化工学报 ›› 2020, Vol. 71 ›› Issue (6): 2743-2751.DOI: 10.11949/0438-1157.20200077

收稿日期:2020-01-19

修回日期:2020-03-22

出版日期:2020-06-05

发布日期:2020-06-05

通讯作者:

朱庆山

作者简介:桑元(1994—),男,硕士研究生,基金资助:

Yuan SANG1,2( ),Maoqiao XIANG1,Miao SONG1,2,Qingshan ZHU1,2(

),Maoqiao XIANG1,Miao SONG1,2,Qingshan ZHU1,2( )

)

Received:2020-01-19

Revised:2020-03-22

Online:2020-06-05

Published:2020-06-05

Contact:

Qingshan ZHU

摘要:

传统气-固反应工艺制备TiN粉体存在难以逾越的内扩散控制过程,导致制备高纯、正化学计量比的TiN粉体至今存在巨大困难。提出了流态化化学气相沉积工艺(FBCVD)制备高质量TiN粉体,即基于TiCl4-N2-H2体系,在往复运动的TiN种子粉体上沉积新生高质量TiN粉体的新方法。实验发现,当TiN种子粉体粒径大于52.95 μm时,即使在1000℃沉积2 h也不会失流,同时在TiN种子粉体上获得了亚微米级的结节状新生TiN颗粒。通过氧氮分析仪和XRD分析发现,新方法显著提升了粉体的氮含量,获得了近化学计量比的TiN0.96,且氧含量下降了约40%。此外,流化床中气相沉积TiN的生长模式为岛状生长模式,为工业中制备高质量TiN粉体提供了一种新的方法。

中图分类号:

桑元, 向茂乔, 宋淼, 朱庆山. 流化床化学气相沉积法制备近化学计量比的TiN粉体[J]. 化工学报, 2020, 71(6): 2743-2751.

Yuan SANG, Maoqiao XIANG, Miao SONG, Qingshan ZHU. Preparation of nearly-stoichiometric TiN powder by chemical vapor deposition in fluidized-bed[J]. CIESC Journal, 2020, 71(6): 2743-2751.

图1 平均粒径为21.16 μm (a)和52.95 μm (b)的商用氮化钛粉体粒径分布图

Fig.1 Particle size distribution of commercial titanium nitride powder with average particle size of 21.16 μm (a) and 52.95 μm (b)

| 气体 | 气体流量/(ml/min) |

|---|---|

| Ar | 300 |

| TiCl4 | 70 |

| N2 | 70 |

| H2 | 210 |

表1 实验中反应气体的流量

Table 1 Flow of reactant gases in experiment

| 气体 | 气体流量/(ml/min) |

|---|---|

| Ar | 300 |

| TiCl4 | 70 |

| N2 | 70 |

| H2 | 210 |

图3 不同温度TiCl4-N2-H2体系在平衡状态下的Gibbs自由能变化(a)和平衡组分变化(b)

Fig.3 Gibbs free energy change (a) and equilibrium component change (b) of Ticl4-N2-H2 system at different temperatures

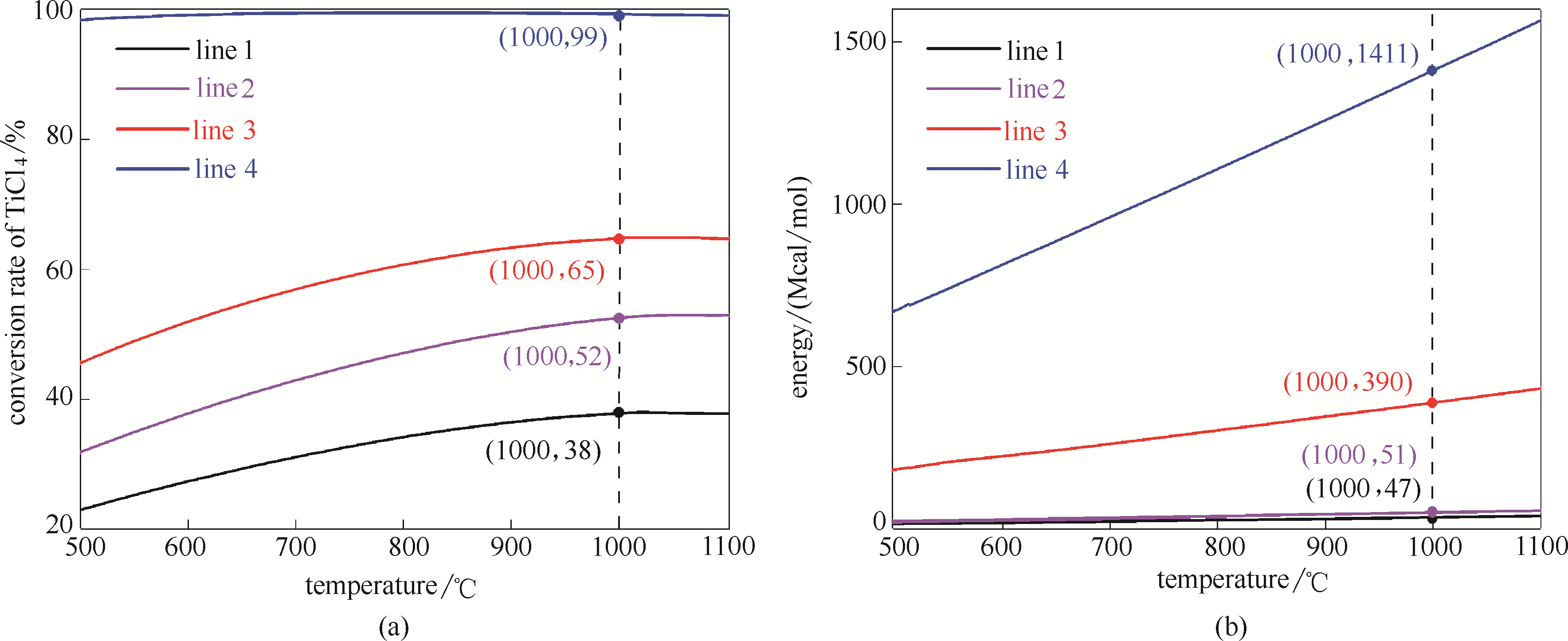

图4 TiCl4-N2-H2体系中不同进料比的TiCl4转化率(a)和理论能量消耗值(b)(1 cal=4.18 J)

Fig.4 Conversion rate of TiCl4 (a) and theoretical energy consumption (b) of different feed ratios in TiCl4-N2-H2 systemline 1—n(TiCl4)∶n(N2)∶n(H2) = 1∶0.5∶2; line 2—n(TiCl4)∶n(N2)∶n(H2) =1∶1∶3; line 3—n(TiCl4)∶n(N2)∶n(H2) = 1∶50∶2;line 4—n(TiCl4)∶n(N2)∶n(H2) = 1∶0.5∶200

图5 进料摩尔比为 n(TiCl4)∶n(N2)∶n(H2) = 1∶1∶3时不同温度下沉积产物中Cl元素含量

Fig.5 Content of Cl in products deposited at different temperatures when feed molar ratio is n(TiCl4)∶n(N2)∶n(H2) =1∶1∶3

图6 不同粒径种子粉体流化压降曲线(a),平均粒径为21.16 μm的TiN种子粉体沉积后的宏观照片(b),平均粒径为21.16 μm种子粉体沉积后的SEM图(c),平均粒径为52.95 μm种子粉体沉积后的SEM图(d)

Fig.6 Fluidization pressure drop of TiN seeds with different particle size (a), macro photos (b) and SEM (c) of TiN seeds with average particle size of 21.16 μm after deposition, SEM of seeds with an average particle size of 52.95 μm after deposition (d)

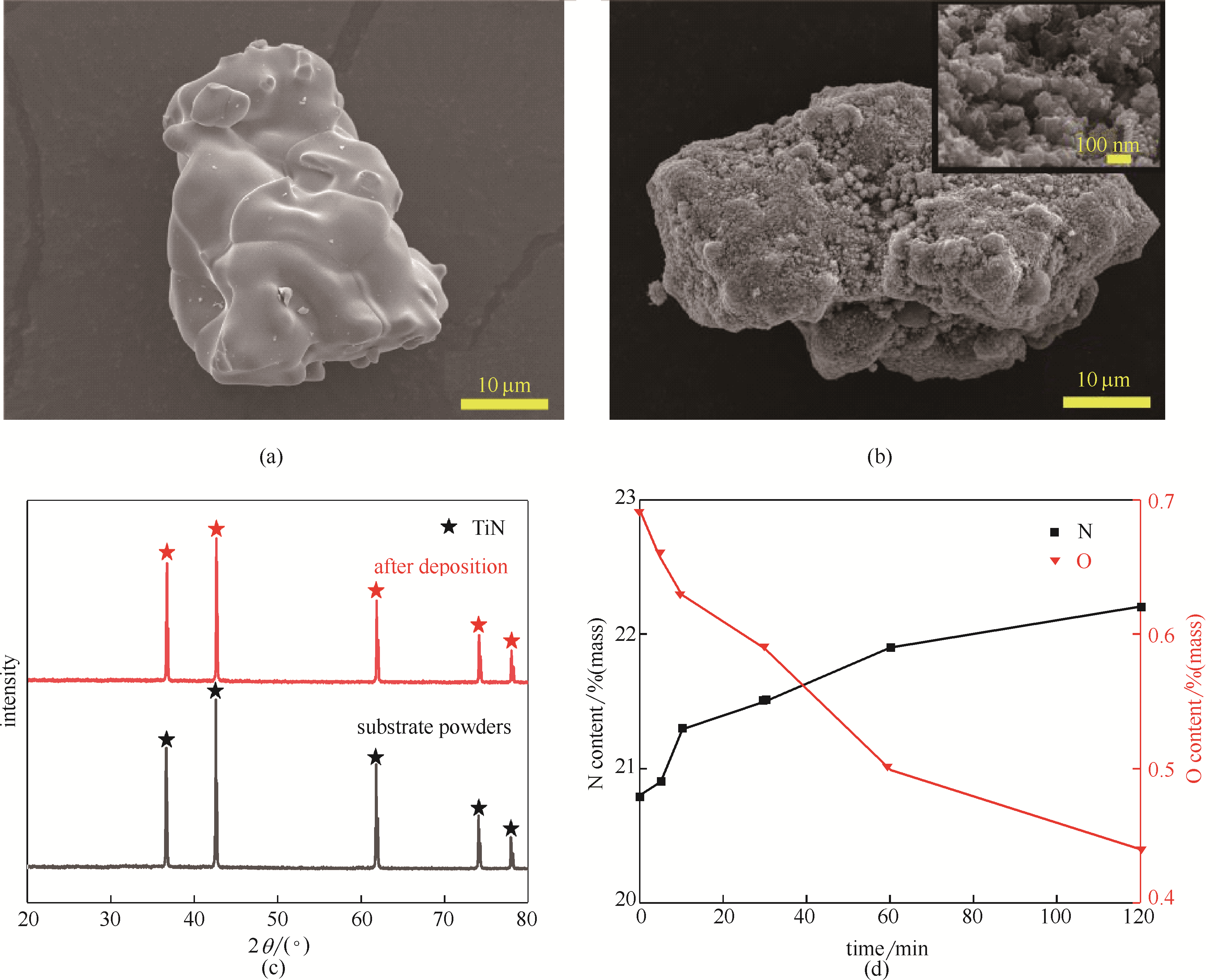

图7 52.95 μm种子粉体沉积120 min前后的SEM图[(a)、(b)],沉积前后TiN种子的XRD谱图(c),沉积后种子中N和O含量与沉积时间的关系(d)

Fig.7 SEM of 52.95 μm seeds before and after 120 min deposition [(a)—(b)], XRD patterns of TiN seeds before and after deposition (c), relationship between content of O/N in seeds and deposition time (d)

| 1 | Nagakura S, Kusunoki T, Kakimoto F, et al. Lattice parameter of the non-stoichiometric compound TiNx[J]. J. Appl. Cryst., 1975, 8(1): 65-66. |

| 2 | Liang H L, Jin X, Zhou D Y, et al. Thickness dependent microstructural and electrical properties of TiN thin films prepared by DC reactive magnetron sputtering[J]. Ceram. Int., 2015, 42(2): 2642-2647. |

| 3 | Liu M J, Dong Y Z, Wu Y M, et al. Titanium nitride nanocrystals on nitrogen-doped graphene as efficient electrocatalysts for oxygen reduction reaction[J]. Chem. J. Eur., 2013, 19(44): 14781-14786. |

| 4 | He P, Wang Y, Zhou H S. Titanium nitride catalyst cathode in a Li-air fuel cell with an acidic aqueous solution[J]. Chem. Commun., 2011, 47(38): 10701-10703. |

| 5 | Musthafa O T, Sampath S. High performance platinized titanium nitride catalyst for methanol oxidation[J]. Chem. Commun., 2008, 7(1): 67-69. |

| 6 | Gray B M, Hector A l, Jura M, et al. Effect of oxidative surface treatments on charge storage at titanium nitride surfaces for supercapacitor applications[J]. J. Mater. Chem. A., 2017, 5(9): 4550-4559. |

| 7 | Dong S M, Chen X, Cui G L, et al. One dimensional MnO2/titanium nitride nanotube coaxial arrays for high performance electrochemical capacitive energy storage[J]. Energy Environ Sci., 2011, 4(9): 3502-3508. |

| 8 | Kim W M, Kim S H, Lee K S, et al. Titanium nitride thin film as an adhesion layer for surface plasmon resonance sensor chips[J]. Appl. Surf. Sci., 2012, 261(Complete): 749-752. |

| 9 | Wang Y, Yuan H Y, Lu X L, et al. All solid-state pH electrode based on titanium nitride sensitive film[J]. Electroanalysis, 2006, 18(15): 1493-1498. |

| 10 | Ishii S, Shinde S L, Jevasuwan W, et al. Hot electron excitation from titanium nitride using visible light[J]. ACS Photonics, 2016, 3(9): 1552-1557. |

| 11 | Ajikumar P L, Kamruddin M, Nithya R, et al. Surface nitridation of Ti and Cr in ammonia atmosphere[J]. Scr. Mater., 2004, 51(5): 361-366. |

| 12 | Wexler D, Calka A, Mosbah A Y. Ti-TiN hardmetals prepared by in situ formation of TiN during reactive ball milling of Ti in Ammonia[J]. J. Alloy Compd., 2000, 309(1/2): 201-207. |

| 13 | Lee K O, Cohen J J, Kenneth B. Fluidized-bed combustion synthesis of titanium nitride[J]. P. Combust. Inst., 2000, 28(1): 1373-1380. |

| 14 | Zhang H, Li F, Jia Q. Preparation of titanium nitride ultrafine powders by sol-gel and microwave carbothermal reduction nitridation methods[J]. Ceram. Int., 2009, 35(3): 1071-1075. |

| 15 | Luo M, Gao J Q, Zhang X, et al. Processing of porous TiN/C ceramics from biological templates[J]. Materials Letters, 2007, 61(1): 186-188. |

| 16 | Mosbah A, Calka A, Wexler D. Rapid synthesis of titanium nitride powder by electrical discharge assisted mechanical milling[J]. J. Alloy Compd., 2006, 424(1/2): 279-282. |

| 17 | 石青娟. 非化学计量比TiNx的制备及相稳定性研究[D]. 秦皇岛: 燕山大学, 2009. |

| Shi Q J. Study of the preparation and phase stability of non-stoichiometric TiNx[D]. Qinhuangdao: Yanshan University, 2009. | |

| 18 | Song M, Xiang M Q, Yang Y F, et al. Synthesis of stoichiometric TiN from TiH2 powder and its nitridation Mechanism[J]. Ceram. Int., 2018, 44(14): 16947-16952. |

| 19 | Drygaś M, Czosnek C, Paine R T, et al. Two-stage aerosol synthesis of titanium nitride TiN and titanium oxynitride TiOxNy nanopowders of spherical particle morphology[J]. Chem. Mater., 2006, 18(13): 3122-3129. |

| 20 | Bang J H, Suslick K S. Dual templating synthesis of mesoporous titanium nitride microspheres[J]. Adv. Mater., 2009, 21(31): 3186-3190. |

| 21 | Yoo J B, Yoo H J, Jung H J, et al. Titanium oxynitride microspheres with the rock-salt structure for use as visible-light photocatalysts[J]. J. Mater. Chem. A., 2016, 4(3): 869-876. |

| 22 | Berge L M, Gruner W. Investigation of the effect of a nitrogen-containing atmosphere on the carbothermal reduction of titanium dioxide[J]. Int. J. Refract. Met. H., 2002, 20(3): 235-251. |

| 23 | 戴遐明, 李庆丰. 粉体的气、固相合成[J]. 中国粉体技术, 2000, 10(6): 15-20. |

| Dai X M, Li Q F. Vapor and solid synthesis of powders[J]. China Powder Science and Technology, 2000, 10(6): 15-20. | |

| 24 | 刘志宏, 张淑英, 刘智勇. 化学气相沉积制备粉体材料的原理及研究进展[J]. 粉末冶金材料科学与工程, 2009, 14(6): 359-363. |

| Liu Z H, Zhang S Y, Liu Z Y. Principle and research development of powder materials prepared by chemical vapor deposition[J]. Mater. Sci. Eng. Powder. Metall., 2009, 14(6): 359-363. | |

| 25 | Shin D H, Yong C H, Uhm H S. Production of nanocrystalline titanium nitride powder by atmospheric microwave plasma torch in hydrogen/nitrogen gas[J]. J. Am. Ceram. Soc., 2005, 88(10): 2736-2739. |

| 26 | Wen Q, Qian W Z, Nie J Q, et al. 100 mm long, semiconducting triple-walled carbon nanotubes[J]. Adv. Mater., 2010, 22(16): 1867-1871. |

| 27 | 刘马林. 流化床-化学气相沉积技术在先进核燃料制备中的应用进展[J]. 化工进展, 2019, 38(4): 1646-1653. |

| Liu M L. Research activities on FB-CVD technology application in advanced nuclear fuel fabrication[J]. Chem. Ind. & Eng. Pro., 2019, 38(4): 1646-1653. | |

| 28 | Du J, Dutta S, Ydstie B E. Modeling and control of solar-grade silicon production in a fluidized bed reactor[J]. AIChE J., 2014, 60(5): 1740-1751. |

| 29 | Luo X, Wu S, Yang Y, et al. Deposition characteristics of titanium coating deposited on SiC fiber by cold-wall chemical vapor deposition[J]. Mater. Chem. Phys., 2016, 184: 189-196. |

| 30 | Slavens G J. Vapor-phase reactions to prepare titanium nitride powder[R]. Report of Investigations. United States: Bureau of Mines, 1992. |

| 31 | He S Y, Sun H Y, Hu C Q, et al. Direct reduction of fine iron ore concentrate in a conical fluidized bed[J]. Powder Technology, 2017, 313: 161-168. |

| 32 | Geldart D. Types of gas fluidization[J]. Powder Technology, 1973, 7(5): 285-292. |

| 33 | 郭慕孙, 李洪钟. 流态化手册[M]. 北京: 化学工业出版社, 2008: 110. |

| Guo M S, Li H Z. Handbook of Fluidization[M]. Beijing: Chemical Industry Press, 2008: 110. | |

| 34 | Lei C, Zhu Q S, Li H Z. Experimental and theoretical study on the fluidization behaviors of iron powder at high temperature[J]. Chemical Engineering Science, 2014, 118: 50-59. |

| 35 | Roberts G C, Nenes A. A continuous-flow streamwise thermal-gradient CCN chamber for atmospheric measurements[J]. Aerosol. Sci. Technol., 2005, 39(3): 206-221. |

| 36 | Zhu L P, Ohashi M, Yamanaka Y. Novel synthesis of TiN fine powders by nitridation with ammonium chloride[J]. Materials Research Bulletin, 2002, 37(3): 475-483. |

| 37 | Koch R, Hu D Z, Das A K. Compressive stress in polycrystalline Volmer-Weber films[J]. Phys. Rev. Lett., 2005, 94(14): 146101. |

| 38 | Eichfeld S M, Colon V O, Nie Y F. Controlling nucleation of monolayer WSe2 during metal-organic chemical vapor deposition growth[J]. 2D Mater, 2016, 3(2): 025015. |

| 39 | 张军, 张磊, 李国栋, 等. 化学气相沉积ZrB2涂层的微观形貌及晶粒择优生长[J]. 材料研究学报, 2017, 31(3): 168-174. |

| Zhang J, Zhang L, Li G D, et al. Micro-morphology and preferential growth of ZrB2 coating prepared by chemical vapor deposition[J]. Chinese Journal of Materials Research, 2017, 31(3): 168-174. |

| [1] | 李珍宝, 李超, 王虎, 王绍瑞, 黎泉. MPP抑制铝镁合金粉尘爆炸微观机理研究[J]. 化工学报, 2023, 74(8): 3608-3614. |

| [2] | 何汉兵, 刘真, 陈勇, 王小锋, 曾婧. 直写成型电极锰氧化物粉末的合成与浆料调控[J]. 化工学报, 2023, 74(5): 2239-2247. |

| [3] | 衣思敏, 马亚丽, 刘伟强, 张金帅, 岳岩, 郑强, 贾松岩, 李雪. 微晶菱镁矿蒸氨及水化动力学研究[J]. 化工学报, 2023, 74(4): 1578-1586. |

| [4] | 王燕, 何佳, 杨晶晶, 林晨迪, 纪文涛. 草酸盐和碳酸氢盐抑制聚乙烯粉尘爆炸特性[J]. 化工学报, 2022, 73(9): 4207-4216. |

| [5] | 杨克, 王辰升, 纪虹, 郑凯, 邢志祥, 毕海普, 蒋军成. 聚多巴胺包覆混合粉体抑制甲烷爆炸的实验研究[J]. 化工学报, 2022, 73(9): 4245-4254. |

| [6] | 葛世轶, 杨遥, 黄正梁, 孙婧元, 王靖岱, 阳永荣. 基于静电分选解析聚乙烯颗粒生长与形貌演变[J]. 化工学报, 2022, 73(4): 1585-1596. |

| [7] | 尚慧俊, 黎亨利, 刘家义, 潘锋, 杜占, 孙林兵. Co对WO3-Co3O4预还原的影响及其产物碳化性能[J]. 化工学报, 2022, 73(12): 5592-5604. |

| [8] | 向茂乔, 耿玉琦, 朱庆山. 氮化硅粉体制备技术及粉体质量研究进展[J]. 化工学报, 2022, 73(1): 73-84. |

| [9] | 纪文涛, 李璐, 李忠, 何佳, 杨晶晶, 王燕. 聚磷酸铵抑制PMMA粉尘爆炸特性研究[J]. 化工学报, 2022, 73(1): 461-469. |

| [10] | 陆海峰, 曹嘉琨, 郭晓镭, 刘海峰. 基于颗粒间相互作用的细颗粒粉体料仓下料过程分析[J]. 化工学报, 2021, 72(8): 4047-4054. |

| [11] | 侯玉洁, 梁琳, 江子旭, 闫兴清, 于小哲, 吕先舒, 喻健良. 惰性气体对粉尘爆炸泄放特性影响的实验研究[J]. 化工学报, 2021, 72(5): 2887-2895. |

| [12] | 周剑, 江倩, 杨怡, 冯厦厦, 仲兆祥, 邢卫红. 烧结助剂对低温制备碳化硅多孔陶瓷性能的影响[J]. 化工学报, 2021, 72(4): 2293-2299. |

| [13] | 田逢时, 董欣欣, 疏学明, 赵金龙. 蛭石粉末及离子溶液改性后膨胀率和灭火有效性分析[J]. 化工学报, 2021, 72(3): 1761-1768. |

| [14] | 魏娟, 王玉军, 骆广生. 铝源孔容和焙烧升温过程对碳热还原法制备氮化铝粉体的影响[J]. 化工学报, 2021, 72(2): 1156-1168. |

| [15] | 谢春杰, 何然, 庹新林, 杨万泰. 对位芳纶气凝胶粉体的制备与性能研究[J]. 化工学报, 2021, 72(12): 6361-6370. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||

京公网安备 11010102001995号

京公网安备 11010102001995号