程远, 肖剑飞, 刘鑫, 董亚萍. 水热生长碱式硫酸镁纳米线结晶动力学研究[J]. 化工学报, 2022, 73(7): 3038-3044. |

| [8] | 殷海青, 马祎明, 万旭兴, 董伟兵, 张玉龙, 吴送姑. 碳酸锂气液固三相反应结晶过程研究[J]. 化工学报, 2022, 73(3): 1207-1220. |

| [9] | 陈雪梅, 王彤, 高玉箔, 彭鼎程, 罗雨婷. 利用激光诱导石墨烯实现高效太阳能界面蒸发[J]. 化工学报, 2022, 73(12): 5648-5659. |

| [10] | 敬鹏程, 陈立涛, 闫传梁, 姜传祥, 夏煜翔, 于常宏, 王昊天. 超声波悬浮TBAB溶液液滴表面半笼型水合物生长过程研究[J]. 化工学报, 2022, 73(11): 4893-4902. |

| [11] | 贺冲, 白进, 郭晶, 孔令学, 鲁浩, 李怀柱, 秦育红, 李文. 气氛和化学组成对高铁煤灰熔融特性的影响机理[J]. 化工学报, 2022, 73(10): 4648-4658. |

| [12] | 郑海峰, 贾晟哲, 王崧成, 韩瑞, 韩丹丹, 高振国, 龚俊波. 超细晶体的研究进展[J]. 化工学报, 2022, 73(10): 4285-4297. |

| [13] | 丰闪闪, 刘晓斌, 郭石麟, 何兵兵, 高振国, 陈明洋, 龚俊波. 锂枝晶的成核、生长与抑制[J]. 化工学报, 2022, 73(1): 97-109. |

| [14] | 徐健玮, 梁颖宗, 罗向龙, 陈健勇, 杨智, 陈颖. 液化天然气深冷-膜蒸馏海水淡化系统集成与分析[J]. 化工学报, 2021, 72(S1): 437-444. |

| [15] | 于筱溪, 闫真真, 蒋其辉, 吴霞, 张余晓, 王晓娟, 黄方. 溴化1-辛基-3-甲基咪唑聚集状态对蛋白质结晶的影响研究[J]. 化工学报, 2021, 72(9): 4854-4860. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号